Abstract

The agriculture and horticulture industries generate many by-products while processing commodities, leading to significant environmental and societal dilemmas. Bioactive compounds obtained from by-products of plants are also known as ingredients in traditional medicines and the food industry due to their potential health benefits for humans as antioxidant, anti-inflammatory, and antimicrobial agents. On the other hand, an extensive array of colorants from natural sources has been scrutinized recently in different sectors to mitigate the negative ecological impacts of synthetic dyes, especially in modern textile manufacturing. Approaching these matters, this paper reviews various chemical compositions of plant secondary metabolites, including flavonoids, tannins, phenolic acids, essential oils, tulipalins, and factors that influence the isolation process. Moreover, the article offers an updated view of the advanced technologies for extraction, focusing on eco-friendly solvents such as water, supercritical carbon dioxide, and deep eutectic solvents. Eventually, a comparison of different extraction methods is highlighted to devise the most appropriate strategy for industries.

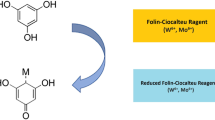

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

With a history spanning millennia, agriculture, including the horticulture industry, has undergone notable development and stands as one of the most paramount fields of human knowledge. Additionally, it has a vital role to support and develop other industries such as cosmetics, pharmaceuticals, and nutraceuticals. Correspondingly, the agriculture industry produces a significant number of residues during the agricultural production process, which can be known as by-products [1]. As a solution, the concept inception of circular bioeconomy is applied to reduce the losses induced by food waste disposal, comprising agricultural by-products. The key point of circular bioeconomy is to diminish environmental—societal and economic—costs, economic competitiveness intensification, and to mitigate poverty and hunger. Moreover, the circular bioeconomy focuses on “waste-to-wealth” concept that creates new technologies, jobs, and livelihoods [2]. Therefore, by-products valorization from plants is one of the crucial biomass to decrease the pollution risks for the environment and, significantly, to enable sustainable development and a generally circular bioeconomy [1, 3]. Those production by-products are traditionally treated as wastes and are typically landfilled or burned, resulting in an observable production of carbon dioxide (CO2) [4]. In this regard, by-products, consisting of roots, flowers, seeds, leaves, buds, fruits, etc. from agriculture and horticulture, are attractive options because of their low cost and biodegradability, besides featuring essential properties [5]. Originating from plants, secondary metabolites are chemical substances that gain diverse beneficial health effects in humans and animals. Some of them are performed as defense compounds against diseases, predators, ultraviolet radiation, parasites, and oxidants, to facilitate the reproductive processes (for example, attractive fragrance and coloring agents) [6]. Bioactive compounds are referred to as secondary plant metabolites that present as natural constituents in plants, including food, which contribute health benefits beyond the fundamental nutrition value of the plants. Some of the bioactive compounds are hydroxybenzoic acids, hydroxycinnamic acids, carotenoids, flavonoids, stilbenes, and lignans [6,7,8]. Several notable attributes of bioactive compounds are antimicrobial, antioxidant, antiviral, anticancer, and antiradical activities [9]. Other applications of bioactive compounds from plants are providing colors for food [10], dyes for textiles [11, 12], dye-sensitized solar cells [13], and fragrance [14].

Excluding the benefits of minimizing the volume of crops residues, the efficient use of by-product resources is proposed to reduce the production costs of natural antimicrobial agents and colorants [15]. Beyond the goal of employing natural compounds and reducing by-product quantities, 92 million tons of textile waste were produced in 2015, and the volume is expected to increase by 62% by 2030 [16]. Many papers have therefore studied the current state of sustainability innovation concerning textile industry. Specifically, researchers have employed frameworks to find novel approaches to remodeling traditional textile methods and processes, which incorporate the basic principles of the circular economy in the textile industry [17,18,19]. These ideas indicate preventive measures to mitigate emissions and effluents from the textile chains by substituting some synthetic compounds with organic natural materials such as bamboo fibers, natural dyes, and less toxic chemical products [20].

Awarding these matters, extracting bioactive compounds from agriculture and horticulture by-products is an essential topic. Particularly, the bioactive substances can be served as natural antimicrobial agents and colorants for the textile industry. To enhance the contribution to the circular economy, innovative technologies including using green solvents will be focused to investigate the possibility of isolating bioactive compounds sustainably. This paper critically considers floral waste such as roses and tulips, vegetable by-products such as tomato and cucumber crop residues, and garden waste like fall foliage. It also conducts and discusses a general outlook, including an order of magnitude estimate of the global potential of horticultural and vegetable production streams. This review paper also points to the bottlenecks that could hinder the implementation of advanced technologies, in which the parameter extraction, solvents used, superiorities, and drawbacks of various isolation methods are comprehensively studied.

2 A general outlook on agricultural and horticultural production streams

This paper analyzes the phenolic-based agricultural by-products in the context of global horticulture and vegetable production. The world’s largest ornamental markets in 2019 and fresh vegetable producers in 2020 are shown in Figs. 1 and 2 respectively. According to the vision of the Association Internationale des Producteurs de l’Horticulture (AIPH) in 2019 [21], China, Japan, and North America (the USA and Canada) were the major mature producer countries for both the production and consumption of the horticultural industry. From a global perspective, Europe will be one of the world’s most prominent actors in horticultural production and consumption growth over the next decade, following the lead of major markets like China, Japan, and North American countries [23]. The global horticultural market was approximately USD 70 billion in 2017 and is expected to reach 100 billion USD by 2027. The Netherlands has been the international flower market leader for years, with a 60% market share. However, it is projected to decline to 35% in 2027, with continued market growth in absolute terms. The market growth decline of the Netherlands is related to the sharp forecast growth rate in Asia at 80%, and in Europe and North America at a relatively modest growth rate of 20% by 2027 [24].

Major producers of ornamentals in the world in 2019 (adapted from [21])

Global production of fresh vegetables in 2020; (a) by region and (b) worldwide (adapted from [22])

Among flowers, roses are still the absolute number one in cut flower production, where red-colored roses represent 30% of the market. About 10 billion rose stems are sold annually worldwide. Otherwise, potted roses (80 million potted plants per year) and garden roses (220 million plants per year) are also important. In the economic overview of roses, the largest rose production areas are India (61,000 hectares) and China (14,348 hectares) [21, 25]. In the Netherlands, rose production has reduced rapidly, decreasing from 850 to 238 hectares in 2016. The reduction in rose production in the Netherlands is more rapid than the overall decrease in total cut flowers [25]. Although the strongest rose production sites are outside Europe, the production of cut roses still shows promise in some countries such as the southern parts of Germany, France, and Italy because of their suitable conditions for rose cultivation [26].

Moreover, the world’s fresh vegetable production (Fig. 3) promptly increased between 2000 and 2019. In Fig. 3, the five main vegetable types accounted for 42–45% of the total amount during the period: tomatoes (16% in 2019); dry onions (9%); cucumbers and gherkins (8%); cabbages (6%); and eggplants (5%). Generally, until 2020, Asia, particularly China and India, where tomatoes, onions, and cucumbers accounted for a considerable volume, produced the largest amount of vegetables [27]. The production volume expansion in recent years therefore boosts biomass availability, opening new opportunities for recovering and expanding the bioproducts field [28], especially its capacity as a good source of phenolic compounds [29].

