Abstract

This study presents a method for effective pectin extraction from the laminae of three tobacco varieties as a means of biomass valorisation. Two pre-treatment methods (cold ethanol vs. accelerated solvent extraction [ASE] with ethanol) were compared for their capacities to produce a high pectin yield. Enzymatic extraction of pectin was also tested as a green extraction procedure and compared to the acid extraction approach. The optimisation experiments revealed that cold ethanol extraction followed by acid hydrolysis is the most convenient method for pectin extraction; the optimal set of conditions for hydrolysis were identified as 90°C, pH 1.5, and 4 h of extraction. Applying these optimised conditions to the three Nicotiana rustica tobacco varieties yielded pectin recoveries of 66.2%, 57.8%, and 56.7% from the NRT63, Bakoum Miena, and NRT61 samples, respectively. Tobacco pectins were found to have a medium molecular weight and low methoxy content. These results highlight the potential of tobacco residues as feedstock for to produce pectin with dietary applications.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Tobacco is a globally significant crop, with annual production ranging between 5.9 and 7.6 million tonnes over the last 30 years (https://www.statista.com/statistics/261189/global-tobacco-production-since-1980/, last accessed at 11:45 (CET) on Monday 5th September 2022). Tobacco cultivation occupies ~4.3 million hectares of agricultural land spread across 124 countries [1]. Of these, China and Brazil jointly contribute the majority with total production of ~3.8 million tonnes per year [2]. Considering that only 75% of the plant is utilised, tobacco residues generated globally may amount to at least 1.4 million tonnes [2]. The conventional means of disposal of these residues, such as incineration and landfill, result in significant environmental issues such as soil structural changes and groundwater contamination. Additionally, these practices do not generate any economic value from the residues [1, 3]. It would be advantageous—in both environmental and economic terms—if these residues could be used as feedstocks to produce high-value commodities and fuels.

Conveniently, the large quantities of tobacco residues produced allow for the development of practical and economical logistical operations and technical processes for the valorisation of this feedstock. Its potential for valorisation results from the myriad of high value compounds found in this feedstock, including alkaloids, diterpenoids, flavonoids, proteins, polyphenols, pectins, and sugars [1, 4,5,6]. Among these substances, pectin is of particular importance due to its broad-reaching applications in the food and pharmaceutical industries. Pectin is largely used as a gelling and thickening agent in jams and confectionary products [7]. The diversity in pectin structures may result in the polysaccharide exhibiting unique properties ranging from emulsification, antioxidant, prebiotic, antimicrobial, and anticancer depending on the modification and structural properties of the native pectin [2, 8,9,10,11]. Recently, pectin was found to be suitable for application in the manufacture of bio-based, sustainable films and coatings for food packaging [12].

Pectin is one of the major polysaccharides of the plant cell wall (together with cellulose and hemicellulose) and is a heteropolysaccharide consisting of α-(1-4)-linked galacturonic acid (GalA) and (1-2)-linked rhamnose units connected to either -α-(1-5)-linked L-arabinose or (1-4)-linked β-D-galactose side chains. Occasionally, several of the C-6 carboxyl units of the GalA backbone are esterified with methoxyl groups or exist as uronic acids [13]. Due to its association with the plant cell wall, pectin extractability depends on the cell wall matrix composition. Numerous methods have been devised to selectively liberate the pectin from the plant tissue, including hot acid treatment, microwave-assisted extraction, ultrasound-assisted extraction, enzymatic extraction, extraction with chelating agents, and alkaline treatment [2, 14,15,16]. The microwave and ultrasound-assisted methods have only been applied on the laboratory scale and may be technologically challenging to scale up. Extraction with chelating agents presents the challenge of eliminating the chelators after the extraction process, while alkaline extraction decreases the degree of methylation and length of the GalA chain by β-elimination [16].

Hot acid extraction is generally applied in commercial pectin production, as this method produces the highest yield and can conveniently be scaled up [7, 17,18,19,20]. Furthermore, the use of hydrochloric (HCl) acid is recommended in many reports [19, 21, 22]. The enzymatic treatment method is encouraged as it is more environmentally friendly, since the generation of hazardous waste materials associated with acid treatment is significantly reduced or avoided. Careful enzyme selection may result in high pectin yields per amount of solvent/chemical needed [14, 23]. Pectin has therefore been extracted using enzymes from different raw materials under various conditions, depending on the nature of the feedstock and the process economics [24].

The efficient extraction of pectin from tobacco samples requires a rigorous approach that considers the following: (I) the tobacco sample contains a slightly lower pectin content compared to pre-existing commercial sources (citrus peels and apple pomace), (II) the high amount of extractives and bioactive components present the tobacco biomass may interfere with pectin extraction, and (III) the tobacco biomass is generally highly recalcitrant compared to alternative pectin sources [5, 25,26,27,28]. To this end, it is crucial to implement a pre-treatment step aimed at pre-extracting a majority of the extractives prior to the pectin extraction step. Amongst the several polar and nonpolar solvent systems applied to the recovery of extractives from the tobacco biomass, ethanol systems have been identified as a proficient solvent for the selective recovery of extractives and bioactive components such as nicotine, rutin, sclareol, limonene, linoleic acid, phytol, farnesol, and α-pinene [27, 29,30,31]. In a biorefinery concept, the recovered extractives from the pre-treatment step can be further valourized for additional revenue generation.

The global market for pectin is estimated at 319 million USD corresponding to a production of 40,000 tonnes per year with a reported average annual growth rate of 6% [32]. The majority of the commercial pectin is obtained from apple and citrus peels, and there is need to identify and develop pectin extraction processes from other types of feedstocks. This work explores the potential of developing a scalable process for an efficient and sustainable production of pectin from tobacco residues. The laminae of three tobacco varieties were studied, including detailed compositional analyses of these samples. A multi-stage pretreatment-hydrolysis process was then developed to maximise pectin recovery from these feedstocks. In this process, the biomass is pretreated to remove extractives and bioactive components before the subsequent hydrolysis step to extract the pectin. The extracted pectins were also characterised in terms of degree of esterification (DE), composition, and molecular weight (MW) to provide insight into their potential applications. The results provide a significant knowledge base to build a foundation for stakeholders and decision makers to consider the potential of tobacco residue as a source of commercial pectin production [33].

2 Materials and methods

2.1 Materials

Dried samples of the laminae (leaves) of three Nicotiana rustica tobacco varieties (Bakoum Miena, NRT63, and NRT61) were cultivated in 2021 in Italy following common agricultural practices (Table 1), as provided by Philip Morris International (Italy/Switzerland). These samples were milled using a rotor beater mill SR 300 (Retsch GmbH, Haan, Germany) to a particle size <200 μm. The milled samples were then stored at room temperature until they were utilised.

2.2 Characterization of raw materials and pectin extracts

2.2.1 Moisture and ash contents

The moisture contents of samples were determined according to the weight losses recorded when samples were dried overnight in a convection oven at 105°C. As described by NREL [34], the ash content of samples was determined by incineration using a L-240H1SN muffle furnace (Nabertherm, Lilienthal, Germany) operated with a ramping temperature program. Complete biomass incineration is achieved when a furnace temperature of 575°C is reached and maintained for 3 h.

2.2.2 Extractive contents

The determination of extractive contents of the tobacco biomass was carried out using an Accelerated Solvent Extractor (ASE) 200 unit (Dionex Corp., Sunnyvale, CA, USA). The extraction was initially carried out separately with 95% ethanol (EE) and deionised (DEI) water (WE) as solvents. This step was followed by a sequential extraction (SE) using DEI water and 95% ethanol in that order. The ASE 200 unit was operated using the NREL standard protocol for automated extraction [35]. Samples were placed in 11-mL ASE cells and pressured to 1500 PSI using analytical grade nitrogen gas, maintained at 100°C. The heating time was 5 min, while the static time was 7 min. The samples were taken through three static cycles with a total flush volume of 150% of extraction cell volume. The extraction solvent (containing the extractives) was collected into a vial corresponding to the extraction cell.

