Abstract

The accumulation of feather waste is a critical problem in solid waste management; therefore, microbial management of waste is highly significant. Consequently, the keratinolytic capacity of some bacteria isolated from the keratinous waste area was evaluated. The most promising isolate coded as L10 showed the highest feather degradation efficiency 72.7% was identified as Bacillus cereus L10 using 16S rRNA gene sequencing. The effect and contribution of independent process variables were studied by Plackett–Burman design. The optimal values of the independent variables obtained from the Plackett–Burman design were chicken feather, 1%; K2HPO4, 0.3%; KH2PO4, 0.05%; MgSO4 7H2O, 0.01%; yeast extract, 0.05%; inoculum size 4% with pH 7 and incubation period 5 days at 35 °C. The optimal parameters were validated resulting in the enhancement of keratinase production (9.602 U/ml), protein concentration (521.17 µg/ml), and feather degradation (94%) along with a 4.56-fold increased of keratinase production. The enzyme is relatively thermostable, completely stable between 30 and 80 °C for 1 h and retained 97.66% of its activity at 100 °C. B. cereus L10 was able to degrade different types of keratins. Interestingly, the feather hydrolysate from optimized keratinase production medium showed plant growth promoting activity by producing indole-3-acetic acid (IAA). The feathers hydrolysate produced a great benefit by its use as a soil biofertilizer through enhancing the germination of Triticum aestivum. The important implication of keratinase in laundry detergent and leather industry was examined. Results revealed that the enzyme achieved great efficiency in removing protein and blood-rich stains within 30 min at 36 °C in addition to its thoroughly dehairing of cow-hide after 40 h incubation without any damage. The dehaired pelt exhibited a smooth, velvety, and white color surface, good flexibility. Therefore, our study presents an effective method to turn waste into wealth.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Keratin biomass is one of the most complicated biological materials. It is responsible for the majority of skin appendages such as hair, nails, tortoiseshells, horns, beaks, claws, and feathers [1]. For instance, millions of tonnes of keratinous materials are produced each year as waste or byproducts of animal meat manufacturing [2, 3]. According to a survey by the US Department of Agriculture, the output of meat produced in 2020 was about 100.5 million tonnes which had the parallel result of producing more than 4.7 million tonnes of poultry feathers around the world [4]. According to the United Nations of Food and Agriculture Organization (FAO), more than 24.8 billion chickens will be produced annually in 2030 over the world, and 37.0 billion in 2050 [5]. Keratin is introduced as the third most abundant polymer in nature, following cellulose and chitin [6].

Disulfide bridges produced between cysteine residues in keratin polypeptides are primarily responsible for the great stability and tight conformation of keratin [7]. Improper disposal and management of this “difficult to decompose” keratinous waste is one of the most pressing problems facing industries [8]. Because the excessive dumping rate of these wastes leads to nitrate intrusion into groundwater and phosphorus runoff into adjacent water bodies, it also emits different pollutants including hydrogen sulfide, nitrous oxide, and ammonia, which have negative health and environmental consequences. Furthermore, feather waste can be a habitat for pathogenic organisms such as Vibrio and Salmonella, as well as promote the growth of bacterial or viral pathogens in lakes and streams [9,10,11].

Chicken feathers are the most significant abundant byproduct, which consists of keratin (~ 91%), moisture (~ 8%), and lipid (~ 1%), in addition to representing 5–7% of the chicken body weight [12, 13]. Keratinous compound materials are unique materials because they are very abundant in certain amino acids, especially the sulfur-containing amino acid, cysteine, and other amino acids like proline, arginine, glycine, and the essential amino acids threonine, valine, and leucine [14, 15]. In addition, they have high mineral contents like N, P, K, Fe, Mg, Ca, Mn, Zn, and Cu [14].

The process of dissolving and extracting keratin is complicated in comparison with extracting other natural polymers such as collagen, chitosan, and starch. Therefore, the widespread use of keratin relies on cost-effective and fast extraction hydrolysis methods. The current extraction strategies include physical, chemical, and biological methods [16]. The generation of hydrolyzed keratin by physical or chemical treatment requires a high temperature. In this way, amino acids (e.g., tryptophan, lysine, and methionine) that are sensitive to heat could be destroyed. After that, the dietary value of hydrolysates would be reduced, resulting in low solubility and value [17].

Furthermore, these high-temperatures, high-pressure treatments produce a significant amount of sulfur and ammonia waste gasses, making physical or chemical treatments inefficient and polluting [18]. Therefore, biological degradation with the keratinase represents a promising alternative technique and is eco-friendly for recycling keratinous wastes, especially poultry feathers, leading to the formation of highly nutritious value products [19]. Keratinase enzyme is naturally produced by a variety of microorganisms including bacteria (e.g., Bacillus licheniformis, B. subtilis, B. paralicheniformis, Microbacterium sp., and Pseudomonas sp.), fungi (e.g., Fusarium, Aspergillus, Trichoderma, Penicillium, and Doratomyces), yeasts (e.g., Trichosporon and Candida sp.), and actinomycetes (e.g., Thermoactinomyces candidus and Streptomyces sp.) [20, 21].

Microbial keratinases have been accepted for numerous potential applications in the medical, biotechnological, and industrial fields. It has been found that using keratinase to degrade feathers produces beneficial feather hydrolysates (which contain peptides and free amino acids) that can be used as a highly protein-rich meal for animals and as a nitrogenous fertilizer for plants [9]. Keratinase has been widely employed in the sector of detergents, after their introduction as a detergent ingredient in 1914; their use in detergent composition accounts for a large part of their total sales (89%) [22]. Tanneries and leather manufacturing have accepted the use of keratinase because it is an active enzyme for dehairing techniques and can be an effective replacement for harmful chemicals [13, 23, 24]. Furthermore, advanced biodegradation technologies for chicken feathers may provide a cost-effective, more efficient, and environmentally friendly method for processing feathers. Microbial digestion of keratinous biomass has become one of the preferable approaches for the sustainable conversion of cheap and readily available keratin-rich agricultural wastes into valuable products [25, 26].

Therefore, the present study aimed to isolate effective keratinolytic bacteria showing rapid feather degradation from keratin waste dump sites. It also aims to optimize keratinase activity using Plackett–Burman methodology and investigate its potential applications in various fields as an effective thermostable enzyme. The current research provides significant implications for the enzyme in biofertilizers in agriculture, in addition to the detergent and leather industries.

2 Materials and methods

2.1 Keratin-substrate

Chicken feathers collected from a local poultry manufacturer were used as a keratin substrate [27]. The feathers were washed properly with tap water to remove impurities and blood residue, and then washed with a detergent; after that, it was washed with distilled water and dried at 60 °C for 24 h. The dried feathers were crushed into small fragments using a blender; fine feather powder was obtained by sieving with a pore size of 160 µm and then stored in the refrigerator in an airtight container for use as a substrate for enzyme assay. The grinded feathers were used for fermented media (Figure S1).

