Abstract

Treatment of wastewater has become vital to prevent environmental pollution in recent years. Adsorption is an easily applicable, low-cost and efficient method and is the subject of this study. In this study, an adsorbent was synthesized to be used in heavy metal removal using chitosan and starch. The composite was characterized by Fourier transform infrared (FTIR) spectrophotometry, X-ray powder diffraction (XRD), thermogravimetric analysis (TGA), and scanning electron microscopy (SEM), energy-dispersive X-ray (EDX) analysis. It was determined that the composite had an amorphous and compact structure. Adsorption experiments were carried out under the optimized parameters such as solution pH, concentration, adsorbent amount, equilibrium time, and temperature. It shows that during adsorption, with the increase in pH, the adsorption efficiency and adsorption capacity first increase and then a fluctuation occurs. The highest adsorption efficiency and Q value were reached at pH 3.46 as 78% and 0.038 mol/kg, respectively. Moreover, the adsorption capacity (Q) reached its highest value with a value of 0.067 mol/kg in the presence of 30 mg adsorbent. Equilibrium experiments were validated by the Langmuir, Freundlich, Temkin and Dubinin–Radushkevich isotherm models. To investigate the adsorption mechanism, pseudo-first-order (PFO) and pseudo-second-order (PSO) kinetic models were used. It was determined that the adsorption process followed the D-R isotherm (R2 = 0.99) and PSO (R2 = 0.99). Therefore, the existence of chemical adsorption can be mentioned. Thermodynamic parameters enthalpy (∆H), Gibbs free energy (∆G) and entropy change (∆S) were investigated. The adsorbate-adsorbent interactions were studied by density functional theory (DFT).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Water is polluted in many ways, such as wastewater from the leather and chemical industries, electroplating and paint industries [1]. Industrially polluted water often contains significant amounts of toxic heavy metals. Thus, water bodies polluted with Pb, Cr, Hg, Cu, Cd, Zn, and Ni, pose an important environmental problem [2,3,4]. Removal of the ions of these metals from industrial wastewater has become imperious in many research efforts [5,6,7].

Most industries are encouraged to minimize the metal content in wastewater. Applied methods include precipitation, adsorption [8], ion exchange [9], chemical oxidation [10], coagulation [11], flocculation [12], reverse osmosis, and membrane filtration [13,14,15].

Lead (Pb+2) is one of the commonest hazardous heavy metal [16]. Human organs and tissues, bones, liver, kidney, and brain, accumulate of Pb(II) and this leads to serious health disorders, such as encephalopathy, seizures, mental retardation, anaemia, and nephropathy [14].

Chitosan, cellulose, starch, and alginate are polysaccharide homopolymers. They are abundant in nature. Therefore, their use in the removal of heavy metal ions is comparably cost-effective. Their adsorption capacity, mechanical stability, and hydrophilicity can be improved in composite forms [17,18,19].

Chitosan (poly-β-(1 → 4)-2-amino-2-deoxy-D-glucose) is a nitrogen-containing (amino-based) polysaccharide produced in large quantities by N-deacetylation of chitin [20, 21]. Because of its non-toxic, biocompatible, and biodegradable properties, it is also exploited in medicine, cosmetics, food industry, and in the production of biological membranes [22]. The biggest advantage of chitosan is the availability of substitutable positions in its chemical structure. It has very powerful heavy-metal chelating moieties, amino and hydroxyl groups [23]. And nanofibers containing chitosan have been thoroughly investigated via a number of heavy-metal adsorption experiments [24].

Starch, another versatile natural polysaccharide, is also used in food, cosmetics, and pharmaceuticals [25, 26]. Starch is a mechanically stable adsorbent with its rich hydroxyl groups, and high surface area. It has recently received significant attention in wastewater treatment efforts [27,28,29].

This research focuses on the preparation of a chitosan-starch composite and its use in Pb(II) removal from aqueous media, as metals are mostly ionized in an aqueous environment. Langmuir and Freundlich isotherms were used to fit the adsorption equilibrium data. Adsorption kinetics were calculated by pseudo-first-order, and pseudo-second-order models. The negative ∆G and ∆H values indicated that the Pb adsorption reaction of the chitosan-starch composite was exothermic and spontaneous, respectively. The binding energy for the interaction between adsorbent and adsorbate was 11.416 eV. This high interaction energy can be explained by the Hard and Soft Acid–Base Principle. Pb2+, thanks to -NH2 groups in the structure of the chitosan, could act as a soft base. The reaction mechanism was closely related to the chemical hardness values of the adsorbent and adsorbate.

