Abstract

Herein, bentonite-chitosan nanocomposite (BT-CS nanocomposite) has been synthesized and exploited, for the first time, as a dual adsorbent for the removal of both of an anionic (Reactive Red 195 (RR)) and a cationic (Crystal Violet (CV)) dyes from aqueous solution. The adsorption behavior of the exploited nano-adsorbent towards the dyes under investigation were scrutinized in batch experiments as a function of several factors such as contact time, pH value, adsorbent dose, initial dye concentration, stirring rate, and temperature. The prepared nano-adsorbent achieved superior removal efficiency of 99.4 and 99.8% within 20 min at optimum pH value of 3 and 5 using adsorbent dose of 0.1 g and 0.08 g at room temperature for RR and CV dyes, respectively. Also, the developed nano-adsorbent affords higher removal efficiency of CV dye against broad pH range of 2–9. Moreover, the developed nano-adsorbent achieved significant antibacterial behavior against various pathogenic bacterial and record clear inhibition zone of 21 mm against Escherichia coli (ATCC 8739). Langmuir adsorption model and pseudo-second order adsorption can fully depict the BT-CS nanocomposite adsorption properties for both of RR and CV dyes. Furthermore, thermodynamic studies showed that the process was spontaneous and endothermic with increased in randomness. The prepared dual adsorbent in this study exhibited reversible dyes adsorption with an excellent regeneration efficiency. Whereas, after 5 successive adsorption–desorption cycles, the adsorption efficiency of the synthesized adsorbent was 99% and 98% for RR and CV dyes, respectively, affirming its capability to economically decontaminate the industrial wastewater comprising RR and CV dyes.

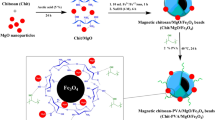

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Industrial effluent is a major source of aquatic environmental contamination, posing a severe danger to the ecological system’s and human health's safety [1]. Colored dye wastewater contamination has greatly expanded in recent years as a result of the rapid growth of associated industries [2]. Dyes are extensively utilized as coloring agents in various industries, including foods, paint, textiles, cosmetics, leather, papermaking, and plastics [3]. Dyes are classified as either synthetic or natural dyes. Synthetic dyes outperform natural dyes in terms of a numerous desirable characteristics such as simplicity of use, high fastness, highly color range, and availability making them a good candidate for various industrial applications [4, 5]. Among the various synthetic dyes, Crystal Violet (CV) and Reactive Red (RR) dyes have attracted much attention owing to their severe hazardous impacts on the ecosystem. Whereas, CV is considered as a biohazard substance based on its toxic, clastogenic and potential carcinogenic effect [7]. Furthermore, RR has highly toxic impact resulting in skin and eye irritation in addition to it is mutagenic and carcinogenic effect. Additionally, dyes causes reduction in aqueous photosynthesis resulting in the eutrophication phenomenon [8]. Thus, there is an imperative necessity to evolve a new strategy for CV and RR removal. Although there are several techniques such as electrochemical [9, 10], coagulation/flocculation [11, 12], biological treatment [13, 14], and ozonation [15, 16] have been reported for CV and RR treatment. However, most of these techniques are either economically unfavorable or technically complicated which hinder them to be applied in practice. For example, flocculation and coagulation generate a large amount of sludge [17], electrochemical and ozonation require high investment costs [18, 19], and biological process takes long contact time [20]. Contrariwise, the adsorption technique has several merits including cheapness, simple design, and easy operation [21, 22]. This is in addition to its capability to remove soluble and insoluble organic pollutants without any hazardous by-products [23]. There are many adsorbing materials have been used to remove dyes from aqueous solution such as activated carbon, coconut shell, fly ash, and sepiolite [24,25,26,27]. Moreover, natural clays have gained popularity as low-cost adsorbents owing to their widespread availability and flexibility to be modified to enhance surface area and adsorption capacity [28]. Among natural clays, bentonite has been assured to be a promising adsorbent for dyes removal because of its large specific surface area, high ion exchange capacity, highly porous structure, and superior adsorption capacity [29]. As a typical clay mineral, bentonite (BT) is largely made up of montmorillonite, which is made up of two tetrahedral silica sheets sandwiched between one octahedral alumina sheet [30]. Bentonite has been broadly applied for the cationic contaminates removal using a combination of adsorption and ion exchange methods. However, the bentonite adsorption capacity towards anionic dyes is limited. Therefore, the modifications of bentonite come to be necessary to increase its adsorption performance against all contaminates either positively or negatively charged one [31]. Therefore, natural polymers or biopolymers such as starch, chitin, and chitosan have lately been studied for dye removal techniques due to their availability, relatively inexpensive, non-toxicity, biodegradability, and simplicity of handling [32]. Among these biopolymers, chitosan (CS) or poly (β-1–4)-2-amino-2-deoxy-D-glucopyranose is synthesized through chitin deacetylation, received considerable attention for dyes adsorption [33]. This biopolymer is an efficient adsorbent of dyes because it contains a high density of both of hydroxyl (–OH) and primary amine (–NH2) groups that function as active adsorption sites enhancing its capability to adsorb both anionic and cationic molecules [34, 35]. Besides, although microbes are advantageous to some industrial transformation processes, they have harmful effects when present in water above the permitted safe level [36, 37]. This is attributed to severe changes to the physicochemical composition of the water and in turn led to negative impact on the aquatic ecosystem [38,39,40]. Therefore, this study presents new design and fabrication of efficient, antibacterial, and cost-effective nano-adsorbent via one-pot fabrication approach derived from naturally abundant BT clay sheets decorated with thin layer of recycled biopolymer chains (CS) for removal of cationic and anionic toxic dyes and inhibit the bacterial growth. Hence, the newly developed nano-adsorbent addresses the CS drawbacks such as low stability at low pH. Thus, can be promising and potential adsorbent for removal of various toxic dyes and heavy metals from wastewater at broad range of pH. Hence, in this study the natural bentonite has been modified by chitosan to prepare the bentonite-chitosan nanocomposite (BT-CS nanocomposite) as eco-friendly, sensitive, antibacterial, and dual nano-adsorbent for efficient CV and RR removal. The developed nanocomposites were elucidated using microscopic and spectroscopic techniques, TGA, and BET analysis. Various adsorption factors were studied.