2.2 Samples collection and bacterial isolation

Samples of soil were collected from a chicken farm’s waste and a leather storehouse in Hosh Essa, EL Beheira, Egypt. 0.1 g of each sample was vortexed in 10 ml sterile distilled water; 1 ml of soil suspension was cultivated in 25-ml Erlenmeyer flask containing 50-ml chicken feather medium (CFM) [28], composed of (g/L): K2HPO4, 3.0; KH2PO4, 1.0; MgSO4, 0.2; pH 7; supplemented with the feather, 10 (chicken feather cut into small pieces) as sole carbon and nitrogen source and incubated in shaking incubator at 200 rpm for a week at 30 °C for enrichment. From the flask that showing turbidity and feather disintegration, 1 ml was withdrawn and mixed with 9 ml of sterilized saline solution. Then, 1 ml of the supernatant was spread on the CFM agar plates and incubated at 30 °C for 4 days. Colonies that showed different growth and morphology were selected and purified by repeated screening on Luria–Bertani medium (LB) [29] and preserved on slants of the same medium at 4 °C for further study.

2.3 Screening for proteolytic activity by bacterial isolates

The capacity of selected isolates to hydrolyze casein in skimmed milk (SM) was performed according to the method of Riffel and Brandelli [30] with some modifications. Proteolytic capabilities were investigated on CFM agar using 50 ml pasteurized skimmed milk (containing solid protein 0.03 g/ml) instead of feather. The plates were cultivated with bacterial isolates using toothpicks and then incubated at 37 °C for 48 h, measuring the halo zone formed around the colony every 6 h, then determining the clear zone index by dividing the clear zone diameter by the colony diameter.

2.4 Keratin degradation by bacterial isolates

Bacterial isolates were grown in a submerged fermentation performed in 100-ml Erlenmeyer flasks with 20-ml chicken feather medium (CFM) pH 7.0; each flask inoculated with 2% (v/v) of bacterial suspension (OD600 ≈ 1.6) was used as a fresh inoculum from 24 h slant [27]. Cultivated flasks were incubated in an orbital shaker (200 rpm) for 48 h at 37 °C. pH was measured immediately after the completion of the fermentation using a pH meter (MARTINI Mi 150 pH). The fermentation broth was sampled for analysis of protein concentration and percentage of feather degradation by the standard assay method.

The cultures were filtered via pre-weighed filter paper Whatman no. 1 to recover unutilized feathers. The residues were then cleaned using distilled water to eliminate bacterial cells, and the remaining chicken feathers were oven dried at 70 °C for 24 h to reach a constant weight, which was utilized to calculate the degradation percentage [31]. The following equation was used to estimate the degradation percentage:

where mi is the dry feather’s initial weight before fermentation, and mf is the feather’s weight after fermentation. While the filtrates were centrifuged for 10 min at 4000 rpm, and the clear supernatant was used for determining the protein concentration [32]. The isolate L10 exhibiting the highest feather degradation and extacellular protein content was selected as a promising isolate in the present study.

2.5 Molecular identification of keratin-degrading bacteria

The isolate L10 was molecularly identified by sequencing the partially amplified 16S rRNA gene, using polymerase chain reaction (PCR). The 16S rRNA gene was amplified using the forward primer 5′-AGAGTTTGATCCTGGCTCAG-3′ and reverse primer 5′-GGTTACCTTGTTACGACTT-3′. The PCR mixture contained 8 μL DNA templates, 1 µl forward primer (20 Pico mol), 1 µl reverse primer (20 Pico mol), 25 µl My Taq Red Mix, and 15 μl nuclease-free water. Steps of the thermal cycler condition were carried out with 94 °C initial denaturation for 6 min, followed by 35 cycles of 94 °C denaturation for 45 s, 56 °C annealing for 45 s, 72 °C extension for 1 min, and 72 °C final extension for 5 min. The sequencing of the 16S rRNA gene was then carried out by Sigma Company (St. Nazeeh Khalifa, Heliopolis, Cairo, Egypt). The nucleotide sequences were compared to reference sequences in the database using the basic local alignment search tool (BLASTn) software system from the National Center for Biotechnology Information (NCBI) [33].

2.6 Significant factors that affected the keratinase production by Plackett–Burman design

Plackett–Burman design (PBD) was used to screen key components in terms of their main effects and significance [34]. B. cereus L10 keratinase production was optimized by screening ten factors with two levels, namely, feather (X1), K2HPO4 (X2), KH2PO4 (X3), MgSO4 7H2O (X4), NaCl (X5), yeast extract (X6), incubation time (X7), inoculum size (X8), pH (X9), and agitation (X10). The levels of each factor are listed in Table 1 with the coded and uncoded form of high (+ 1) and low (− 1) values by using the statistical software Minitab 16 (Stat-Ease, Minneapolis, MN, USA). Keratinase activity (U/ml) was evaluated as a response.

2.7 Keratinase assay

The keratinase activity was measured by using tiny chicken feather powder as a substrate. The reaction mixtures containing feather powder (4 mg) suspended in 750 µl of tris–HCl buffer 0.05 M (pH 8), and 750 µl of culture supernatant was incubated for 30 min in a water bath at 50 °C. The enzyme reaction was stopped by placing the reaction mixture in ice for 15 min, followed by cooling centrifugation at 5000 rpm for 15 min. Afterward, the resulting supernatant was used to measure the amount of amino acids released by using Lowry et al. (1951) with tyrosine as a standard against a control having only the substrate and inactived enzyme. The amount of enzyme required to release 1 µg of tyrosine per minute per ml of the enzyme was defined as a unit of keratinase activity (U) [35]. All assays were performed in triplicate. The following equation was used to calculate keratinase activity:

2.8 Validation of the predicted optimal conditions

The optimized feather medium (OFM) and culture conditions obtained from Plackett–Burman design was inoculated with 4% (v/v, O.D600 ≈ 1.7) B. cereus L10 of 24 h seed culture grown in nutrient broth and incubated with shaking (200 rpm) at 37 °C for 168 h. Aliquots were withdrawn from the fermentation medium periodically at 12 h intervals for estimation keratinase activity, protein production, and residual feathers remaining to determine the optimum time for maximum enzyme production.

2.9 Degradation of different keratinous sources by B. cereus L10

The ability of B. cereus L10 to degrade different keratinous substrates (duck feather, turkey feather, horn and hoof of cows, sheep wool, nails, and human hairs) was investigated. All of the substrates were cleaned as described previously and cut into small pieces ≈ 1 cm. An optimized medium of 20 ml pH 7.0 in a 100-ml Erlenmeyer flask supplemented separately with 1% of each keratinous substrate autoclaved and inoculated with 4% (v/v, O.D600 ≈ 1.6) of bacterial inoculum. Fermentation was carried out at 37 °C, 200 rpm for 120 h. The culture was inspected for visible degradation of keratinous substrates against control a sterile optimized medium containing keratinous substrates. The samples were collected, centrifuged, and subjected to extracellular keratinase activity and extracellular protein content.

