Abstract

In this study, in the process of valorizing melon biomass into food powder at 360, 540, 720 and.

900 W power values; Drying rate, moisture rate, effective moisture diffusion, SMER-SEC energy consumption and greenhouse gas emission (GHG) values of production processes were investigated. It was determined that the average drying rates of the samples varied between 0.2393–0.9376 g moisture/g dry matter.minute. According to microwave power values, the effective moisture diffusion values of the products were found to vary between 5.47 × 10–7-2.27 × 10–6 m2/s. It was determined that the average SMER values of the drying processes varied between 0.024–0.047 kg/kWh and SEC values varied between 21.12–40.93 kWh/kg. According to the drying processes, NOX, SO2 and CO2 values were calculated to vary between 0.210–1.106, 0.00–2.919 and 49.50–200.168 g, respectively. It was found that the most suitable microwave power in terms of drying kinetics, energy consumption and greenhouse gas values was 900 W.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The 45% of agricultural products produced in the world are waste [1, 2]. One of the factors that cause waste is due to the fact that agricultural products are not dried and preserved under appropriate conditions. Drying is the reduction of the moisture content in the products to the storable moisture value by thermal method. The main purpose here is to prevent deterioration caused by oxidative and enzymatic reactions, and while this is achieved, it is important to preserve the taste, aroma and color properties of the product.

There are many methods used for drying agricultural products. Drying is briefly the process of removing moisture content from the fresh product. The aim of this process is to prevent spoilage that may occur as a result of enzymatic reactions and to preserve the aroma, taste and colour properties of the products in this process [3]. The oldest known drying method is drying in the sun and shade by laying in open areas. Although it provides significant advantages in terms of environment and cost, sun drying has some disadvantages due to the fact that it cannot be carried out at all times of the year, large areas are needed, it cannot be reduced to the desired moisture level and it is adversely affected by environmental effects (dust, rain, wind, insects, birds, etc.) [4,5,6]. Another method widely used in the drying industry is the conventional artificial drying method. Convective drying is a process that causes the moisture in the gaps to evaporate with the convective heat transfer effect of heated air in order to transfer heat to the gaps within the product [7]. This method has some disadvantages such as initial installation cost, Huang et al. [8] hard, shiny materials and low energy efficiency, high energy consumption values. Convective drying method provides a more homogeneous heat distribution in the product compared to open drying, drying faster and better quality end products can be obtained [9,10,11]. Another drying method that has recently become popular is microwave drying. In the drying process with this method, unlike the hot air drying process, the rays produced by the dryer enter the product and diffuse the moisture it contains from the inside outwards. This leads to a decrease in drying time and less energy consumption [12]. The microwave method is widely used in drying processes due to its short drying time, low energy consumption and positive quality features [13]. Microwave is based on the principle of converting the kinetic energy created by the electromagnetic field energy affecting the polar molecules and ions in the moist product into thermal energy. Many molecules in food (such as water and fat) are electric dipoles. They have a positive charge at one end and a negative charge at the other end, and therefore they exhibit rotational motion as they try to stabilize themselves with alternating electricity. This effect caused by microwave rays causes friction in the rapid movement of bipolar molecules and causes heat distribution in the product exposed to microwave radiation. Microwave heating is most efficient on moisture (liquid) and much less effective on fats and sugars, which have less molecular dipole moment [14]. Fruits with a short shelf life are dried by thermal method and turned into fruit, chips and powder to obtain healthy products with high market value [9]. Fruit and vegetable powder production is increasing day by day on a global scale. According to 2017 data, the global market value of fruit powder alone is 13.52 million dollars and this value is expected to increase by 2025 [15, 16]. The commercial value of products converted into powder increases more than other dry products and provides a transportation advantage with the decrease in weight-volume ratio. In addition, the processing and alternative use of products converted into powder becomes easier [17]. Another drying method used in powder production is foam drying. This method is preferred for drying products with high sugar content and heat sensitive products. The foam drying method is a feasible process as it is both economical and practical [18]. In the foam drying process, the material is dried after being converted into puree or liquid form. Heat-mass transfer increases due to the increased surface area of the foamed product. This phenomenon positively affects the drying kinetics of the product, reduces energy consumption and increases quality [19, 20]. One of the drying methods used in biological powder production is microwave-assisted drying. Microwave assisted drying is more energy efficient and takes up less volume than methods such as open drying, tray drying, and cabinet drying [21]. In microwave-assisted drying processes, microwave waves produced in the range of 1 mm to 1 m produce energy in the product. This accelerates the heat-mass transfer in the product more than other methods, accelerates drying and saves energy. Additionally, it does not create waste and is an environmentally friendly method [22]. It is stated that microwave-assisted drying processes reduce drying time by 50% compared to other traditional drying processes. In addition, it is an important method in terms of simple operation, low cost, high efficiency and greenhouse gas emissions [23].