2.2.3 Lignocellulosic sugars and lignin

The constituent sugars of lignocellulose (glucose, xylose, mannose, galactose, arabinose, and rhamnose) and lignin in the raw material and pectin extract samples were obtained and separated following a procedure based on the NREL protocol [36]. The first step involved a two-stage acid hydrolysis, where the sample was treated with 72% H2SO4 followed by the addition of water and subsequent autoclaving. The resulting mixture was filtered to separate the hydrolysate from the acid-insoluble residue (AIR), with the AIR content determined gravimetrically. The difference between the AIR and its ash content constitutes the Klason lignin. The acid-soluble lignin (ASL) was calculated from the absorbance (at 205 nm) of aliquots of the hydrolysate measured with an 8452 UV-Visible spectrophotometer (Agilent Technologies, Santa Clara, CA, USA) as described previously [37,38,39].

Quantification of sugars liberated in the hydrolysis step was undertaken using a Dionex ICS-3000 chromatography system as described previously [40]. The samples were first diluted with a melibiose (used as an internal standard) solution of known concentration followed by filtration of samples using 0.2-μm syringe filters into vials for analysis on the chromatography system.

The Dionex ICS-3000 chromatography system comprised (I) an electrochemical detector (using Pulsed Amperometric Detection, PAD), (II) a gradient pump, (III) a temperature-controlled column (with detector), and (IV) an autosampler. The autosampler injected 10 μL of the sample, and sugar separation was achieved using Dionex Carbo-Pac PA1 guard and analytical columns connected in sequence. Sugar separation occurred within 30 min using deionized water as the eluent (flow rate of 1 mL/min, and a column/detector temperature of 18°C). The column was regenerated after each run using a 300 mM NaOH aqueous solution and then re-equilibrated with water prior to the next injection. PAD requires alkaline conditions for the analysis of carbohydrates. To achieve this, NaOH (300 mM concentration) was injected with a Dionex pump (flow rate of 0.3 mL/min) to the eluent stream (post-column). The chromatographic settings allowed for resolution between and quantification of arabinose, galactose, rhamnose, glucose, xylose, mannose, and melibiose in a single injection. Relative response factors were identified via sugar standard samples injected at fixed times in the analytical order. Sugar losses associated with the autoclaving processes were accounted for by putting sugar standards through the same process and using the recovery rates as correction factors for the data obtained for samples, as described by Sluiter et al [36].

2.2.4 Uronic acids content

The uronic acids contents of raw material and pectin extract samples were determined by high-pressure ion exchange chromatography (HPAEC) and electrochemical detection. The chromatography system, flow rates, and detectors were as described in Section 2.2.3. Separation of the uronic acids was achieved using sodium hydroxide and a sodium acetate elution gradient [41, 42]. An increase in sodium acetate concentration with respect to sodium hydroxide in the elution gradient allows the release of uronic acids (4-O-methyl-D-glucuronic acid, galacturonic acid, and glucuronic acid) from the column packing and their subsequent separation. The program was deployed after 35 min following the sugars determination program described above [40].

2.2.5 Molecular weight determination

The pectin extract samples were subjected to size exclusion chromatography (SEC) to analyse the MWs, number average molar mass (Avg Mn), and polydispersity indexes (PDIs) of the pectin. The samples were first diluted with DEI water followed by filtration using 0.2-μm syringe filters into vials for analysis on the SEC system. The SEC system was equipped with a pump (Dionex ICS-5000 DP), an autosampler (Dionex AS) and an RI detector (RI-101 series; Shodex, Munich, Germany). The separation was carried out using two analytical columns in sequence, Ultrahydrogel 2000 Å (12 μm, 7.8 mm × 300 mm) followed by Ultrahydrogel 250 Å (6 μm, 7.8 mm × 300 mm), at a temperature of 30°C. DEI water containing 0.5 g/L sodium azide was used as the eluent at a flow rate of 1 mL/min. An Ultrahydrogel 125 Å (6 μm, 7.8 mm × 300 mm) was used as a guard column.

2.2.6 Determination of degree of esterification

The DEs of the pectin extracts was determined by a titrimetric method described earlier [43], but with some modifications. A 0.2-g dried sample of pectin extract was dissolved in 100 mL of distilled water. After the sample was completely dissolved, five drops of phenolphthalein were added, and the solution was titrated with 0.1 N NaOH. The volume of the 0.1 N NaOH solution used was recorded as the initial titre (V1). Subsequently, 10 mL of 0.1 N NaOH was added to a neutralised poly-GalA after determination of the free carboxy groups. The solution was allowed to stand for 30 min to ensure the saponification of the esterified carboxy groups of the polymer. A total of 10 mL of 0.1 N HCl was subsequently added to neutralise the solution under vigorous stirring. The excess HCl was titrated with 0.1 N NaOH until a faint pink colour persisted after vigorous shaking (end point). The volume of the 0.1 N NaOH (indicative of the number of esterified carboxy groups) was recorded as the final titre (V2). The DE was then calculated using Eq. (1).

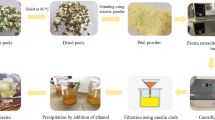

2.3 Process of pectin extraction from tobacco residue

As shown in Fig. 1, the process of pectin extraction developed in this work is divided into three stages: (I) pre-treatment of tobacco samples, (II) pectin extraction from pre-treated samples, and (III) pectin separation. These processes are described in the sections below. Each of these stages was investigated and tailored to maximize the production of pectin from the biomass. However, the main optimisation study was conducted on the extraction stage as it was found to be the most crucial step to maximize pectin yield, purity, and recovery. It should be noted that preliminary extraction experiments and optimisation runs were carried out on the Bakoum Miena sample, since it was the variety that was available in a quantity sufficient to complete all the investigative runs. The resulting preferred conditions were then applied to the NRT63 and NRT 61 samples for comparison with the Bakoum Miena sample.

2.3.1 Pre-treatment of tobacco samples

Two pre-treatment approaches were applied to the tobacco samples to remove the extractives and bioactive components prior to the extraction of the pectin. These pre-treatment methods are described below.

2.3.2 Cold ethanol pre-treatment

Ten (10) grams of powdered tobacco residues was weighed and placed in a reaction vessel, and 100 mL of 85% (v/v) of aqueous ethanol solution were added. The resulting mixture was incubated at 25°C for 4 h under magnetic stirring at 200 rpm. The mixture was allowed then to settle for approximately 1 h, after which the aqueous alcohol supernatant was separated from the insoluble solids. The clear supernatant containing the extractives was filtered, leaving the solid material. The solids were then washed with 200 mL of water to remove any residual alcohols and released extractives. This mixture was centrifuged (10,000 rpm for 20 min) to separate the wash supernatant from the solids. The solids were then subjected to acid or enzymatic hydrolysis in Section 2.3.3 to extract the pectin.

Ethanol pre-treatment using the ASE-200 solvent extractor

ASE-solvent extraction pre-treatment was carried out using a Dionex ASE-200 solvent extractor (Thermo Fisher Scientific, Waltham, MA, USA). The extraction cell was loaded with a measured quantity of tobacco sample, closed, and fitted to the oven with the needle mechanism placed on the collection vial. Pressure was then applied to seal the cell. The aqueous ethanol solvent (95% [v/v]) was pumped into the cell at 1500 psi until it was filled with the solvent, usually with 1 mL of solvent escaping into the collection vial (a mechanism where the sensor ensures that the cell is filled with the solvent). At this point, the static valve closed and the flow stopped. The cell was then heated for about 5 min to ensure that the sample attained thermal equilibrium at 100°C. This was followed by the 7-min static period for the solvent to dissolve the extractives. During the heating and static periods, the set pressure (1500 psi) in the cell was maintained by means of a valve that periodically opened and closed. After the static phase, flushing was carried out where the static valve opened, and the extract flowed into the collection vial. The static and flushing steps were carried out two additional times with a fresh batch of solvent per cycle. The last cycle ended with a purging step where the remaining solvent was displaced with a purge gas (nitrogen). The collection vial now contained all the solvent together with the extractives extracted from the sample. After this, the residual pressure was released from the extraction cell, and the pressure was vented from the system. The cell was then unloaded from the oven and returned to the tray with the needle mechanism removed from the vial. The solid residues obtained from the cells were then dried overnight at 40°C and later taken for acid or enzymatic hydrolysis (in Section 2.3.3) to extract pectin.