Fresh vegetable production globally from 2000 to 2019 (adapted from [27])

3 Phytochemical compounds in plants

The main classes of polyphenols in plants include flavonoids, phenolic acids, tannins, stilbenes, and lignans. These polyphenolic compounds are presented in Fig. 4, and some chemical structures are illustrated in Fig. 5. Flavonoids and phenolic acids account for 60% and 30% of the total dietary polyphenols respectively [30]. Overall, phenolics are primarily found in fruit and vegetables, including horticultural and ornamental crops, teas, and cereals. They are often associated with mono- or polysaccharides and functional derivatives such as esters or methyl esters. Phenolics also possess various hydroxylation patterns, and they can appear in acylated and glycosylated forms [31].

The abundant phenolic compounds in some agricultural and horticultural by-products are exhibited in Table 1. Quercetin, phenolic acids, catechins, and tannins are the main compounds in rose plants’ leaves, buds, and flowers [32,33,34,35]. Other chemical constituents include flavonoids, triterpenes, polysaccharides, fatty acids, organic acids, carotenoids, vitamins, and essential oils. Specifically, the phenolic compounds in rose leaves such as ellagitannins (73.69 mg/g of plant dry weight (DW)), gallotannins (21.23 mg/g of plant DW), and hydroxycinnamates (1.47 mg/g of plant DW) were found to be significant. The report also showed that petals accumulated anthocyanins (ANCs), flavonoids (flavonol and dihydroflavonols), and water-soluble polysaccharides, while root samples contained catechin and proanthocyanidins [34].

The fall foliage presents an attractive opportunity to obtain valuable polyphenolic compounds. Manninen et al. [36] studied the collected fall leaves to extract carotenoids and ANCs. The ANC content varied from 0 to 2.8 mg/g of plant DW, with an average of 0.6 mg/g, and carotenoid content ranged from 0 to 83 mg/g, with an average of 26 mg/g. Lisandru et al. [37] studied the extracts from cherry fall leaves. They observed that the carotenoid content was more dominant than the ANC content, and the ANC composition was inversely proportional to carotenoid yield.

From the perspective of agricultural by-products, Silva et al. [38] found phenolic compounds such as gallic acids, chlorogenic acid, rutin, caffeic acid, ferulic acid, and quercetin were abundant in this order in tomato plants comprising stems, leaves, and roots. Another study by Guuntekin et al. [39] reported that the number of phenolic compounds was highest (7.14%) in the extract of tomato stalks compared to other plants. For the most widely grown vegetables in Europe and the USA, around 33 kg of leaf and stem biomass is gathered for every 100 kg of tomato fruit harvested. Each tomato plant produces an average of 0.75 kg of leaf biomass, resulting in a total of 15 tons per hectare [40].

In addition, cucumber (Cucumis sativus L.) stems are unique in that they contain sphingolipid glycosides, which distinguishes them from other field residues [41,42,43]. An equivalent amount (36.6%) of stem and leaf biomass is found in cucumber plants grown in the greenhouse under supplemental light [44]. C. sativus L. leaf extracted with acetone contains alkaloids, glycosides, steroidal terpenes, flavonoids, saponins, reducing sugars, and tannins [45]. The identification of chemical compounds reveals phenols, flavonoids, carotenoids, alkaloids, glycosides, tannins, and terpenes in methanol (MeOH) and ethanol (EtOH) extract from cucumber leaves (C. sativus L.) [46]. Meanwhile, Mallik and Akhter [47] claimed that the EtOH extracts of cucumber leaves and stems showed the absence of flavonoids and reducing sugars, while the presence of alkaloids, glycosides, saponins, sterol, and tannins was found instead. Table 2 lists all the conditions, solvents used, methods, and extracted bioactive compounds from agricultural and horticultural by-products in detail.

3.1 Flavonoids

Flavonoids form one of the major subclasses of polyphenols, representing the most significant group of compounds among over one million metabolites in plants. They consist of two or more aromatic rings, and each ring possesses at least one hydroxyl group and is linked by a three-carbon bridge [52,53,54]. Flavonoids have the most comprehensive color range, from pale yellow to intense violet. Moreover, flavonoids protect against ultraviolet (UV) radiation due to their capacity to absorb the most energetic solar wavelengths, e.g., UV-B and UV-A. This property of flavonoids is the decisive factor for aquatic plants’ evolution and terrestrial existence [55, 56].

Flavonoids primarily have six major subclasses based on their complexity in the chemical structure: flavones, flavanols, isoflavones, flavonols, flavanones, and ANCs [57]. Among these subclasses, ANCs are studied more comprehensively than others, as they are attractive components of the targeted crop residues. ANC originates in flavonol; it has the basic structure of the flavylium ion. ANC is in the form of a glycoside, while an anthocyanidin is known as an aglycone. Anthocyanidins are grouped into 3-hydroxyanthocyanidin, 3-deoxyanthocyanidin, and O-methylated anthocyanidins, whereas ANCs are in the forms of anthocyanidin glycosides and acylated ANCs [58]. Flavonoids are well-known for the red, blue, and purple colors that ANCs produce [36, 58, 59].

ANCs are water-soluble and stored in cell vacuoles. The empirical formula for the flavylium ion of ANC is C15H11O+, with a molecular weight (MW) of 207.24 g/mol. ANCs, glycosylated ANCs, and proanthocyanidins (polymers that produce ANCs when hydrolyzed, or “condensed” tannins) contribute to the color of flowers and fruit, with a range from reddish purple to intense blue. The most common ANCs are cyanidin, pelargonidin, peonidin, petunidin, and malvidin. ANCs are present in higher plants, e.g., in juvenile leaves and senescing plants [58]. For example, in the fall foliage of sugar maple trees (Acer saccharum), the red expression is influenced by foliar nitrogen concentration. Leaves with lower concentrations of nitrogen tend to turn red earlier than those with higher concentrations [60].

3.2 Phenolic acids

Phenolic acids form one-third of phenolic compounds. They are carboxylic acids derived from either benzoic or cinnamic acid. They can be in free and conjugated, and soluble and insoluble states. Hydroxycinnamic acids have nine carbon atoms (C6–C3), but those found in vegetables have seven carbons. Typically, they have a benzene ring, a carboxylic group, and one or more hydroxyl and methoxy groups in the molecule [61]. In contrast, benzoic acids have seven carbon atoms (C6–C1), including gallic and protocatechuic acids [61, 62]. Hydroxycinnamic acids comprise 4-hydroxycinnamic acid, ferulic acid, caffeic acid, and sinapic acid. Hydroxybenzoic derivatives include 4-hydroxybenzoic acid, protocatechuic acid, vanillic acid, gallic acid, and syringic acid [62]. Hydroxybenzoic acids can be found in very low contents in edible plants, while hydroxycinnamic acids are one of the most abundant phenolic compounds. Hydroxycinnamic acids are present in coffee, medicine plants, fresh fruit, and vegetables in free form (rarely) or associated with polysaccharides in the cell wall [63, 64]. For example, ferulic acids are linked to polysaccharides (cellulose, hemicellulose, pectin, and glycoprotein), lignins, and suberin [65].