One of the products that are dried and turned into powder is melon fruit. Melon is a delicious, juicy fruit with a unique smell and yellow-orange colours. The main pigment substances found in melon are carotene, lutein, cryptoxanthin and phytoene [20], violaxanthin [24], neoxanthin and zeaxanthin [25]. However, melon is a product rich in beta-carotene, vitamin C, fiber, folic acid and potassium. In addition to being economically valuable, it also has a high water content, which reduces its shelf life. For this reason, it is dried and turned into fruit, chips and powder to enable consumption out of season. Some studies have been conducted in the literature on foam drying of melon fruit. Melon powder was produced by the hot air assisted foam drying method at temperatures of 50, 60 and 70 ºC. In the study, the highest drying rate was determined in the foam drying method at 70 ºC. It was found that the effective diffusion values of foamed samples were higher than the samples dried without foaming [26]. They dried cantaloupe variety melon with the hot air assisted foam drying method at 40, 55 and 70 ºC temperatures and 3.5 mm thickness. It was determined that the effective diffusion values of the drying processes varied between 1.216 × 10–8-9.483 × 10–9 m2/s. Activation energy values were determined to vary between 31.714–33.043 kJ/mol. The Weibull model best predicted the drying behavior of the product [27]. They investigated the effect of Gum Arabic substance on the product, which they used at the rates of 0, 5, 10 and 15% in a hot air dryer at a constant temperature of 55 ºC, to turn the cantaloupe variety melon fruit into powder. In terms of foam properties, the best results were obtained when using Gum Arabic at a rate of 10% [28]. No study has been found using the microwave-assisted foam drying method in the production of melon powder. In this respect, the study is thought to be original. In addition, for the first time in this study, whipped cream foaming agent was used in the production of melon powder.

The aim of this study is to investigate the effects of microwave-assisted foam drying processes on the drying rate, moisture content, effective moisture diffusion, specific moisture absorption rate (SMER), specific energy consumption (SEC) and greenhouse gas emission parameters of melon biomass into valorization food powder.

2 Material and Method

2.1 Agents and preparation of puree

Fresh melons used in the drying study were purchased from a local semp market in Tokat province. The melons were first washed with tap water and sliced lengthwise. The moisture content of melon samples on a wet basis was determined as 82.47% ± 0.23. The 10% pure water was added to turn the melon slices into puree. It was processed with a WARNING brand HGB2WTG4 model, 220–240 V, 50–60 Hz, (400 W) glass blender for.

0.5 min. To foam the prepared puree, add 2% UNIFO FOOD and SAV. TRADE. Inc. DAPHNE brand whipping agent produced by has been added. The 5% Parmor brand maltodextrin (C12H22O11) was added to stabilize the foam and to monopolize the produced powder. The entire mixture was processed in a glass blender for 2 min.

