Abstract

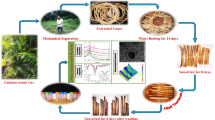

This study investigates the feasibility of deploying aloe vera, banana, and corn husk fibers that have been treated with sodium hydroxide (NaOH) as reinforcements in composites. The application of NaOH treatment resulted in a substantial enhancement in the tensile strength of all fibers. Among them, banana fibers exhibited the greatest value, reaching 189.7 MPa. The fibers that were treated also showed elevated aspect ratios, especially in the case of banana fibers (178.57), indicating an increased potential for reinforcing. The use of scanning electron microscopy (SEM) showed that the treatment resulted in a surface morphology that was roughened. The fibers that were treated showed enhanced thermal stability, as determined by thermogravimetric analysis (TGA) and differential thermal analysis (DTA). FT-IR spectroscopy verified changes in the chemical composition of the fibers, while XRD examination revealed that both untreated and treated fibers had a structure that was both amorphous and polycrystalline. The results emphasize the potential of NaOH-treated natural fibers, particularly banana fibers due to their exceptional strength, as eco-friendly substitutes for synthetic reinforcements in composites.

Similar content being viewed by others

Data availability

All data relevant to the study are included in the article.

References

Karimah A, Ridho MR, Munawar SS, Adi DS, Ismadi DR, Subiyanto B, Fatriasari W, Fudholi A (2021) A review on natural fibers for development of eco-friendly bio-composite: characteristics, and utilizations. J Market Res 13:2442–2458

Karimah A, Ridho MR, Munawar SS, Ismadi, Amin Y, Damayanti R, Lubis MAR, Wulandari AP, Nurindah, Iswanto AH, Fudholi A, Asrofi M, Saedah E, Sari NH, Pratama BR, Fatriasari W, Nawawi DS, Rangappa SM, Siengchin S (2021) A comprehensive review on natural fibers: technological and socio-economical aspects. Polymers 13(24):4280, https://doi.org/10.3390/polym13244280

BabuT N, Bandaru S, Vattikuti M (2018) Comparative study on orientation of fibers in epoxy composites reinforced with aloe-vera and palmyra fibers. Int J Mech Eng Technol IJMET 9:747–760

Balaji N, Natrayan L, Kaliappan S, Patil PP, Sivakumar NS (2024) Annealed peanut shell biochar as potential reinforcement for aloe vera fiber-epoxy biocomposite: mechanical, thermal conductivity, and dielectric properties. Biomass Convers Biorefin 14:4155–4163. https://doi.org/10.1007/s13399-022-02650-7

Shahapurkar K, Ramesh S, Nik-Ghazali N-N, Gebremaryam G, Kanaginahal G, Venkatesh C, Soudagar MEM, Fouad Y, Kalam MA (2024) Tensile, compressive, and fracture behavior of Habeshian chopped banana/epoxy core sandwich woven banana composite. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-024-05455-y

Kavitha V, Aparna G (2021) A review on banana fiber and its properties. Asian J Pharm Res Dev 9:118–121. https://doi.org/10.22270/ajprd.v9i3.956

Bharath KN, Puttegowda M, Yashas Gowda TG, Arpitha GR, Pradeep S, Rangappa SM, Siengchin S (2023) Development of banana fabric incorporated polymer composites for printed circuit board application. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-023-04249-y

Dharmalingam S, Sasikumar T (2023) Mechanical, wear, and flammability properties of silanized cow dung biosilica-dispersed corn husk fiber-reinforced epoxy composites. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-023-05082-z

Kambli ND, Samanta KK, Basak S, Chattopadhyay SK, Patil PG, Deshmukh RR (2018) Characterization of the corn husk fibre and improvement in its thermal stability by banana pseudostem sap. Cellulose 25:5241–5257. https://doi.org/10.1007/s10570-018-1931-z

Sari NH, Wardana ING, Irawan YS, Siswanto E (2017) The effect of sodium hydroxide on chemical and mechanical properties of corn husk fiber. Orient J Chem 33:3037–3042. https://doi.org/10.13005/ojc/330642

