Abstract

Bio-based zwitterionic surfactant attracts increasing attention to its application potential of surfactant flooding for enhanced oil recovery because of its environmental friendliness, renewability, and stable interfacial performance under high salinity and high temperature. However, bio-based zwitterionic surfactants which can be applied at the temperature higher than 100°C are still rare. In this paper, a new surfactant, phenyloleamide ethyl hydroxysulfonyl quaternary ammonium salt (PEHSQA), was obtained from biomaterial methyl oleate through alkylated, amidated, and quaternized reactions. As N, N-dimethyl propanediamine (a common amidated reagent in the synthesis of bio-based zwitterionic surfactants derived from fatty acids and esters) has one more carbon atom than N,N-dimethyl-1,2-ethanediamine, the latter was adopted as the amidated reagent optimizing the hydrophilic head of surfactant to improve the interfacial activity, especially the thermal resistance. The interfacial tension (IFT) between Daqing oil and stratum water could be maintained at 2.13×10−3 mN/m with the aid of 1 g/L PEHSQA. Furthermore, the IFT could be maintained at the level of 10−3 mN/m under the condition of 120 °C, with added NaCl of 20 g/L or Ca2+ of 2500 mg/L respectively. The optimization of reducing carbon number in the hydrophilic head of the bio-based zwitterionic surfactant can make a better balance between hydrophilicity and hydrophobicity offered by long fatty carbon chain, which can improve the interfacial activity especially the thermal resistance effectively.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Bio-based surfactants attract increasing attention to their application potential of surfactant flooding for enhanced oil recovery because of their environmental friendliness and renewability [1,2,3,4,5]. Surfactant flooding is an effective approach to enhance the crude oil recovery ratio after the natural eruption and water flooding [6, 7], which can improve the crude oil recovery ratio from three aspects, lowering the interfacial tension (IFT) between oil and water [8, 9], changing the wettability of the surface of oilfield rock [10, 11], and helping form microemulsion [12,13,14,15]. Compared with the conventional petro-based surfactants with relatively fixed and simple structures [16], bio-based surfactants can better meet the requirements of the above principles of surfactant flooding and achieve a better oil-flooding effect via various structural modifications.

Bio-based surfactants for oil flooding can be divided into nonionic, anionic, cationic, and zwitterionic according to the difference in ion types [17,18,19,20,21]. Among the types, bio-based zwitterionic surfactant with both positive and negative charge centers shows electric neutrality, which has stable interfacial performance under high salinity and high temperature [22,23,24,25]. In the past research, a series of zwitterionic surfactants (aryl oleamide carboxyl quaternary ammonium salt) was obtained from biomaterial oleic acid through alkylated, amidated, and quaternized reactions [26]. When using benzene as the raw material of alkylation, taking N,N-dimethyl-1,2-ethanediamine as the substitute of N,N-dimethyl propanediamine in amidation could make the surfactant has better interfacial performance. On the other hand, the sulfonyl group was used to replace the carboxyl group and the hydroxyl group was introduced into the hydrophilic head [23]. As a result, the interfacial performance of the new surfactant (SPODP) had an enhancement. The surfactant SPODP can maintain the IFT between crude oil and stratum water at the ultralow level (~10−3 mN/m) at 95 °C. However, it is still not enough to be applied in reservoirs with temperature higher than 100 °C [27,28,29]. To solve the problem, the structure of the surfactant needs to be further optimized.

In this paper, the structure of the new surfactant was optimized on the basis of SPODP which used N,N-dimethyl-1,2-ethanediamine as the substitute of N,N-dimethyl propanediamine to decrease the carbon number of hydrophilic head, as the stronger hydrophilicity can have a better balance with the hydrophobicity offered by the long fatty carbon chain, the optimization aims to improve the interfacial performance, especially the thermal resistance of the new surfactant.

2 Materials and methods

2.1 Materials

The chemicals adopted included methanol (Adamas, 99.9%), ethanol (Adamas, 99%), sodium carbonate (Greagent, 99.5%), sodium hydroxide (Maclin, 95%), benzene (Collins, 99%), sodium chloride (Yuanye, 99.5%), N,N-dimethyl-1,2-ethanediamine (Maclin, 99%), methyl oleate (Yuanye, 98%), sodium 3-chloro-2-hydroxypropanesulfonate (Yuanye, 98%), methanesulfonic acid (TCI, 98%), cocamidopropyl betaine (Yuanye, 98%), and petroleum sulfonate (Daqing Oil Field).