2.2 Dryer

Normal microwave (NM): A Vestel brand and MD-GD23 model microwave oven was used in the microwave drying process. The microwave oven has a total output power of 900 W and its dimensions are height × width × depth, respectively, 305 mm × 508 mm × 385 mm. The products were placed in glass petri dishes and dried on the rotating glass tray in the oven at 360, 540, 720 and 900 W power values. All dried samples were ground with a Beko brand 2166 model (700 W) food processor for 1.5 min to convert them into powder.

2.3 Moisture content

Equation number 1 was used to determine the moisture content of the samples according to dry basis (d.b.) [29].

Here: Mi; Initial weight (g), Ml; Last weight (g).

2.4 Drying rate (DR)

Equation 2 was used to determine the drying rates of the samples [30].

Here: Mt: Moisture content (g moisture/g dry matter), dt; minute, DR; Drying rate (g moisture/g drying matter per minute).

2.5 Moisture rate (MR)

Equation 3 was used to determine the rate of moisture removed from the samples during the drying processes [31].

Here; MR: Moisture rate, M; Instant moisture content of the product (g moisture/g dry matter), Me; Equilibrium moisture content of the product (g moisture/g dry matter), Mo; It is the initial moisture content of the product (g water/g dry matter).

2.6 Effective moisture diffusion

Equation 4 was used to calculate the effective moisture diffusion values of the moisture moving away from the samples during the drying processes [32].

Here: Deff: Effective diffusion value (m2/s), L; Half of the thickness value (m) of the product.

2.7 Total energy consumption values

Polaxtor brand PLX-15366 model energy analyzer (± 0.02 kWh) was used to measure the energy consumption values of the drying processes.

2.7.1 Specific moisture absorption rate (SMER)

Equation 5 will be used to calculate the specific moisture absorption rates of drying processes [33].

Here: SMER: Specific moisture removal rate (kg/kWh).

2.7.2 Specific energy consumption (SEC)

Equation 6 was used to calculate the specific energy consumption values of drying processes [34].

Here: SEC: Specific energy consumption (kWh/kg), P: Microwave power value (W), t: Drying time,

mw; amount of moisture removed (kg).

2.8 Greenhouse gas emissions (GHG)

The amounts of greenhouse gases released into the atmosphere during drying processes were calculated by Nazari et al. [35] method [36].

2.9 Statistical analysis

The SigmaPlot10 to create mathematical models of dried samples (P < 0.05). program was used. SPSS17 to statistically evaluate the findings obtained within the scope of the study. Duncan's multiple comparison test (P < 0.05) was performed in the program.

3 Results and Discussion

3.1 Moisture and drying rate

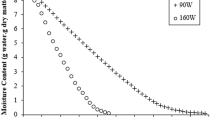

The moisture and drying rate curves of drying processes are given in Fig. 1.

According to Fig. 1, in the drying processes, the moisture content of melon puree was dried from 4.71 ± 0.0071 g moisture/g dry matter to 0.03 ± 0.00018 moisture/dry matter. Increasing the microwave power value decreased the drying time of the samples. The average duration of the drying processes varied between 19.5–5.0 min. If the power value increased from 360 to 900 W, the drying time decreased by 74.36%.

This is because microwave energy produces heat by vibrating the moisture in the product, so increasing microwave power creates more vibration per unit time. Zia et al. [37] dried watermelon slices with a vacuum-assisted microwave dryer under 400 mmHg vacuum pressure value and 160, 320 W conditions. They reported that the average drying times determined for 160 and 320 W power values were 52 and 24 min. In the study, increasing the microwave power value reduced the drying time by 53.85% on average. The fact that the microwave power values were close to each other did not have as much effect on the drying time as detected in this study. The average drying rates of melon samples were determined as 0.2393–0.9376 g moisture/g dry matter.minute. As the microwave power value increased, the drying rate of the samples increased. The reason for this is that as the microwave power value increases, more moisture is removed from the product per unit time. Haryanto et al. [38] found that drying conditions and physical effects have an increasing effect on the drying rate of the dried product., Özbek, [39] and Mouhoubi et al. [40] was stated in the studies.