2.10 Thermal stability of keratinase of B.cereus strain L10

The influence of temperature on enzyme stability was performed by incubating the enzyme solution over a range of temperatures (10 to 100 °C) for 1 h; it was possible to determine how temperature affected the stability of the enzyme [36]. A standard enzyme assay was used to determine the residual enzyme activity. The enzyme activity at room temperature (20 °C) was considered 100%.

2.11 Application

2.11.1 Plant growth promoting activities B. cereus L10

Production of plant growth promoting hormone indole acetic acid (IAA) by B. cereus L10 grown on optimal feather medium was investigated. IAA in the supernatants was estimated by mixing 2 ml of Salkowski reagent (0.5 M FeCl3, 35% H2SO4; (1:49)) with 1 ml of the culture supernatant; development of a pink color was indicative of IAA production [37].

2.11.2 Feather hydrolysate as biofertilizer

Feather hydrolysate has been applied for its effect on the germination of wheat seeds and the promotion of growth [38]. The experiment was carried out in plastic cups with 300 g of sandy soil washed with HCl and dried, then planted with 50 seeds of wheat (Triticum aestivum). The addition of 60 ml diluted feather hydrolysate in the ratio of 1:4 along with water for seed germination and frequently irrigating with 30 ml diluted hydrolysate requires for plant growth in the test, and the control group received the same amount of pure water sprayed on the plants instead of feather hydrolysate. All seeded cups were incubated in laboratory under ambient conditions for 10 days. Thereafter, germinated seeds were counted to calculate the germination percentage. Lengths of seedlings root and shoot and fresh weight and the number of lateral roots were also recorded. The dry weight was recorded after drying at 60 °C to a constant weight.

2.11.3 The cleaning properties of B. cereus L10 keratinase

Evaluation of the feasibility and compatibility of B. cereus L10 keratinase as a laundry detergent additive elucidated according to the procedure of Paul and Emran [22, 39]. Cotton fabrics and medical aprons (surgical cloths made from polyester fabric) pieces (5 cm2) were stained with 0.1 ml of fresh blood and a milk product with chocolate flavor (Nesquik, Nestle, Borg Al Arab, Alexandria, Egypt) and dried for 1 h at 70 °C. Separate flasks were used to hold the stained cloth pieces separately. One flask containing only 20 ml of tap water as a negative control; the second flask contained tap water (20 ml) with detergent as a positive control, while the third contained tap water (20 ml) with (7 mg/ml) Persil inactivated detergent (endogenous enzymes free, was conducted by boiling the detergents for 30 min), whereas the fourth contained only (20 ml ≈ 9.50 U/ml) crude enzyme solution. Finally, the flask contained tap water (10 ml) with (7 mg/ml) detergent enzymes free with 10 ml crude enzyme solution (≈ 9.50 U/ml). All flasks were maintained for 30 min at 36 °C in a shaking water bath, then washed with tap water and dried for 1 h in the oven at 70 °C. The dried cloth pieces were used to visually test the crude enzyme’s ability to remove stains. Water-treated cloth stained pieces were taken as control.

2.11.4 Dehairing performance of B. cereus L10 keratinase

Fresh raw cowhides were obtained from a local slaughterhouse, cleaned with concentrated sodium chloride and washed several times with water to remove blood, mud, and other impurities before being dried in the air. The obtained hides were cut into square-shape pieces of approximately 5 cm2 by a sharp scissor and then drained. The cowhide pieces were separately placed into a petri dish containing 40 ml of enzyme solution (9.50 U/ml). While the rest was soaked in 40 ml of distilled water as a negative control. In addition, pieces treated separately with 40 ml chemical agents such as sodium sulfide (Na2S) (2%) and calcium oxide (CaO) (2%) were used as a positive control to compare dehairing efficiency [40]. After incubating for 40 h at room temperature (30 °C). The cowhide pieces were washed with tap water and observed for dehairing by a blunt scalpel to check the depilation potential of crude enzyme. The general appearance of skin surface and the quality of the dehairing were observed visually.

3 Results

3.1 Isolations

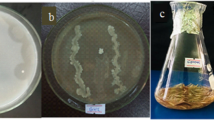

The soil samples used to isolate bacteria on chicken feather medium (CFM) were investigated. The inoculated flasks that showed turbidity and feather disintegration were observed (Figure S2); after purification, a total of 10 bacterial isolates were obtained; five isolates were isolated from feather waste soil designated as F1–F5, and the other five were designated as L6–L10 were isolated from the leather storehouse. The ability of bacterial colonies to grow in a keratin-selective media proved that they are keratinase-producing bacteria.

3.2 Screening of proteolytic activity

All selected isolates displayed significant protease (caseinase) activity on skimmed milk agar plates by forming a zone of clearance with varying halo zone generation. The proteolytic activity has been produced in the first 6 h of incubations. The isolates F1, F5, and L10 showed strong proteolytic activity after 48 h (Fig. 1). The proteolytic activity of these 10 isolates was used as a primary indicator in subsequent experiments such as various biotechnological applications.

3.3 Determination of keratinolytic activity of bacterial isolates

After 48 h of fermentation on basal chicken feather medium (CFM), the degradation potential of feathers varied depending on the tested isolate, ranging from 6.2% for isolate F4 to 72.7% for isolate L10; also, total protein concentrations were estimated to be 146.0 µg/ml and 406.83 µg/ml for isolate L6 and L10, respectively (Fig. 2). The fermentation broth of L10 turned yellow with powder-like consistency, and feather residue had unrecognizable structures remaining. The pH of the fermentation media of all tested strains was in the neutral range except for strain L10 shifted to alkaline (pH 7.8) (Table S1). So strain L10 was shown to be the most promising isolate with high feather degradation and total protein yield.

3.4 Molecular identification of keratin-degrading bacteria

According to the results of PCR amplification and subsequent partial 16S rRNA gene sequencing, the determined 16S rRNA nucleotide sequence of isolate L10 is about 420 base pairs long. The analysis of the sequence using basic local alignment search tool (BLASTn) results revealed that isolate L10 belonged to the genus Bacillus with a high similarity percentage (> 99.5%) to the B. cereus group. As a result, the L10 isolate was identified as B. cereus L10 and was submitted to the GenBank under accession no. OK483474. A phylogenetic tree was designed using a neighbor-joining approach with related gene sequences from the GenBank (NCBI) database employing the closest homologous sequences in a phylogenetic analysis with the MEGA 11 software (Figure S3).