3.3 Tannins

Tannins are a heterogeneous group and complex phenolic compounds with MWs ranging from intermediate to very high (500–30,000 Dalton (Da)) [66]. Tannins obtain from 12 to 16 phenolic groups and 5 to 7 aromatic rings per 1000 Da. Because of the numerous hydroxyl groups in their structure, it has been demonstrated that tannins possess various biological activities, e.g., antioxidant and antitumor activities [67, 68]. Tannins can conjugate with proteins, carbohydrates, nucleic acid, and alkaloids, either by non-covalent bonds primarily driven by hydrogen bonding and hydrophobic interactions or by covalent binding after polyphenol activation [68, 69].

Tannins fall into two main classes: hydrolyzable tannins and condensed tannins. The other two classes of tannins are complex tannins and phlorotannins. Specifically, hydrolyzable tannins are subdivided into gallotannins and ellagitannins. Gallotannins produce gallic acids and their derivatives from hydrolysis, while ellagitannins produce ellagic acid after hydrolysis [70]. Moreover, condensed tannins have 3 to 8 repetition units and mainly originate in flavan-3-ol and flavan-3,4-diol structures [70, 71]. Hydrolyzable tannins can be found in the fruit, leaves, seeds, and bark of plants of the Leguminosae, Fabaceae, Combretaceae, and Anacardiaceae families [72]. On the other hand, condensed tannins represent 90% of total commercial tannins worldwide. Condensed tannins and their flavonoid precursors are widely distributed in nature, particularly in various Acacia (wattle or mimosa bark extract), Schinopsis (quebracho wood extract), Tsuga (hemlock bark extract), Pinus (bark extract), and Rhus (sumach extract) species [73].

3.4 Essential oils from flowers

The volatile organic compounds are called essential oils, with a molecular weight lower than 300 g/mol. These volatile compounds have a high vapor pressure at atmospheric pressure and room temperature. They belong to various chemical classes, e.g., alcohols, ethers or oxides, aldehydes, ketones, and esters [74]. However, the amounts and types of essential oil are determined by the plant parts e.g., leaves, buds, fruits, flowers, herbs, twigs, bark, wood, roots, and seeds. Another decisive factor is the plant species, as they are derived from terpenes and their oxygenated derivatives such as aromatic terpenoids, aliphatic acid esters, and phenolic compounds [75]. The average extracted oil content in flowers is 0.035% but varies from 0.03 to 0.05%. They typically have a yellow to yellow-green color and characteristic odor [76, 77].

3.5 Carotenoids in fall leaves

ANCs are not the only color-producing compounds present in fall leaves. Additionally, carotenoids contribute to the bright fall colors, as they absorb light in the range of 400–500 nm. Unlike ANCs, carotenoids are synthesized during the growing season to enable or protect photosynthetic light capture [37, 78]. Carotenoids are non-polar compounds belonging to a class of isoprenoid compounds. They are organic molecules of a C40 polyene backbone containing terminal ionone rings at both ends. The conjugated double bonds of carotenoids make them good light absorbers. The absorbed wavelengths depend on the number and nature of double bonds and other attached substituents. Carotenoids are classified into two types: (1) hydrocarbon carotenes, which include α-carotene, β-carotene, γ-carotene, and lycopene; (2) xanthophylls, which contain oxygen and therefore differ from carotenes. Xanthophylls are therefore more polar compounds than carotenes [15, 79,80,81,82]. Carotenoids occur in plants with 0.07–0.2% of the dry mass. They appear primarily as free carotenoids in leaves and as esterified carotenoids in other tissues. They are commonly found in higher plants’ flowers, fruits, leaves, and roots, e.g., carrots, peaches, tomatoes, paprikas, annatto, and pumpkins [15]. Most leaves contain similar carotenoid composition, while flowers possess individually characteristic carotenoid profiles, which rely on each plant species [79].

3.6 Tulipalin from tulip biomass

Tuliposides are the glucose esters of 4-hydroxy-2-methylenebutanoate and 3,4-dihydroxy-2-methylenebutanoate, the major secondary metabolites in tulips (Tulipa gesneriana). Tulipalins are tulipalin A and tulipalin B, which are the lactonized aglycons of tuliposides: 6-tuliposide A 6-O-(4′-hydroxy-2-methylenebutanoyl-D-glucopyranose and 6-tuliposide B 6-O-[(3S)-3,4–dihydroxy-2-methylidenebutanoyl]-D-glucopyranose [83, 84]. In nature, the 6-tuliposide A and B were found in tulip tissues such as petals, pistils, leaves, stems, bulb scales, and roots [85]. The tuliposides are unstable and are readily chemically converted into their corresponding lactone forms, tulipalin A and tulipalin B (Fig. 6) [84]. In general, tulipalins have the common structure α-methylene-γ-butyrolactone, of which tulipalin A is the simplest α-methylene-γ-butyrolactone first extracted from Erythronium americanum for its anticancer properties [49, 86].

4 Bioactive compounds as antimicrobial agents and colorants for textiles

Apart from being known as plant-derived colorants, bioactive components from plants are also acknowledged for their antimicrobial properties [87, 88]. In textiles, the growth of bacteria on fabrics causes undesirable effects such as unpleasant odors, skin infections, fabric stains, discoloration, and material deterioration. Hence, microbial activity prevention from plants becomes necessary to contribute bioproducts for textiles. For example, ANCs have not only benefited from antioxidant and anti-obesity effects, but they also possess antimicrobial activity against a wide range of microorganisms. ANCs extracted from blueberry, bilberry, raspberry, blackcurrant, and strawberry can inhibit the growth of gram-positive and gram-negative bacteria [58, 89,90,91]. Additionally, antimicrobial finishing in clothing can prevent the formation of foul odors due to bacterial processes in sweat. Colorful and antibacterial ANCs from Cinnamomum camphora waste (fall leaves) extract were considered a potential dyeing agent for wool fibers, valorizing their application in biomedical textiles [92].

Food, cosmetics, and textile industries also use microbial carotenoids for coloration purposes. In textile production, carotenoids are investigated as potent antimicrobial agents [78]. Carotenoids were extracted from annatto by different solvents, and their microbial inhibition activities were observed against Escherichia coli, Klebsiella pneumoniae, Pseudomonas aeruginosa, Bacillus subtilis, and Staphylococcus aureus. The leaf extracts displayed high antibacterial activity even in low concentrations, while the fruit extracts obtained a similar effect in higher concentrations [93].

Tannins have an antibacterial effect, which is explained by the ability to pass through the bacterial cell wall up to the internal membrane, interfere with cell metabolism, and destroy the cell [94]. The abundance of tannins in various natural dyes is reported to contribute strong antibacterial effects against common pathogens [95, 96]. Gupta et al. [97] studied the antibacterial effect of tannin-containing natural dyes against bacteria. Besides E. coli and K. pneumonia, Proteus vulgaris is known to convert urea to ammonia, resulting in unpleasant odors. The study claimed that most of the tested substances were more effective than the commercial antimicrobial Fabshield, as 99% of these bacterial colonies were reduced. In another article, Zhang et al. [98] discovered that tannic acid–treated silk also exhibited excellent antibacterial properties, with an inhibition rate of 99%. Tannin with a metal salt is therefore suggested for improving the antibacterial properties of hospital textiles. It could also be applicable in sports or domestic clothing to avoid unpleasant odors [99].