3.2 Effective moisture diffusion values

The ln MR curves of drying processes are given in Fig. 2.

According to Fig. 2, it was seen that lnMR values varied between 0-(-8). Effective moisture diffusion values for drying processes are given in Table 1.

According to Table 1, microwave power values affected the effective moisture diffusion of drying processes. Effective moisture diffusion values of drying processes varied between 5.47 × 10–7-2.27 × 10–6 m2/s. Increasing the microwave power value increased the effective diffusion value. Falade et al. [41] conducted a watermelon drying study using the osmotic-oven drying method. In the study, they reported that the effective moisture diffusion value varied between 1.030 × 10−8–3.549 × 10−9 m2/s. Fernandes et al. [42] dried watermelon using the ultrasound pre-treated osmotic-hot air drying method. They found that the effective moisture diffusion values of the drying processes varied between 5.00–8.55 × 10–9 m2/s. The reason why the values in the literature are lower than the values obtained in this study is that the drying methods are different. In addition, the drying kinetics (moisture rate, drying rate) of hot air dryers are generally lower than microwave dryers [43]. It has been observed that the values determined in the literature and the values determined within the scope of this study are compatible with each other.

3.3 Energy consumption values

Energy consumption curves of drying processes are given in Fig. 3.

According to Fig. 3, the specific energy consumption and specific moisture absorption rates of the drying processes changed the microwave power values. It was determined that the average SMER values of the drying processes varied between 0.024–0.047 kg/kWh and the SEC values varied between 21.12–40.93 kWh/kg. Aktaş et al. [44] carried out a watermelon drying study in an infrared-assisted solar type dryer. They reported that within the scope of the study, maximum energy consumption values varied between 0.3–0.6 kWh. Tuçkal et al. [45] dried melon slices with a heat pump convective dryer. In the study, they reported that SMER values ranged between 0.150–0.215 kg/kWh. The reason why SMER and energy consumption values determined in the literature are higher than the values determined in this study is that the drying methods are different. The use of convective type dryers caused an increase in the drying time and energy consumption of the product when compared to this study. Within the scope of the study, total energy consumption values decreased because the increase in microwave power value reduced the drying time of the product. A similar situation was reported by Wu et al. [46], Moradi et al. [47] and Khampakool et al. [48] was found in their study.

3.4 Greenhouse gas emission (GHG) values

GHG values in drying processes are given in Table 2.

According to Table 2, it was determined that GHG values decreased as microwave power values increased. This is because the drying time of the product decreases at high microwave power values, and the amount of energy consumed by the dryer also decreases. This situation caused the GHG values to decrease. Kaveh et al. [49] dried peanuts using hot air, hot air assisted infrared and hot air assisted microwave drying methods. They reported that the lowest GHG values were detected in the hot air assisted microwave dryer. Within the scope of this study, it was determined that NOX values varied between 0.210–1.106 g, SO2 values between 0.00–2.919 g and CO2 49.50–200.168 g for all drying processes. Kaveh et al. [50] stated that the highest and lowest CO2 greenhouse gas emissions in green pea drying studies were 225.80 and 29.70 g/kg moisture, respectively.

The reason why the values in the literature are higher than the values in this study is that the drying processes were carried out in industrial type convective dryers. For this reason, the amount of energy consumed by dryers is higher. Motevali and Koloor [51] investigated the GHG values of different drying systems. The lowest CO2 and NOx greenhouse gas emissions were determined as 38.55 g and 1.54 g, respectively, in the microwave drying system. It has been observed that the GHG values determined in the microwave dryer in the literature are compatible with the GHG values determined using microwave within the scope of this study.