3.5 Plackett–Burman design

The design pattern for selecting significant parameters for the production of keratinases and the relevant responses (keratinase activity (U/ml) has been shown in Table 2; numerous variables with high and low degrees of impact in various combinations cause response variance (0.38–7.32 U/ml), with the 11th run showing the highest keratinase production. p-values of the test ≤ 0.05 were used to determine which factors had a significant impact on the response. The F value of the model (27.04) implies that it was significant. The accuracy of determination coefficient R2 (99.63%,) and adjusted R2 (95.95%) reveals the adequacy and fitness of the experimental model. The analysis of variance (ANOVA) was performed to check the statistical significance of the regression model analysis at the significance level (p ≤ 0.05) (Table S2). Among all of examined variables, only fermentation time displayed the significance effect (p = 0.044) on the yield of keratinase. The Pareto chart was identifed as a useful tool for determining the most signifcant effects in the order of significance (Fig. 3).

3.6 Verification experiment of the predicted optimal conditions

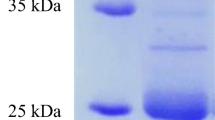

A verification experiment was used to compare the predicted optimal levels of independent factors with anti-optimized and basal condition settings to determine the efficiency of the applied Plackett–Burman statistical design (Table 3). Figure 4 shows the growth of B. cereus L10 on the optimized feather medium (OFM) with the following composition: chicken feather, 1% (w/v); K2HPO4, 0.3% (w/v); KH2PO4, 0.05% (w/v); MgSO4 7H2O, 0.01% (w/v); yeast extract, 0.05% (w/v); inoculum size 4% (v/v) with pH 7 and incubation period 2 days at 35 °C. The high level of keratinolytic activity reached 7.317 U/ml. The effect of incubation time on keratinase production under previously optimized conditions was investigated, and the results revealed that the keratinolytic activity reached a maximum titer (9.602 U/ml) after 120 h, with increased by 4.56-fold ≈ 456.15% when compared with that obtained under the original medium fermentation conditions (2.105U/ ml). Feather degradation reached 94% and protein content is 521.17 µg/ml (Fig. 5).

Verification experiments of the applied Plackett–Burman statistical design for comparing keratinase production by B. cereus L10 grown on basal, optimized, and anti-optimized media. Values are presented as mean and standard deviation; different letters indicate significant differences according to one way ANOVA test (p ≤ 0.05)

3.7 Effect of different substrates on keratinase production

B. cereus L10 can degrade different types of keratinous substrats (Figure S4). High keratinase activity (10.553 U/ml) was produced in the case of sheep wool and protein content (561.83 µg/ml). Human nails showed the lowest keratinase activity (6.239 U/ml), with protein content (300.00 µg/ml). Other types of keratin ranged between these two values (Fig. 6).

Effect of different substrates on keratinase production and protein concentrations using optimum feather medium after 120 h of incubation period. Values are presented as mean and standard deviation; different letters in the same test indicate significant differences according to one way ANOVA test (p ≤ 0.05)

3.8 Thermal stability of keratinase

The thermal stability profile of B. cereus L10 keratinase (Fig. 7) manifestly showed that the enzyme was highly stable at various temperature ranges up to 80 °C, maintaining greater than 97.66% of original activity after incubation for 1 h at 100 °C.

3.9 Application

3.9.1 Plant growth promoting activities B. cereus L10

One of the interesting results was the production of indole acetic acid (IAA) (54.6 ± 3.8 µg/ml), observed after 5 days of incubation in the improved feather medium without supplementation of L-tryptophan (Figure S5). The capability of B. cereus L10 to form feather hydrolysate and synthesize IAA is an important feature to be considered a plant growth-promoting bacteria (PGPB).

3.9.2 Feather hydrolysate as a biofertilizer

Feather hydrolysate was used in the soil to assess seed germination, growth, and development of Triticum aestivum (wheat). The seed germination was faster in soil treated with feather hydrolysate (98%) in comparison to the control (23%). Germination was early in treated soil and started in the third day compared to the control without feather hydrolysate. This control seemed weak and started germination in the fourth day. The germination rate continued to increase over the 10 days. Furthermore, the application of feather hydrolysate (leads to a signifcant increase in wheat seedling length, fresh and dry weights, and the number of laterall roots weight) significantly increased shoot and root lengths, plant fresh and dry weights, and the number of laterall roots compared to the control without treatment (Fig. 8; Table 4).

3.9.3 The Cleaning properties of B. cereus L10 keratinase

The crude enzyme was used to remove blood and a chocolate-flavored milk product stains. The results demonstrated the enzyme’s effectiveness in eliminating stains with or without the use of inactivated detergent, as shown in Fig. 9. The addition of prepared enzyme (9.50 U/ml) with detergent (Persil) greatly increases the cleaning quality of the chocolate-flavored milk stains from cotton fabrics and resulted in the chocolate stain remaining slightly in the cotton fabrics; however, it was seen that using detergent only failed in removing chocolate stain and it still fully retained in cotton fabrics. Also, keratinolytic enzyme is very effective in removing blood stains on cotton fabrics and medicinal aprons which were washed with detergent combined with keratinase enzyme. The results revealed that B. cereus L10 keratinase displayed stability and compatibility with the detergent. Furthermore, keratinase independently could remove the blood stains with excellent results in copmparison to that obtained with detergent only.

3.9.4 Evaluation of dehairing efficiency

The dehairing efficacy of the B.cereus L10 keratinase on cowhides was assessed. After 40 h of incubation with 40 ml of enzyme solution (9.50 U/ml), keratinase could effectively remove hair completely from cowhides, and hair could be manually scraped away without harming the skin’s quality compared to the positive and negative control (Fig. 10). In addition, the dehaired pelt exhibited a smooth, velvety, and white color surface, good flexibility, without observable damage, and no scars. On the other hand, chemical dehairing (2% Na2S) was unable to completely remove hair from cowhides after 40 h, and portions of hair could still be seen on the skin with a harsh, thickened, hard in touch, whereas chemical treatment hides treated with 2% CaO, showed that the dehaired pelts were not only yellow, but also have hard, cracked, and wrinkled appearance. The control cowhide, incubated in water under the same conditions, showed no sign of hair removal (Fig. 10). The results revealed that keratinase from B. cereus L10 could efficiently accomplish the dehairing process and with satisfactory properties. The amount of soluble protein resulting from the dehairing solution was measured for improving sustainable benefits (Table S3).