2 Materials and methods

2.1 Chemicals used

Starch, epichlorohydrin (ECH), erythrosine B, Ethanol (EtOH), hydrochloric acid (HCl), chitosan, sodium hydroxide (NaOH), and sodium tripolyphosphate (TPP) were of analytical grade and were obtained from Merck and Sigma-Aldrich companies.

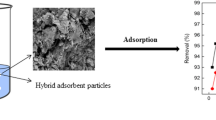

2.2 Preparation of chitosan-starch composites

Double cross-linked chitosan-starch composite beads were prepared by mixing chitosan and starch at room temperature (25 °C): 4 g chitosan and 4 g starch in 160 mL (5% v/v) acetic acid (Fig. 1). The suspension was stirred vigorously for 2 h. Then, 160 mL (0.01 M) epichlorohydrin (ECH) pH 10.0 was added to the suspension and stirred vigorously for an additional 1 h. The suspension was added dropwise to the solution containing 500 mL (0.05 M) sodium tripolyphosphate (NaTPP). The mixture was stirred at 100 rpm for 3 h. The beads formed were filtered, and washed with distilled water to remove excess NaTPP, and were then dried at 37 °C. Before use, the beads were ground [30, 31].

2.3 Characterization of the biosorbent

The synthesized chitosan-starch composite was analyzed by Fourier Transform Infrared (FTIR) Spectrometer (ATR, Bruker, Tensor II), Scanning Electron Microscope (SEM), Energy Dissipative X-Ray (EDX) at CUTAM Central Laboratory (Sivas Cumhuriyet). University, Turkey) and ultraviolet–visible spectroscopy (TESCAN MIRA3 XMU, T-60, China).

2.4 Effect of PZC on the biosorbent

Biosorbent, 0.1 g, was dissolved in a series of 0.1 mol L−1 KNO3 solutions, pH1.0 and 12.0. For the adjustment of pH, HCl or NaOH (0.1 mol L-1) were used. PZC values were obtained by plotting initial pH values against ΔpH. Final pH was recorded after 24 h [32].

2.5 Batch adsorption experiments

2.5.1 Pb2+ adsorption from aqueous solution

Batch technique was used in all the adsorption studies, and adsorbed Pb2+ concentrations were determined by spectrophotometry (Perkin Elmer UV/Vis Spectrophotometer Lambda 25) using PAR [4-(2-pyridylazo) resorcinol)]: equilibrium solution, 50 µL, was added to 3.5 × 10–3 mol L−1 PAR solution, prepared in 0.7 M Tris/HCl (pH 8.5) buffer. The absorbance was read at 518.5 nm against the PAR reference [33]. The adjustment curve was created for the concentration range where the concentration absorbance change was linear [34].

Change in Adsorption with pH

The adsorbent, 0.05 g, was used within the pH in the range between 1.0 and 5.5, prepared with HCl or NaOH. This solution was interacted with 10 mL of 50 mg L−1 Pb2+ solutions.

Adsorption Variation with Concentration

After the completion of adsorption reaction, the ion concentration was measured. The adsorption pH was chosen as 5.8. Experimental isotherms showing the variation of adsorption with concentration were created, and the relevant parameters were derived using their fit with Langmuir, Freundlich and Dubinin-Radushkevich (DR) isotherms.

Change in Adsorption with Adsorbent Mass

Chitosan-starch composite, 30, 50, 100, or 250 mg, was added to 10 mL of 50 mg L−1 Pb2+ solution and the ion concentrations at equilibrium were measured after 24 h.

Change in Adsorption with Time

Sixty millilitres of 50 mg L−1 Pb2+ were added to 0.05 g adsorbent, and ion concentration change in the equilibrium solutions over time was detected at time intervals, using 1 mL aliquots for 24 h, and kinetic parameters were obtained.

Change in Adsorption with Temperature

Ten millilitres of 50 mg L−1 constant Pb2+ concentration solutions were added on 0.05 g adsorbent and the variation of adsorption with temperature was investigated at 5, 25, 40, and 50 °C. Thermodynamic parameters were derived from the variation of adsorption with temperature.