2 Experimental

2.1 Materials and methods

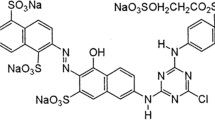

All materials were of analytical grade and used as purchased. High molecular weight chitosan (CS) was obtained from Sigma-Aldrich. NaOH (sodium hydroxide) pellets were supplied by Honeywell-Germany. HCl (hydrochloric acid) was obtained from Merck. The bentonite clay (BT) in the Na-form was purchased from Chemicals for Modern Building (CMB, Giza, Egypt). The commercially available water-soluble Reactive Red 195 (RR) and Crystal Violet dye (CV) were obtained from Sigma-Aldrich and used as received without any further purification. Stock solutions of RR and CV dyes were prepared in bi-distilled water. The desired concentrations were obtained by dilution. The concentrations of the studied dyes were measured using spectrophotometric method. Calibration curves of the two dyes were prepared by measuring their absorbance against concentration at λmax 541 nm for RR and 584 nm for CV using UV–vis spectrophotometer. The final concentration of the dye was estimated spectrometrically corresponding to λmax of the dye according to Beer-Lambert equation [41].

2.2 Preparation of bentonite-chitosan nanocomposite

The chitosan coated bentonite nanocomposite was prepared according to the reported method [42]. In details, 1 g of deacetylated CS was dissolved into 200 mL of 5% (v/v) hydrochloric acid followed by magnetic stirring for 24 h. Afterwards, 20 g of BT was added slowly to the CS solution and then, the dispersion was magnetically stirred for 3 h. In order to precipitate the dissolved chitosan onto bentonite, 1.0 mol L−1 of NaOH aqueous solution was added drop by drop until a pH 7.0 was obtained. The nanocomposite was vacuum filtered and the cake dried in an oven overnight at 60 °C. The dried nanocomposite obtained was grinded and final particles size was found to be in the range of 53 to 160 µm.

2.3 Adsorbent characterization

Fourier transform infrared (FTIR) spectra of BT, CS and the as-prepared BT-CS nanocomposite were carried out using Pye-Unicam Sp-883 Perkins-Elmer spectrophotometer between 4000 cm−1 and 400 cm−1 using KBr pellet technique. Furthermore, the XRD patterns of them were recorded by utilizing D8 Discover, Bruker diffractometer (Germany) at 40 kV and 40 mA current within 3° ≤ 2θ ≤ 80°. The BT, CS, and the nano-adsorbent thermal stability were analyzed using SDT Q600 V20.9 Build 20 thermogravimetric (TGA) analyzer at a heating rate of 10 °C/min under nitrogen atmosphere up to 750 °C. The morphological and chemical composition of BT and the synthesized BT-CS nanocomposite were scrutinized using TEM (Transmission Electron Microscope, a JEOL-jem 2100, Japan) and SEM (scanning electron microscope, FESEM, 210 QUANTAFEG250, Eindhoven, the Netherlands) attached with EDX Unit (Energy dispersive X-ray analysis) with accelerating voltage 20 kV.

2.4 Batch adsorption studies

The batch method was applied to investigate the adsorption efficiency of the synthesized BT-CS nanocomposite towards RR and CV removal. Whereas, batch adsorption experiment was conducted using 0.1 g of the nano-adsorbent with 50 mL of dye solutions at constant temperature (25 ± 1 °C) by magnetic stirring of the mixture solution at constant rate. After the required time, the adsorbent was isolated from the solution by filtration through a 45 µm Whatman filter paper. The synthesized BT-CS nanocomposite adsorption efficiency was investigated in terms of many variables including the pH value, contact time, initial dye concentration, stirring rate, adsorbent dosage, and solution temperature. Where, it was estimated as follow:

whereas Co and Ce are the initial and equilibrium dye concentration (mg L−1). Furthermore, the adsorbent adsorption capacity, qe (mg dye per g dry adsorbent) can be estimated from the equation:

where V (in liter) is the solution volume and w (in gram) is the mass of dry adsorbent.

2.5 Antimicrobial activity studies

Antibacterial and antifungal properties of BT-CS nanocomposite against Gram-negative ((Escherichia coli (ATCC 8739) and Pseudomonas aeruginosa (ATCC 90274)), Gram-positive ((Bacillus subtilis (ATCC 6633) and Staphylococcus aureus (ATCC 6538)) bacteria, Candida albicans (ATCC 10221), and Aspergillus fumigatus were determined by using agar diffusion method (supporting information). Afterwards, the inhibition zone for bacterial growth was detected visually and immediately photographed.

3 Results and discussion

3.1 The BT-CS nanocomposite characterization

The surface morphology of BT and BT-CS nanocomposite were elucidated using SEM analysis. Figure 1 displays SEM image of raw BT (Fig. 1a, b) and BT-CS nanocomposite at low (Fig. 1c) and high magnification (Fig. 1d). The roughness and irregular surface morphology of BT was visualized in Fig. 1a affirming the porous structure of BT and this is clearly illustrated at high magnification SEM image. However, upon modification of BT with CS chains, the sharp edges observed and indicated by red arrows on the raw bentonite material is smoothened and the distinguished gray parts have darkened as shown in Fig. 1b. This could be an indication of successful coating of the chitosan onto the bentonite material [42, 43]. In addition, the EDX was used to evaluate the elemental composition of BT (Fig. 1e) and BT-CS nanocomposite (Fig. 1f). As indicated in Fig. 1e and f, there is an increase in the weight percent of carbon element. This is in addition to the appearance of a new characteristic peak for nitrogen confirming the BT-CS nanocomposite preparation. The morphological characteristic of BT and BT-CS nanocomposite were further investigated using TEM as clarified in Fig. 2a and b, respectively. As indicated, Fig. 2a reflects the sheet like morphology of the raw BT [44], while in case of BT-CS nanocomposite, Fig. 2b confirms the coating of BT surface with CS nanoparticles with an average size of 34.43 nm (Fig. 2b).