2.3.3 Pectin extraction

The pectin extraction step involved the liberation and solubilisation of the protopectin from the cell matrix for subsequent separation. This was achieved either by acid or enzymatic treatment as described below.

Pectin extraction by acid treatment

A weighed amount (10 g) of the pre-treated tobacco sample was mixed with 100 mL of 0.01 N aqueous HCl solution, and the pH was adjusted to the desired level (pH 1.5) by the addition of 3 N HCl solution. The resulting mixture was stirred at 100 rpm for 2 h at 90°C. After the hydrolysis process, the samples were cooled to room temperature. The mixture was then centrifuged at 10,000 rpm for 20 min. The collected supernatant was further filtered through 2–3-μm filter paper to remove any suspended solids. The collected supernatant was further treated as described in Section 2.3.4 to obtain the pectin extract. To identify an operating regime that best achieved pectin liberation and solubilisation from the cell walls during acid hydrolysis, a set of conditions (incubation temperatures of 85°C, 90°C, and 95°C; pH of 2.0, 1.5, and 1.4; and incubation times of 1.5, 2, and 2.5 h) were tested.

Pectin extraction by enzymatic treatment

An amount (10 g) of the pre-treated tobacco sample was placed in a reaction vessel, then 100 mL of 0.01 N sodium citrate buffer pH 5.0 was added, followed by the addition of the chosen enzyme. The resulting mixture was incubated at 50°C for 12 h at 100 rpm. After the hydrolysis process, the mixture was kept at 100°C for 5 min to stop enzyme activity. The mixture was then cooled down to room temperature and centrifuged at 10,000 rpm for 20 min to obtain the supernatant. The collected supernatant was further filtered through 2–3-μm filter paper to remove any suspended solids. The collected supernatant was further treated as described in Section 2.3.4 to obtain the pectin extract. The tested parameters included: type of commercial enzyme (SunoTM036 [Metgen, Kaarina, Finland], Celluclast 1.5L [Sigma-Aldrich, Burlington, MA, USA] and a Cellulase enzyme blend [Sigma-Aldrich]), pH (4.5, 4.8, and 5.0), incubation time (12, 16, and 24 h) and enzyme dosage (24, 50, 100, 200, and 300 mg enzyme/g substrate).

2.3.4 Pectin separation

The pectins in the supernatants resulting from the Section 2.3.3 were recovered from the supernatant by precipitation. This was achieved by dispersion of the filtered supernatants into ethanol, isopropanol or acetone. The amount of precipitation solvent to be added was calculated such that the solvent concentration of the resulting mixture would be 70% (v/v). The resulting mixture was stored at 4°C for 12 h to allow the pectin to precipitate. The precipitated pectin was separated by centrifugation (10,000 rpm, 20 min), washed twice with cold 70% (v/v) ethanol, and centrifuged again. The obtained wet pectin was then dried at 40°C in an oven until a constant weight was obtained. The obtained pectin extracts were analysed for lignocellulosic sugars, lignin, and uronic acids to determine the efficiency of the extraction process.

2.3.5 Calculation of pectin extract yield, purity, and recovery

The efficiency of the extraction processes was evaluated based on three parameters: (I) pectin yield, (II) pectin purity, and (III) pectin recovery.

The yield of pectin was determined gravimetrically according to equation (2).

Pectin purity was based on the GalA content of the extract since it constituted the main structural unit of the pectin. The purity was therefore determined by equation (3).

The pectin recovery determines how much of the GalA content of the starting biomass was extracted in the pectin extract. It was calculated using equation (4).

2.4 Statistical method of acid hydrolysis optimisation

The temperature, time, and pH were varied in a factorial design with 3 (60, 75, and 90°C), 2 (2 and 6 h), and 2 (pH 1.0 and 1.5) levels, respectively (total experimental runs, n = 12) to identify the factors of significance (p-value < 0.05) and determine the preferred set of conditions for efficient pectin extraction from tobacco biomass. Once the experiments were completed, the pectin extract samples were subjected to compositional analysis to determine the yield, purity, and recovery percentages. The results obtained were analysed using Statistica software, version 13.5 (TIBCO Software, Palo Alto, CA, USA).

3 Results and discussion

3.1 Raw material composition

The composition of tobacco residues was evaluated to better understand the nature of the biomass and which extraction methodology to apply. Water extraction was avoided so that water-soluble polysaccharides remained undisturbed. Knowing the ethanol extractive concentrations is crucial as they interfere with the extraction of polysaccharides and proteins from the biomass. For this reason, the ethanol-extracted sample was subjected to a standard two-step hydrolysis method to determine the concentration of structural components in the biomass.

Table 2 summarises the lignocellulosic composition of the tobacco samples. The results show that they contained high amounts of ethanol-soluble extractives and ash that might interfere with the pectin extraction process. Bakoum Miena has the highest percentage of extractives (27.78%) and lowest percentage of ash (17.55%), while NRT61 and NRT63 have similar extractives (20.75% and 19.81%, respectively) and ash contents (25.78% and 28.33% respectively). The high ash content of the tobacco laminae samples appears to be an intrinsic property of the biomass, as authors have reported the tobacco leaf sample to have ash contents of 17 to 26.2% [44, 45]. Potassium was found to be the highest constituent of the ash due to how readily the plant can absorb the macronutrient. Also, high potassium content is desirable as it increases tobacco leaf sweetness and combustibility [46].

The ethanol-soluble extractive comprises reducing sugars, alkaloids, organic acids, polyphenols, lipids, waxes, pigments, resins, and a fraction of water-soluble salts [45]. The mass balance of the samples’ components accounted for 77.31%, 76.90%, and 77.72% for Bakoum Miena, NRT63, and NRT61, respectively, which indicates the presence of other extractives such as proteins, pigments, starch, lipids, and tannins that were not quantified.

Sample contents of GalA (the main structural unit of pectin) ranged from 7 to 8% of dry matter (DM), with Bakoum Miena being the highest at 8.15% DM. Pectin is quite heterogenous in nature and is considered a polydisperse polymer with the structure differing at various regions along the polymer chain [47]. Consequently, the pectin structure could consist of homogalacturonan (HG), rhamnogalacturonan I (RG-I), and rhamnogalacturonan II (RG-II). This implies that a fraction of the neutral sugars (glucan, arabinan, galactan, and rhamnan) detected in the biomass samples (Table 2) may be representative of the residues linked to the main GalA backbone [48]. As a result, the true pectin content of the tobacco biomasses could be higher than just the GalA content. Nevertheless, GalA content has been widely adopted as a conservative measure of pectin content [16, 49, 50]. The pectin contents obtained here are within the ranges of values for a variety of tobacco samples reported in literature [4, 25, 51]. Furthermore, the pectin contents of the tobacco samples are close to that of apple pomaces (3.5 to 14.32% DM), making them attractive candidates for sustainable pectin extraction [52].

3.2 Effect of pre-treatment type on pectin extraction

The pre-treatment step to remove the extractives was carried out using aqueous ethanol to obtain alcohol-insoluble residue for pectin extraction (acid extraction method, Section 2.3.3). Samples of the Bakoum Miena tobacco residues were tested for two ethanol pre-treatment methods: (a) cold ethanol pre-treatment and (b) ASE extraction pre-treatment.

The ASE pre-treatment process rendered a pectin extract yield of 11.0% DM that was higher than the 8.5% DM obtained from the cold ethanol pre-treatment. However, the pectin extracts obtained after cold ethanol pre-treatment had a low ash content of 6% DM compared to the 19% DM obtained with the ASE pre-treatment process. A low ash content (<10%) is highly desirable in a commercial grade pectin as it is necessary for good gel formation [24, 53]. Correspondingly, the purity (GalA content) of the pectin from the cold ethanol pre-treatment (44.0%) was higher than the ASE pre-treatment (38.2%) counterpart.