4 Conclusion

It has been observed that microwave power values are effective in turning melon biomass into powder. It has been observed that microwave power levels affect the drying kinetics, energy consumption and greenhouse gas values of the product. As the mychordala strength values increased, the moisture content of functional food powders increased and their drying time decreased. However, effective moisture diffusion values were positively affected. Energy consumption values of drying processes were affected by microwave power values at different levels. As the power values increased, the drying time decreased, thus the energy consumption values decreased. Microwave power values affected greenhouse gas values at different levels. In groups with the same energy production method and fuel type, NOx, SO2 and CO2 values showed the lowest emissions at 900 W microwave power value. In this study, it was determined that the most appropriate microwave power value for the melon powder production process was 900 W in terms of drying kinetics, effective moisture diffusion, energy consumption and greenhouse gas values. A microwave power value of 900 W is recommended for melon powder production.

Data availability

Data will be used upon appropriate request.

References

FAO (2011) Energy-smart food for people and climate. https://www.fao.org/4/i2454e/i2454e00.pdf. Accessed 2/3/2017

Dias PGI, Sajiwanie JWA, Rathnayaka RMUSK (2020) Chemical composition, physicochemical and technological properties of selected fruit peels as a potential food source. Int J Fruit Sci 20:240–251. https://doi.org/10.1080/15538362.2020.1717402

Bonazzi C, Dumoulin E (2011) Quality changes in food materials as ınfluenced by drying processes. Modern Drying Technol 3:1–35. https://doi.org/10.1002/9783527631667.ch1

Purohit P, Kumar A, Kandpal TC (2006) Solar drying vs. open sun drying: A framework for financial evaluation. Sol Energy 80(12):1568–1579. https://doi.org/10.1016/j.solener.2005.12.009

Sharma A, Chen CR, Lan NV (2009) Solar-energy drying systems: A review. Renew Sustain Energy Rev 13(6–7):1185–1210. https://doi.org/10.1016/j.rser.2008.08.015

Taşkın O, İzli G, İzli N (2021) Physicochemical and morphological properties of european cranberrybush powder manufactured by freezedrying. Int J Fruit Sci 21(1):1008–1017. https://doi.org/10.1080/15538362.2021.1971141

Zhou J, Tian C, Ren C, Omran M, Tang J, Zhang F, Chen G (2024) Dynamics characteristics and microstructure evolution of Sc2O3–ZrO2 ceramic powders during microwave drying. Ceram Int. https://doi.org/10.1016/j.ceramint.2024.01.200

Huang W, Zhang Y, Qiu H, Huang J, Chen J, Gao L, Omran M, Chen G (2022) Drying characteristics of ammonium polyvanadate under microwave heating based on a thin-layer drying kinetics fitting model. J Market Res 19:1497–1509. https://doi.org/10.1016/j.jmrt.2022.05.127

Morais RMSC, Morais AMMB, Dammak I, Bonilla J, Sobral PJA, Laguerre JC, Afonso MJ, Ramalhosa ECD (2018) Functional Dehydrated Foods for Health Preservation. J Food Qual https://doi.org/10.1155/2018/1739636

Yan JK, Wu LX, Qiao ZR, Cai WD, Ma HL (2019) Effect of different drying methods on the product quality and bioactive polysaccharides of bitter gourd (Momordica charantia, L.) slices. Food Chem 277:588–596. https://doi.org/10.1016/j.foodchem.2018.08.012

Boateng ID, Yang XM (2020) Effect of different drying methods on product quality, bioactive and toxic components of Ginkgo biloba L. seed. J Sci Food and Agric https://doi.org/10.1002/jsfa.10958.