Parre A, Karthikeyan B, Balaji A, Udhayasankar R (2020) Investigation of chemical, thermal and morphological properties of untreated and NaOH treated banana fiber. In: Materials today: Proceedings. Elsevier Ltd, pp 347–352

Dev B, Rahman A, Alam R, Repon R, Nawab Y (2023) Mapping the progress in natural fiber reinforced composites: preparation, mechanical properties, and applications. Polym Compos 44:3748–3788. https://doi.org/10.1002/pc.27376

Balaji A, Purushothaman R, Udhayasankar R, Vijayaraj S, Karthikeyan B (2020) Study on mechanical, thermal and morphological properties of banana fiber-reinforced epoxy composites. J Bio Tribocorros 6. https://doi.org/10.1007/s40735-020-00357-8

Mishfa KF, Alim MdA, Repon MdR, Habibullah M, Tonmoy MAH, Jurkonienė S, Shukhratov S (2024) Preparation and characterization of snake plant fiber reinforced composite: a sustainable utilization of biowaste. SPE Polymers 5:35–44. https://doi.org/10.1002/pls2.10108

Balaji A, Arunkumar S, Madhanagopal A, Purushothaman R (2023) Coir/banana hybrid composites reinforced with poly vinyl ester for mechanical, water absorption and thermal characterization. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-023-04615-w

Igathinathane C, Pordesimo LO, Columbus EP, Batchelor WD, Methuku SR (2008) Shape identification and particles size distribution from basic shape parameters using ImageJ. Comput Electron Agric 63:168–182. https://doi.org/10.1016/j.compag.2008.02.007

Thornton JA (1973) Sputter coating— its principles and potential. SAE Transactions 82:1787–1805. http://www.jstor.org/stable/44717585

Vyas D, Chokshi S (2018) A review on effect of fiber treatment on tensile strength of natural fiber composites. Int J Emerg Technol Innov Res 5(7):15–18. http://www.jetir.org/papers/JETIRA006003.pdf

Balasubramani V, Nagarajan KJ, Karthic M, Pandiyarajan R (2024) Extraction of lignocellulosic fiber and cellulose microfibrils from agro waste-palmyra fruit peduncle: water retting, chlorine-free chemical treatments, physio-chemical, morphological, and thermal characterization. Int J Biol Macromol 259:129273. https://doi.org/10.1016/j.ijbiomac.2024.129273

Tian W, Qi L, Zhou J, Guan J (2014) Effects of the fiber orientation and fiber aspect ratio on the tensile strength of Csf/Mg composites. Comput Mater Sci 89:6–11. https://doi.org/10.1016/j.commatsci.2014.03.004

Giridharan R, Anerudh N, Mithun Srivan MM, Jenarthanan MP (2020) A study on investigation of tensile properties of aloe vera fiber reinforced epoxy composites. In: Proceedings of ICDMC 2019. Lecture notes in mechanical engineering. Springer, Singapore. https://doi.org/10.1007/978-981-15-3631-1_31

Mwaikambo LY, Mwaikambo LY (2006) Review of the history, properties and application of plant fibres. African J Sci Technol 7:121

Mohanty AK, Misra M, Drzal LT (2005) Natural fibers, biopolymers, and biocomposites. CRC Press

Majid Ali (2012) Natural fibres as construction materials. J Civil Eng Construction Technol 3. https://doi.org/10.5897/JCECT11.100

Thakur VK, Siṅgha AS (2013) Biomass-based biocomposites. Smithers Rapra, Shropshire

Rao KMM, Prasad AVR, Babu MNVR, Rao KM, Gupta AVSSKS (2007) Tensile properties of elephant grass fiber reinforced polyester composites. J Mater Sci 42:3266–3272. https://doi.org/10.1007/s10853-006-0657-8

Sustainable composite structures Driving architectural design with material innovation: a design research approach. In: Sustainable buildings and structures. (2015) CRC Press, pp 125–134

Faruk O, Bledzki AK, Fink H-P, Sain M (2012) Biocomposites reinforced with natural fibers: 2000–2010. Prog Polym Sci 37:1552–1596