4 Discussion

Green technology is concerned with sustainability for a clean environment and has accelerated the quest for microbes with efficient biotechnological and industrial potential [41,42,43]. The bioconversion of feather waste into nutritional valuable products with a microbial enzyme keratinase is an excellent strategy for dealing with such obstinate environmental wastes [43]. Based on feather keratin growth and distinct zone hydrolysis on casein agar plates, 10 different colonies were selected for chicken feather degradation. Screening on skimmed milk was an important step in identifying isolates with proteolytic potential [30, 44]. The isolate L10 was found to degrade chicken feathers with the highest efficiency (73%) within 48 h of fermentation accompanied by the highest level of protein content 407 µg/ml and identified as B. cereus L10 by sequencing the 16S rRNA. Similarly, different strains of Bacillus sp. are employed for the degradation of keratinous wastes [31, 45,46,47,48]. The continued exploration of new keratinolytic strains of the B. cereus group often leads to the potentiality for discovering new keratinases with varied properties for novel vistas of keratinous material exploitation [49]

There is no definite medium for maximizing the induction of enzymes because different microbial strains require different culture conditions required for maximum productivity of enzymes. The Plackett–Burman design)PBD (was a major indicator for choosing the process variables that had a significant influence on keratinase production. The incubation time was considered the most effective factor influencing the yield of B.cereus L10 keratinase. The optimal conditions were validated resulting in the increment of keratinase yield by 9.602 U/ml ≈ 4.56-fold. The results in this study are in agreement with those recorded by several researchers after statistical optimization of process parameters, e.g., Sharma et al. [46] achieved about 4.92-folds of keratinase production by B. velezensis NCIM 5802; Jana et al. [45] showed 5 fold enhanced titers of keratinase. However, Ramnani and Gupta [50] obtained a 3.5-fold increase in keratinase output by Bacillus licheniformis RG1.

Besides, the percentage of feather degradation would be optimized and reached 94% after 5 days; this result was significantly faster than the other keratinolytic strains previously reported by Park and Son [51]; reported complete degradation of chicken feathers by Bacillus megaterium was achieved upon 7 days of incubation. According to Williams et al. [52], the ability of Bacillus licheniformis PWD-1 to hydrolyzed chicken feathers completely required 10 days. Hong et al. [53] detected 65% of feather weight was lost within 2 days by Chryseobacterium sp. P1-3, while Kshetri et al. [28] observed that Chryseobacterium sediminis RCM-SSR-7 recorded degraded 84% feather degradation in 84 h.

B.cereus L10 keratinase exhibited extremely thermal stability in the temperature range of 20–80 °C and retained 97.66% of the activity at 100 °C for 60 min. As a result, this protein is categorized as a thermo-stable keratinase and could be widely used in various biotechnological applications. The keratinase activity of B. cereus L10 exceeds Bacillus aerius NSMk2 whose activity was only stabilized at 50 °C and retained 50% activity at 90 °C after 30 min [36].

B. cereus L10 could utilize different keratinous substrates such as chicken feather, duck feather, turkey feather, horn, hoof, sheep wool, nails, and human hairs with no need for another carbon or nitrogen source, and the results revealed that sheep wool was the promising substrate for keratinase induction, followed by the other keratin substrates. B.cearus L10 showed different levels of keratinolytic activities when cultured on different keratinous substrate; these may be due to the difference in the percentage of protein content in each substrate, for example, feather dry matter contains ~ 90% protein [54, 55], while wool contains up to 95% by weight of pure keratin [56].

An important implication of our study is that B. cereus L10 was investigated for its ability to produce indole-3-acetic acid (IAA). IAA is a significant plant hormone that has a significant impact on plant growth and development, by enhancing cell division, cell elongation, cell differentiation, embryogenesis, apical dominance, and root growth and stimulating water and nutrient uptake [48, 57,58,59]. Several microorganisms have been found to produce IAA utilizing various precursors, such as tryptophan-mediated IAA synthesized by Pseudomonas fluorescens [60], and Fusarium species can produce the plant hormone IAA from tryptophan via the intermediary of indole-3-acetamide (IAM) [61].

The current study presented an innovative ability of strain L10 to synthesize IAA in feather medium without the need to supplement tryptophan, and an increased IAA synthesized was obtained with increasing the concentration of chicken feathers, which is since the hydrolysis of feather resulted in tryptophan biosynthesis from keratin which serves as an inducer for IAA synthesis [62]. According to these results, the culture broth of B. cereus L10 could be useful as a biofertilizer. Many studies show that feather hydrolysate can promote plant development, suggesting that it could be used in agriculture to enhance agricultural output and quality [63].

The finding was quite surprising using the feather hydrolysate of B.cereus L10 as a soil biofertilizer in comparison to the control trial. Through a study of the germination of Triticum aestivum (wheat), the seeds were selected owing to its importance in crops in all worlds; soil supplemented with feather hydrolysate showed earlier seed germination with a very high germination percentage of 98% versus 23% control. Our finding was in agreement with others stated that feather hydrolysate achieved through microbial degradation has been reported as promising fertilizer for various plants [14, 64,65,66,67].

The feather hydrolysate greatly enhanced the growth of plants over control plants grown without feather hydrolysate supplements. This might be due to the presence of many types of amino acids, nutrients, and plant hormones in feather hydrolysate which has a great effect on plants. The supernatant of Bacillus cereus-treated feathers has been shown to contain around 17 amino acids eight of which were essential amino acids, namely, lysine, leucine, methionine, isoleucine, valine, phenylalanine, threonine, and tryptophan [68, 69]. In addition, Mabrouk [70] recorded the total amount of free amino acids in Streptomyces sp. MS-2 feather hydrolysate was nearly 51 times greater than the control. Moreover, Sobucki et al. [71] recorded that feather hydrolysate contained a high amounts of nitrogen, calcium, potassium, iron, magnesium, copper, and zinc produced by the activity of Bacillus sp.. Furthermore, the presence of amino acids and proteins is essential in the genetic and physiological processes of plants [72, 73].

Another important implication of these findings is that the use of detergent supplemented with crude keratinase on stained cloth resulted in a better stain removal than the use of detergent alone. Commercial detergent contains several additives as bleaching agents (formic acid, sodium chlorite, sodium nitrate, hypochlorite, and peroxides), softening builders and surfactants. These additives have several drawbacks, containing toxic fume products, high energy, time consumption, fabric strength reduction, and the potential for significant fiber damage. So enzymatic washed of fabrics was a common procedure in the textile sector to achieve special finishing effects [22]. It was worth to mention that B.cereus L10 keratinase can be use as alternative to detergent for removal of blood stains. As a reason, hemoglobin in the blood (containing globin protein) was broken down into peptides as a result of proteolytic by the keratinase [22]. Our study concluded that the keratinase enzyme produced by B. cereus L10 has a great capacity for eliminating protein stains from cloth; it might be employed as a keratinolytic protease additive in detergent powders or solutions. Generally, it is speculated that the high stability of enzymes with detergents indicated its suitability for use as a detergent additive. There have also been several reports on the compatibility of microbial keratinases with commercial laundry detergents which validated its suitability for potential use as a detergent additive [74].