The constituents of the stratum water are listed in the Table S1 (Supporting Information).

2.2 Synthesis method

The synthesis steps of the new surfactant consist of alkylated, amidated, and quaternized reactions. Firstly, methyl oleate was mixed with benzene in a molar ratio of 1:6 under the effect of alkylated catalyst methanesulfonic acid (5 times molar amount of methyl oleate) and heated at 75 °C for 8 h, then water washing was adopted to remove methanesulfonic acid. Secondly, sodium hydroxide was chosen to catalyze the amidation in a high-pressure reactor, methyl phenyl oleate and N, N-dimethyl-1,2-ethanediamine was mixed in a molar ratio of 1:6 and heated at 165 °C for 8 h, and evaporation was adopted to remove excess N,N-dimethyl-1,2-ethanediamine. Finally, 3-chloro-2-hydroxypropanesulfonate was selected as the reagent of quaternization. The amidated product and the quaternized reagent in a molar ratio of 1:1.2 were added into water/ethanol (volume ratio 1:2) and heated at 105 °C for 8 h under the catalyzation of sodium carbonate (equal to the molar amount of amidated product). After evaporation to remove the solvent, the crude product of quaternized reaction was dissolved using methanol to separate the catalyst, redundant quaternized reagent, and by-product. The summary of the synthetic process of PEHSQA is drawn in Scheme 1.

2.3 Characterization of the synthesized compounds

To confirm the conversion rate and the successful synthesis of each step, GC-MS (Instrument model: Shimadzu TQ-8040) was used to test the products of alkylated and amidated reactions, while HPLC-MS (Instrument model: Shimadzu LCMS-8045) was used to test the crude product of quternized reaction and 1H NMR (Instrument model: Bruker AVANCEIII 400MHz) was used to test the purified final product. The conversion rate can be calculated according to the peak area of raw materials and products, and the compounds can be identified by the characteristic m/z in the MS (methyl oleate, 296; alkylated product, 374; amidated product, 430; amidated product (hydrogen positive ionization), 431; quaternized product (sodium positive ionization), 591).

2.4 Thermal stability test

A thermogravimetric analyzer (TGA, Instrument model: Shimadzu TGA-50) was adopted to test the thermal stability of PEHSQA. The sample of PEHSQA was heated from the initial temperature of 30 °C and the heating finally stopped at 800 °C, and the temperature rose by 20 °C per minute with the protection of nitrogen.

2.5 Determination of surface activity

The surface tensions of the PEHSQA solution of different concentrations were tested with the aid of a surface tension tester (Instrument model: Dataphysics DACT-25) at 25 °C (room temperature) [30]. The adsorption amount (ΓCMC) of the surfactant was obtained using Gibbs adsorption isotherm equation (Eq. 1) in which η is 1 when the type of surfactant is zwitterionic and the single molecule occupation area (ACMC) of surfactant was gained via Eq. 2 [30, 31].

2.6 Contact angle measurement

The change of contact angle was measured by a contact angle measuring instrument (Kruss DSA-25S). Before the measurement, the quartz sheet was infiltrated by Daqing oil to simulate the surface of oil sandstone. Afterward, the liquid to be measured was dropped on the quartz sheet to detect the contact angle at 25 °C. The final result of the contact angle was the average value of the right and left contact angles.

2.7 Evaluation of interfacial tension

The dynamic IFTs between Daqing oil and stratum water with the aid of the surfactant of various concentrations were tested with the aid of an interfacial tension tester (Kruss SDT) at 45 °C (the stratum temperature of the Daqing Oil Field [23]). The salinity tolerance of PEHSQA was tested with extra NaCl or Ca2+ added into 1.0 g/L PEHSQA solution based on the salinity of stratum water at 45 °C. The thermal resistance of PEHSQA was tested from 45 to 120 °C (the operating limit temperature of the instrument) and the concentration of PEHSQA was 1.0 g/L as well.