2.6 Details of density functional theory calculations

All DFT-calculations were performed using the B3LYP exchange–correlation functional [35, 36] and hybrid electronic basis set combining 6-31G(d) [37] for elements H, C, N, O and the lanl2dz [38] for Pb. The dispersion corrections D3 proposed by Grimme [39] were also included to take into account the weak non-covalent interactions, using the graphics processor-based TeraChem software [40,41,42,43]. Geometry optimization was carried out with the efficient geomeTRIC energy minimizer [44].

3 Results and discussion

3.1 Characterization studies

3.1.1 FTIR analysis

The chemical structure of the synthesized chitosan-starch composite, before and after Pb+2 adsorption, was investigated by FTIR spectroscopy (Fig. 2a and b). The broad peak occurring at 3248 cm−1 is attributable to a stretch O–H of the composite. It may also indicate N–H stretching. Peaks at 2929, 1633, 999–1013 cm−1 can be attributed to C-H, O–H, and C-O stretchings, respectively [45]. The peak seen at 2102 cm−1 represented minor starch components (lipid and protein) [46]. The small peak at 1632 cm−1 can be attributed to the C = O double bond stretch of the amide group, and the peak at 898 cm−1 to the C-H stretch of the cross-linked chitosan molecule, respectively [47]. After Pb2+adsorption, slight shifts were observed in the position of the functional groups (Fig. 2b). Some electrostatic or chelation interactions between Pb2+ and functional groups of the composite could be responsible for these changes [48]. An overall decrease in peak intensity was also obvious.

3.1.2 XRD characterization

The peaks at 2θ = 23.39° and 18.45° were characteristic of starch (Fig. 3), and those of chitosan was located at 23° [49]. After the adsorption, the density decreased in all composite peaks, due to Pb2+ adsorption.

3.1.3 Thermal analysis

The thermal stability of the composite was investigated in a temperature range between 22 and 890 °C, and was examined by TGA (Fig. 4a and b). Weight loss below 100 °C represented the evaporation of water and volatile substances. Antioxidants may also be degraded [50, 51]. In the range between 260 °C and 375 °C, the decomposition step accelerated. Chitosan chain may be split [52]. At this stage, chitosan amino moieties were expected to decompose. Starch can decompose into glycerol at about 290 °C [51]. Glucose units of starch undergo depolymerisation [46]. Finally, chitosan decomposes by pyrolysis up to approximately 600 °C. The cyclic structures of starch are degraded [50, 51]. Decomposition process caused a dramatic mass loss, 70%. After adsorption although the degradation stages were similar, the mass loss was 67% (Fig. 4b).

3.1.4 SEM–EDX characterization

Composite morphology and elemental analysis were investigated by SEM and EDX (Fig. 5a, b, c and d). It can be said that the chitosan-starch composite had a compact structure (Fig. 5a). This may be due to the strong interaction between cross-linked chitosan, starch and NaTPP [47]. After Pb2+ adsorption, a flattening and smoothing of the surfaces occurred due to swelling.

3.2 Data of adsorption

3.2.1 Effect of pH

The pH value of the adsorbate solution is very important in the adsorption process. The surface charge and degree of ionization of the adsorbent depend on the pH of the solution [53]. In understanding pH effect on adsorption, pHpzc was investigated first [54]. pHpzc is the pH value at which the net surface charge of the adsorbent is zero, and it is important for electrostatic interactions. It has been reported that cationic ions are better adsorbed when the solution pH is higher than pHpzc, whereas anionic ions are better adsorbed when the solution pH is lower than pHpzc [55]. Chitosan-starch composite pHpzc was 5.12 (Fig. 6a). The adsorbent surface becomes protonated with H+ ions when the pH is less than 5.12. The surface becomes anionic, with OH− ions, when pHpzc is greater than 5.12 (Fig. 6b). As Pb precipitates at high pH values, adsorption efficiency and Q decreases [56]. This may be because when pH is greater than 5, Pb hydrolyzes and therefore precipitates, making adsorption difficult [57].

The results showed that with the increase of pH, the adsorption efficiency and adsorption capacity firstly increased and then fluctuations occured. The highest adsorption efficiency and Q value were reached at pH 3.46 as 78% and 0.038 mol/kg, respectively. As the pH increases, the OH− ion in the environment would also increase, and some Pb salts might form [58].