In the current study, it was discovered that B. cereus L10 keratinase can be a useful leather dehairing agent that has no negative effects on the leather (does not cause skin collagen damage) and could completely dehair leather after 40 h without the use of any chemical. Whereas chemicals have noxious consequences such as cause damage, harsh texture, and lower quality of leather. As a result, the proposed poultry waste–degrading keratinase outperforms chemicals in terms of not only dehairing but also leather quality. Furthermore, enzymatic dehairing reduces reliance on toxic chemicals (sulfide, lime, and amines) commonly employed in tanneries, hence protecting human health and wildlife by reducing pollution in soil, water, and the overall environment [13].

Enzymatic dehairing has a greater benefit over typical chemical techniques in that it removes hair from the basis without hurting the collagen of the skin [36, 75, 76]. The use of biocatalysts to replace inorganic sulfide demonstrated significant benefits in terms of environmental protection and unhairing efficiency. Keratinolytic protease is a good biocatalyst for hydrolyzing disulfide bond-rich proteins in hair, and it does not harm leather [77, 78], compared to the chemicals that had bad effects on the quality of skin making severely cut without removing the hair completely, making keratinase a good alternative to the chemical dehairing techniques now utilized in industry. Because of its great properties, this enzyme is a great option for the development of eco-friendly cleanliness and smart leather processing techniques that produce high-quality leather in a short time.

Data availability

Data will be available on reasonable request.

References

Wang B, Yang W, McKittrick J, Meyers MA (2016) Keratin: structure, mechanical properties, occurrence in biological organisms, and efforts at bioinspiration. Prog Mater Sci 76:229–318

Li Z, Reimer C, Picard M, Mohanty AK, Misra M (2020) Characterization of chicken feather biocarbon for use in sustainable biocomposites. Frontiers in Materials 7:3

Ivanović N, Ilić T, Ćirić MZ, Todorović V, Djuričić I, Dabetić N (2023) Agri-food by-products as a source of sustainable ingredients for the production of functional foods and nutraceuticals. Arch Pharm 73(Notebook 3):190–204

Qiu J, Wilkens C, Barrett K, Meyer AS (2020) Microbial enzymes catalyzing keratin degradation: classification, structure, function. Biotechnol Adv 44:107607

Alexandratos N, Bruinsma J (2012) World agriculture towards 2030/2050: the 2012 revision

Pandey SC, Pande V, Sati D, Gangola S, Kumar S, Pandey A, Samant M (2019) Microbial keratinase: a tool for bioremediation of feather waste. In Smart bioremediation technologies (pp. 217–253). Academic Press. https://doi.org/10.1016/C2018-0-01652-7

Callegaro K, Brandelli A, Daroit DJ (2019) Beyond plucking: feathers bioprocessing into valuable protein hydrolysates. Waste Manage 95:399–415

Bhari R, Kaur M, Singh RS, Pandey A, Larroche C (2018) Bioconversion of chicken feathers by Bacillus aerius NSMk2: a potential approach in poultry waste management. Bioresour Technol Rep 3:224–230

Tamreihao K, Mukherjee S, Khunjamayum R, Devi LJ, Asem RS, Ningthoujam DS (2019) Feather degradation by keratinolytic bacteria and biofertilizing potential for sustainable agricultural production. J Basic Microbiol 59(1):4–13

Verma A, Singh H, Anwar S, Chattopadhyay A, Tiwari KK, Kaur S, Dhilon GS (2017) Microbial keratinases: industrial enzymes with waste management potential. Crit Rev Biotechnol 37(4):476–491

Pettett LM, Kurtböke DI (2004) Development of an environmentally friendly biofertilizer with keratin degrading and antibiotic producing actinomycetes. Actinomycetologica 18(2):34–42

Verma A, Negi P, Singh VK (2019) Experimental analysis on carbon residuum transformed epoxy resin: chicken feather fiber hybrid composite. Polym Compos 40(7):2690–2699

Akhter M, Wal Marzan L, Akter Y, Shimizu K (2020) Microbial bioremediation of feather waste for keratinase production: an outstanding solution for leather dehairing in tanneries. Microbiol Insights 13:1178636120913280

Gurav RG, Jadhav JP (2013) A novel source of biofertilizer from feather biomass for banana cultivation. Environ Sci Pollut Res 20:4532–4539

Škerget M, Čolnik M, Zemljič LF, Gradišnik L, Semren TŽ, Lovaković BT, Maver U (2023) Efficient and green isolation of keratin from poultry feathers by subcritical water. Polymers 15(12):2658

Shavandi A, Silva TH, Bekhit AA, Bekhit AEDA (2017) Keratin: dissolution, extraction and biomedical application. Biomaterials Sci 5(9):1699–1735

De Oliveira Martinez JP, Cai G, Nachtschatt M, Navone L, Zhang Z, Robins K, Speight R (2020) Challenges and opportunities in identifying and characterising keratinases for value-added peptide production. Catalysts 10(2):184

Li ZW, Liang S, Ke Y, Deng JJ, Zhang MS, Lu DL, Luo XC (2020) The feather degradation mechanisms of a new Streptomyces sp. isolate SCUT-3. Commun Biol 3(1):191

Ghasemi Y, Shahbazi M, Rasoul-Amini S, Kargar M, Safari A, Kazemi A, Montazeri-Najafabady N (2012) Identification and characterization of feather-degrading bacteria from keratin-rich wastes. Ann Microbiol 62(2):737–744

Kuo JM, Yang JI, Chen WM, Pan MH, Tsai ML, Lai YJ, Lin CY (2012) Purification and characterization of a thermostable keratinase from Meiothermus sp. I40. Int Biodeterior Biodegradation 70:111–116

Abdel-Fattah AM, El-Gamal MS, Ismail SA, Emran MA, Hashem AM (2018) Biodegradation of feather waste by keratinase produced from newly isolated Bacillus licheniformis ALW1. J Genet Eng Biotechnol 16(2):311–318

Paul T, Das A, Mandal A, Halder SK, Jana A, Maity C, Mondal KC (2014) An efficient cloth cleaning properties of a crude keratinase combined with detergent: towards industrial viewpoint. J Clean Prod 66:672–684

Hamiche S, Mechri S, Khelouia L, Annane R, El Hattab M, Badis A, Jaouadi B (2019) Purification and biochemical characterization of two keratinases from Bacillus amyloliquefaciens S13 isolated from marine brown alga Zonaria tournefortii with potential keratin-biodegradation and hide-unhairing activities. Int J Biol Macromol 122:758–769

Suharti S, Riesmi, MT, Hidayati A, Zuhriyah UF, Wonorahardjo S, Susanti E (2018) Enzymatic dehairing of goat skin using keratinase from Bacillus sp. MD24, a newly isolated soil bacterium. Pertanika J Trop Agric Sci 41(3):1449–1461

Paul T, Das A, Mandal A, Halder SK, DasMohapatra PK, Pati BR, Mondal KC (2014) Valorization of chicken feather waste for concomitant production of keratinase, oligopeptides and essential amino acids under submerged fermentation by Paenibacillus woosongensis TKB2. Waste Biomass Valorization 5:575–584