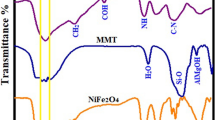

The structural characteristic of the BT, CS, and the synthesized BT-CS nanocomposite were elucidated using FT-IR as clarified in Fig. 3a, b, and c, respectively. For BT, the bands noticed at 3697 and 3622 cm−1, which are typical to -OH group of bentonite located inside the sheet (Fig. 3a), appeared with the same intensity and position in case of BT-CS nanocomposite (Fig. 3c) indicating that CS was not intercalated into the silicate layer. At the same time, the band detected at 3440 cm−1 which is related to -OH groups on the clay surface (Fig. 3a) is shifted to lower frequency of 3422 cm−1 in case of BT-CS nanocomposite (Fig. 3c) suggesting interfacial interaction between CS and BT surface [45, 46]. However, as compared to the spectra of pristine CS (Fig. 3b), the frequency of vibration band noticed at 1563 cm−1, which corresponds to the deformation vibration of protonated amine group, is shifted toward lower frequency value of 1542 cm−1 in case of the nano-adsorbent as declared in Fig. 3c. This shift appeared due to the electrostatic interaction between amine groups and the negatively charged sites in the clay structure [47, 48].

The thermal stability of BT, CS, and their nanocomposite was evaluated using thermogravimetric analysis as indicated in Fig. 4a, b, and c, respectively. As pronounced in Fig. 4a, the first mass loss before 100 °C is attributed to the trapped moisture. While the second mass loss starts at 450 °C is related to the dehydration of -OH groups of bentonite [49, 50]. The thermogram of CS (Fig. 4b) also represents initial mass loss below 100 °C due to the trapped moisture. This is in addition to the main decomposition step which starts at 243 °C as a result of the decomposition of CS chains leaving char residue of about 27% [51]. On the other hand, the BT-CS nanocomposite thermogram was found to be similar to that of BT only showing high thermal stability of the synthesized BT-CS nanocomposite rather than the CS only. Furthermore, by comparing the three thermograms of BT, CS, and BT-CS nanocomposite, it was found that the BT-CS nanocomposite was synthesized in ratio of 10:90 (wt %) of chitosan to bentonite layers.

The crystal structure of the virgin chitosan, BT, and BT-CS nanocomposite was scrutinized using XRD as declared in Fig. 5a, b, and c, respectively. Figure 5a shows the X-ray diffraction patterns of chitosan; thus, the organized crystalline structure of chitosan is indicated by the diffraction patterns of chitosan which were detected at 9.2 and 19.6° and 20° [52]. For BT, the characteristic diffraction peak was noticed at 2θ of 6.9° corresponding to a d001 spacing of 1.26 nm (Fig. 5a) [53]. On the other hand, as declared, after the BT was coated with CS, the XRD patterns underwent no significant change, suggesting that the crystalline structure was not destroyed and the reactions occurred only on the surface of the BT, also diffraction peaks of CS was noticed (Fig. 5c). Although there are no obvious shifts of this peak noticed after the addition of chitosan molecules (Fig. 5c), corroborating that the chitosan did not enter the silicate layers of the bentonite affirming that there is no any change in the basal spacing of it. However, the peak becomes relatively boarder and less intense as indicated in Fig. 5c which confirm that the interaction of bentonite with chitosan caused a slight distortion of the intrinsic lattice arrangement of the silicate layers, causing a relative decrease in the crystallinity [54].

3.2 Uptake measurements using batch method

The adsorption efficiency of the as-prepared nano-adsorbent has been evaluated in terms of various factors which impact the dyes (RR and CV) removal from their aqueous solutions including the effect of pH, temperature, stirring rate, adsorbent dosage, initial dye concentration, and contact time to properly achieve the optimum parameters displaying the maximum removal efficiency of dyes under investigation.

3.2.1 Effect of pH

Hydrogen ion concentration in the adsorption process is considered as one of the most important parameters that influence the adsorption behavior of dyes in aqueous solutions. This is in addition to its impact on the solubility of the dyes in the solution, it also has the capability to replace some of the positive ions found in the active sites and affects the degree of ionization of the adsorbate during the reaction. Hence, adsorption of dyes on the adsorbent materials under consideration was studied at different pH values (2–9, varied using HCl and/or NaOH) to achieve the maximum dye removal as declared in Fig. 6a and Table S1 (supporting information). It is obvious that the maximum removal efficiency of 99.40% of RR dye has been achieved at lower pH value of 3 (Fig. 6a). Afterwards, the RR removal efficiency was gradually decrease with increasing the solution pH up to 9 and was found to be 24% as listed in Table S1 (Fig. 6a). This higher removal efficiency was stemmed from the protonation of the amine groups of the chitosan at such lower pH value (3) which is necessary for the anionic (sulphonic) groups attraction of RR [55]. On the contrary, at higher pH values the decrease in removal efficiency may be related to the abundance of hydroxyl ions which compete with RR anions for the same adsorption sites [56]. While in the case of CV, the removal efficiency was nearly independent of the pH within the examined pH range (Fig. 6a). Therefore, original solution pH of 5.0 was used for further studies. This could be due to the strong CV-nanocomposite hydrophobic interactions, which is a general tendency of organic molecules to associate physically with the adsorbents [57].

3.2.2 Effect of adsorbent dosage

The adsorbent dosage impact on the dyes removal has been examined by varying the mass of BT-CS nanocomposite from 0.025 to 0.15 g mixed with dyes solution of initial concentration of 50 mg L−1 for each dye as shown in Fig. 6b and Table S2. As indicated, with increasing the adsorbent dosage from 0.025 to 0.15 g at pH 3 and 5 for RR and CV dyes, respectively, the removal efficiency increased from 93.30 to 98.80% and from 68.0 to 99.4% using 0.08 and 0.1 g of the as-prepared nano-adsorbent in case of CV and RR dyes, respectively. This is due to the gradual increase of adsorption sites available and susceptible for anchoring anionic and cationic dyes at the adsorbent surface with increasing dose (Fig. 6b).