3.2.2 Effect of adsorbent amount

The effect of different adsorbent amounts (30, 50, 100, 200 mg) on adsorption was studied (Fig. 7). It was determined that Q decreased as the amount of adsorbent increased. This may be due to the fact that as the amount of adsorbent increased, the active sites on the surface became saturated and agglomeration occurred [59]. At high adsorbent dose, the surface area might begin to decrease due to the overlap of the adsorbent’s active sites [60, 61]. The highest adsorption efficiency was reached with 100 mg, and the adsorption capacity (Q) reached its highest value with 30 mg adsorbent.

3.2.3 Isotherms

Lead adsorption of chitosan-starch composite was investigated by Langmuir, Freundlich, Temkin and Dubinin-Radushkevich (D-R) isotherm models. The Langmuir isotherm (Eq. 1) indicates that the adsorbent surface is homogeneous and the presence of monolayer adsorption. Here, Qm refers to the maximum adsorption capacity and b refers to the Langmuir constant. RL in Eq. 2 gives information on the suitability of the isotherm adsorption process. If RL is equal to 1, it means that the adsorption is linear, between 0 and 1 it is favourable, if it is greater than 1, it is unfavourable [56]. Freundlich isotherm (Eq. 3) expresses a heterogeneous adsorbent surface and multilayered adsorption [62]. The Temkin isotherm (Eq. 4) is used to determine the heat of adsorption between adsorbent and adsorbate. Here At, BT, and B are constants. The D-R isotherm calculates (Eq. 5) and characterizes the free energy in the adsorption process. KDR is the D-R isotherm constant, and \(E\) (Eq. 7) is the free energy constant [63].

Non-linear (Fig. 8) and linear (Fig. 9) forms of isotherm models were applied. The D-R isotherm showed the best fit to the q and C curves (Table 1) (Fig. 8). In Langmuir isotherm, Qm was 99.01. RL values resided between 0 and 1, indicating a favourable adsorption. The highest R2 value (0.99) was found with the D-R isotherm. The E value was 500 kJ/mol (Table 1), indicating a chemical adsorption [64]. The regression values delineated the models as D-R > Freundlich > Langmuir > Temkin.

3.2.4 Kinetics

Examination of kinetic models is important for understanding the adsorption mechanism [56]. To investigate the adsorption mechanism, pseudo-first-order (PFO) and pseudo-second-order (PSO) kinetic models were used. PFO and PSO were expressed in Eqs. 8 and 9, respectively. k1 is the kinetic model constant for PFO, k2 is the kinetic model constant for PSO.

Regression values were used for the the suitability of the kinetic models (Figs. 10 and 11). Pb2+ adsorption on the chitosan-starch composite suited to PSO with an R2 value of 0.99 (Table 2). Nonlinear regression analysis (graphs for PFO and PSO) (Fig. 10), indicated that the experimental qt data was in a better agreement with the qt values. The highest R2 value of linear regression was 0.99. This result indicated a chemisorption, taken place between the chitosan-starch composite and Pb2+ [56, 60].

3.2.5 Adsorption thermodynamics

Thermodynamic parameters enthalpy (∆H), Gibbs free energy (∆G) and change in entropy (∆S) were investigated between 288 and 323 K (Eqs. 10-12). Ln Kc vs. 1/T values were plotted (Van't Hoff equation, Eq. 11; Fig. 12) (Table 3). The ideal gas constant R was 8.314 J/mol.K. Negative ∆H indicated that Pb2+ adsorption on chitosan-starch composite was exothermic. Negative ∆G values also point out that adsorption was spontaneous and favourable [65]. ∆G decreased as the temperature increased (Table 3). This result showed that a spontaneous adsorption process took place [65]. As the temperature increased, the spontaneous reaction also increased [46]. The positive ∆S value was brought about an increased randomness between the solid/solution interface [66].

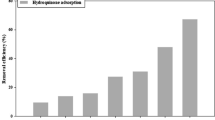

3.2.6 Recovery

Reusability of adsorbents is important in terms of sustainability. The reusability of the chitosan-starch composite was tested thrice in a NaOH solution and 65% recovery of the activity was achieved (Fig. 13). Desorption was executed at different concentrations of HCl, NaOH and ethanol eluents, and the best result was obtained with 0.1 M in NaOH (Fig. 14).

After the third round of adsorption/desorption, adsorbent activity was 65%. This result can be attributed to the dissolution or degradation of the adsorbent [46]. The alkaline environment might adversely affect the structure of starch, causing partial degradation by breaking its hydrogen bonds [67].