Essential oils also act as antimicrobial compounds and alternatives for treating infectious diseases, e.g., a disease caused by Herpes simplex virus [100, 101]. By inducing disturbances in membrane-embedded proteins, hindering respiration, and altering ion transportation processes, essential oils exhibit significant microbial prevention properties that ultimately cause bacterial death [102]. Sufficient in vitro data also proved that essential oils could be utilized as antibacterial agents to inhibit a wide range of bacterial strains, comprising Listeria monocytogenes, Salmonella typhimurium, E. coli O157:H7, Shigella dysenteriae, S. aureus, etc. [103, 104]. Walentowska and Foksowicz-Flaczyk [105] successfully applied essential oil from thyme. They evaluated its potential to restrain bacterial growth in linen and cotton fabric. The results showed that using the essential oil of thyme as a finishing agent could highly impede the growth of bacteria for linen-cotton type fiber blends.

For tulipalins from tulip biomass, there are seldom studies that use tulipalins as antimicrobial agents for textiles, despite tulipalins and tuliposides showing strong antimicrobial effects [106]. For example, tulipalins can resist the growth of cancer cells [86], and some gram-positive and gram-negative bacteria [83] such as methicillin-resistant S. aureus [107].

5 Extraction methods

The extraction of antimicrobials from natural sources is one of the most essential steps before the treatment of textile to achieve the target antimicrobial activity. In general, the conventional extraction techniques are maceration, Soxhlet extractions, and hydro-distillation [108]. Maceration is an inexpensive and straightforward technique for obtaining essential oil and bioactive compounds. In this method, the material is soaked in a container by immersing the sample in the solvent with or without stirring. This method consumes extensive solvents and time, and the extraction yield is low. Solvent and time consumption can be reduced by using Soxhlet extraction; yet in Soxhlet extraction (automatic continuous extraction), thermo-labile compounds may be degraded during the procedure [109, 110]. On the other hand, hydro-distillation is a traditional technique for extracting essential oils from plants. Organic solvents are not involved in this process and can be performed before dehydration. There are three types of hydro-distillation: water, water and steam, and direct steam distillation. It has three steps: hydro diffusion, hydrolysis, and decomposition by heat. However, volatile components in plants may be lost when high extraction temperatures are employed, which limits their use for thermo-labile compound extraction [108].

Traditionally, solvent extraction is the common method for isolating bioactive compounds, which applies the mechanisms of a solid matrix [111]. The diffusivity and solubility of bioactive compounds from raw materials promote the extraction process [110]. A solvent is chosen for its selectivity and the ability to extract phenolic compounds (Table 3). The solvent affects the constituent elements in plant cells through a chemical or biophysical alteration. For example, MeOH is used to extract lower MW polyphenols. Alternatively, higher MW polyphenols are extracted with aqueous acetone. Water is a suitable solvent for extracting phenolic acids and their glucosides. It provides higher extraction yields than organic solvents such as MeOH, EtOH, or butanol, particularly under ultrasonic treatment [112, 113]. Moreover, flavonols such as quercetin show high solubility in alcohols, as higher isolation yields are obtained with an increasing percentage of EtOH up to 70% v/v [114]. A few common organic solvents can be listed, from least polar to most polar, such as hexane < chloroform < ethyl acetate < acetone < EtOH < MeOH < water [115, 116]. In addition to the organic solvents, some reagents or salts are utilized industrially to isolate bioactive compounds. As an example of tannin extraction, tannin solution in water generally results in an acidic environment; it forms insoluble precipitates due to the tannin self-condensation reaction. On an industrial scale, reagents such as sodium sulfite (Na2SO3), sodium carbonate (Na2CO3), sodium bisulfite (NaHSO3), EtOH, or sodium hydroxide (NaOH) are therefore normally used [71, 117]. The addition of alkali will increase the pH and the incorporation of EtOH will improve extraction efficiency [118]. Similarly, the addition of salts such as Na2SO3 and Na2CO3 increases the extraction yield of tannins and reduces the viscosity of the extracts derived from the tannin self-condensation reactions [119].

Nevertheless, the observed drawbacks of conventional extraction processes are, e.g., longer extraction times, expensive and high-purity solvents, an excessive amount of energy and solvent used, low extraction selectivity, and poor-quality extracts [108, 120]. Various novel technologies have therefore been investigated to overcome these challenges. The non-conventional extraction techniques use green solvents, including pressurized fluids, deep eutectic solvents (DESs), bio-based solvents, some auxiliaries such as microwave, pulse electric field, and ultrasound [112, 121, 122].

5.1 Solvent extraction

Besides techniques based on the use of compressed fluids as extracting agents and methods with advanced auxiliaries, finding appropriate solvents having low toxicity and diminished environmental effects, elevated extraction ability, and biodegradability is important [123]. Ionic liquids (ILs) are known as novel solvents for extracting phenols besides other green solvents such as hot water or conventional organic liquids. ILs are defined as salts that present as liquids at room temperature and have melting points or glass transition temperatures below 100 °C. ILs are better solvents than water, as they have greater solubility power. Depending on their unique chemical properties, ILs gain many merits in destroying the cell walls and capturing the targets by chemical selectivity, thus, improving the efficiency of the extract in a short time. On the other hand, ILs gain some major disadvantages such as a high cost and poor solvent recovery [123,124,125,126]. ILs are classified based on their physical properties, which are named as neutral ILs, acidic ILs, basic ILs, ILs with amphoteric anions, functionalized ILs, protic ILs, chiral ILs, supported ILs, bio-ILs, poly-ILs, and energetic ILs [127]. Because of a variety of ions combination, ILs can be acknowledged as “designer solvents” that alter their physical properties to tackle the challenges of common volatile organic solvents [128]. In solid–liquid extraction, ILs were used to extract flavonoids from Larix decidua tree bark, in which [C4C1im]Br (25% wt) was evaluated to be the best solvent. The results from the antioxidant activity of extracts, energy-saving process, and flavonoid extractability were very positive, confirming their potential in different applications [129]. Sillero et al. [130] developed a new procedure to extract rutin from the leaves of A. theophrasti using IL [C4mim]Br based on ultrasonic- and microwave-assisted extraction. The isolated rutin from that method yielded 5.49 mg/g, increasing 2.01 folds than that of heating reflux extraction with MeOH.