2.8 Oil washing experiment

To estimate the oil washing efficiency of different surfactants, firstly, Daqing oil and quartz sand were mixed with a weight ratio of 1:4 to obtain simulated oil sand, after aging for 7 days at 45 °C (the temperature of Daqing Oil Field), the simulated oil sand and 1g/L surfactant solution (prepared with stratum water) were mixed with a weight ratio of 1:10, and then, the mixture was placed in a table with the rotating speed of 50 rpm at 45 °C for 24h; finally, the liquid was separated and the residual sand was dried at 45 °C [32, 33]. The oil washing efficiency (Φ) can be calculated by Eq. 3 [33]:

in which m1 is the weight of the simulated oil sand, m2 is the weight of the residual sand, and moil is the weight of Daqing oil mixed with quartz sand.

3 Results and discussion

3.1 The characterization of the synthesized compounds

The new surfactant (PEHSQA) was obtained from biomaterial methyl oleate through alkylated, amidated, and quaternized reactions. And then, the conversion rates of alkylation and amidation were calculated to be 93.5% and 99.2% according to the results of GC-MS respectively (Supporting Information: Fig. S1, S2, S3, S4, S5, S6). In addition, the conversion rate of quaternized reaction was calculated to be 91.0% according to the HPLC-MS results (Fig. 1). The belongingness of chromatographic peaks was confirmed by characteristic m/z in the MS respectively, and the conversion rates were calculated according to the relevant area of product peak and residual raw material peak. Besides, the details of calculating the conversion rates of alkylated, amidated, and quaternized reactions were placed in the Supporting Information.

Furthermore, the purified product of quaternized reaction was detected by 1H NMR. Here is the result (400 MHz, CD3OD): δ 8.57 (–CO–NH–), 7.29–7.13 (–C6H5), 4.63 (–CH2–CH(OH)–), 4.19–4.12 (–CH2–CH(OH)–), 3.84–3.81 (–NH–CH2–; –CH2–SO3–), 3.69–3.56 (–CH2–N(CH3)2–), 3.34–2.89 (–N(CH3)2–), 2.72 (–CH–C6H5), 2.38–2.17(–CH2–CO–), 1.62–1.58 (–CH2–CH(C6H5)–; –CH2–CH2–CO–), 1.46–1.23 (–(CH2)n–3–CH2–CH2–CO–; – (CH2)m–1–CH3), 0.94–0.75 (–CH2–CH3) (Supporting Information: Fig. S7).

3.2 Thermal stability

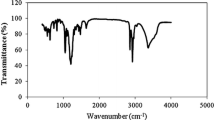

The TGA curve of the sample of PEHSQA is shown in Fig. 2. The weight of the PEHSQA sample first decreased slightly with a 5% loss from 30 to 236 °C and then decreased violently with a 75% loss from 236 to 506 °C. Finally, the weight of the sample decreased slowly from 506 to 800 °C.

For the new surfactant PEHSQA, as the small weight reduction from 30 to 236 °C can be attributable to the loss of moisture and impurities [34], its decomposition temperature is up to 236 °C which is higher than the temperature of common high-temperature reservoirs [27,28,29].

3.3 Surface properties

The surface tension (SFT) of PEHSQA solution of different concentrations was tested at 25 °C. The results are summarized in Fig. S8(a) (Supporting Information). According to the point of inflection, the critical micelle concentration (CMC) was identified to be 1.42×10−5 mol/L and the surface tension at CMC (SFTCMC) could be confirmed to be 30.61 mN/m. Besides, the contact angle of the simulative stratum water on the surface of simulative oil sandstone was 62.7° and could be reduced to 49.2° with the aid of 1g/L PEHSQA (Supporting Information: Fig. S8(b) and S8(c)).

The ΓCMC and ACMC were calculated according to Eq. 1 and Eq. 2 respectively. The relevant parameters of PEHSQA and SPODP and a common anionic surfactant linear alkylbenzene sulfonate (LAS) are summarized in Table 1 [23, 35]. Compared with SPODP and LAS, PEHSQA has lower CMC and SFTCMC, and it presented that PEHSQA has better efficiency in lowering surface tension at 25 °C which may be due to the hydrophilicity of the head groups having a proper balance with the hydrophobicity of the long carbon chain. In addition, PEHSQA can effectively change the wettability of the rock surface to be more water-wet. That is beneficial for the crude oil to break away from the rock surface which could increase the oil recovery efficiency [10, 11].