Ramalingum N, Bhagwat P, Permaul K, Pillai S (2022) Production, characterization, and application of Pseudomonas aeruginosa S-04 keratinase for feather utilization. Biomass Convers Biorefinery 1–13. https://doi.org/10.1007/s13399-022-03218-1

Nnolim NE, Okoh AI, Nwodo UU (2020) Proteolytic bacteria isolated from agro-waste dumpsites produced keratinolytic enzymes. Biotechnol Rep 27:e00483

Kshetri P, Roy SS, Sharma SK, Singh TS, Ansari MA, Prakash N, Ngachan SV (2019) Transforming chicken feather waste into feather protein hydrolysate using a newly isolated multifaceted keratinolytic bacterium Chryseobacterium sediminis RCM-SSR-7. Waste Biomass Valorization 10:1–11

Bertani G (2004) Lysogeny at mid-twentieth century: P1, P2, and other experimental systems. J Bacteriol 186(3):595–600

Riffel A, Brandelli A (2006) Keratinolytic bacteria isolated from feather waste. Braz J Microbiol 37:395–399

Reddy MR, Reddy KS, Chouhan YR, Bee H, Reddy G (2017) Effective feather degradation and keratinase production by Bacillus pumilus GRK for its application as bio-detergent additive. Biores Technol 243:254–263

Lowry O, Rosebrough N, Farr AL, Randall R (1951) Protein measurement with the Folin phenol reagent. J Biol Chem 193(1):265–275

Altschul SF, Madden TL, Schäffer AA, Zhang J, Zhang Z, Miller W, Lipman DJ (1997) Gapped BLAST and PSI-BLAST: a new generation of protein database search programs. Nucleic Acids Res 25(17):3389–3402

Plackett RL, Burman JP (1946) The design of optimum multifactorial experiments. Biometrika 33(4):305–325

Isaac GS, Abu-Tahon MA (2016) Dehairing capability of alkaline keratinase produced by new isolated Cochliobolus hawaiiensis AUMC 8606 grown on chicken feather. Rom Biotechnol Lett 22(6):12147–12154

Bhari R, Kaur M, Singh RS (2019) Thermostable and halotolerant keratinase from Bacillus aerius NSMk2 with remarkable dehairing and laundary applications. J Basic Microbiol 59(6):555–568

Tamreihao K, Devi LJ, Khunjamayum R, Mukherjee S, Ashem RS, Ningthoujam DS (2017) Biofertilizing potential of feather hydrolysate produced by indigenous keratinolytic Amycolatopsis sp. MBRL 40 for rice cultivation under field conditions. Biocatal Agric Biotechnol 10:317–320

Verma A, Singh H, Anwar MS, Kumar S, Ansari MW, Agrawal S (2016) Production of thermostable organic solvent tolerant keratinolytic protease from Thermoactinomyces sp. RM4: IAA production and plant growth promotion. Front Microbiol 7:1189

Emran MA, Ismail SA, Abdel-Fattah AM (2020) Valorization of feather via the microbial production of multi-applicable keratinolytic enzyme. Biocatal Agric Biotechnol 27:101674

Sivasubramanian S, Manohar BM, Rajaram A, Puvanakrishnan R (2008) Ecofriendly lime and sulfide free enzymatic dehairing of skins and hides using a bacterial alkaline protease. Chemosphere 70(6):1015–1024

Derhab N, Elkhwesky Z (2023) A systematic and critical review of waste management in micro, small and medium-sized enterprises: future directions for theory and practice. Environ Sci Pollut Res 30(6):13920–13944

Derhab N, El-Metwally MM, Mabrouk ME, Mohammed YM (2022) Feather degrading fungi: isolation, identification and measuring the proteolytic activity using solid-state fermentation technique. J Agri Environ Sci 21(2):1–18

Gopinath SC, Anbu P, Lakshmipriya T, Tang TH, Chen Y, Hashim U, ..., Arshad, MK (2015) Biotechnological aspects and perspective of microbial keratinase production. BioMed Res Int 2015. https://doi.org/10.1155/2015/140726

Saha S, Dhanasekaran D (2010) Isolation and screening of keratinolytic actinobacteria form keratin waste dumped soil in Tiruchirappalli and Nammakkal, Tamil Nadu, India. Curr Res J Biol Sci 2(2):124–131

Jana A, Halder SK, Dasgupta D, Hazra S, Mondal P, Bhaskar T, Ghosh D (2020) Keratinase biosynthesis from waste poultry feathers for proteinaceous stain removal. ACS Sustain Chem Eng 8(48):17651–17663

Sharma I, Pranaw K, Soni H, Rawat HK, Kango N (2022) Parametrically optimized feather degradation by Bacillus velezensis NCIM 5802 and delineation of keratin hydrolysis by multi-scale analysis for poultry waste management. Sci Rep 12(1):17118

Venkatachalam M, Rathinam A, Rao JR, Krishnan C (2022) Bioconversion of animal hair waste using salt-and sulphide-tolerant Bacillus sp. KLP1 and depilation using keratinase. Int J Environ Sci Technol 19(7):6389–6398

Bhange K, Chaturvedi V, Bhatt R (2016) Ameliorating effects of chicken feathers in plant growth promotion activity by a keratinolytic strain of Bacillus subtilis PF1. Bioresources Bioprocess 3:1–10

Kokwe L, Nnolim NE, Ezeogu LI, Sithole B, Nwodo UU (2023) Thermoactive metallo-keratinase from Bacillus sp. NFH5: characterization, structural elucidation, and potential application as detergent additive. Heliyon 9(2). https://doi.org/10.1016/j.heliyon.2023.e13635

Ramnani P, Gupta R (2004) Optimization of medium composition for keratinase production on feather by Bacillus licheniformis RG1 using statistical methods involving response surface methodology. Biotechnol Appl Biochem 40(2):191–196

Park GT, Son HJ (2009) Keratinolytic activity of Bacillus megaterium F7–1, a feather-degrading mesophilic bacterium. Microbiol Res 164(4):478–485

Williams CM, Richter CS, MacKenzie JM Jr, Shih JC (1990) Isolation, identification, and characterization of a feather-degrading bacterium. Appl Environ Microbiol 56(6):1509–1515

Hong SJ, Park GS, Jung BK, Khan AR, Park YJ, Lee CH, Shin JH (2015) Isolation, identification, and characterization of a keratin-degrading bacterium Chryseobacterium sp. P1–3. J Appl Biol Chem 58(3):247–251

Bonser RH (1995) Melanin and the abrasion resistance of feathers. Condor 97(2):590–591

Ben Hamad Bouhamed S, Kechaou N (2017) Kinetic study of sulphuric acid hydrolysis of protein feathers. Bioprocess Biosyst Eng 40:715–721