Since 2003, another advanced selection in solvent extraction has been the substitution of traditional solvents for DESs, a novel technology still in development. Principally, DES is usually known as a subclass of ILs because of many similar characteristics, such as low volatility, low flammability, and broad electrochemical and thermal stability windows. However, these materials are considered inexpensive to synthesize and can be produced by biodegradable and non-toxic constituents [131]. DESs contain large and nonsymmetric ions that possess lattice energy and thus have low melting points [134]. Also, DESs can be characterized by a very large depressing freezing point. They are liquid at temperatures lower than 150 °C, and most of them are liquid between room temperature and 70 °C [135]. In general, DESs are obtained by the complexation of a non-toxic quaternary ammonium salt with a metal salt or a naturally derived uncharged hydrogen-bond donor (organic acids, polyalcohols, sugars, amino acids) in a particular molar ratio [121, 123]. At the optimum component ratio, the mixture obtains the deepest eutectic point. When the temperature exceeds the eutectic point, the mixture will be liquid. Otherwise, it will be solid [129]. For example, ammonium salt mixed with urea in the ratio of 2:1 (urea:salt) leads to the freezing point from –38 to 113 °C for the corresponding DES. In addition, the anion of choline-derived salts also influences the freezing points of DESs. The freezing point of DES made of choline-derived salts and urea decreases in the order: F– > NO3– > Cl– > BF4–, proposing a correlation with the hydrogen bonding strength [135]. Because of the affordable prices, biodegradability, pharmaceutically acceptable toxicity, and sustainability, DESs gain significant attraction as alternatives to conventional solvents to extract phenolic compounds [136,137,138,139], including bioactive flavonoids [129,130,131,132,133]. As an example, rutin was extracted from flower buds of Sophora japonica by choline chloride–based DESs. The solvents showed extremely low toxicity and substantial biodegradability [140]. In a different paper, choline chloride–betaine hydrochloride–ethylene glycol formed DES with the mole ratio of 1:1:2, combined 20% v/v water was proposed to extract and separate flavonoids. The study indicated that DESs could be used as green solvents for the extraction of active components in plant matrices [141]. Despite there are many possible combinations between quaternary ammonium salt and hydrogen-bond donors to make DESs, the predictive comprehension of structure–property relationships of DESs is ambiguous. For instance, tunning high viscosity of DESs is not approached entirely; thus, it hinders applications of DESs in many technologies [131]. As a consequence, to reduce the viscosity, increase the mass transfer, and improve the extraction efficiency, water is often used to control the polarity of DESs and the dissolution of the target compounds [142, 143].

Bio-based solvents can be an alternative besides ILs and DESs, which are produced by renewable sources. The raw materials that are considered feedstocks in biorefinery are usually: agricultural, such as waste from production; forestry, and wood processing; processing waste from other industries, and biomass of marine origin, including algae [144]. The manufacture of bio-based solvents consists of the fermentation of vegetable oils, carbohydrates, and the steam distillation of wood [145]. The most common bio-based solvents are 2-methyl tetrahydrofuran, glycerol, ethanol, γ-valerolactone, p-cymene, and D-limonene. Those solvents are produced from feedstocks such as cellulose, hemicellulose, lignin, and starch [123, 146]. Although they originate from renewable feedstocks, it is essential to mention the energy and solvent consumptions, high cost, and waste generation possibilities. Those factors might influence the valorization of those green solvents [147]. EtOH, ethyl acetate, ethyl lactate, and D-limonene were selected to recover fucoxanthin (an oxygenated carotenoid) from P. tricornutum under pressurized conditions. Among them, D-limonene was the most selective bio-based solvent, although it was not able to extract all fucoxanthin present in biomass unless supercritical fluid under continuous conditions was added [148]. Santos and Martins [149] evaluated the influences of bio-based solvents EtOH, acetic acid, and water on the content of ANC, flavonoids, and phenolics from onions (Allium cepa). The extracts from inions exhibited great antioxidant activities in ABTS, DPPH, and FRAP assays, demonstrating efficient antimicrobial activity against gram-positive bacteria. Especially, bioactive compounds isolated by EtOH 60% v/v showed the best performance that phenol, ANC, and flavonoid content were 3.4, 2.5, and 4.45 times higher than the other solvents, respectively.

5.2 Supercritical fluid extraction

A supercritical fluid (SF) is a liquid with a temperature and pressure above its critical point. SF can diffuse like gas through the solid matrix and dissolve materials like a liquid [150]. SF behaves as a single phase and retains the properties of both gas and liquid. Because SF lacks a phase boundary between gas and liquid, it has no surface tension either. The most significant advantage of SF is its tunability. Close to the critical point, even small changes in temperature and pressure have drastic effects on its density. SF can be adjusted to a more gas-like or liquid-like mobile phase, depending on the material’s solubility [151]. The selection of SF is determined by factors such as safety, hazards, energy requirements, and operability [152].

Among SFs, compressed CO2 fluid is used to extract bioactive compounds. A generalized vapor pressure curve of CO2 and its end are presented in Fig. 7. As the nature of supercritical CO2 fluid (scCO2) is between gas and liquid, it has unusual properties compared to other solvents, e.g., strong solubility and a large mass transfer coefficient; it is non-toxic and easily accessed [153, 154]. However, scCO2 has a disadvantage: It is a non-polar solvent. It therefore needs co-solvents or modifiers like EtOH, MeOH, water, or combinations of co-solvents to increase the polarizability of scCO2 and strengthen the solvating power. The different co-solvent interactions strongly enhance solubility. On the other hand, scCO2 can work as a co-solvent if the mixture contains at least 60% EtOH or water. Conversely, it may act as an anti-solvent when the extract is insoluble in scCO2 during the depressurizing step [155, 156].

Jiao and Kermanshahi [157] used scCO2 to extract haskap berries with water as a co-solvent. ANCs were successfully extracted employing 45 × 106 Pa, 65 °C at 15–20 min. The data showed that using scCO2 and water as a co-solvent would result in a higher extraction yield than using water or EtOH as a solvent, 52.7% and 38.3% respectively. Studies by B. Wang et al. [158] and Lao et al. [159] also showed that high-pressure CO2–H2O (107 Pa, 60 °C, 15–20 min) generated more colorants from red cabbage and purple sweet potato respectively than traditional extraction methods with water and 70% acidified EtOH. Both studies revealed the feasibility of the scCO2–H2O extraction method as a promising technology in the future because of higher extract yields. Despite this, this technology has yet to be applied in the industry and is not used on a large scale because of the high cost of the equipment, enormous technical investments, and difficult control parameters [122, 124].

5.3 Pressurized hot water extraction

Pressurized hot water extraction (PHWE) or “subcritical” water extraction (SWE) is operated between 100 and 374 °C. Usually, the temperature ranges from above the boiling temperature (100 °C, 105 Pa) to below the critical temperature (374 °C, 221 × 105 Pa). The pressure is therefore adjusted to maintain the liquid state of water during the extraction. PHWE is superior because of the fast extraction time and high content of the collected phenolics compounds [160]. In PHWE, water can be heated up to 200 °C, and the change in the dielectric constant of the water with the temperature makes water act like an organic solvent. For example, the dielectric constant of water at 200 °C is about 36, roughly similar to MeOH [112].

The water-based extraction process has been reported to be appealing because of its ready-for-use and cost-free availability, nontoxicity, non-flammability, and acceptance as an eco-friendly solvent [161]. Both high pressure and temperature will disrupt the surface equilibrium. The elevated temperature can overcome some obstacles such as the solute-matrix interaction caused by van der Waals forces, hydrogen bonding, dipole attraction of the solute molecules, and active sites in the matrix [162]. Compared to SF extraction, pressurized liquid extraction, including water as a fluid, provides an inert environment and protects samples from light and oxygen. Additionally, higher temperatures and pressure increase the extraction capacity. Otherwise, the essential advantage of supercritical fluid extraction is the increased capacity of diffusion by the extraction fluid for accessing these compounds in the matrix [163, 164].