3.2.7 Results of DFT calculations

Possible effects of Pb2+ on the geometry and electronic structure of the chitosan-starch composite was investigated. Two-ring simple fragments were used both as chitosan- and starch models (Figs. 15 and 16, respectively). The binding energy of chitosan-starch composite (Fig. 17) was determined by using the equation below:

The binding energy was 2.034 eV (Table 4). It can be seen that Pb2+ is geometrically located near the aromatic oxygen atoms on the chitosan and starch rings (Fig. 18). The presence of the ion significantly changed the electronic structure of the chitosan-starch composite, facilitating charge transfer, and reducing the gap between the frontier orbitals (Table 4). The adsorption energy, 11.416 eV, was obtained using the formula below:

Chemical hardness is defined as the resistance towards electron cloud polarization or deformation of chemical species. Hard acids prefer to coordinate to hard bases, and soft acids prefer the coordinate to soft bases. In CDFT, chemical hardness was calculated as \(\eta ={E}_{LUMO}-{E}_{HOMO}\) based on frontier orbital energies.

4 Conclusion

In this study, chitosan-starch composite was synthesized and used for the adosrption of Pb2+ in aqueous solutions. The synthesized composite was characterized by FTIR, XRD, TG and SEM techniques and its structure was investigated. By optimizing the parameters affecting the adsorption process, 94% lead removal was achieved. It was determined that the adsorption process followed the PSO kinetic model with the D-R isotherm, in which it emerged with a chemical reaction. The maximum adsorption capacity was calculated as 99.01 mg/g. With these results, it is thought that the environmentally friendly composite obtained by using an important biopolymer, chitosan, and starch can be used effectively in water treatment.

Data availability

All data and materials supporting the results of this research are available in the article.

References

Sudha PN (2010) Chitin/chitosan and derivatives for wastewater treatment. In: Kim S-K (ed) Chitin, chitosan, oligosaccharides and their derivatives biological activities and applications. CRC Press, Boca Raton, pp 561–585

Baraka A, Hall P, Heslop JJ (2007) Melamine formaldehyde NTA chelating gel resin; synthesis, characterization and application for copper (II) ion removal from synthetic wastewater. J Hazard Mater 140:86–94

Bose P, Bose M, Kumar S (2002) Critical evaluation of treatment strategies involving adsorption and chelation for wastewater containing copper, zinc and cyanide. Adv Environ Res 7:179–195

Hasany SM, Saeed MM, Ahmed M (2002) Sorption and thermodyamics behaviour of Zn (II) thiocyanate complexes onto polyurethane foam from acidic solutions. J Radioanal Nucl Chem 252:477–484

Jayakumar S, Gomathi T, Sudha PN (2013) Sorption studies of lead (II) onto crosslinked and non crosslinked biopolymeric blends. Int J Biol Macromol 59:165–169

Saravanan D, Gomathi T, Sudha PN (2013) Sorption studies on heavy metal removal using chitin/ bentonite biocomposite. Int J Biol Macromol 53:67–71

Ramasubramaniam S, Govindarajan C, Nasreen K, Sudha PN (2014) Removal of cadmium (II) ions from aqueous solution using chitosan/starch polymer blend. Compos Interf 21(2):95–109

Akgül M, Karabakan A (2011) Promoted dye adsorption performance over desilicated natural zeolite. Microporous Mesoporous Mater 145(1–3):157–164

Zewail TM, Yousef NS (2015) Kinetic study of heavy metal ions removal by ion exchange in batch conical air spouted bed. Alex Eng J 54(1):83–90

Chafi M, Gourich B, Essadki AH, Vial C, Fabregat A (2011) Comparison of electrocoagulation using iron and aluminium electrodes with chemical coagulation for the removal of a highly soluble acid dye. Desalination 281:285–292

Osugi ME, Rajeshwar K, Ferraz ER, de Oliveira DP, Araújo AR, Zanoni MVB (2019) Comparison of oxidation efficiency of disperse dyes by chemical and photoelectrocatalytic chlorination and removal of mutagenic activity. Electrochim Acta 54(7):2086–2093

Pang FM, Kumar P, Teng TT, Kailas L (2009) Wasewater removal of lead, zinc and iron by coagulation flocculation. J Taiwan Inst Chem Eng 42:809–815

Çelik MS, Çetinus ŞA, Yenidünya AF, Çetinkaya S, Tüzün B (2023) Biosorption of Rhodamine B dye from aqueous solution by Rhus coriaria L. plant: Equilibrium, kinetic, thermodynamic and DFT calculations. J Molec Struct 1272:134158