3.4 Interfacial performance

3.4.1 Effect of surfactant concentration

The interfacial tension results of PEHSQA showed that the IFT could be maintained at the ultralow level when the concentration of PEHSQA was 0.05 g/L, 0.5 g/L, 1.0 g/L, 1.5 g/L, 2g/L, 2.5g/L, and 3.0 g/L (Fig. 3a) and the equilibrium interfacial tension (IFTequ) has the minimum at 1.0g/L (Fig. 3b). However, for the petroleum sulfonate (PS) which is the industry product widely applied with alkali in the oil recovery of the Daqing Oil Field and cocamidopropyl betaine (CAB, a common commercial bio-based zwitterionic surfactant), the IFT was not able to be maintained in ultralow level at 0.5 g/L, 1.0 g/L, and 3.0 g/L which is the common range of industrial consumption (Fig. 3c, d).

Surfactant molecule has both hydrophilic head and hydrophobic chain, which can play a role as the link between the oil phase and the water phase, thereby reducing the repulsion between them, and thus the IFT can be reduced. Therefore, for the new surfactant PEHSQA, the surfactant molecules dissolve in the water phase at the beginning and then move to the oil-water interface due to the hydrophobic interaction between the hydrophobic chain and the oil phase, which causes the IFT to decline. And when the quantity of surfactant molecules at the interface between oil and water attains saturation, the IFT remains stable.

However, on the one hand, for petroleum sulfonate, as its hydrophilicity is poor, the surfactant molecules have the trend of migrating from the water phase to the oil phase. During the process of the migration, the amount of surfactant molecules at the interface between oil and water first has growth and then declines until the migration of surfactant molecules has finished; in consequence, the IFT declines at first and then increases correspondingly. On the other hand, due to the high hydrophilicity of cocamidopropyl betaine, the surfactant molecules tend to stay in water phase rather than migrating to the interface; thus, the IFT could not be reduced effectively. In summary, compared to petroleum sulfonate and cocamidopropyl betaine, the new surfactant PEHSQA is more efficient in reducing oil-water interfacial tension which can maintain the IFT at 2.13×10−3 mN/m with no added alkali and that is better than SPODP (5.50×10−3 mN/m).

3.4.2 Salinity tolerance

Due to the equilibrium interfacial tension (IFTequ) between the Daqing oil and the simulated stratum water being smallest when the concentration of PEHSQA was 1.0 g/L, the concentration was chosen to detect the salinity tolerance. The IFTequ declined when the concentration of extra NaCl has an increase from 0 to 1 g/L, and then increased with the continued increase of extra NaCl concentration. In general, the IFTequ was able to be maintained at the level of 10−3 mN/m when the extra NaCl concentration was not more than 20 g/L (Fig. 4a) which was lower than SPODP (saturated NaCl). Similarly, the IFTequ declined at first when the concentration of extra Ca2+ has an increase from 0 to 500 mg/L, and then increased with the growth of extra Ca2+ concentration. In summary, the IFTequ was able to be maintained at the ultralow level when the concentration of extra Ca2+ was not more than 2500 mg/L (Fig. 4b) which was higher than SPODP (500 mg/L).

Sodium and calcium are usually considered counter ions which have a remarkable influence on the interfacial activity of surfactant [36]. When the proper amount of sodium or calcium is added into the solution of surfactants, it can reduce the repulsion between anionic hydrophilic groups which can make the surfactant molecules more closely arranged at the oil-water interface [37]. However, when the amount of sodium or calcium is superfluous, the cations has damage to the hydration film around the hydrophilic heads of surfactant molecules, which makes the surfactant molecules migrate into the oil phase and the amount of surfactant molecules at the interface between oil and water has a decline; consequently, the IFTequ increases [23]. Due to containing more positive charge, the effect of calcium is more significant than sodium [38]. The changes in surfactant molecular arrangement were reflected in the decrease and increase of oil-water interfacial tension accordingly.