In PHWE, the use of the optimal high temperature is preferred to the highest temperature. The typical extraction pressure is 5 × 106–107 Pa, but the extraction time depends on the operating parameters such as the amount of water used, temperature, and pressure [160]. PHWE at 100–110 °C appears to be a potent alternative to organic solvents in extracting polyphenolic compounds [165]. The tannins were isolated by PHWE from Phyllanthus niruri at a temperature of 100 °C and pressure of 107 Pa. The PHWE achieved the highest overall tannin and corilagin yield with the shortest extraction time compared to the Soxhlet and SF extraction methods [166]. In another study, gallic acids, ellagic acids, and corilagin from Terminalia chebula Retz. PHWE extracted fruits at temperatures (120–220 °C) and waterflow rates (2–4 mL/min) at a pressure of 4 × 106 Pa. The extracts had the highest phenolic compound content with the highest antioxidant activity, revealing the efficiency of PHWE [167]. Chopping or macerating materials together with the homogenization steps can also increase economic feasibility for industrial purposes [168].

5.4 Ultrasound-assisted extraction

Ultrasound-assisted extraction (UAE) uses the cavitation and strong shear force generated by ultrasound with frequencies ranging between 20 kHz and 100 MHz to improve the extraction and shorten the extraction time [169, 170]. This sonication forms microbubbles, oscillates quickly, and eventually collapses strongly when the acoustic pressure is sufficiently high. The collapse occurs near the solid surface to produce high-speed micro-jets of liquid onto the surface. When these jets are associated with shocking waves, they can break solid surfaces. The behavior is based on two contrasting mechanisms. The first describes the high pressure and temperature produced in the bubbles during adiabatic compression. It is accountable for the cleavage of molecular bonds and radical forming. The second involves micro-discharges because of the high electrical field [169, 171, 172].

UAE is an inexpensive and valuable technology that does not require complex equipment. UAE has been broadly utilized in the extraction of compounds from leaves [173], stalks [114], fruit and berries such as strawberries [174], and plant seeds [175]. The main factors during extraction are ultrasound power, temperature, a solvent with low vapor pressure, extraction time, and sonication mode (continuous or pulsed). These elements determine the extracts’ yield and composition. Non-optimized parameters could lead to the degradation of thermo-labile compounds. If the solvent is too viscous, it will increase the wave amplitude because it is necessary to obtain the mechanical vibrations for the cavitation [171, 172, 176]. A temperature range between 20 and 70 °C can increase the extraction yield. The influence of temperature is explained by the increase of the amount of cavitation bubbles, large solid–liquid contact areas, and solvent diffusivity improvement. The effect therefore enhances the desorption and solubility of the interest compounds. However, if the temperature is near the solvent’s boiling point, the extraction yield will decrease due to the thermal instability of biomass which causes the degradation of bioactive compounds [171, 177, 178]. Notably, most of the works in UAE focus on the application of continuous ultrasound field, and few researchers considered pulsating acoustic field. Although there are no essential differences between modes of UAE such as efficiency of extraction and times, pulse mode results in great energy saving compared to continuous UAE, better temperature control, and a reduction in corrosion on the ultrasound probe tip [176, 179,180,181].

UAE coupled with DES was considered an alternative green method to conventional technologies. Thus, combining DESs and UAE has the benefits of both methods, such as a shorter extraction time and lower solvent consumption than conventional solvent extraction [182, 183]. Sukor et al. [184] introduced intensified DES-mediated ultrasound extraction of tannic acids from onion peels. Using DES in extraction gave a higher tannic acid yield than MeOH. The concentration of tannic acids was maximized by adjusting the DES ratio to 1:1, the solid-to-solvent ratio to 1:10, and the duty cycle to 10%. Aslan Türker and Doğan [185] used a mixture of choline chloride with five different components. Among the tested DESs, choline chloride–based DES prepared with citric acid obtained the best solvent. This finding demonstrated that ultrasound could be used as a substituent energy source. Using DESs would also improve the flavonoid yield and maintain the color of the black carrot extract.

5.5 Pulse electric field extraction

The pulse electric field (PEF) method or pulse electric field pre-treatment is known for improving the pressing, drying, extracting time, and diffusing process without using a high temperature [108, 186]. It is an emerging non-thermal green process for isolating phytochemical compounds from plant parts such as leaves, roots, and fruit [152]. In principle, PEF destroys cell membrane structures to improve extraction. An electric potential pass through the membrane of a living cell in the electric field. The molecules are separated according to the charge in the cell membrane, whose functions are based on the dipole nature of the membrane molecules. Afterward, a drastic permeability increase is induced by the repulsion occurrence when the transmembrane potential exceeds 1V [108].

The impact of PEF on bioactive compounds depends on the field strength, specific energy input, pulse number, treatment temperature, and properties of the materials to be treated [187]. PEF treatment at a moderate electric field (from 500 to 1000 V/cm for 10–4–10–2 s) is found to damage the cell membrane of plant tissue with localized heating, resulting in the inactivation of enzymes and microorganisms. Hence, this can prevent the degradation of heat-sensitive compounds [188,189,190]. The industrial batch PEF extraction of polyphenols from grape peels is normally carried out at 50–60 °C for 20 h [191]. Corrales et al. [192] extracted ANCs from grape by-products using different isolation methods. The result indicated that PEF remarkably enhanced the extraction of ANC monoglucosides compared to the number of acylated glucosides extracted. PEF treatment is preferable before the maceration step in the winemaking process to reduce the extraction time. The performance of the ANC content and total extracted polyphenolic amount increased significantly after the maceration process when the electric field strength increased from 5 to 10 kV/cm [193].

5.6 Microwave-assisted extraction

Compared to conventional solid–liquid extraction, microwave-assisted extraction (MAE) gains higher efficient recovery and superior product quality at a low cost. MAE uses microwave energy to generate the molecular movement rotation of liquid under a permanent dipole, which results in the fast heating of both solvent and samples. This technology extends efficiency and reduces extraction time with low solvent consumption and a high level of automation [194, 195]. During microwave heating, the temperature radiation elevates the temperature of solids and solvents, and the subsequent viscosity of the extract is reduced; it thus promotes the solubility of the compounds, e.g., tannins. In addition, microwave radiation breaks the plant cells’ microstructure. This leads to the reduction of the mass transfer resistance of the components and encourages the diffusion of components from the source materials [196, 197]. MAE has recently been applied to extract various plant resources such as purple sweet potato, red cabbage, blackberry, cranberry, and sour cherry. However, the utilization of MAE and UAE technologies should be controlled with caution, as these methods can destroy the structure of flavonoids and tannins by attributing high temperature and excessive vibration to the samples respectively [122, 124].

5.7 Extraction methods for tulipalins

Few studies focus on extracting tuliposides from tulip biomass, despite the studies of their antibacterial activity [49, 107]. Typically, α-methylene-γ-butyrolactones have been prepared by the organic synthetic method [198]. Nevertheless, researchers have used tulip biomass years later to recover α-methylene-γ-butyrolactones with facile synthetic schemes. Tuliposides are considered the storage form of active tulipalins. Despite the conversion of tuliposides to tulipalins occurring non-enzymatically in nature due to their chemical lability, they can be converted spontaneously to tulipalin under neutral to basic conditions in vitro [199, 200].

Generally, the precursors of tulipalins would be converted into their active counterparts under stress with ethylene gas or an enzyme-mediated condition [201]. For example, Kato et al. [49] facilely extracted tulipalins from tulip tissue (petals). The extract was dissolved in cold water affording a tuliposide-containing extract of the tulip flowers. Potassium phosphate (KPi) buffer was then added to the extract. The procedure was then followed by incubation with and without the partially purified tuliposide-converting enzyme from the tulip bulb. The results showed that the yield of tulipalins was significantly higher than the extract incubated without tuliposide-converting enzyme, suggesting the potential applicability of tulipalins production. The study also indicated that using non-polar organic solvents was more effective than solvents with alkenes.