3.2.3 Effect of stirring rate

The stirring rate influence on RR and CV dyes removal has been illustrated in Fig. 7a and Table S3 as adsorption of RR and CV dyes have carried out at various stirring rate range from 0 to 250 rpm. As declared, the removal efficiency increased from 38.0 to 99.4% for RR and from 60.0 to 99.8% for CV when stirring rate increased from 0 to 200 rpm. This phenomena could be attributed to the fact that stirring reduces the boundary-layer resistance and increases the mobility of the system. Besides, increasing stirring rate lowers the external mass transfer effect, thus promotes the intimate contact between the two phases (adsorbent and adsorbate) [58].

3.2.4 Effect of temperature

The effect of temperature on the dyes removal was investigated by constructing the dyes adsorption at different temperature degrees of 25, 35, 45, and 55 °C. As pronounced in Fig. 7b and Table S4, the change in temperature degree has almost no effect on the dyes removal percentage (it has aslight increase in removal percentage). Thus, the further studies were performed at the room temperature.

3.2.5 Effect of contact time

Equilibrium time is an important parameter for an economical wastewater treatment system. The adsorption kinetics is one of the most important data in order to understand the mechanism of the adsorption and to discuss the performance of the adsorbents. For a given substance to be effective as an adsorbent, its adsorption rate must be fast and quantitative. The effect of contact time on the dyes adsorption was investigated at different time intervals in the range of 3–30 min. The results shown in Fig. 8a and Table S5 revealed that the removal efficiency of dyes adsorbed gradually increased until 20 min reaching about 99.4 and 99.8% for RR and CV, respectively, with no extra significant adsorption was observed after this interval of contact time. Whereas, BT-CS nanocomposite surface almost saturated after 20 min. The initial adsorption rate of RR and CV showed a remarkable increase for more than 90% of RR dye and CV dye adsorbed in the first 3–10 min. The rapid increase in the adsorbed amount of dyes was stemmed from the available pores and vacant adsorption sites in BT-CS nanocomposite which fill up gradually and the adsorption becomes slower with time till achieving complete saturation after 20 min [59].

3.2.6 Effect of the initial dye concentration

Dye adsorption is a mass transfer process that can generally be defined as the accumulation of dye at the interface between the solid/liquid phases. For this reason, the influence of initial dye concentration was investigated while keeping the other parameters constant as pronounced in Fig. 8b and Table S6. As clarified, the amount of dye adsorbed was gradually increased with increasing the initial concentration. This occurs because the initial dye concentration provides a driving force to overcome the resistance to mass transfer of the dye between the aqueous and solid phases [60]. The increase in initial dye concentration also enhances the interaction between dye and adsorbent. Therefore, an increase in initial concentration of RR and CV dyes enhances their adsorption uptake (Fig. 8b).

3.3 Adsorption isotherms

Adsorption isotherms are very important for the optimization of the adsorption system. The equilibrium relationship between adsorbent and adsorbate are best explained, and the maximum capacity of adsorption can be determined by the adsorption isotherm. Therefore, the Langmuir and Freundlich models are applied to evaluate the adsorption isotherms of RR and CV dyes adsorption on the synthesized BT-CS nanocomposite as indicated in Fig. 9a and b and Table 1. Where, the Langmuir isotherm, which describe the monolayer adsorption of adsorbate on a homogeneous surface of adsorbent, is studied using the subsequent equation [61]:

where qe is the amount of dye adsorbed at the equilibrium (mg g−1), Ce is the supernatant concentration at the equilibrium state of the system (mg L−1), KL is the Langmuir constant (L mg−1), and qm is the maximum adsorption capacity (mg g−1). On the other hand, the Freundlich model (relates to multilayer adsorption of adsorbate on heterogeneous sites of the adsorbent surface) is expressed as follows [62]:

where KF is the Freundlich constant (L g−1) which is related to the bonding energy. KF can be defined as the adsorption or distribution coefficient and represents the quantity of dye adsorbed onto adsorbent at unit equilibrium concentration, and n is the adsorption intensity or heterogeneity factor. Therefore, as clarified in Table 1, the data are well-fitting to Langmuir model (regression coefficient (R2) > 0.99, Fig. 9a) than the Freundlich model (R2 < 0.9, Fig. 9b) which affirm the physical mechanism of RR and CV dyes adsorption onto the BT-CS nanocomposite [63].

3.4 Adsorption kinetics

The kinetic parameters of RR and CV dyes removal by BT-CS nanocomposite have been evaluated using the pseudo-first order (Fig. 10a) and pseudo-second order (Fig. 10b) kinetic models based on Eqs. 3 and 4, respectively, as illustrated in Table 2 [64, 65].

where qe and qt are the quantities of dyes adsorbed on BT-CS nanocomposite surface at equilibrium and at time (t), respectively, in mg g−1. While, k1 and k2 are the 1st and 2nd order rate constants, respectively. As declared, the correlation coefficient values for the pseudo-first order kinetic model are low for both dyes. Moreover, a significance difference between the experimental and calculated qe was observed, indicating a poor pseudo-first order fit to the experimental data. On contrary, the pseudo-second order kinetic showed a linear fit with extremely high R2 values (≥ 0.999) for RR and CV dyes and a fairly accordance between the calculated qe value and the experimental one.