3.4.3 Thermal resistance

The concentration of 1 g/L was chosen to detect the thermal resistance of PEHSQA as well. The dynamic IFTs between Daqing oil and the simulated stratum water with the aid of 1 g/L PEHSQA at various temperatures are shown in Fig. 5a. With the growth of temperature, the IFTequ decreased to the minimum at 60 °C, and then rose to 7.98×10−3 mN/m at 120 °C (Fig. 5b). In general, the IFTequ was able to be maintained at the ultralow level when the temperature rose from 45 to 120 °C.

The interfacial thermal resistance is the ability of surfactants to maintain the IFTequ at the ultralow level at high temperature which means that the interfacial thermal resistance of PEHSQA is up to 120 °C. Obviously, the optimization of the hydrophilic head to reduce the carbon number makes the interfacial thermal resistance of PEHSQA have a notable improvement based on SPODP (95 °C).

Compared to 45 °C, the ionization extent of the ionic groups of surfactant molecules has an increase at 60 °C, which leads to the weakening of the interaction between anion and cation groups of single surfactant molecule and the strengthening of the interaction between anion and cation groups of different surfactant molecules. In consequence, the surfactant molecules arranged more closely at the interface between oil and water, which makes the amount of surfactant molecules staying at the interface between oil and water have an increase; consequently, the IFTequ decreases. Nevertheless, with the gradual increase of temperature from 60 to 120 °C, on the one hand, the hydrogen bonds between the water and surfactant molecules are broken by degrees, which reduces the hydrophilicity of the surfactant molecules and thus the surfactant molecules are inclined to migrate to the oil phase correspondingly [39]; on the other hand, the molecular thermal motion becomes violent which causes that the interaction between anion and cation groups of different surfactant molecules is weakened; consequently, the surfactant molecules which stay at the interface between oil and water have a more loose arrangement. Under the conjoint effect of these two aspects, there is a decline of the amount of surfactant molecules at the interface between oil and water which leads to the rising of the IFT at last.

3.5 Optimal conditions of lowest interfacial tension

To obtain the optimal conditions of lowest interfacial tension, the IFTs between Daqing oil and stratum water with the aid of 1 g/L PEHSQA at 60 °C (optimal surfactant concentration and temperature) added different concentrations of NaCl or Ca2+ were detected. The IFTequ had an increasing growth with the rising concentration of NaCl or Ca2+ (Fig. 6). Different from the effect of NaCl or Ca2+ at 45 °C, there was no proper amount of NaCl or Ca2+ which could promote the decline of IFTequ. Obviously, the rising temperature made the NaCl and Ca2+ tolerance of PEHSQA decrease. In summary, the optimal condition of lowest interfacial tension is 1g/L PEHSQA at 60 °C without added NaCl or Ca2+.

3.6 Oil washing efficiency

The oil washing efficiency results of the three surfactants PEHSQA, PS, and CAB are summarized in Table 2 which were 57.2%, 48.0%, and 20.4% respectively. The oil washing efficiency presented consistent trend with the interfacial performance of the three surfactants as PEHSQA having the lowest interfacial tension while CAB having the highest interfacial tension between Daqing oil and stratum water, which proved that improved interfacial activity could promote oil-flooding effectively.

4 Conclusions

A new zwitterionic surfactant PEHSQA was obtained from biomaterial methyl oleate through alkylated, amidated, and quaternized reactions. After optimizing the structure of hydrophilic head, the interfacial performance of PEHSQA especially its thermal resistance had a significant improvement. The interfacial tension (IFT) between Daqing oil and stratum water could be maintained at 2.13×10−3 mN/m with 1 g/L PEHSQA without added alkali. Furthermore, the IFT was still able to be maintained at the ultralow level at up to 120 °C. And its decomposition temperature was up to 236 °C which is enough to meet the requirements of the application in most high-temperature reservoirs. In addition, the salt and calcium tolerance of PEHSQA can reach 20 g/L and 2500 mg/L respectively based on the salinity of the stratum water. Finally, PEHSQA can increase the wettability of rock surface to be more water-wet which is advantageous to oil-flooding as well. As a result, PEHSQA shows a better oil washing efficiency than traditional petro-based surfactant petroleum sulfonate and common commercial bio-based surfactant cocamidopropyl betaine. The optimization of the hydrophilic head of PEHSQA can give some reference to improving the interfacial performance and expanding the application in high-temperature reservoirs of bio-based zwitterionic surfactants.