Yılmaz A, Alibaş İ (2021) The impact of drying methods on quality parameters of purple basil leaves. J Food Process Preserv 45:e15638. https://doi.org/10.1111/jfpp.15638

Huang W, Zhang Y, Lu J, Chen J, Gao L, Omran M, Chen G (2023) Microwave drying method investigation for the process and kinetics of drying characteristics of high-grade rutile TiO2. Ceram Int 49(10):15618–15628. https://doi.org/10.1016/j.ceramint.2023.01.152

Sutar PP, Prasad S (2008) Microwave drying technology-recent developments and R&D needs in India. In: Proceedings of 42nd ISAE annual convention, during February 1–3. https://www.researchgate.net/publication/265144607_Microwave_drying_technology-recent_developments_and_RD_needs_in_India

Hexa Research (2018) Global fruit powder market size and forecast, by product (speciality fruits, conventional fruits), by application (food & beverages, pharmaceutical, nutraceutical, others), and trend analysis, 2015–2025. In: Market research report-food beverages, p 59. https://www.marketdataforecast.com/market-reports/fruit-powders-market

Turkiewicz IP, Wojdylo A, Tkacz K, Lech K, Michalska-Ciechanowska A, Nowicka P (2020) The influence of different carrier agents and drying techniques on physical and chemical characterization of Japanese quince (Chaenomeles japonica) microencapsulation powder. Food Chem 323:e126830. https://doi.org/10.1016/j.foodchem.2020.126830

Majid I, Nanda V (2017) Effect of sprouting on the physical properties, morphology and flowability of onion powder. J Food Measure Charact 11:2033–2042. https://doi.org/10.1007/s11694-017-9586-2

Qadri OS, Osama K, Srivastava AK (2020) Foam mat drying of papaya using microwaves: Machine learning modeling. J Food Process Eng 43:e13394. https://doi.org/10.1111/jfpe.13394

Kadam DM, Wilson RA, Kaur Manisha S (2012) Influence of foam mat drying on quality of tomato powder. Int J Food Prop 15:211–220. https://doi.org/10.1080/10942911003763701

Yano M, Kato M, Ikoma Y, Kawasaki A, Fukazawa Y, Sugiura M, Matsumoto H, Oohara Y, Nagao A, Ogawa K (2005) Quantitation of carotenoids in raw and processed fruits in Japan. Food Sci Technol Res 11:13–18. https://doi.org/10.3136/fstr.11.13

Kusuma HS, Sembiring LI, Aisahasnati S (2023) Microwave-assisted drying of Cymbogopon nardus leaves: Kinetics, moisture diffusivity, energy, and emission study. J Stored Prod Res 102:102130. https://doi.org/10.1016/j.jspr.2023.102130

Kusuma HS, Lantip GIA, Mutiara X, Iqbal M (2023) Evaluation of Mini Bibliometric Analysis, Moisture Ratio, Drying Kinetics, and Effective Moisture Diffusivity in the Drying Process of Clove Leaves using Microwave-Assisted Drying. Appl Food Res 3(1):100304. https://doi.org/10.1016/j.afres.2023.100304

Kusuma HS, Lantip GIA, Mutiara X, Lestari FW, Jaya DEC, Illiyanasafa N, Nida RA, Sari TA, Diwiyanto YM, Listiawati V, Alparisi A, Lutfah ZD, Rahmadhani N, Setyaningtyas WA, Sualiman MA (2024) Experimental investigation in the drying process of moringa leaves using microwave drying: Drying kinetics, energy consumption, and CO2 emission. Appl Food Res 4(1):100401. https://doi.org/10.1016/j.afres.2024.100401

Laur LM, Tian L (2011) Provitamin A and vitamin C contents in selected California-grown cantaloupe and honeydew melons and imported melons. J Food Compost Anal 24:194–201. https://doi.org/10.1016/j.jfca.2010.07.009

Khachik F, Beecher GR, Goli MB, Lusby WR (1991) Separation, identification, and quantification of carotenoids in fruits, vegetables and human plasma by high performance liquid chromatography. Pure Appl Chem 63:71–80. https://doi.org/10.1351/pac199163010071

Asokapandian S, Venkatachalam S, Swamy GJ, Kuppusamy K (2015) Optimization of foaming properties and foam mat drying of muskmelon using soy protein. J Food Process Eng 39(6):692–701. https://doi.org/10.1111/jfpe.12261