Pectin recovery can be considered the most important measure of extraction efficiency since it is a collective measure of the effectiveness of the pre-treatment and hydrolysis processes. The ASE pre-treatment yielded a higher pectin recovery (45.7%) compared to cold ethanol pre-treatment (40.4%). However, the application of pressurised liquid extraction on a large scale may be technically challenging and expensive due to the severity of the pre-treatment conditions. In addition, further purification processes may be required to reduce the ash content of the extract and increase its purity, which will lead to additional downstream processing costs.

The mass balance across the main stages of pectin extraction, from pre-treatment down to the pectin extraction and purification stages (Fig. 2), suggests that the ASE pre-treatment process removed about 28.2% of the total solids of the biomass, whereas the cold ethanol wash removed only 13.2%, indicating that ASE pre-treatment removes more extractives from the biomass. The ethanol supernatant recovered from the pre-treatment process was tested for sugars and uronic acids, and these were only present in negligible amounts or not detected at all. Washing the biomass with water after the cold ethanol pre-treatment process is an essential step responsible for removal of about 58% of the ash content of the biomass (Fig. 2). As a result, the pectin extract had a lower ash content, similar to commercial grade pectin. Therefore, cold ethanol wash pre-treatment followed by a water wash appears to be the more desirable pre-treatment method as it might be relatively easier to scale up. Therefore, the rest of the investigative experimental runs were carried out using the cold ethanol pre-treatment and water wash process prior to pectin extraction.

3.3 Isolation of pectin from acid hydrolysate

To improve pectin recovery and purity from the obtained supernatant (by acid extraction method, Section 2.3.3), investigations were also carried out to identify an ideal solvent for the precipitation (isolation) of the pectin from the acid hydrolysate. Acetone and isopropanol were tested as alternatives to ethanol as these are reported as the most suitable solvents for pectin precipitation [54]. Pectin recovery from precipitation with acetone was only slightly higher than with ethanol, while isopropanol yielded the lowest pectin recovery (Fig. 3). It was concluded that ethanol would be the preferred precipitating agent, as the recovery yield improvement with the other tested solvents was not significant and because ethanol is typically favoured by industries when scale-up is considered [55]. A report by Garna et al [50] stated that ethanol precipitation guarantees up to 98% recovery of the pectin content of the hydrolysate solution after acid hydrolysis. Therefore, further pectin precipitations in the subsequent experimental runs were performed with ethanol.

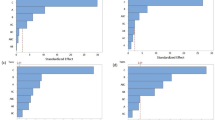

3.4 Pectin extraction by acid extraction

The pre-treated samples were subjected to acid extraction using different set of conditions previously reported in literature as suitable for pectin extraction [48, 56, 57]. This was done to determine the range of conditions that would achieve sufficient pectin liberation from the cell walls to the extracting acid solution to provide a suitable departing point for the subsequent optimisation. The Fig. 4 shows that as the severity of the extraction condition increased in the tested range, so did the amount of pectin extracted. The pH and temperature appear to be crucial parameters influencing the outcome.

Within the tested pH range, pectin recovery increased with decreasing pH, with the highest value of 49.3% at pH 1.4. This indicates that increasing the acid strength may result in greater recovery of pectin from the biomass, as reported elsewhere [17]. Essentially, high concentrations of hydrogen ions in the solvent facilitates the extraction of the protopectin [58]. Concomitantly, high acid strength will increase the solubilisation of non-pectic substances present as impurities in the extract, despite the high yield of pectin obtained [50].

With regards to the effect of temperature, the general observation is that pectin recovery increased with higher temperatures. The lowest pectin recovery was obtained at 85°C, whereas the highest was obtained at 95°C. Increasing the temperature to more than 95°C is not advisable due to the significant energy implications and requirement of pressure reactors. Furthermore, an accelerated hydrolysis of the pectin could occur at elevated temperatures, which would lead to lower recovery of extracted pectin. A similar observation was found regarding extraction time: extending the reaction time improved pectin recovery. The GalA units of the pectin are bound by α-(1, 4) glycosidic bonds, and sufficient time is needed to soften this matrix to enable pectin recovery [17]. On the other hand, a prolonged reaction time could destroy pectin’s glycosidic and ester bonds, leading to significant reductions in the MW and gelling properties of the recovered pectin [57] (Fig. 4).

3.5 Enzymatic extraction of pectin

Acid extraction is the most used method for pectin extraction because it is convenient, inexpensive, and usually allows for high pectin yields and recoveries [32]. However, recent trends have directed attention towards biotechnology hydrolysis approaches (i.e., using enzymes). Two main categories of enzymes are used: (I) enzymes that degrade and isolate the specific pectin fragments and (II) enzymes that deconstruct the plant cell wall and isolate whole pectin molecules [49]. In this study, the latter approach employed cellulases, a group of cellulose-hydrolysing enzymes. Three different commercial types of these cellulase complexes (SunoTM036, Celluclast 1.5L, and Cellulase) were applied to the pre-treated solids obtained from Bakoum Miena under various processing conditions. The results of these experiments are presented in Fig. 5.

Our results showed that the enzymatic approach produced inferior outcomes compared to the acid extraction approach. The pectin extract yields obtained with enzymes were comparable to those obtained with the acid extraction process; however, the pectin purities and recoveries obtained with the enzymatic method were significantly lower than those obtained with acid hydrolysis. The low pectin purities obtained with the enzymatic approach can be partly explained by the fact that the enzymatic method is able to solubilise undesirable compounds, which increases the content of impurities [55]. This is particularly true for tobacco biomass as it is known to contain about 3000 different chemical compounds [4].

Of the three enzymes tested, Celluclast 1.5L showed the highest pectin yield, purity, and recovery (9.2%, 12.2%, and 12.7%, respectively). A trend of increased pectin yield, purity, and recovery with increasing enzyme dosage was observed, with the highest of these values (11.3%, 12.2%, and 17.9%, respectively) obtained at the highest enzyme dosage of 300 mg enzyme/g substrate. For bioethanol production from lignocellulosic biomass, the dosage of 5 to 50 units/g cellulose is used, and this is often considered as the highest contributor to operation costs [59]. The high enzyme dosage used in our experiments would translate into increased operating cost, and the extra enzyme remaining free in the solvent could degrade the solubilised pectin, which would be counterproductive to pectin recovery [59, 60].

Pectin yield, purity, and recovery all demonstrated a direct relationship with the reaction time within the tested range. This is because the enzymes required sufficient time to penetrate the tobacco matrix and liberate the pectin component [23, 55]. Limiting the reaction temperature to the domain of optimal enzymatic stability and activity limits the rate of mass transfer, thereby prolonging the reaction time. The highest pectin recovery, which was still much lower than the acid extraction method, was obtained only after 24 h of reaction time. These prolonged treatment times are considered typical for effective pectin extraction from raw materials using enzymes [61, 62]. However, the extended periods could have implications on the capital investment, operating costs, and productivity of a scaled-up process [14].

3.6 Cascaded approach for pectin extraction

A cascaded approach for pectin extraction was explored, where the solid residues obtained from enzymatic hydrolysis of the Bakoum Miena samples were subjected to acid hydrolysis. This was done to consider the use of enzyme in a pre-extraction step prior to the acid hydrolysis. The intention was to possibly reduce the use of mineral acid, which can generate significant quantities of environmentally hazardous waste that requires treatment before disposal. Figure 6 details the outcomes of this approach. There was an improvement of hydrolysis compared with when only enzymes were used. For example, when the enzymatic hydrolysis with Celluclast 1.5L was followed with acid hydrolysis, the pectin purity and recovery increased from 12.2% and 12.7%, respectively, to 42.0% and 25.6%, respectively. However, these results were still inferior compared to the acid-only process. Comparing the extracts from the best-case scenarios of the various hydrolysis methods applied (Figs. 4, 5, and 6), the acid hydrolysis method yielded both the highest pectin purity and recovery. This is consistent with observations in literature that the purity of the extract from acid hydrolysis is usually higher than that from enzymatic hydrolysis [15].