Ajitha P, Vijayalakshmi K, Saranya M, Gomathi T, Rani K, Sudha PN, Sukumaran A (2017) Removal of toxic heavy metal lead (II) using chitosan oligosaccharide-graft-maleic anhydride/polyvinyl alcohol/silk fibroin composite. Int J Biol Macromol 104:1469–1482

Wang S, Liu Y, Yang A, Zhu Q, Sun H, Sun P, … Dong L (2022) Xanthate-Modified Magnetic Fe3O4@ SiO2-based polyvinyl alcohol/chitosan composite material for efficient removal of heavy metal ions from water. Polymers 14(6), 1107

Yarkandi NY (2014) Removal of lead (II) from waste water by adsorption. Int J Curr Microbiol App Sci 3:207–228

Sardar UR, Bhargavi E, Devi I, Bhunia B, Tiwari ON (2018) Advances in Exopolysaccharides Based Bioremediation of Heavy Metals in Soil and Water. A Critical Review Carbohydr Polym 199:353–364

Mohammed N, Grishkewich N, Tam KC (2018) Cellulose Nanomaterials: Promising Sustainable Nanomaterials for Application in Water/wastewater Treatment Processes. Environ Sci Nano 5:623–658

Na Y, Lee J, Lee SH, Kumar P, Kim JH, Patel R (2020) Removal of heavy metals by polysaccharide: A review. Polymer-Plastics Technol Mater 59(16):1770–1790

Muzzarelli RA (1973) Natural chelating polymers. Alginic acid, chitin and chitosan, vol 55. Pergamon Press, Oxford, p 83

Rinaudo M (2006) Chitin and chitosan: Properties and applications. Prog Polym Sci 31(7):603–632

Kyzas GZ, Bikiaris DN, Mitropoulos AC (2017) Chitosan adsorbents for dye removal: a review. Polym Int 66(12):1800–1811

Dong L, Shan C, Liu Y, Sun H, Yao B, Gong G, … Wang S (2022) Characterization and mechanistic study of heavy metal adsorption by facile synthesized magnetic xanthate-modified chitosan/polyacrylic acid hydrogels. Int J Environ Res Public Health 19(17):11123

Surgutskaia NS, Di Martino A, Zednik J, Ozaltin K, Lovecká L, Bergerova ED, … Sedlarik V (2020) Efficient Cu2+, Pb2+ and Ni2+ ion removal from wastewater using electrospun DTPA-modified chitosan/polyethylene oxide nanofibers. Separation Purific Technol 247:116914

Sessini V, Arrieta MP, Kenny JM, Peponi L (2016) Processing of edible films based on nanoreinforced gelatinized starch. Polym Degrad Stab 132:157–168

Zhang Z, Huang J, Jiang S, Liu Z, Gu W, Yu H, Li Y (2013) Porous starch based self-assembled nano-delivery system improves the oral absorption of lipophilic drug. Int J Pharm 444(1–2):162–168

Ma X, Liu X, Anderson DP, Chang PR (2015) Modification of porous starch for the adsorption of heavy metal ions from aqueous solution. Food Chem 181:133–139

Dhakshinamoorthy A, Asiri AM, Alvaro M, Garcia H (2018) Metal organic frameworks as catalysts in solvent-free or ionic liquid assisted conditions. Green Chem 20(1):86–107

Fang Y, Lv X, Xu X, Zhu J, Liu P, Guo L, Cui B (2020) Three-dimensional nanoporous starch-based material for fast and highly efficient removal of heavy metal ions from wastewater. Int J Biol Macromol 164:415–426

Wan Ngah WS, Teong LC, Wong CS, Hanafiah MAKM (2012) Preparation and characterization of chitosan–zeolite composites. J Appl Polym Sci 125(3):2417–2425

Çetinkaya HF, Cebeci MS, Kaya S, Jalbani NS, Maslov MM, Marzouki R (2023) Removal of erythrosine B dye from wastewater using chitosan boric acid composite material: experimental and density functional theory findings. J Phys Org Chem 36(12):e4400

Çetinkaya S, Eyupoglu V, Çetintaş Hİ, Yenidünya AF, Kebabcı Ö, Tüzün B (2023) Removal of Erythrosine B dye from wastewater by Penicillium italicum: experimental, DFT, and molecular docking studies. J Biomolec Struct Dynam 41(23):14212–14223