Salahi MR, Mohebbi M, Taghizadeh M (2014) Foam-mat drying of cantaloupe (Cucumis melo): optimization of foaming parameters and ınvestigating drying characteristics. J Food Process Preserv 39(6):1798–1808. https://doi.org/10.1111/jfpp.12414

Li TS, Sulaiman R, Rukayadi Y, Ramli S (2021) Effect of gum Arabic concentrations on foam properties, drying kinetics and physicochemical properties of foam mat drying of cantaloupe. Food Hydrocoll 116:e106492. https://doi.org/10.1016/j.foodhyd.2020.106492

Yağcıoğlu A (1999) Agricultural products drying technique. Bornova, İzmir. https://kutuphane.tarimorman.gov.tr/vufind/Record/13629

Doymaz İ, Tugru IN, Pala M (2006) Drying characteristics of dill and parsley leaves. J Food Eng 77:559–565. https://doi.org/10.1016/j.jfoodeng.2005.06.070

Maskan M (2000) Microwave/air and microwave finish drying of banana. J Food Eng 44:71–78. https://doi.org/10.1016/S0260-8774(99)00167-3

Corzo O, Bracho N, Pereira A, Vasquez A (2008) Weibull distribution for modeling air drying of coroba slices. LWT-Food Sci Technol 41:2023–2028. https://doi.org/10.1016/j.lwt.2008.01.002

Surendhar A, Sivasubramanian V, Vidhyeswari D, Deepanraj B (2019) Energy and exergy analysis, drying kinetics, modeling and quality parameters of microwave-dried turmeric slices. J Therm Anal Calorim 136:185–197. https://doi.org/10.1007/s10973-018-7791-9

Motevali A, Abbaszadeh A, Minaei S, Khoshtaghaza MH, Ghobadian B (2012) Effective moisture diffusivity, activation energy and energy consumption in thin-layer drying of jujube (Zizyphus jujube Mill). J Agric Sci Technol 14:523–532. https://www.researchgate.net/publication/285788703_Effective_Moisture_diffusivity_activation_energy_and_energy_consumption_in_thin-layer_drying_of_jujube_Zizyphus_jujube_Mill

Nazari S, Shahhoseini O, Sohrabi-Kashani A, Davari S, Paydar R, Delavar-Moghadam Z (2010) Experimental determination and analysis of CO2, SO2 and NOx emission factors in Iran’s thermal power plants. Energy 35:2992–2998. https://doi.org/10.1016/j.energy.2010.03.035

Kaveh M, Chayjan RA, Taghinezhad E, Sharabiani VR, Motevali A (2020) Evaluation of specific energy consumption and GHG emissions for different drying methods (Case study: Pistacia Atlantica). J Clean Prod 259. https://doi.org/10.1016/j.jclepro.2020.120963.

Zia S, Khan MR, Aadil RM (2023) Kinetic modeling of different drying techniques and their influence on color, bioactive compounds, antioxidant indices and phenolic profile of watermelon rind. Food Measure 17:1068–1081. https://doi.org/10.1007/s11694-022-01674-x

Haryanto B, Hasibua R, Lubis AH, Wangi Y, Khosman H, Sinaga AW (2020) Drying rate of turmeric herbal (Curcuma longa L.) using tray dryer. J Physics: Conf Ser 1542:012056. https://doi.org/10.1088/1742-6596/1542/1/012056

Özbek HN (2021) Radio frequency-assisted hot air drying of carrots for the production of carrot powder: Kinetics and product quality. LWT 152:e112332. https://doi.org/10.1016/j.lwt.2021.112332

Mouhoubi K, Boulekbache-Makhlouf L, Mehaba W, Himed-Idir H, Madani K (2021) Convective and microwave drying of coriander leaves: Kinetics characteristics and modeling, phenolic contents, antioxidant activity, and principal component analysis. J Food Proces Eng 45:e13932. https://doi.org/10.1111/jfpe.13932