3.7 Effects of operating conditions on pectin extract yield

After identifying acid extraction as the more suitable approach to efficiently extract pectin from the tobacco sample, specific efforts were directed at improving the preferred range of hydrolysis conditions to maximise the efficiency of the pectin extraction from the Bakoum Miena sample.

As shown in Table 3, the measured pectin extract yield varied between 3.8% and 8.8%. The conditions that achieved the highest pectin yield from tobacco biomass were a temperature of 90°C, pH 1.5, and 6 h of extraction (Run 12). As shown in Fig. 7, temperature and pH had a profound influence on the yield of pectin extracted, but the influence of time was less significant. One reason for this could be the fact that pectin extract yield is not a true measure of extraction efficiency since the pectin extract is only a gravimetric estimation of the mass percentage of the extract, and as such it considers neither its quality nor its purity. To this end, we also investigated the relationships between the extraction conditions and the pectin purity and recovery as discussed in the sections below.

3.8 Effects of operating conditions on pectin extract purity

The highest pectin purity (56.3%) was obtained at 90°C, pH 1.0, and 6 h (Run 10). Generally, consistently high pectin purities were recorded within the 90°C temperature domain, except for Run 12 where purity was 44.3%. These results were corroborated by the steep gradient of the temperature against purity plots (Fig. 8). The effects of pH and time on the purity were not very evident. It is possible that the ranges of pH and time tested did not allow for significant changes in pectin extract purity. This could bode well in the context of scaled up pectin production, where fluctuations in operating conditions are to be expected. In this scenario, consistent product quality could be maintained regardless of minor fluctuations in operating conditions that may occur.

3.9 Effects of operating conditions on pectin recovery

Table 3 shows that the highest pectin recovery (48.7%) was obtained at 90°C, pH 1.5, and 6 h (Run 12), which corresponds to the conditions for the highest pectin extract yield. Similar to the pectin purity, temperature appears to profoundly influence pectin recovery (Fig. 9), whereas pH and time do not appear to have significant effects within the selected ranges.

The highest pectin recovery obtained with the 90°C, pH 1.5, and 6 h conditions (Run 12) may indicate that these are near the optimal conditions for pectin recovery. However, the results from Run 11 (90°C, pH 1.5, and 2 h extraction) indicate that even as pectin yield and recovery may increase with extraction time, the trade-off is a decrease in pectin purity. The reduction in purity could be due to enhanced solubilisation of non-pectic substances that may have precipitated together with the pectin during the extraction process. Another reason could be that the severe extraction conditions may have further degraded the solubilised pectin into monomers, which were not precipitated as part of the pectin extract. To improve purity, a compromise could be limiting the reaction time to 4 h. Consequently, the favourable conditions for optimum recovery, yield, and purity of pectin were 90°C, pH 1.5, and 4 h of extraction time.

3.10 Pectin extraction efficiencies from three tobacco varieties

Using the optimal acid hydrolysis conditions determined above, pectin was extracted from samples of the three tobacco varieties. Table 4 summarises the extraction conditions and results, including the DEs of the obtained pectins. Overall, pectin recovery was significantly improved compared to previously obtained values (Table 3). The highest pectin yield (10.6%), purity (48.7%), and recovery (66.2%) were obtained in the tobacco variety NRT63. When based on the GalA content, the purities of pectin obtained from these tobacco samples are comparable to those obtained from the apple pomace derived from the apple variety “Blanca de Asturias” (38.0% to 47.1%) [63].

3.11 Degree of esterification of pectin extracts

The DEs of the pectin extracts obtained with acid hydrolysis were determined since they were the only ones with sufficient product quality to warrant characterisation (Table 4). Generally, the pectin extracts had a DE less than 50%, which classifies them as the low methyl ester (LM) pectin. These undergo gelling in the presence of calcium ions and contain minimal amounts of sugar [55]. They are used in the food industry to make low-sugar jams, pastries, and preparations designed to have low sweetness. LM pectin also functions as fat substitute in baked goods and as an acid stabiliser in protein drinks like drinking yoghurt [64]. It should be noted that the DE of the pectin extract is heavily dependent on the nature of the biomass, as well as on the extraction conditions. Harsh extraction conditions such as high temperatures, high acidic strength (very low pH <1.5) and prolonged reaction times could result in increased de-esterification of the polygalacturonic chains.

3.12 Sugar composition of pectin extracts

Table 5 provides an overview of the sugar compositions of the samples obtained from the optimisation experimental runs. Among the neutral sugars, glucose, galactose, and rhamnose constituted the majority. This implies the possible presence of the rhamnogalacturonan backbone and arabinan- and/or arabinogalactan-rich side chains in the pectin polymer. Therefore, the pectin extracted from these tobacco samples may predominantly consist of rhamnogalacturonan. This is consistent with observations made by other authors on the structure of the pectic polysaccharides found in tobacco [5, 65]. The particularly high glucose contents detected in the pectin extracts (compared to the other neutral sugars), suggests that the hydrolysed cellulose oligomers are intertwined with the pectin in tobacco, since pectin and cellulose are chemically and physically bound to each other in the cell wall [15].

Xylose and mannose were only present in low amounts and were due to contamination from co-extraction of hemicelluloses and other carbohydrate materials. The extracts’ total sugar contents (including GalA) were mostly within the range of 55 to 70%, which corresponded to those reported for the pectin extracts obtained from other biomasses like cocoa pod husks and sugar beet pulp [15, 55]. The ash contents of the extracts ranged from 6.1 to 19.1%. The Bakoum Miena variety generally yielded pectin extracts with low ash contents. However, the total sugar contents were also low, indicating substantial presence of other extractives (“Others” in Table 5) that precipitate with the pectin gel [55]. These other extractives were within the range of 23.2 to 40.2%. The GalA contents of the extracted pectins ranged from 35.7 to 56.5%. The same ranges were reported by other researchers when they used different food waste streams to extract pectin [66]. They claimed that such pectin extracts can be used for different applications based on their functionalities.

3.13 Molecular weight analysis of pectin extracts

The pectin samples produced by acid extraction were subjected to SEC for MW and PDI analyses. Table 6 presents the data obtained for the three tobacco varieties. The results demonstrate that the extracted pectins contained a considerable quantity of low MW (<1 kDa) impurities. The chromatograms from the SEC analysis of the NRT61 and NRT63 samples showed three peaks compared to two for the Bakoum Miena sample. Some authors reported the presence of sugars, amino acids, alkaloids, pigments, and other unknown impurities in pectin extracted from tobacco samples that were solubilised during the extraction process and inevitably precipitated together with the pectin [2, 25]. This is expected due to the complex nature of the tobacco biomass.

Samples NRT61 and NRT63 yielded similar SEC results (Table 6). Three peaks were observed in the chromatograms; two seem to be pectin fractions (high and low MW), and the third peak comprises the very-low MW impurity fraction. The lower MW pectin peaks (peak #2 in both samples) were suspected to be pectic oligosaccharides.

According to the literature, the MWs of pectins extracted from tobacco plants range from 100 to 200 kDa [67]. The MW >300 kDa for Peak 1 (seen in all three samples) and high PDIs may suggest the presence of pectin-protein-polyphenol complexes or simply pectin-polyphenol complexes. It is usual to detect the presence of proteins or pectin-protein complexes in the extracted pectin as has been reported in several works [18, 48, 50, 53, 55]. The presence of protein in the pectin may augur well for certain applications of the pectin since the protein and esterified carboxylic groups on the galacturonic chains contribute significantly to the emulsification properties of pectin [15, 68].