3.5 Thermodynamic study

For a full description of RR and CV reaction with the nano-adsorbent, thermodynamic parameters such as reaction favorability (spontaneous or non-spontaneous), exothermic or endothermic, and randomness increase or decrease with temperature have been studied. Thermodynamic parameters, entropy (∆S) and enthalpy (∆H), have been estimated according to Van’t Hoff plot as the intercept and slope of the relation between ln KC and 1/T, respectively (Fig. S1). Afterwards, the Gibbs free energy was calculated based on these values as listed in Table 3. The positive values of both of ΔH° and ΔS° indicate the endothermic nature of adsorption process and more randomness state, respectively. The negative values of ΔG° indicate that adsorption onto the adsorbent is a feasible and spontaneous process for both of RR and CV dyes.

3.6 Elution and regeneration cycles

Beside the several factors that have been optimized like the effect of pH, temperature, stirring rate, adsorbent dosage, initial dye concentration, and contact time, the regeneration of the prepared nanocomposite is of intrinsic importance for the removal process, not only to increase the adsorbent reusability, but also to enhance the commercial viability of it. Therefore, in order to regenerate the biosorbent material, a desorption step was carried out after each adsorption cycle. To this end, the adsorbed BT-CS nanocomposite with dyes was exposed to washing with 0.01 mol L−1 of NaOH and HCl for RR and CV dyes, respectively, then washed with water and then exposed to dyes for adsorption. This study was carried out in five consecutive adsorption–desorption cycles as clarified in Fig. 11. After the fifth cycle, the prepared nano-adsorbent still maintained a superior adsorption efficiency values of 99% and 98% for RR and CV dyes, respectively, affirming the regeneration ability and reusability of the as-synthesized BT-CS nanocomposite. Moreover, the SEM image of BT-CS after three cycles of adsorption–desorption was taken to affirm the chemical stability of developed nano-adsorbents as indicated in Fig. S2.

3.7 Application

In order to verify the applicability of the prepared nano-adsorbent for dyes removal in a real sample, the prepared nanocomposite has been utilized to RR dye removal in two mixtures containing different concentrations of different dyes (Methylene blue and Reactive black) rather than the dye under investigation (RR) as illustrated in Table S7. Whereas, after the three dyes (Methylene blue, Reactive black, and Reactive Red) have been mixed and treated with the nanocomposite, it revealed a promising removal efficiency values for RR dye in despite of the presence of other dyes as declared in Table 4 and Fig. S3, confirming the capability of the prepared nano-adsorbent for RR dye removal in different matrices and its ability for being applied in the routine analysis.

3.8 Antimicrobial activities

Antibacterial and antifungal properties of BT-CS nanocomposite against five different pathogens strains of Gram-negative (Escherichia coli (ATCC 8739) and Pseudomonas (ATCC 90274)), Gram-positive (Bacillus subtilis (ATCC 6633) and Staph. aureus (ATCC 6538)) bacteria, and also as antifungal against Candida albicans (ATCC 10221) and Aspergillus fumigatus have been investigated, as displayed in Fig. S4. The inhibition zone for bacterial growth under and around the tested BT-CS nanocomposite was seen visually. The results of the antibacterial and antifungal activity tests suggest that the synthesized BT-CS nanocomposite showed a great antibacterial and antifungal activity with a very clear inhibition zone with a diameter of 14, 15, 21, 11, 16, and 9 mm against Bacillus subtilis (ATCC 6633), Staph. aureus (ATCC 6538), Escherichia coli (ATCC 8739), Pseudomonas aeruginosa (ATCC 90274), Candida albicans (ATCC 10221), and Aspergillus fumigatus, respectively, as indicated in Table 5.

3.9 Comparative study

In order to reveal the preferability of the as-prepared nanocomposite for the RR and CV dyes removal over the reported ones, a comparative study has been constructed between the prepared nano-adsorbent and the other previously published ones as indicated in Tables 6 and 7. As indicated, the exploited nano-adsorbent displayed the highest removal efficiency for both RR and CV dyes [65,66,67,68,69,70,71,72,73,74,75,76,77,78,79] using lower adsorbent dose [67, 68, 70, 73,74,75,76,77,78,79] after shorter contact time [66,67,68,69,70,71, 73,74,75,76,77] than the reported ones affirming its superior performance for the removal of the dyes under investigation.

4 Conclusion

The present work shows that the prepared BT-CS nanocomposite is an effective dual adsorbent for the removal of Reactive Red 195 and Crystal Violet dyes from aqueous solutions. The influence of reaction parameters as initial dye concentration, temperature, adsorbent dosage, time, pH, and stirring rate on dye adsorption was investigated. The obtained data affirm the capability of the prepared BT-CS nanocomposite as a promising dual adsorbent for both of RR and CV dyes with displaying high removal efficiency of 99.4 and 99.8% after 20 min of contact time with stirring rate of 200 rpm at room temperature with using initial dye concentration of 50 mg L−1 at pH 3 and 5 for RR and CV dyes, respectively. Additionally, the developed nano-adsorbents successfully inhibit the growth of bacterial and fungi recording promising clear antibacterial inhibition zone. The adsorption experimental results were obeying the pseudo-second order model and fitted to Langmuir isotherm model. Thermodynamic studies showed that the process was spontaneous and endothermic. The desorption study of RR and CV dyes exhibited the excellent regenerative efficiency (up to fifth cycle) of composite using 0.01 mol L−1HCl and 0.01 mol L−1 NaOH for RR and CV dyes, respectively. These characteristics make the BT-CS composite promising in the field of wastewater treatment.

Data availability

Available based on request.