Similarly, Nomura et al. [50] explained a novel method: tulipalin B was directly formed from the precursor glucose ester 6-tuliposide B by an endogenous Pos-converting enzyme. The compounds were suspended in KPi buffer for 2 h at 4 °C. The combination of gum and resin contained contaminated starch granules, which were removed with a cheesecloth and water solution (equilibrated with 1 M NaCl). Nomura and co-workers also adopted coconut shell–derived activated charcoal (Yashi coal) as an absorbent of the hydrophobic impurities for partial purification of the flower extracts. Kerssemakers in 2018 [51] also introduced a method to extract tulipalin A from tulip bulbs by cutting them into smaller pieces to enhance the surface area. Artificial stressing of the bulb using ethylene gas triggered the mechanism, which eventually led to the conversion of tuliposides. Toluene and demi-water at 4 °C were used as solvents. The study also suggested that decreased polarity resulted in a higher affinity for non-polar solvents. As a result, tulipalin A would be more soluble in non-polar solvents such as benzene or toluene.

6 Impact of the extraction parameters

The effectiveness of the extraction process is principally based on the polarity of solvents because it contributes to the selectivity of the partition system. Therefore, the significant impacts of solvents on the extraction process are the extraction yield, composition profiles, and antioxidation activity of the extract [202]. Besides many selections of solvent as mentioned in Sect. 5, other conditions such as solid-to-solvent ratio, time and temperature, pH of the medium, and particle size of the matrix strongly influence the extraction efficiency [110].

6.1 Time, solid-to-solvent ratio, and temperature

Time, solid-to-solvent ratio, and extraction temperature are vital parameters to optimize to decrease the energy cost of the procedures. Many researchers enhanced the solubility of solute and the diffusion coefficient of the extraction process by elevating time and temperature. However, beyond a certain value, the phenolic compounds can be denatured [203]. The extracting time and temperature vary among studies. For example, the thermal stability of tannins is limited, and they therefore last from roughly 2 to 6 h at high temperatures (80–120 °C), and up to 24 h when the temperature is lower (25 °C) [71]. Sood and Gupta [204] reported that total phenol content extracted from pomegranate peel decreased with increased time and temperature. The same result was shown in the study of Silva et al. [205]. It indicated that 46.8 min with 58.2 °C was the most appropriate duration to extract phenols from Inga edulis leaves, which excessive time was not useful to extract more phenol content. If the temperature is elevated sufficiently, the time to reach equilibrium for the extraction of phenol compounds will be shortened. Nevertheless, long extraction time results in partially extracted polyphenols exposed to oxygen and light that were determined to degrade the extracts [206,207,208].

It is reported that the lower solid-to-solvent ratios would lead to higher extraction yields. Yet, too low solid-to-solvent ratios might lead to an excessive amount of solvent and a longer concentration time [110]. Also, at low solid-to-solvent ratios, the differences between the extraction efficiencies are usually inconsiderable. Thus, this parameter is generally optimized at a certain value [124]. In the study of Wang et al. [209], the increase of solvent used enhanced the flavonoid extract until the point 1:30 w/v, and then the yield decreased. Similarly, although several solid-to-solvent ratios from low to high were used to isolate bioactive compounds, the optimum conditions were not at the highest ratio but at a specific value, which was 1:4 w/v among from 1:1 to 1:7 w/v [210], or 1:8 w/v among 1:2 to 1:10 w/v [211].

A temperature range between 20 and 80 °C can promote higher analytic solubility by accelerating both the mass transfer rate and solubility. The viscosity and surface tension of solvents decrease at higher temperatures, which permit solvents to solvate phenolic compounds more efficiently and enhance the extraction rate. In contrast, some phenolic compounds such as ANCs start to degrade at high temperatures (above 70 °C). It is therefore pivotal to have the correct temperature to control the stability of phenolic compounds and reduce the thermal degradation of flavonoids [112, 212, 213]. For example, the thermostability of ANC is in a temperature range of 80–120 °C, and ANC starts to degrade following the first-order kinetics model in a temperature range of 120–180 °C [214, 215]. Using a temperature that is too high (above 150 °C) during the extraction degraded some antioxidant compounds in grape biomass and cultured red-wine berries [216, 217]. Additionally, tannins were extracted from Quercus infectoria (Manjakani) galls at different temperatures (50, 75, and 100 °C). The temperature effects on tannin content and antioxidant activity were thoroughly examined. The results suggested that the highest concentration of tannin and its highest antioxidant activity was achieved when the temperature was at 75 °C [218].

6.2 pH of the medium

Under the same time and temperature, the yield of chemical extraction depends on the types of solvents with varying polarities and pH. Phenolic compounds such as hydroxycinnamic acids and hydroxybenzoic acids are covalently linked to the polysaccharides of the cell walls by ester bonds. In addition, they are linked by ester or ether bonds to form lignin components. In mild alkaline hydrolysis, ester bonds are cleaved, and the ester-bonded phenolic compounds are released. On the other hand, in acidic conditions, alkyl-aryl-ether bonds are cleaved, and the ether-bonded compounds are released. As a result, many extraction methods are operated under mild alkaline or acidic conditions [219]. The polyphenol yield obtained from vine shoots was examined by basifying water with NaOH and EtOH. The results demonstrated that basified water with NaOH produced a higher polyphenol yield. The finding indicated that NaOH and EtOH had opposing action mechanisms, potentially caused by the carboxylic acid group in phenolic compounds. In an alkaline solution, the COOH group becomes COO–, which is soluble in water and not in EtOH [220]. Other studies found that the highest extraction yield of hydroxycinnamic acid glycosides from flaxseeds was obtained in alkaline hydrolysis by NaOH solution [221].

It has also been shown that acetic acid (about 7% v/v) or trifluoroacetic acid (TFA) (about 3% v/v) is more sufficient than mineral acids because mineral acids may cause the loss of the attached acyl group [222]. The use of hydrochloric acid (HCl) in many studies is therefore restricted, as it may break down the acylate groups. To acquire the best yield of flavonoid extraction, weak organic acids like formic acid, acetic acid, citric acid, tartaric acid, and phosphoric acid or low concentrations of strong acids such as 0.5–3.0% of TFA and less than 1.0% of HCl are suggested [112, 223]. Furthermore, sulfured water can be used as an alternative extraction solvent to reduce the use of organic solvents and extraction costs [224]. Ju and Howard [165] demonstrated that sulfured extraction possessed the highest flavonoid yield compared to subcritical water extraction and conventional solvent extraction (60% v/v MeOH at 50 °C for 1 h). Notably, most of the ANC compounds provide stability in acidic conditions and start to degrade at higher pH. Conversely, at higher pH or alkaline conditions, e.g., petanin, the degradation resistance occurs at pH 8 [58, 225].

6.3 The particle size of the matrix

The ideal temperature and the particle size of the samples are the essential factors that affect the yield during extraction. A smaller size prefers higher mass transfer facilitation. The smaller the particle size, the shorter path of the solvent to penetrate the solid matrices [226]. The reduction of the particle diameter is associated with the increased surface area. It therefore increases the contact area between the solvent and the samples [227]. Phenolics can be extracted from fresh, dried, and frozen plant samples. Pre-treated plant samples are usually air-dried and/or freeze-dried because freeze-drying generally retains more phenolics than air-drying [112, 228].