Considering that the SEC data of the tobacco-derived pectins did not conclusively show the true MWs, the samples were subjected to several washings and filtrations to separate the phenolics and other low MW impurities. Table 7 shows that the impurity peak (<1 kDa) disappeared, and the MWs of the pectin peaks and PDI decreased, providing a better presentation of the true MW of the pectin content. The partially purified pectins are highly water soluble due to the removal of the impurities which hitherto prevented the proper solubilisation of the extracted pectin.

The MW of a standard pectin sample obtained from Sigma-Aldrich is 650 kDa (Table 7), which is higher than pectin samples obtained from tobacco laminae (Tables 6 and 7). This standard pectin was obtained from citrus fruits which is one of the most used feedstocks for pectin extraction. Citrus pectins can have MWs between 134 and 965 kDa depending on the extraction conditions and the nature of the biomass [69,70,71] According to a publication [72] on citrus peel pectins, the medium MW (185 kDa) pectin fraction obtained exhibited both low viscosity and hypocholesterolemic activity. This suggests that the medium MW fractions obtained from the tobacco samples may be suitable for dietary fibre applications compared against higher MW (750 kDa) pectin, which exhibits high viscosity and low solubility, and low MW (66 kDa) pectin that lacks hypocholesterolemic activity.

3.14 Biorefinery potential of pectin extraction from tobacco biomass

The developed pectin extraction process involves the use of ethanol to remove extractives that interfere with the pectin extraction step, in addition to the step where ethanol is also used to precipitate the pectin. Casas-Orozco et al [73] stated that the highest energy consumption processes in the commercial production of pectin from orange peels are those related to the use of ethanol. While ethanol pre-treatment makes the process potentially expensive, the economics of the process can be improved if there is revenue associated with these fractionated extractives. The polyphenols hold a significant economic value if they can be extracted as a co-product of the pectin extraction process.

Depending on the nature of the residue, the yields of pectin alone may be low and influence the cost of the process, but sequential extraction of high-value polysaccharides together with other bioactive fractions (e.g., ethanol extractives) has the potential to make the process economically feasible and more environmentally sustainable. Recent works have highlighted the immense economic potential for the coextraction of pectin and other high-value products and biofuels such as polyphenols, bioethanol, biogas, and anthocyanins from agricultural wastes in a biorefinery concept [74,75,76,77].

Polysaccharides extracted from tobacco may have unique properties that will allow the recovered products to be used in nutraceutical applications and as functional medicines. A recent review highlighted that some pectin complexes have hypocholesterolemic, antitussive, immunoregulatory, anti-inflammatory, wound healing, anticoagulant, anticancer, gastroprotective, antidiabetic, antioxidant, and haemostatic activities [78].

4 Conclusions

A multi-stage pretreatment-hydrolysis extraction process was optimized for efficient pectin extraction from the laminae of three tobacco varieties The cold ethanol pre-treatment was found to be more appropriate for tobacco biomass since it helped remove certain extractives as well as ash, thus producing a pectin extract of relatively higher purity. The results from a series of experiments and analyses comparing acid and enzyme extraction of pectin from tobacco residue samples demonstrated that acid hydrolysis was the superior method for solubilising the protopectin for extraction as pectin. Temperature, pH, and reaction times were found to play important roles in the yield and quality of pectin extracted. Optimisation of the acid hydrolysis conditions produced pectin recoveries of 66.2%, 57.8%, and 56.7% from the NRT63, Bakoum Miena, and NRT61 samples, respectively.

The pectins from these samples can be classified as LM pectins based on their DEs. Such pectins have numerous applications in the food and pharmaceutical industries, depending on their physicochemical properties. The SEC analysis of the obtained pectins indicated that they were of the medium MW range. Ultimately, the results demonstrate that tobacco residues can be considered as a suitable alternative feedstock for commercial pectin production. However, the substantial presence of extractives suggests that a biorefinery approach, in which other high-value commodities are also produced alongside pectin, would be economically more advantageous. In conclusion, this work provides a useful starting point for more comprehensive studies on the biorefinery potential of tobacco waste that may facilitate more effective valorisation of this abundant biomass resource.

Data availability

The data supporting this research is provided in the manuscript.

References

Samanta AK, Chikkerur J, Roy S et al (2019) Xylooligosaccharides production from tobacco stalk xylan using edible acid. Curr Sci 117:1521–1525. https://doi.org/10.18520/cs/v117/i9/1516-1521

Zhang M, Zeng G, Pan Y, Qi N (2018) Difference research of pectins extracted from tobacco waste by heat reflux extraction and microwave-assisted extraction. Biocatal Agric Biotechnol 15:359–363. https://doi.org/10.1016/j.bcab.2018.06.022

Mumba PP, Phiri R (2008) Environmental Impact Assessment of Tobacco Waste Disposal. Int J Environ Res 2:225–230. https://doi.org/10.22059/ijer.2010.197

Davis DL, Nielsen MT (2001) Tobacco: Production, Chemistry and Technology. Blackwell Science Ltd, London

Leffingwell JC (1999) Chemical Constituents of Tobacco Leaf and Differences among Tobacco Types. In: Davis DL, Nielson MT (eds) Tobacco: Production. Chemistry And Technology. Blackwell Science Ltd, Georgia, pp 265–284

Akpinar O, Erdogan K, Bakir U, Yilmaz L (2010) Comparison of acid and enzymatic hydrolysis of tobacco stalk xylan for preparation of xylooligosaccharides. LWT - Food Sci Technol 43:119–125. https://doi.org/10.1016/j.lwt.2009.06.025

Rodríguez Robledo V, Isabel Castro Vázquez L (2020) Pectin - Extraction, Purification, Characterization and Applications. In: Masuelli MA, Blumenberg M (eds) Pectins - Extraction. Purification, Characterization and Applications. IntechOpen, pp 1–19

Yue F, Xu J, Zhang S et al (2022) Structural features and anticancer mechanisms of pectic polysaccharides: A review. Int J Biol Macromol 209:825–839. https://doi.org/10.1016/j.ijbiomac.2022.04.073

Keizman D, Frenkel M, Peer A et al (2021) Modified citrus pectin treatment in non-metastatic biochemically relapsed prostate cancer: Results of a prospective phase ii study. Nutrients 13:4295–4305. https://doi.org/10.3390/nu13124295

Basak S, Annapure US (2022) Trends in “green” and novel methods of pectin modification - A review. Carbohydr Polym 278:118967–118967. https://doi.org/10.1016/j.carbpol.2021.118967

Eliaz I, Raz A (2019) Pleiotropic effects of modified citrus pectin. Nutrients 11:2619–2637. https://doi.org/10.3390/nu11112619

Roy S, Priyadarshi R, Łopusiewicz L et al (2023) Recent progress in pectin extraction, characterization, and pectin-based films for active food packaging applications: A review. Int J Biol Macromol 239:124248. https://doi.org/10.1016/j.ijbiomac.2023.124248

Ciriminna R, Chavarría-Hernández N, Hernández AIR, Pagliaro M (2015) Pectin: A new perspective from the biorefinery standpoint Rosaria. Biofuel Bioprod Biorefin 9:368–377. https://doi.org/10.1002/bbb.1551

Adetunji LR, Adekunle A, Orsat V, Raghavan V (2017) Advances in the pectin production process using novel extraction techniques: A review. Food Hydrocoll 62:239–250. https://doi.org/10.1016/j.foodhyd.2016.08.015

Abou-Elseoud WS, Hassan EA, Hassan ML (2021) Extraction of pectin from sugar beet pulp by enzymatic and ultrasound-assisted treatments. Carbohydr Polym Technol Appl 2:100042. https://doi.org/10.1016/j.carpta.2021.100042

Zhu X, Liu B, Zheng S, Gao Y (2014) Quantitative and structure analysis of pectin in tobacco by 13C CP/MAS NMR spectroscopy. Analyt Methods 6:6407–6413. https://doi.org/10.1039/c4ay01156b

Liew SQ, Chin NL, Yusof YA (2014) Extraction and Characterization of Pectin from Passion Fruit Peels. Agric Agric Sci Procedia 2:231–236. https://doi.org/10.1016/j.aaspro.2014.11.033