References

Hu Q, Bin L, Li P, Fu F, Guan G, Hao X, Tang B (2021) Highly efficient removal of dyes from wastewater over a wide range of pH value by a self-adaption adsorbent. J Mol Liquid 331:115719

Guo W, Umar A, Du Y, Wang L, Pei M (2020) Surface modification of bentonite with polymer brushes and its application as an efficient adsorbent for the removal of hazardous dye orange I. Nanomaterials 10:1112

Huang Z, Li Y, Chen W, Shi J, Zhang N, Wang X, Li Z, Gao L, Zhang Y (2017) Modified bentonite adsorption of organic pollutants of dye wastewater. Mater Chem Phys 202:266–276

Kurniawan A, Sutiono H, Indraswati N, Ismadji S (2012) Removal of basic dyes in binary system by adsorption using rarasaponin–bentonite: revisited of extended Langmuir model. Chem Eng J 189:264–274

Chowdhury S, Saha P (2010) Sea shell powder as a new adsorbent to remove Basic Green 4 (Malachite Green) from aqueous solutions: equilibrium, kinetic and thermodynamic studies. Chem Eng J 164(1):168–177

Attia NF, Shaltout SM, Salem IA, Zaki AB, El-Sadek MH, Salem MA (2022). Sustainable and smart hybrid nanoporous adsorbent derived biomass as efficient adsorbent for cleaning of wastewater from Alizarin Red dye. Biom Con Biore. https://doi.org/10.1007/s13399-022-02763-z

Ganea IV, Nan A, Baciu C, Turcu R (2021) Effective removal of crystal violet dye using neoteric magnetic nanostructures based on functionalized poly (benzofuran-co-arylacetic acid): investigation of the adsorption behaviour and reusability. Nanomaterials 11(3):679

Kamranifar M, Khodadadi M, Samiei V, Dehdashti B, Sepehr MN, Rafati L, Nasseh N (2018) Comparison the removal of reactive red 195 dye using powder and ash of barberry stem as a low-cost adsorbent from aqueous solutions: isotherm and kinetic study. J Mol Liquid 255:572–577

El Brychy R, Rguiti MM, Rhazzane N, Mellaoui MD, Abbiche K, Abali, M, Bazzi L, Hilali M, El Issami S, Groenen-Serrano K, Zejli, H (2021) Electrochemical degradation of crystal violet using Ti/Pt/SnO2 electrode. Appl Sci 11(18):8401

Gündüz Z, Atabey M (2019) Effects of operational parameters on the decolourisation of reactive red 195 dye from aqueous solutions by electrochemical treatment. Int J Electrochem Sci 14:5868–5885

Fosso-Kankeu E, Webster A, Ntwampe IO, Waanders FB (2017) Coagulation/flocculation potential of polyaluminium chloride and bentonite clay tested in the removal of methyl red and crystal violet. Arab J Sci Eng 42(4):1389–1397

Thammachai K, Charoensuk C (2021) Coagulation of reactive red 195 dye by using polyaluminium chloride as coagulant. IAIP Conf Proc 2396:030007

Mani S, Bharagava RN (2017) Isolation, screening and biochemical characterization of bacteria capable of crystal violet dye decolorization. Int J Appl Adv Sci Res 2:70–75

Sahasrabudhe M, Pathade G (2012) Decolourization and degradation of CI Reactive Red 195 by Georgenia sp. CC-NMPT-T3. Indian J Exp Biol 50(4):290–299

Wu J, Gao H, Yao S, Chen L, Gao Y, Zhang H (2015) Degradation of crystal violet by catalytic ozonation using Fe/activated carbon catalyst. Sep Purif Technol 147:179–185

Zhang R, Yuan DX, Liu BM (2015) Kinetics and products of ozonation of CI Reactive Red 195 in a semi-batch reactor. Chinese Chem Lett 26(1):93–99

Baccar E, Yangui R (2013) Removal of water pollutants by adsorption on activated carbon prepared from olive-waste cakes and by biological treatment using ligninolytic fungi. Doctoral Thesis, Universitat Autònoma de Barcelona

Gupta VK (2009) Application of low-cost adsorbents for dye removal–a review. J Environ Manag 90(8):2313–2342

Ulson SMDAG, Bonilla KAS, de Souza AAU (2010) Removal of COD and color from hydrolyzed textile azo dye by combined ozonation and biological treatment. J Hazard Mater 179(1–3):35–42

Saini RD (2017) Textile organic dyes: polluting effects and elimination methods from textile waste water. Int J Chem Eng Res 9(1):121–136

Chinoune K, Bentaleb K, Bouberka Z, Nadim A, Maschke U (2016) Adsorption of reactive dyes from aqueous solution by dirty bentonite. Appl Clay Sci 123:64–75

Belbachir I, Makhoukhi B (2017) Adsorption of Bezathren dyes onto sodic bentonite from aqueous solutions. J Taiw Instit Chem Eng 75:105–111

Frag EY, Elashery SA, Ali AMA (2023) A Simple carbon electrode for the potentiometric determination of N, N, N-Trimethyl-1-nonanammonium bromide as a cationic surfactant in formation water samples. J Anal Chem 78(1):105–112

Abd El-Latifa MM, Ibrahim AM (2010) Removal of reactive dye from aqueous solutions by adsorption onto activated carbons prepared from oak sawdust. Desal Water Treat 20(1–3):102–113

Bello OS, Ahmad MA (2012) Coconut (Cocos nucifera) shell based activated carbon for the removal of malachite green dye from aqueous solutions. Sep Sci Technol 47(6):903–912

Gupta VK, Ali I (2001) Removal of DDD and DDE from wastewater using bagasse fly ash, a sugar industry waste. Water Res 35(1):33–40

Barka N, Ouzaouit K, Abdennouri M, El Makhfouk M (2013) Dried prickly pear cactus (Opuntia ficus indica) cladodes as a low-cost and eco-friendly biosorbent for dyes removal from aqueous solutions. J Taiw Instit Chem Eng 44(1):52–60

Usman MA, Oribayo O, Adebayo AA (2013) Bleaching of palm oil by activated local bentonite and kaolin clay from Afashio. Edo-Nigeria Chem Proc Eng Res 10(2008):1–12

Tahir H, Sultan M, Qadir Z (2013) Physiochemical modification and characterization of bentonite clay and its application for the removal of reactive dyes. Int J Chem 5(3):19

Orolínová Z, Mockovčiaková A (2009) Structural study of bentonite/iron oxide composites. Mater Chem Phys 114(2–3):956–961

Rostami E, Norouzbeigi R, Rahbar A (2018) Thermal and chemical modification of bentonite for adsorption of an anionic dye. Adv Environ Technol 4(1):1–12