Data availability

The datasets are available from the corresponding author on reasonable request.

References

Zhang QQ, Cai BX, Xu WJ, Gang HZ, Liu JF, Yang SZ, Mu BZ (2015) Novel zwitterionic surfactant derived from castor oil and its performance evaluation for oil recovery. Colloid Surface A 483:87–95. https://doi.org/10.1016/j.colsurfa.2015.05.060

Saxena N, Goswami A, Dhodapkar PK, Nihalani MC, Mandal A (2019) Bio-based surfactant for enhanced oil recovery: interfacial properties, emulsification and rock-fluid interactions. J Pet Sci Eng 176:299–311. https://doi.org/10.1016/j.petrol.2019.01.052

Chen SY, Li XL, Zhou YJ, Lu Y, Chen BS, Zhang JN (2021) Systematic investigation of the physicochemical properties of eco-friendly biobased anionic-nonionic surfactants for enhanced oil recovery. J Mol Liq 323(350):114628. https://doi.org/10.1016/j.molliq.2020.114628

Ge MR, Miao SJ, Liu JF, Gang HZ, Yang SZ, Mu BZ (2021) Laboratory studies on a novel salt-tolerant and alkali-free flooding system composed of a biopolymer and a bio-based surfactant for oil recovery. J Pet Sci Eng 196:107736. https://doi.org/10.1016/j.petrol.2020.107736

Negi H, Singh RK (2023) A review on lignin utilization in petroleum exploration, petroleum products formulation, bio-fuel production, and oil spill clean-up. Biomass Convers Bior 13:1417–1428. https://doi.org/10.1007/s13399-020-01126-w

Han X, Lu M, Fan YX, Li YX, Holmberg K (2021) Recent developments on surfactants for enhanced oil recovery. Tenside Surfact Det 58(3):164–176. https://doi.org/10.1515/tsd-2020-2340

Chowdhury S, Shrivastava S, Kakati A, Sangwai JS (2022) Comprehensive review on the role of surfactants in the chemical enhanced oil recovery process. Ind Eng Chem Res 61:21–64. https://doi.org/10.1021/acs.iecr.1c03301

Yuan CD, Pu WF, Wang XC, Sun L, Zhang YC, Cheng S (2015) The effects of interfacial tension, emulsification and surfactant concentration on oil recovery in surfactant flooding process for high temperature and high salinity reservoirs. Energ Fuel 29(10):6165–6176. https://doi.org/10.1021/acs.energyfuels.5b01393

Yang WP, Lu J, Wei B, Yu HY, Liang TB (2021) Micromodel studies of surfactant flooding for enhanced oil recovery: a review. ACS Omega 6:6064–6069. https://doi.org/10.1021/acsomega.0c05750

Hou BF, Jia RX, Fu ML, Huang YQ, Wang YF (2019) Mechanism of wettability alteration of oil-wet sandstone surface by a novel cationic gemini surfactant. Energ Fuel 33(5):4062–4069. https://doi.org/10.1021/acs.energyfuels.9b00304

Das S, Katiyar A, Rohilla N, Nguyen QP, Bonnecaze RT (2020) Wettability alteration and adsorption of mixed nonionic and anionic surfactants on carbonates. Langmuir 36:15410–15422. https://doi.org/10.1021/acs.langmuir.0c03022

Santanna VC, Curbelo FDS, Dantas TNC, Neto AAD, Albuquerque HS, Garnica AIC (2009) Microemulsion flooding for enhanced oil recovery. J Pet Sci Eng 66:117–120. https://doi.org/10.1016/j.petrol.2009.01.009

Jeirani Z, Jan BM, Ali BS, See CH, Saphanuchart W (2014) Pre-prepared microemulsion flooding in enhanced oil recovery: a review. Petrol Sci Technol 32(2):180–193. https://doi.org/10.1080/10916466.2011.586968

Bera A, Kumar T, Ojha K, Mandal A (2014) Screening of microemulsion properties for application in enhanced oil recovery. Fuel 121:198–207. https://doi.org/10.1016/j.fuel.2013.12.051