Mohamed H (2016) Extraction and Characterization of Pectin from Grapefruit Peels. MOJ Food Process Technol 2:31–38. https://doi.org/10.15406/mojfpt.2016.02.00029

Cinkmanis I, Muizniece-Brasava S, Viluma I et al (2005) Extraction of pectin from apple pomace. Eng Rural Dev 19:1934–1939. https://doi.org/10.22616/ERDev.2020.19.TF549

Guo X, Meng H, Zhu S et al (2016) Stepwise ethanolic precipitation of sugar beet pectins from the acidic extract. Carbohydr Polym 136:316–321. https://doi.org/10.1016/j.carbpol.2015.09.003

Hwang JK, Kim CJ, Kim CT (1998) Extrusion of apple pomace facilitates pectin extraction. J Food Sci 63:841–844. https://doi.org/10.1111/j.1365-2621.1998.tb17911.x

Kalapathy U, Proctor A (2001) Effect of acid extraction and alcohol precipitation conditions on the yield and purity of soy hull pectin. Food Chem 73:393–396. https://doi.org/10.1016/S0308-8146(00)00307-1

Jeong HS, Kim HY, Ahn SH et al (2014) Optimization of enzymatic hydrolysis conditions for extraction of pectin from rapeseed cake (Brassica napus L.) using commercial enzymes. Food Chem 157:332–338. https://doi.org/10.1016/j.foodchem.2014.02.040

Zaidel DNA, Rashid JM, Hamidon NH et al (2017) Extraction and characterisation of pectin from dragon fruit (hylocereus polyrhizus) peels. Chem Eng Trans 56:805–810. https://doi.org/10.3303/CET1756135

Niu F, Xie W, Huang C et al (2021) Development of an analysis method for determination of pectin in tobacco by solid state 13C CP /MAS NMR. J Univ Sci Technol China 51:637–646. https://doi.org/10.52396/JUST-2021-0106

Eda S, Kato K (1978) Galactan Isolated From The Midrib Of The Leaves Of Nicotiana Tabacum. Agric Biol Chem 42:2253–2257. https://doi.org/10.1080/00021369.1978.10863346

Laszlo C, Kaminski K, Guan H et al (2022) Fractionation and Extraction Optimization of Potentially Valuable Compounds and Their Profiling in Six Varieties of Two Nicotiana Species. Molecules 27:8105–8125. https://doi.org/10.3390/molecules27228105

Eda S, Kato K (1980) Pectin isolated from the midrib of leaves of nicotiana tabacum. Agric Biol Chem 44:2793–2801. https://doi.org/10.1080/00021369.1980.10864410

Fauzantoro A, Muharam Y, Gozan M (2017) Improvement of Nicotine Yield by Ethanolic Heat Reflux Extraction of Nicotiana tabacum var. Virginia Origin of Ponorogo. Int J Appl Eng Res 12:13891–13897

Banožić M, Babić J, Jokić S (2020) Recent advances in extraction of bioactive compounds from tobacco industrial waste-a review. Ind Crops Prod 144:112009. https://doi.org/10.1016/j.indcrop.2019.112009

Scheijen M, Brandt-de Boer B, Boon J et al (1989) Evaluation of a Tobacco Fractionation Procedure Using Pyrolysis Mass Spectrometry Combined with Multivariate Analysis. Beitr Tab Int/ Contrib Tob Res 14:261–282. https://doi.org/10.2478/cttr-2013-0604

Sundarraj AA, Ranganathan TV (2017) A Review-Pectin from Agro and Industrial Waste. Int J Appl Environ 12:1777–1801

Akin-Ajani OD, Okunlola A (2022) Pharmaceutical Applications of Pectin. In: Masuelli MA, Blumenberg M (eds) Pectins - Extraction. Purification, Characterization and Applications. IntechOpen

National Renewable Energy Laboratory (U.S.) and Sluiter A (2008) Determination of Ash in Biomass: Laboratory Analytical Procedure (LAP).

National Renewable Energy Laboratory (U.S.) and Sluiter A (2008) Determination of Extractives in Biomass: Laboratory Analytical Procedure (LAP)

National Renewable Energy Laboratory (U.S.) and Sluiter A (2008) Determination of Structural Carbohydrates and Lignin in Biomass: Laboratory Analytical Procedure (LAP)

Hatfield R, Fukushima RS (2005) Can lignin be accurately measured? Crop Sci 45:832–839. https://doi.org/10.2135/cropsci2004.0238

Hayes DJM (2013) Mass and compositional changes, relevant to biorefining, in Miscanthus x giganteus plants over the harvest window. Bioresour Technol 142:591–602. https://doi.org/10.1016/j.biortech.2013.04.108

TAPPI (2006) Acid-insoluble lignin in wood and pulp (Reaffirmation of T 222 om-02) https://www.tappi.org/content/SARG/T222.pdf. Accessed 20 June 2022

Hayes DJM (2012) Development of near infrared spectroscopy models for the quantitative prediction of the lignocellulosic components of wet Miscanthus samples. Bioresour Technol 119:393–405. https://doi.org/10.1016/j.biortech.2012.05.137

Pisanó I, Gottumukkala L, Hayes DJ, Leahy JJ (2021) Characterisation of Italian and Dutch forestry and agricultural residues for the applicability in the bio-based sector. Ind Crops Prod 171:113857–113873. https://doi.org/10.1016/j.indcrop.2021.113857

Basumallick L, Rohrer J (2017) Determination of Uronic Acids and Wood Sugars in Wood-Based Hydrolysates. Thermo Fisher Scientific, Sunnyvale, CA, USA

Luisa Franchi M (2014) Evaluation of Enzymatic Pectin Extraction by a Recombinant Polygalacturonase (PGI) From Apples and Pears Pomace of Argentinean Production and Characterization of the Extracted Pectin. J Food Process Technol 5:8–11. https://doi.org/10.4172/2157-7110.1000352

Popova VT, Ivanova TA, Stoyanova AS et al (2020) Chemical constituents in leaves and aroma products of nicotiana rustica L. Tobacco. Int J Food Stud 9:146–159. https://doi.org/10.7455/IJFS/9.1.2020.A2

Bokelman G, Ryan W (1985) Analyses of Bright and Burley Tobacco Laminae and Stems. Beitr Tab Int/ Contrib Tob Res 13:29–36. https://doi.org/10.2478/cttr-2013-0553

Ferreira HS, Oliveira SS, Santos DCMB et al (2019) Characterisation of the mineral composition of tobacco products (cigar, shredded and rope). Microchem J 151:104196. https://doi.org/10.1016/j.microc.2019.104196

Sundar Raj AA, Rubila S, Jayabalan R, Ranganathan TV (2012) A Review on Pectin: Chemistry due to General Properties of Pectin and its Pharmaceutical Uses. Sci Rep 1:1–4. https://doi.org/10.4172/scientificreports.550

Dranca F, Oroian M (2018) Extraction, purification and characterization of pectin from alternative sources with potential technological applications. Food Res Int 113:327–350. https://doi.org/10.1016/j.foodres.2018.06.065

Dranca F, Oroian M (2019) Optimization of Pectin Enzymatic Extraction from Malus domestica ‘Fălticeni’ Apple Pomace with Celluclast 1.5L. Molecules 24:2158

Garna H, Mabon N, Robert C et al (2007) Effect of extraction conditions on the yield and purity of apple pomace pectin precipitated but not washed by alcohol. J Food Sci 72:C001–C009. https://doi.org/10.1111/j.1750-3841.2006.00227.x

Feng JW, Zheng S, Maciel GE (2004) EPR investigations of charring and char/air interaction of cellulose, pectin, and tobacco. Energy Fuels 18:560–568. https://doi.org/10.1021/ef0301497

Antonic B, Jancikova S, Dordevic D, Tremlova B (2020) Apple pomace as food fortification ingredient: A systematic review and meta-analysis. J Food Sci 85:2977–2985. https://doi.org/10.1111/1750-3841.15449