Inbaraj BS, Chien JT, Ho GH, Yang J, Chen BH (2006) Equilibrium and kinetic studies on sorption of basic dyes by a natural biopolymer poly (γ-glutamic acid). Biochem Eng J 31(3):204–215

Kanmani P, Aravind J, Kamaraj M, Sureshbabu P, Karthikeyan S (2017) Environmental applications of chitosan and cellulosic biopolymers: a comprehensive outlook. Bior Technol 242:295–303

Ngah WW, Teong LC, Hanafiah MM (2011) Adsorption of dyes and heavy metal ions by chitosan composites: a review. Carbohydr Polym 83(4):1446–1456

Giannakas A, Pissanou M (2018) Chitosan/bentonite nanocomposites for wastewater treatment: a review. SF J Nanochem Nanotech 1:1010

Attia NF, Diab MA, Attia AS, El-Shahat MF (2021) Greener approach for fabrication of antibacterial graphene-polypyrrole nanoparticle adsorbent for removal of Mn2+ from aqueous solution. Synth Met 282:116951

Wen X, Chen F, Lin Y, Zhu H, Yuan F, Kuang D, Jia Z, Yuan Z (2020) Microbial indicators and their use for monitoring drinking water quality—a review. Sustainability 12:2249

Pal D, Gupta CD (1992) Microbial pollution in water and its effect on fish. J Aquat Anim Health 4:948–1039

Das SK, Khan MMR, Parandhaman T, Laffir F, Guha AK, Sekaran G, Mandal AB (2013) Nano-silica fabricated with silver nanoparticles: antifouling adsorbent for efficient dye removal, effective water disinfection and biofouling control. Nanoscale 5:5549–5560

Fernandez M, Hudson JA, Korpela R, de los Reyes-Gavilan CG (2015) Role of microorganisms present in dairy fermented products in health and disease. BioMed Res Int 2015:204173

Kumar V, Gill KD (2018) Photometry: colorimeter and spectrophotometer. In: Basic concepts in clinical biochemistry: a practical guide, chap 5. Springer, Singapore, pp 17–20

Mbakop S, Nthombeni N, Onyango MS, Leswifi TY (2016, May) Evaluation of chitosan-bentonite composite performance towards remediation of sulphate containing effluent. In: Proceedings of Sustainable Research and Innovation Conference. JKUAT, pp 65–70

Banik N, Jahan SA, Mostofa S, Kabir H, Sharmin N, Rahman M, Ahmed S (2015) Synthesis and characterization of organoclay modified with cetylpyridinium chloride. Bang J Sci Indust Res 50(1):65–70

Abukhadra MR, Refay NM, El-Sherbeeny AM, Mostafa AM, Elmeligy MA (2019) Facile synthesis of bentonite/biopolymer composites as low-cost carriers for 5- fluorouracil drug; equilibrium studies and pharmacokinetic behavior. Int J Biolo Macromol 141:721–731

Ravindra Reddy T, Kaneko S, Endo T, Lakshmi Reddy S (2017) Spectroscopic characterization of bentonite. J Lasers Opt Phot 4:1–4

El‐Dib FI, Hussein MH, Hefni HH, Eshaq G, ElMetwally AE (2014) Synthesis and characterization of crosslinked chitosan immobilized on bentonite and its grafted products with polyaniline. J Appl Polym Sci 131(22):41078

Masheane M, Nthunya L, Malinga S, Nxumalo E, Barnard T, Mhlanga S (2016) Antimicrobial properties of chitosan-alumina/f-MWCNT nanocomposites. J Nanotechnol 2016:5404529

Diab MA, Attia NF, Attia AS, El-Shahat MF (2020) Green synthesis of cost-effective and efficient nanoadsorbents based on zero- and two-dimensional nanomaterials for Zn2+ and Cr3+ removal from aqueous solutions. Synth Met 265:116411

Li Y, Zhan J, Huang L, Xu H, Li H, Zhang R, Wu S (2014) Synthesis and photocatalytic activity of a bentonite/gC 3 N 4 composite. Rsc Adv 4(23):11831–11839

Futalan CM, Kan CC, Dalida ML, Hsien KJ, Pascua C, Wan MW (2011) Comparative and competitive adsorption of copper, lead, and nickel using chitosan immobilized on bentonite. Carbohyd Polym 83(2):528–536

Neto CDT, Giacometti JA, Job AE, Ferreira FC, Fonseca JLC, Pereira, a. M. R. (2005) Thermal analysis of chitosan-based networks. Carbohyd Polym 62(2):97–103

Kaur P, Choudhary A, Thakur R (2013) Synthesis of chitosan-silver nanocomposites and their antibacterial activity. Int J Sci Eng Res 4(4):869–872

Wang JH, Young TH, Lin DJ, Sun MK, Huag HS, Cheng LP (2006) Preparation of clay/PMMA nanocomposites with intercalated or exfoliated structure for bone cement synthesis. Macromol Mater Eng 291(6):661–669

Attia NF, Zakria AM, Nour MA, Abd El-Ghany NA, Elashery SEA, S. E. A. (2023) Rational strategy for construction of multifunctional coatings for achieving high fire safety, antibacterial, UV protection and electrical conductivity functions of textile fabrics. Mater Today Sust 23:100450

Mohamed MEB, Attia NF, Elashery SEA (2021) Greener and facile synthesis of hybrid nanocomposite for ultrasensitive iron (II) detection using carbon sensor. Micro Meso Mater 313:110832

Frag EY, Mohamed NM, Elashery SEA (2021) Exploitation of o-benzoyl benzoic acid as an efficient electroactive material for selective determination of Cr (III) ions in pharmaceutical samples and industrial waste water using carbon sensor. Anal Chim Acta 1154:338322