Mahboob A, Kalam S, Kamal MS, Hussain S, Solling T (2022) EOR perspective of microemulsions: a review. J Pet Sci Eng 208:109312. https://doi.org/10.1016/j.petrol.2021.109312

Cui MW, Feng ZY (2021) Interfacial properties of petroleum sulfonate for oil displacement in separation process. Chem Eng Commun 208(8):1160–1166. https://doi.org/10.1080/00986445.2020.1758678

Ganie K, Manan MA, Ibrahim A, Idris AK (2019) An experimental approach to formulate lignin-based surfactant for enhanced oil recovery. Int J Chem Eng 4120859. https://doi.org/10.1155/2019/4120859

Haghighi OM, Zargar G, Manshad AK, Ali M, Takassi MA, Ali JA, Keshavarz A (2020) Effect of environment-friendly non-ionic surfactant on interfacial tension reduction and wettability alteration; implications for enhanced oil recovery. Energies 13:3988. https://doi.org/10.3390/en13153988

Valea TOD, Magalhães RSD, Almeida PFD, Matos JBTL, Chinalia FA (2021) The impact of alkyl polyglycoside surfactant on oil yields and its potentialeffect on the biogenic souring during enhanced oil recovery (EOR). Fuel 280:118512. https://doi.org/10.1016/j.fuel.2020.118512

Chen SY, Zhou YJ, Liu HJ, Yang JJ, Wei YY, Zhang JN (2019) Synthesis and physicochemical investigation of anionic−nonionic surfactants based on lignin for application in enhanced oil recovery. Energy Fuels 33:6247–6257. https://doi.org/10.1021/acs.energyfuels.9b01114

Chen SY, Li XL, Zhou YJ, Lu Y, Chen BS, Zhang JN (2020) Systematic investigation of the physicochemical properties of eco-friendly biobased anionic-nonionic surfactants for enhanced oil recovery. J Mol Liq 323:114628. https://doi.org/10.1016/j.molliq.2020.114628

Zhao JH, Dai CL, Ding QF, Du MY, Feng HS, Wei ZY, Chen A, Zhao MW (2015) The structure effect on the surface and interfacial properties of zwitterionic sulfobetaine surfactants for enhanced oil recovery. RSC Adv 5:13993–14001. https://doi.org/10.1039/c4ra16235h

Chen ZZ, Gang HZ, Liu JF, Mu BZ, Yang SZ (2019) A thermal-stable and salt-tolerant biobased zwitterionic surfactant with ultralow interfacial tension between crude oil and formation water. J Pet Sci Eng 181:106181. https://doi.org/10.1016/j.petrol.2019.06.045

Gbadamosi A, Hussai SMS, Kamal MS, Patil S, Solling T, Hassan SF, Wang JX (2023) Evaluating the potential of zwitterionic surfactants for enhanced oil recovery: effect of headgroups and unsaturation. Energy Fuels 37:5078–5086. https://doi.org/10.1021/acs.energyfuels.3c00093

Chen SY, Li XL, Lei Q, Han YH, Zhou XP, Zhang JN (2023) Synthesis, characterization and performance of lignin carboxyl betaine zwitterionic surfactants for application in enhanced oil recovery. RSC Adv 13:16352–16362. https://doi.org/10.1039/d3ra02028b

Zhang QQ, Cai BX, Gang HZ, Yang SZ, Mu BZ (2014) A family of novel bio-based zwitterionic surfactants derived from oleic acid. RSC Adv 4:38393–38396. https://doi.org/10.1016/j.petrol.2019.06.045

Zhou M, Zhao JZ, Wang X, Yang Y (2013) Research on surfactant flooding in high-temperature and high-salinity reservoir for enhanced oil recovery. Tenside Surfact Det 50:175–181. https://doi.org/10.3139/113.110245

Jin FY, Li QH, He Y, Luo Q, Pu WF (2020) Experimental study on enhanced oil recovery method in Tahe high-temperature and high-salinity channel sand reservoir: combination of profile control and chemical flooding. ACS Omega 5:5657–5665. https://doi.org/10.1021/acsomega.9b03306