Ismail NSM, Ramli N, Hani NM, Meon Z (2012) Extraction and characterization of pectin from dragon fruit (Hylocereus polyrhizus) using various extraction conditions. Sains Malays 41:41–45

Yapo BM, Wathelet B, Paquot M (2007) Comparison of alcohol precipitation and membrane filtration effects on sugar beet pulp pectin chemical features and surface properties. Food Hydrocoll 21:245–255. https://doi.org/10.1016/j.foodhyd.2006.03.016

Hennessey-Ramos L, Murillo-Arango W, Vasco-Correa J, Astudillo ICP (2021) Enzymatic Extraction and Characterization of Pectin from Cocoa Pod Husks (Theobroma cacao L.) Using Celluclast® 1.5 L. Molecules 9:1473. https://doi.org/10.3390/molecules26051473

Venkatanagaraju E, Bharathi N, Sindhuja RH, Chowdhury RR (2020) Pectins: Extraction and Purification of Pectin from Agro-Industrial Wastes. In: Masuelli MA, Blumenberg M (eds) Pectins - Extraction. Purification, Characterization and Applications. IntechOpen

Xue ZH, Zhang X, Zhang ZJ, Liu JH, Wang YF, Chen DX, Long LS (2011) Optimization of Pectin Extraction from Citrus Peel by Response Surface Methodology. Food Sci 18:128–132

Kertesz AJ (1951) The Pectic Substances. Interscience Publishers, New York

Davis R, Tao L, Scarlata C et al (2015) Process Design and Economics for the Conversion of Lignocellulosic Biomass to Hydrocarbons: Dilute-Acid and Enzymatic Deconstruction of Biomass to Sugars and Catalytic Conversion of Sugars to Hydrocarbons. National Renewable Energy Lab (NREL), Golden CO, USA

Vasco-Correa J, Zapata Zapata AD (2017) Enzymatic extraction of pectin from passion fruit peel (Passiflora edulis f. flavicarpa) at laboratory and bench scale. LWT - Food Sci Technol 80:280–285. https://doi.org/10.1016/j.lwt.2017.02.024

Dominiak M, Søndergaard KM, Wichmann J et al (2014) Application of enzymes for efficient extraction, modification, and development of functional properties of lime pectin. Food Hydrocoll 40:273–282. https://doi.org/10.1016/j.foodhyd.2014.03.009

Sabater C, Corzo N, Olano A, Montilla A (2018) Enzymatic extraction of pectin from artichoke (Cynara scolymus L.) by-products using Celluclast®1.5L. Carbohydr Polym 190:43–49. https://doi.org/10.1016/j.carbpol.2018.02.055

Morales-Contreras BE, Wicker L, Rosas-Flores W et al (2020) Apple pomace from variety “Blanca de Asturias” as sustainable source of pectin: Composition, rheological, and thermal properties. LWT - Food Sci Technol 117:108641. https://doi.org/10.1016/j.lwt.2019.108641

Tiwari AK, Saha SN, Yadav VP et al (2017) Extraction and Characterization of Pectin From Orange Peels. Int J Biotechnol Biochem 13:39–47. https://doi.org/10.1016/j.foodchem.2019.01.200

Sun HH, Wooten JB, Ryan WS et al (1987) Structural characterization of a tobacco rhamnogalacturonan. Carbohydr Polym 7:143–158. https://doi.org/10.1016/0144-8617(87)90056-7

Müller-Maatsch J, Bencivenni M, Caligiani A et al (2016) Pectin content and composition from different food waste streams. Food Chem 201:37–45. https://doi.org/10.1016/j.foodchem.2016.01.012

Bokelman GH (1984) Determination of Uronic Acids in Tobacco by Decarboxylation. J Agric Food Chem 32:562–565. https://doi.org/10.1021/jf00123a036

Thakur BR, Singh RK, Handa AK (1997) Chemistry and Uses of Pectin - A Review. Crit Rev Food Sci Nutr 37:47–73. https://doi.org/10.1080/10408399709527767

Wang YT, Lien LL, Chang YC, Wu JSB (2013) Pectin methyl esterase treatment on high-methoxy pectin for making fruit jam with reduced sugar content. J Sci Food Agric 93:382–388. https://doi.org/10.1002/jsfa.5772

Wang W, Feng Y, Chen W et al (2021) Citrus pectin modified by microfluidization and ultrasonication: Improved emulsifying and encapsulation properties. Ultrason Sonochem 70:105322. https://doi.org/10.1016/j.ultsonch.2020.105322

Morales-Contreras BE, Contreras-Esquivel JC, Wicker L et al (2017) Husk Tomato (Physalis ixocarpa Brot.) Waste as a Promising Source of Pectin: Extraction and Physicochemical Characterization. J Food Sci 82:1594–1601. https://doi.org/10.1111/1750-3841.13768

Yamaguchi F, Uchida S, Watabe S et al (1995) Relationship between Molecular Weights of Pectin and Hypocholesterolemic Effects in Rats. Biosci Biotechnol Biochem 59:2130–2131. https://doi.org/10.1271/bbb.59.2130

Casas-Orozco D, Villa AL, Bustamante F, González LM (2015) Process development and simulation of pectin extraction from orange peels. Food Bioprod Process 96:86–98. https://doi.org/10.1016/j.fbp.2015.06.006

Manhongo TT, Chimphango A, Thornley P, Röder M (2021) An economic viability and environmental impact assessment of mango processing waste-based biorefineries for co-producing bioenergy and bioactive compounds. Renew Sust Energ Rev 48:111216. https://doi.org/10.1016/j.rser.2021.111216

Manhongo TT, Chimphango A, Thornley P, Röder M (2021) Techno-economic and environmental evaluation of integrated mango waste biorefineries. J Clean Prod 325:129335. https://doi.org/10.1016/j.jclepro.2021.129335

Arora A, Banerjee J, Vijayaraghavan R et al (2018) Process design and techno-economic analysis of an integrated mango processing waste biorefinery. Ind Crops Prod 116:24–34. https://doi.org/10.1016/j.indcrop.2018.02.061

Mugwagwa LR, Chimphango AFA (2019) Box-Behnken design based multi-objective optimisation of sequential extraction of pectin and anthocyanins from mango peels. Carbohydr Polym 219:29–38. https://doi.org/10.1016/j.carbpol.2019.05.015

Zaitseva O, Khudyakov A, Sergushkina M et al (2020) Pectins as a universal medicine. Fitoterapia 146:104676. https://doi.org/10.1016/j.fitote.2020.104676

Funding

Philip Morris International is the sole source of funding and sponsor of this research.

Author information

Authors and Affiliations

Contributions

Oscar K. K. Bedzo: conceptualization, investigation, writing – original draft. Lalitha D. Gottumukkala: resources, project administration, conceptualization, funding acquisition, writing - review & editing, supervision. Daniel J. Hayes: conceptualization, resources, writing - review & editing, supervision, project administration, funding acquisition; Kacper Kaminski and Nikolai V. Ivanov: choosing, sourcing and preparation of relevant Nicotiana genus plant species, varieties and tissues; manuscript review & editing. Giuseppe Lo Sasso and Julia Hoeng: conceived the study, manuscript review & editing, Walter Schlage and Fernando David Goffman: contributed to the design of the study, manuscript review & editing.

Corresponding author

Ethics declarations

Ethical approval

This article followed the ethical standard of the institute.

Consent to participate

All authors consented to participation in this research.

Consent for publication

All authors consented to publish this research in this journal.

Competing interests

OKKB, LDG, and DJH declare no known competing interests that could have influenced the work detailed in this paper. GLS, JH, KK, NVI, WKS, and FDG are employees of Philip Morris International or had worked for Philip Morris International under contractual agreements (WKS and FDG).

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Bedzo, O.K.K., Gottumukkala, L.D., Sasso, G.L. et al. Process development for efficient pectin extraction from tobacco residues and its characterisation. Biomass Conv. Bioref. (2023). https://doi.org/10.1007/s13399-023-04750-4

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-023-04750-4