Bayazit ŞS, İnci İ (2013) Adsorption of Pb (II) ions from aqueous solutions by carbon nanotubes oxidized different methods. J Ind Eng Chem 19(6):2064–2071

Baybaş D (2018) Amidoksimleştirilmiş Yarı-IPN ile Sulu Çözeltiden Pb2+ Giderimi. Dokuz Eylül Üniversitesi Mühendislik Fakültesi Fen ve Mühendislik Dergisi 20(60):776–796

Lee C, Yang W, Parr RG (1988) Development of the Colle-Salvetti correlation-energy formula into a functional of the electron density. Phys Rev B 37:785

Becke Ad (1993) Density-functional thermochemistry. III. The role of exact exchange. J Chem Phys 98:5648

Francl MM, Pietro WJ, Hehre WJ, Binkley JS, Gordon MS (1982) Self consistent molecular orbital methods. XXIII. A polarization type basis set for second row elements. J Chem Phys 77:3654–3665

Wadt R, Willard R, Hay JP (1985) Ab initio effective core potentials for molecular calculations. Potentials for main group elements Na to Bi. J Chem Phys 82:284–298

Grimme S, Antony J, Ehrlich S, Krieg H (2010) A consistent and accurate ab initio parametrization of density functional dispersion correction (DFT-D) for the 94 elements H-Pu. J Chem Phys 132:154104

Ufimtsev IS, Martínez TJ (2009) Quantum Chemistry on Graphical Processing Units. 3. Analytical Energy Gradients and First Principles Molecular Dynamics. J Chem Theo Comp 5:2619

Titov AV, Ufimtsev IS, Luehr N, Martínez TJ (2013) Generating Efficient Quantum Chemistry Codes for Novel Architectures. J Chem Theo Comp 9:213

Kästner J, Carr JM, Keal TW, Thiel W, Wander A, Sherwood P (2009) DL-FIND: An OpenSource Geometry Optimizer for Atomistic Simulations. J Phys Chem A 113:11856

Goumans TPM, Catlow CRA, Brown WA, Kästner J, Sherwood P (2009) An Embedded Cluster Study of the Formation of Water on Interstellar Dust Grains. Phys Chem Chem Phys 11:5431

Wang LP, Song C (2016) Geometry optimization made simple with translation and rotation coordinates. J Chem Phys 144:214108

Xu YX, Kim KM, Hanna MA, Nag D (2005) Chitosan-starch composite film: Preparation and characterization. Ind Crops Prod 21(2):185–192

Akinterinwa A, Oladele E, Adebayo A, Ajayi O (2020) Removal of Pb2+ and Cd2+ from Aqueous Solutions using POCl3 Cross-linked Carboxymethyl Derivatives of Legume Starch. Makara J Sci 24(3):4

Singh V, Kumari K (2014) Synthesis and Characterization of Chitosan – Starch Crosslinked Film for Controlled Drug. Int J Mater Biomater Appl 4(1):7–13

Akinterinwa A, Oladele E, Adebayo A, Adamu M (2023) Characterization of aqueous Pb2+ adsorption onto cross-linked-carboxymethyl legume starch phosphate using FTIR and SEM-EDX. Biomass Convers Biorefin 1–15

Ren L, Yan X, Zhou J, Tong J, Su X (2017) Influence of chitosan concentration on mechanical and barrier properties of corn starch/chitosan films. Int J Biol Macromol 105:1636–1643

Perez JJ, Francois NJ (2016) Chitosan-starch beads prepared by ionotropic gelation as potential matrices for controlled release of fertilizers. Carbohyd Polym 148:134–142

Lozano-Navarro JI, Díaz-Zavala NP, Velasco-Santos C, Melo-Banda JA, Páramo-García U, Paraguay-Delgado F, Garcia Alamilla R, Martinez-Hernandez AL, Zapién-Castillo S (2018) Chitosan-starch films with natural extracts: Physical, chemical, morphological and thermal properties. Materials 11(1):120

Jana S, Trivedi MK, Tallapragada RM, Branton A, Trivedi D, Nayak G, Mishra R (2015) Characterization of physicochemical and thermal properties of chitosan and sodium alginate after biofield treatment. Pharm Anal Acta 6(10)