Falade KO, Igbeka JC, Ayanwuyi FA (2007) Kinetics of mass transfer, and colour changes during osmotic dehydration of watermelon. J Food Eng 80:979–985. https://doi.org/10.1016/j.jfoodeng.2006.06.033

Fernandes FAN, Gallão MI, Rodrigues S (2008) Effect of osmotic dehydration and ultrasound pre-treatment on cell structure: Melon dehydration. LWT-Food Sci Technol 41:604–610. https://doi.org/10.1016/j.lwt.2007.05.007

Nizamloğlu NM (2022) Farklı sıcaklık ve mikrodalga güçlerinde kurutulan elma dilimlerinin kurutma özellikleri. Akademik Gıda 20:253–262. https://doi.org/10.24323/akademik-gida.1186984

Aktaş M, Şevik S, Amini A, Khanlari A (2016) Analysis of drying of melon in a solar-heat recovery assisted infrared dryer. Sol Energy 137:500–515. https://doi.org/10.1016/j.solener.2016.08.036

Tunçkal C, Ozkan-Karabacak A, Tamer CE, Yolcı-Omeroglu P, Goksel Z (2022) Mathematical modelling and optimization of melon slice drying with response surface methodology in a heat pump drying system. Latin Am Appl Res 52:101–110. https://doi.org/10.52292/j.laar.2022.851

Wu XF, Zhang M, Bhandaria B (2019) A novel infrared freeze drying (IRFD) technology to lower the energy consumption and keep the quality of Cordyceps militaris. Innov Food Sci Emerg Technol 54:34–42. https://doi.org/10.1016/j.ifset.2019.03.003

Moradi M, Azizi S, Niakousari M, Kamgar S, Khaneghah AM (2020) Drying of green bell pepper slices using an IR-assisted Spouted Bed Dryer: An assessment of drying kinetics and energy consumption. Innov Food Scie Emerg Technol 60:e102280. https://doi.org/10.1016/j.ifset.2019.102280

Khampakool A, Soisungwan S, Park SH (2019) Potential application of infrared assisted freeze drying (IRAFD) for banana snacks: Drying kinetics, energy consumption, and texture. LWT 99:355–363. https://doi.org/10.1016/j.lwt.2018.09.081

Kaveh M, Sharabiani VR, Chayjan RA, Taghinezhad E, Abbaspour-Gilandeh Y, Golpour I (2018) ANFIS and ANNs model for prediction of moisture diffusivity and specific energy consumption potato, garlic and cantaloupe drying under convective hot air dryer. Inf Process Agric 5(3):372–387. https://doi.org/10.1016/j.inpa.2018.05.003

Kaveh M, Abbaspour-Gilandeh Y, Nowacka M (2021) Comparison of different drying techniques and their carbon emissions in green peas. Chem Eng Proces-Proces Intensif 160:e108274. https://doi.org/10.1016/j.cep.2020.108274

Motevali A, Kloor RT (2017) A comparison between pollutants and greenhouse gas emissions from operation of different dryers based on energy consumption of power plants. J Clean Produc 154:445–461. https://doi.org/10.1016/j.jclepro.2017.03.219

Acknowledgements

No data set from any institution was used in this study.

Funding

Open access funding provided by the Scientific and Technological Research Council of Türkiye (TÜBİTAK). This study did not benefit from any funding agency.

Author information

Authors and Affiliations

Contributions

Muhammed Taşova: Planning, data processing, article writing. Samet Kaya Dursun: Laboratory work, data processing.

Corresponding author

Ethics declarations

Compliance with ethical standards

This study has been prepared in accordance with ethical standards.

Conflict of interest

The author in the study has no conflict of interest with any other author.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

TAŞOVA, M., DURSUN, S.K. Comparison of microwave assisted foam drying processes to improve the physicochemical properties and to reduce GHG values of the melon powder processes. Biomass Conv. Bioref. (2024). https://doi.org/10.1007/s13399-024-05680-5

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-024-05680-5