Elmorsi RR, El-Wakeel ST, El-Dein WA, Lotfy HR, Rashwan WE, Nagah M, Shaaban SA, Sayed SA, El-Sherif IY, Abou-El-Sherbini KS (2019) Adsorption of methylene blue and Pb2+ by using acid- activated Posidonia oceanica waste. Sci Rep 9:3356

Zahoor M (2011) Effect of agitation speed on adsorption of imidacloprid on activated carbon. J Chem Soc Pakistan 33(6):305

Mousavi SH, Mohammadi A (2018) Synthesis of β-cyclodextrin-glycine-modified TiO2 nanoparticles for adsorption of dyes from aqueous solutions. Proc Safety Environ Protect 114:1–15

Zhang J, Zhou Q, Ou L (2012) Kinetic, isotherm, and thermodynamic studies of the adsorption of methyl orange from aqueous solution by chitosan/alumina composite. J Chem Eng Data 57(2):412–419

Langmuir I (1918) The adsorption of gases on plane surfaces of glass, mica and platinum. J Am Chem Soc 40(9):1361–1403

Salem MA (2010) The role of polyaniline salts in the removal of direct blue 78 from aqueous solution: a kinetic study. React Funct Polym 70:707–714

Deng J, Lei B, He A, Zhang X, Ma L, Li S, Zhao C (2013) Toward 3D graphene oxide gels-based adsorbents for high-efficient water treatment via the promotion of biopolymers. J hazard Mater 263:467–478

Lagergren S (1898) About the theory of so-called adsorption of soluble substances. Kungliga Svenska Vetenskapsakademiens Handlingar 24:1–39

Ho Y-S, McKay G (1999) Pseudo-second order model for sorption processes. Proc Biochem 34(5):451–465

Mahanna H, Azab M (2020) Adsorption of Reactive Red 195 dye from industrial wastewater by dried soybean leaves modified with acetic acid. Desalin Water Treat 178:312–321

Pérez-Calderón J, Santos MV, Zaritzky N (2018) Reactive RED 195 dye removal using chitosan coacervated particles as bio-sorbent: analysis of kinetics, equilibrium and adsorption mechanisms. J Environ Chem Eng 6(5):6749–6760

Pérez-Calderón J, Santos MV, Zaritzky N (2020) Synthesis, characterization and application of cross-linked chitosan/oxalic acid hydrogels to improve azo dye (Reactive Red 195) adsorption. React Funct Polym 155:104699

Thuy Luong Thi T, Ta HS, Le Van K (2021) Activated carbons from coffee husk: preparation, characterization, and reactive red 195 adsorption. J Chem Res 45(5–6):380–394

Dantas Filho AD, Aroucha EM, Leite RH, Santos FK (2020) Evaluation of adsortive potential of coconut mesocarp in the removal of reactive red dye 195 in aqueous effluents. Matéria (Rio de Janeiro) 25:04

Kiani A, Haratipour P, Ahmadi M, Zare-Dorabei R, Mahmoodi A (2017) Efficient removal of some anionic dyes from aqueous solution using a polymer-coated magnetic nano-adsorbent. J Water Supply: Res Technol, AQUA 66(4):239–248

Attia NF, Mohamed A, Hussein A, El-Demerdash AGM, Kandil SH (2022) Bio-inspired one-dimensional based textile fabric coating for integrating high flame retardancy, antibacterial, toxic gases suppression, antiviral and reinforcement properties. Polym Degrad Stab 205:110152

Fabryanty R, Valencia C, Soetaredjo FE, Putro JN, Santoso SP, Kurniawan A, Ismadji S (2017) Removal of crystal violet dye by adsorption using bentonite–alginate composite. J Environ Chem Eng 5(6):5677–5687

Saad M, Tahir H, Khan J, Hameed U, Saud A (2017) Synthesis of polyaniline nanoparticles and their application for the removal of crystal violet dye by ultrasonicated adsorption process based on response surface methodology. Ultrason Sonochem 34:600–608

Duraipandian J, Rengasamy T, Vadivelu S (2017) Experimental and modeling studies for the removal of crystal violet dye from aqueous solutions using eco-friendly Gracilaria corticata seaweed activated carbon/Zn/alginate polymeric composite beads. J Polym Environ 25(4):1062–1071

Omer AM, Elgarhy GS, El-Subruiti GM, Khalifa RE, Eltaweil AS (2020) Fabrication of novel iminodiacetic acid-functionalized carboxymethyl cellulose microbeads for efficient removal of cationic crystal violet dye from aqueous solutions. Int J Biolo Macromol 148:1072–1083

Kumari HJ, Krishnamoorthy P, Arumugam TK, Radhakrishnan S, Vasudevan D (2017) An efficient removal of crystal violet dye from waste water by adsorption onto TLAC/chitosan composite: a novel low-cost adsorbent. Int J Biolo Macromol 96:324–333

Wang RF, Deng LG, Li K, Fan XJ, Li W, Lu HQ (2020) Fabrication and characterization of sugarcane bagasse–calcium carbonate composite for the efficient removal of crystal violet dye from wastewater. Ceram Int 46(17):27484–27492

Cheruiyot GK, Wanyonyi WC, Kiplimo JJ, Maina EN (2019) Adsorption of toxic crystal violet dye using coffee husks: equilibrium, kinetics and thermodynamics study. Scientific African 5:e00116

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Contributions

SEAE: conceptualization, methodology, writing—original draft preparation, reviewing, and editing supervision. EAA: methodology, investigation, data curation, and writing. NFA: software, data curation, visualization, and investigation. GGM: visualization and investigation. MMEB: visualization, investigation, data curation, reviewing, editing, and supervision.

Corresponding authors

Ethics declarations

Ethical approval

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Elashery, S.E.A., El-Bouraie, M.M., Abdelgawad, E.A. et al. Adsorptive performance of bentonite-chitosan nanocomposite as a dual antibacterial and reusable adsorbent for Reactive Red 195 and crystal violet removal: kinetic and thermodynamic studies. Biomass Conv. Bioref. (2023). https://doi.org/10.1007/s13399-023-05059-y

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-023-05059-y