John MJ, Anandjiwala RD (2008) Recent developments in chemical modification and characterization of natural fiber-reinforced composites. Polym Compos 29:187–207. https://doi.org/10.1002/pc.20461

Satyanarayana KG, Sukumaran K, Mukherjee PS, Pavithran C, Pillai SGK (1990) Natural fibre-polymer composites. Cem Concr Compos 12:117–136. https://doi.org/10.1016/0958-9465(90)90049-4

Gholampour A, Ozbakkaloglu T (2020) A review of natural fiber composites: properties, modification and processing techniques, characterization, applications. J Mater Sci 55:829–892. https://doi.org/10.1007/s10853-019-03990-y

Jannah M, Mariatti M, Abu Bakar A, Abdul Khalil HPS (2009) Effect of chemical surface modifications on the properties of woven banana-reinforced unsaturated polyester composites. J Reinf Plast Compos 28:1519–1532. https://doi.org/10.1177/0731684408090366

Ezema Ike-Eze IC, Aigbodion VS, Ude SN, Omah AD, Offor PO (2019) Ike-Eze et al Experimental study on the effects of surface treatment reagents on tensile properties of Banana fiber reinforced polyester composites. J Mater Environ Sci 10(5):402–410

NorulIzani MA, Paridah MT, Anwar UMK, Mohd Nor MY, H’ng PS (2013) Effects of fiber treatment on morphology, tensile and thermogravimetric analysis of oil palm empty fruit bunches fibers. Compos B Eng 45:1251–1257. https://doi.org/10.1016/j.compositesb.2012.07.027

Monteiro SN, Calado V, Rodriguez RJS, Margem FM (2012) Thermogravimetric behavior of natural fibers reinforced polymer composites—an overview. Mater Sci Eng, A 557:17–28. https://doi.org/10.1016/j.msea.2012.05.109

Dev B, Rahman MdA, Repon MdR, Rahman MM, Haji A, Nawab Y (2023) Recent progress in thermal and acoustic properties of natural fiber reinforced polymer composites: preparation, characterization, and data analysis. Polym Compos 44:7235–7297. https://doi.org/10.1002/pc.27633

Abdullah SAS, Zuhudi NZM, Anuar N, Isa MD (2018) Mechanical and thermal characterization of alkali treated kenaf fibers. IOP Conf Ser Mater Sci Eng 370:012048. https://doi.org/10.1088/1757-899X/370/1/012048

Ismail NF, Mohd Radzuan NA, Sulong AB, Muhamad N, Che Haron CH (2021) The effect of alkali treatment on physical, mechanical and thermal properties of kenaf fiber and polymer epoxy composites. Polymers (Basel) 13:2005. https://doi.org/10.3390/polym13122005

Azwa ZN, Yousif BF, Manalo AC, Karunasena W (2013) A review on the degradability of polymeric composites based on natural fibres. Mater Des 47:424–442. https://doi.org/10.1016/j.matdes.2012.11.025

Barl B, Biliaderis CG, Murray ED (1986) Effect of chemical pretreatments on the thermal degradation of corn husk lignocellulosics. J Agric Food Chem 34:1019–1024. https://doi.org/10.1021/jf00072a022

Liu Y (2013) Recent progress in Fourier transform infrared (FTIR) spectroscopy study of compositional, structural and physical attributes of developmental cotton fibers. Materials 6:299–313. https://doi.org/10.3390/ma6010299

Zhang L, Li X, Zhang S, Gao Q, Lu Q, Peng R, Xu P, Shang H, Yuan Y, Zou H (2021) Micro-FTIR combined with curve fitting method to study cellulose crystallinity of developing cotton fibers. Anal Bioanal Chem 413:1313–1320. https://doi.org/10.1007/s00216-020-03094-6

McAvan BS, Bowsher LA, Powell T, O’Hara JF, Spitali M, Goodacre R, Doig AJ (2020) Raman spectroscopy to monitor post-translational modifications and degradation in monoclonal antibody therapeutics. Anal Chem 92:10381–10389. https://doi.org/10.1021/acs.analchem.0c00627