Eslahi N, Dadashian F, Nejad NH (2013) An investigation on keratin extraction from wool and feather waste by enzymatic hydrolysis. Prep Biochem Biotechnol 43(7):624–648

Brandelli A, Sala L, Kalil SJ (2015) Microbial enzymes for bioconversion of poultry waste into added-value products. Food Res Int 73:3–12

Teale WD, Paponov IA, Palme K (2006) Auxin in action: signalling, transport and the control of plant growth and development. Nat Rev Mol Cell Biol 7(11):847–859

Dastager SG, Deepa CK, Pandey A (2010) Isolation and characterization of novel plant growth promoting Micrococcus sp NII-0909 and its interaction with cowpea. Plant Physiol Biochem 48(12):987–992

Kochar M, Upadhyay A, Srivastava S (2011) Indole-3-acetic acid biosynthesis in the biocontrol strain Pseudomonas fluorescens Psd and plant growth regulation by hormone overexpression. Res Microbiol 162(4):426–435

Tsavkelova E, Oeser B, Oren-Young L, Israeli M, Sasson Y, Tudzynski B, Sharon A (2012) Identification and functional characterization of indole-3-acetamide-mediated IAA biosynthesis in plant-associated Fusarium species. Fungal Genet Biol 49(1):48–57

Jeong JH, Lee OM, Jeon YD, Kim JD, Lee NR, Lee CY, Son HJ (2010) Production of keratinolytic enzyme by a newly isolated feather-degrading Stenotrophomonas maltophilia that produces plant growth-promoting activity. Process Biochem 45(10):1738–1745

Colla G, Hoagland L, Ruzzi M, Cardarelli M, Bonini P, Canaguier R, Rouphael Y (2017) Biostimulant action of protein hydrolysates: unraveling their effects on plant physiology and microbiome. Front Plant Sci 8:2202

Cavello IA, Crespo JM, García SS, Zapiola JM, Luna MF, Cavalitto SF (2015) Plant growth promotion activity of keratinolytic fungi growing on a recalcitrant waste known as “hair waste”. Biotechnol Res Int 2015. https://doi.org/10.1155/2015/952921

Tejada M, Rodríguez-Morgado B, Paneque P, Parrado J (2018) Effects of foliar fertilization of a biostimulant obtained from chicken feathers on maize yield. Eur J Agron 96:54–59

Gousterova A, Nustorova M, Paskaleva D, Naydenov M, Neshev G, Vasileva TE (2012) Assessment of feather hydrolysate from thermophilic actinomycetes for soil amendment and biological control application. Int J Environ Res 6(2):467–474

Sivakumar T, Shankar T, Vijayabaskar P, Ramasubramanian V (2012) Plant growth promoting activity of nickel tolerant Bacillus cereus TS1. J Agric Technol 8(6):2101–2113

Ghosh A, Chakrabarti K, Chattopadhyay D (2008) Degradation of raw feather by a novel high molecular weight extracellular protease from newly isolated Bacillus cereus DCUW. J Ind Microbiol Biotechnol 35(8):825–834

Bhari R, Kaur M, Singh RS (2020) Nutritional enhancement of chicken feather waste by Bacillus aerius NSMk2. Indian J Microbiol 60:518–525

Mabrouk ME (2008) Feather degradation by a new keratinolytic Streptomyces sp. MS-2. World J Microbiol Biotechnol 24:2331–2338

Sobucki L, Ramos RF, Gubiani E, Brunetto G, Kaiser DR, Daroit DJ (2019) Feather hydrolysate as a promising nitrogen-rich fertilizer for greenhouse lettuce cultivation. Int J Recycl Org Waste Agric 8:493–499

Abo Sedera FA, Abd El-Latif AA, Bader LAA, Rezk SM (2010) Effect of NPK mineral fertilizer levels and foliar application with humic and amino acids on yield and quality of strawberry. Egypt J Appl Sci 25:154–169

Bhari R, Kaur M, Sarup Singh R (2021) Chicken feather waste hydrolysate as a superior biofertilizer in agroindustry. Curr Microbiol 78(6):2212–2230

Zhang RX, Wu ZW, Cui HY, Chai YN, Hua CW, Wang P, Yang TY (2022) Production of surfactant-stable keratinase from Bacillus cereus YQ15 and its application as detergent additive. BMC Biotechnol 22(1):1–13

Sultana N, Saha P (2018) Studies on potential application of crude keratinase enzyme from Stenotrophomonas sp. for dehairing in leather processing industry. J Environ Biol 39(3):324–330

Emon TH, Hakim A, Chakraborthy D, Azad AK (2023) Enhanced production of dehairing alkaline protease from Bacillus subtilis mutant E29 by consolidated bioprocessing using response surface modeling. Biomass Convers Biorefinery 1–17. https://doi.org/10.1007/s13399-023-04244-3

Fang Z, Yong YC, Zhang J, Du G, Chen J (2017) Keratinolytic protease: a green biocatalyst for leather industry. Appl Microbiol Biotechnol 101:7771–7779

Arasu M V, Al-Dhabi NA (2023) Improved production of extremophilic protease using low-cost substrate by Bacillus subtilis ZB isolated from extreme environment for tannery effluent treatment. Biomass Convers Biorefinery 1–11. https://doi.org/10.1007/s13399-023-04190-0

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Contributions

“N. D.: performed the experiments, methodology, formal analysis, visualization, writing—original draft, data curation, and validation; M.E.M.M.: supervision, suggestion the main point of this work, conceptualization, methodology, study design, validation, data interpretation, literature search, and writing—review and editing; M. M. E.: supervision, visualization, and validation; and Y. M. M. M.: software, formal analysis, supervision, visualization, and validation. All authors read and approved the final manuscript.”

Corresponding author

Ethics declarations

Ethical approval

The authors declared that they had a written approval from a volunteer to take a sample of fresh blood from his body for their research purpose. This sample has been taken by a specialist in an official hospital to assure health and safety. Regarding fresh raw cowhides, the authors visited animal farm and took the permission from the manager to take a piece of raw cowhides used for trade and manufacturing.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

We have not submitted our manuscript to a preprint server before submitting it to Biomass Conversion and Biorefinery.

Highlights

• Bacillus cereus L10 has a promising capacity to degrade keratinolytic materials.

• The Plackett–Burman design is used to improve keratinase production.

• Hydrolysates produced by B. cereus L10 exhibited plant growth promoting activities and detergent compatibility.

• Thermo-stable keratinase is a widely employed enzyme in biotechnological applications.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Derhab, N., Mabrouk, M.E.M., El-Metwally, M.M. et al. Thermostable keratinase from Bacillus cereus L10: optimization and some potential biotechnological applications. Biomass Conv. Bioref. (2023). https://doi.org/10.1007/s13399-023-04887-2

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-023-04887-2