Liu JB, Zhong LG, Wang C, Li SH, Yuan XN, Liu YG, Meng XH, Zou J, Wang QX (2020) Investigation of a high temperature gel system for application in saline oil and gas reservoirs for profile modification. J Pet Sci Eng 195:107852. https://doi.org/10.1016/j.petrol.2021.108416

Lu T, Lan YR, Liu CJ, Huang JB, Wang YL (2012) Surface properties, aggregation behavior and micellization thermodynamics of a class of gemini surfactants with ethyl ammonium headgroups. J Colloid Interf Sci 377:222–230. https://doi.org/10.1016/j.jcis.2012.03.044

Eastoe J, Nave S, Downer A, Paul A, Rankin A, Tribe K, Penfold J (2000) Adsorption of ionic surfactants at the air-solution interface. Langmuir 16:4511–4518. https://doi.org/10.1021/la991564n

Pei HH, Shan JL, Zhang GC, Zhang GZ, Zhao JW (2021) Selection of optimum surfactant formulations with ultralow interfacial tension for improving the oil washing efficiency. ACS Omega 6:23952–23959. https://doi.org/10.1021/acsomega.1c02930

Li ML, Kang WL, Li Z, Yang HB, Jia RX, He YQ, Kang X, Zheng ZW, Wang YD, Sarsenbekuly B, Gabdullin M (2021) Poly(oxyethylene)-amidoamine based gemini cationic surfactants for oilfield applications: effect of hydrophilicity of spacer group. Phys Fluids 33:072002. https://doi.org/10.1063/5.0058759

Hussain SMS, Mahboob A, Kamal MS (2020) Poly(oxyethylene)-amidoamine based gemini cationic surfactants for oilfield applications: effect of hydrophilicity of spacer group. Materials 13:1046. https://doi.org/10.3390/ma13051046

Smith GA, Huggett A, Jones C, Ortego G (2021) Surface activity and performance properties of gemini salts of linear alkylbenzene sulfonate in aqueous solution. J Surfactants Deterg 24(4):563–574. https://doi.org/10.1002/jsde.12496

Lv KH, Jia KL, Yang YP, Huang WJ, Wu HY, Pan W, Jia H (2019) Effects of additional salts on the interfacial tension of crude oil/zwitterionic gemini surfactant solutions. J Disper Sci Technol 40(7):1031–1038. https://doi.org/10.1080/01932691.2018.1494606

Bera A, Mandal A, Guha BB (2013) Synergistic effect of surfactant and salt mixture on interfacial tension reduction between crude oil and water in enhanced oil recovery. J Chem Eng Data 59(1):89–96. https://doi.org/10.1021/je400850c

Mahmoudvand M, Javadi A, Pourafshary P, Vatanparast H, Bahramian A (2021) Effects of cation salinity on the dynamic interfacial tension and viscoelasticity of a water-oil system. J Pet Sci Eng 206:108970. https://doi.org/10.1016/j.petrol.2021.108970

Qu GM, Xue CL, Zhang MZ, Liang S, Han Y, Ding W (2016) Molecular dynamics simulation of sulfobetaine-type zwitterionic surfactants at the decane/water interface: structure, interfacial properties. J Disper Sci Technol 37:1710–1717. https://doi.org/10.1080/01932691.2015.1135400

Funding

This research was supported by the Fundamental Research Funds for the Central Universities of China (No. 222201817017), the National Natural Science Foundation of China (No. 51574125) and the National Key Research and Development Program of China (No. 2017YFB0308900).

Author information

Authors and Affiliations

Contributions

Wei Wang: experiment and draft manuscript preparation; Ming-Yue Liang, Jian-Qiao Lang, Homely Isaya Mtui: assisting experiment; Shi-Zhong Yang, Bo-Zhong Mu: review and editing of manuscript.

Corresponding author

Ethics declarations

Ethical approval

This is not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

ESM 1

(PDF 530 kb)

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wang, W., Liang, MY., Lang, JQ. et al. A new bio-based zwitterionic surfactant with improved interfacial activity by optimizing hydrophilic head. Biomass Conv. Bioref. (2023). https://doi.org/10.1007/s13399-023-04803-8

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-023-04803-8