Zhang M, Zhang Z, Peng Y, Feng L, Li X, Zhao C, Sarfaraz K (2020) International Journal of Biological Macromolecules Novel cationic polymer modified magnetic chitosan beads for ef fi cient adsorption of heavy metals and dyes over a wide pH range. Int J Biol Macromol 156:289–301

Wang S, Yuan C, Zafar FF, Wei M, Marrakchi F, Cao B, Fu Y (2023) Facile synthesis of chlorella-derived autogenous N-doped porous biochar for adsorption on tetracycline. Environ Pollut 121717

Hashem A, Aniagor CO, Morsy OM, Abou-Okeil A, Aly AA (2022) Apricot seed shell: an agro-waste biosorbent for acid blue193 dye adsorption. Biomass Convers Biorefinery 1–14

Mahyoob W, Alakayleh Z, Abu Hajar HA, Al-Mawla L, Altwaiq AM, Al-Remawi M, Al-Akayleh F (2022) A novel co-processed olive tree leaves biomass for lead adsorption from contaminated water. J Contam Hydrol 248:104025

López-Mesas M, Navarrete ER, Carrillo F, Palet C (2011) Bioseparation of Pb (II) and Cd (II) from aqueous solution using cork waste biomass. Modeling and optimization of the parameters of the biosorption step. Chem Eng J 174(1):9–17

Ramasubramaniam S, Govindarajan C, Nasreen K, Sudha PN (2014) Removal of cadmium ( II ) ions from aqueous solution using chitosan / starch polymer blend. Compos Interf 21(2):95–109

Sadaf S, Bhatti HN (2014) Journal of the Taiwan Institute of Chemical Engineers Batch and fixed bed column studies for the removal of Indosol Yellow BG dye by peanut husk. J Taiwan Inst Chem Eng 45(2):541–553

Yildirim A (2020) Kinetic, equilibrium and thermodynamic investigations for the bio-sorption of dyes onto crosslinked Pleurotus ostreatus -based bio- composite. Int J Environ Anal Chem 00(00):1–16

Barka N, Abdennouri M, El Makhfouk M, Qourzal S (2013) Biosorption characteristics of cadmium and lead onto eco-friendly dried cactus (Opuntia ficus indica) cladodes. J Environ Chem Eng 1(3):144–149

Noreen S, Bhatti HN, Iqbal M, Hussain F, Sarim FM (2020) Chitosan, starch, polyaniline and polypyrrole biocomposite with sugarcane bagasse for the efficient removal of Acid Black dye. Int J Biol Macromol 147:439–452

Liu J, Wang X (2013) Novel silica-based hybrid adsorbents: lead(II) adsorption isotherms. Sci World J 1–7

Bezzina JP, Robshaw T, Dawson R, Ogden MD (2020) Single metal isotherm study of the ion exchange removal of Cu(II), Fe(II), Pb(II) and Zn(II) from synthetic acetic acid leachate. Chem Eng J 394:124862

Samimi M, Shahriari-Moghadam M (2021) Isolation and identification of Delftia lacustris Strain-MS3 as a novel and efficient adsorbent for lead biosorption: Kinetics and thermodynamic studies, optimization of operating variables. Biochem Eng J 173:108091

Hua C, Zhang R, Bai F, Lu P, Liang X (2017) Removal of chromium (VI) from aqueous solutions using quaternized chitosan microspheres. Chin J Chem Eng 25(2):153–158

Han JA, Lim ST (2004) Structural changes in corn starches during alkaline dissolution by vortexing. Carbohyd Polym 55(2):193–199

Funding

Open access funding provided by the Scientific and Technological Research Council of Türkiye (TÜBİTAK).

Author information

Authors and Affiliations

Contributions

MSÇ: conceptualization, methodology, formal Analysis, investigation. OÇ: conceptualization, formal analysis, investigation, writing-review and editing. NK: conceptualization, formal analysis, investigation, writing-review and editing. AFY: writing-original draft Preparation, writing-review and editing. SÇ: conceptualization, methodology, formal analysis, investigation, writing-original draft preparation, writing-review and editing. MMM: conceptualization, formal analysis, writing-review and editing. SK: conceptualization, formal Analysis, writing-original draft preparation, writing-review and editing.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Çelik, M.S., Çaylak, O., Kütük, N. et al. Removal of lead ions (Pb2+) from aqueous solution using chitosan/starch composite material: Experimental and density functional theory findings. Biomass Conv. Bioref. (2024). https://doi.org/10.1007/s13399-024-05287-w

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-024-05287-w