Swaminathan J, Ramalingam M, Saleem H, Sethuraman V, Ameen MTN (2009) FT-IR and FT-Raman vibrational assignment of 2-bromobenzoic acid with the help of ab initio and DFT calculations. Spectrochim Acta A Mol Biomol Spectrosc 74:1247–1253. https://doi.org/10.1016/j.saa.2009.09.054

Sgriccia N, Hawley MC, Misra M (2008) Characterization of natural fiber surfaces and natural fiber composites. Compos Part A Appl Sci Manuf 39:1632–1637. https://doi.org/10.1016/j.compositesa.2008.07.007

Tagore SS, Swaminathan J, Manikandan D, Gomathi S, Nirmal Ram S, Ramalingam M, Sethuraman V (2020) Molecular, vibrational (FT-IR and FT-Raman), NMR and UV spectral analysis of imidazo[1,2-b]pyridazine using experimental and DFT calculations. Chem Phys Lett 739:136943. https://doi.org/10.1016/j.cplett.2019.136943

Almond J, Sugumaar P, Wenzel MN, Hill G, Wallis C (2020) Determination of the carbonyl index of polyethylene and polypropylene using specified area under band methodology with ATR-FTIR spectroscopy. e-Polymers 20:369–381. https://doi.org/10.1515/epoly-2020-0041

Ramadevi P, Sampathkumar D, Srinivasa CV, Bennehalli B (2012) Effect of alkali treatment on water absorption of single cellulosic abaca fiber. Bioresources 7:3515–3524. https://doi.org/10.15376/biores.7.3.3515-3524

Nindiyasari F, Griesshaber E, Zimmermann T, Manian AP, Randow C, Zehbe R, Fernandez-Diaz L, Ziegler A, Fleck C, Schmahl WW (2016) Characterization and mechanical properties investigation of the cellulose/gypsum composite. J Compos Mater 50:657–672. https://doi.org/10.1177/0021998315580826

Alim MdA, Moniruzzaman Md, Hossain MdM, Wahiduzzaman RM, Hossain I, Jalil MA (2022) Manufacturing and compatibilization of binary blends of superheated steam treated jute and poly (lactic acid) biocomposites by melt-blending technique. Heliyon 8:e09923. https://doi.org/10.1016/j.heliyon.2022.e09923

Jalil MA, Moniruzzaman Md, Parvez MdS, Siddika A, Gafur MdA, Repon MdR, Hossain MdT (2021) A novel approach for pineapple leaf fiber processing as an ultimate fiber using existing machines. Heliyon 7:e07861. https://doi.org/10.1016/j.heliyon.2021.e07861

Ben Sghaier AEO, Chaabouni Y, Msahli S, Sakli F (2012) Morphological and crystalline characterization of NaOH and NaOCl treated Agave americana L. fiber. Ind Crops Prod 36:257–266. https://doi.org/10.1016/j.indcrop.2011.09.012

Abraham E, Deepa B, Pothan LA, Jacob M, Thomas S, Cvelbar U, Anandjiwala R (2011) Extraction of nanocellulose fibrils from lignocellulosic fibres: a novel approach. Carbohydr Polym 86:1468–1475. https://doi.org/10.1016/j.carbpol.2011.06.034

Le Moigne N, Navard P (2010) Dissolution mechanisms of wood cellulose fibres in NaOH–water. Cellulose 17:31–45. https://doi.org/10.1007/s10570-009-9370-5

Author information

Authors and Affiliations

Contributions

R. Purushothaman: conceptualization, methodology, data curation, writing—original draft.

A. Balaji: supervision, review and editing, validation.

J. Swaminathan: investigation, formal analysis, visualization.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Informed consent was obtained from all individual participants included in the study.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Purushothaman, R., Balaji, A. & Swaminathan, J. Influence of NaOH treatment on physical, chemical, thermal, and morphological behavior of aloe vera, banana, and corn husk fiber. Biomass Conv. Bioref. (2024). https://doi.org/10.1007/s13399-024-05740-w

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-024-05740-w