Gião et al. [229] proposed that a particle size of 0.2 mm was sufficient to assure a reasonable extraction rate by conducting conventional coffee mill grinding. Moreover, the highest yield of gallic acid (0.15 mg/g DW) was achieved when reducing the particle size to 125 µm. Particles smaller than 125 µm would not be used for the extraction since they tend to float [226]. Bucić-Kojić et al. [230] discovered that the extraction rate of polyphenol compounds from grape seed was extended when the particles were smaller. In this manner, a smaller particle size class (160–125 µm) induces a higher temperature impact on the extraction extent than a bigger particle size class (630 µm). This observation was supported by the highest value of activation energy (Ea) from the model of the solid–liquid extraction kinetics of total polyphenols.

Nevertheless, downsizing material steps such as grinding and milling consumes intense energy, correlated to the device type, dimensioning, and operating mode. Although the particle size range of biomass (ca. 100 µm) is limited at the laboratory scale due to the small powder amount, it cannot be neglected at the industrial scale. Some issues regarding the size handling process are health risks and explosion hazards. It must therefore be considered as soon as the process design in the scale-up procedures is built, as it influences technological options and induces the implementation of safety procedures and risk management [231].

7 Separation and purification methods

During the extraction process, impurities like sugars, oligosaccharides, proteins, and organic acids should be removed to increase the purity of the target molecules. Purification is a tedious, time-consuming, and expensive procedure. Usually, the protocols are optimized according to the targeted phenolic compounds [122]. Centrifugation for 15–20 min at 20,000–25,000 rpm may be applied to separate the crude plant matrix from the extract [232]. In principle, polyphenols can also be separated based on their MW, with the particles with an MW of 3000 Da to 100 kilodaltons (kDa). It can be removed by gel filtration, and higher MW compounds can be separated by regular ultrafiltration membranes [233].

In addition, the solvents used to extract polyphenols can be evaporated in rotary evaporation under vacuum conditions. The separation of phenolic compounds can also be accomplished using solvent separation methods (liquid–liquid phase separation) followed by chromatographic methods [232]. Until now, the common purification methods for polyphenols include column chromatography, membrane separation, high-speed counter-current chromatography, and high-efficiency preparative liquid chromatography [122]. In particular, few papers work with novel techniques to isolate tulipalin A and B, yet it remains feasible to separate tulipalins by high-efficiency preparative liquid chromatography [106] or by solid–liquid separation by vacuum filtration and rotary evaporation [51].

7.1 Column chromatography

Column chromatography is the conventional method for separating impurities and purifying polyphenols. It is also utilized for active molecule isolation and metabolite extraction from a broad variety of samples. Column chromatography is based on the principle of the various distribution coefficients of phenolic compounds between the solid and mobile phases [122, 234]. In principle, compounds are adsorbed, and the elution is based on the differential adsorption of a substance by adsorbents. In column chromatography, stationary phases can be silica, alumina, calcium phosphate, calcium carbonate, starch, etc. With different polarities, compounds are adsorbed for different reasons and desorbed at compatible solvent polarity. In the elution process, fractions get desorbed and pass through the column when solvents are added [235]. Column chromatography is classified into three classes: gas chromatography (GC), liquid chromatography (LC), and supercritical fluid chromatography (SFC). As the titles imply, the mobile phases in the three methods are gas, liquid, and supercritical fluid chromatography, respectively. As illustrated in Table 4, many chromatography methods are categorized into the first two classes. Notably, LC can be performed either in a column or planar surface. On the other hand, GC and SFC are limited to column procedures, so the column walls enclose the mobile phase [236]. The identification of components separated by column chromatography requires additional analytical methods to confirm the fractions. The crude extracts (complex chemical structures) then can be analyzed by many techniques such as thin layer chromatography (TLC), high-performance liquid chromatography, and GC to distinguish and quantify the desired compounds [234].

The typical column for separations is a reverse phase (RP) C18 column. EtOH, MeOH, acetone, and water are commonly used as eluting a solvent. For example, in the case of size exclusion column chromatography, MeOH is more commonly used than EtOH to elute non-tannin compounds, whereas the acetone–water mixture is preferred to the MeOH–water mixture when polymeric procyanidins are the targeted compounds [112]. The adsorption mechanism of flavonoids on the resin is unclear, as multiple interactions occur at the solid–liquid phase, e.g., hydrophobic, dipole–dipole, and hydrogen bonding. Besides, the rates and equilibria of adsorption vary significantly in physical and chemical properties like surface area, pore radius, porosity, solvent, pH, and temperature. Although column chromatography is the most common purification method for bioactive compounds, it has been abandoned because it is too labor-intensive in large-scale production [112, 122].

7.2 Membrane separation

Membrane separation is an efficient method for purifying and concentrating desirable compounds. The semipermeable membrane allows smaller molecules to pass through and retain larger molecules. The membrane selectively restricts the transportation of various chemicals, including solids, liquids, and gases. The membrane separation is based on the pore size of the applied membrane and can be separated into microfiltration, ultrafiltration, nanofiltration, and reverse osmosis [110, 237]. Membrane filtration is operated in two different ways: dead-end and cross-flow modes. The dead-end operation forces all the feed transportation through the membrane, causing build-up and subsequent performance loss; it therefore requires frequent cleaning. In the cross-flow operation, the flow is parallel to the membrane surface, with the inlet stream passing through the membrane in a specific position [237].

In the food and beverage industries, membrane separation operation is based on the particle or molecular size and is driven by pressure. Other membrane technologies such as osmotic distillation, membrane distillation, and pervaporation have been studied recently for the same application area. In particular, ultrafiltration and nanofiltration have gained great interest in separating and purifying bioactive compounds from plant extracts and among agro-food-based industries [238,239,240,241,242]. The membrane process has been used industrially for agro-food by-products such as olive mill wastewater. For example, Karakulski, Kozlowski, and Morawski [243] introduced ultrafiltration technology to decrease the chemical oxygen consumption for the direct sewer discharge of waste.

Table 5 shows the characteristics of polyphenols in terms of their MW. Nanofiltration has a pore size in the range of 0.5–1 nm, and the primary range of the MW cut-off (MWCO) is between 200 and 1000 Da. Ultrafiltration consists of membranes, with the MWCO in the range of 1–300 kDa and a 0.01 µm pore size [242]. Single membrane filtration does not purify the extracts effectively. A sequence of microfiltration, ultrafiltration, and nanofiltration was applied to isolate a bioactive compound from an olive leaf extract. Microfiltration followed by ultrafiltration separated the impurities more prominently than 5 kDa, whereas the nanofiltration recovered the antibacterial and antioxidant polyphenol compounds [244].

7.3 High-performance liquid chromatography

High-performance liquid chromatography (HPLC) is based on the different distribution coefficients of solute molecules in stationary (pack material of column) and mobile (eluent) phases. Depending on the chemical structure of the samples, the molecules are retarded while passing the stationary phase in the column under high pressure. The intermolecular interactions between the sample molecules and packing material determine the retention time. Thus, the separation process is achieved [246].

There are two types of phase systems used in HPLC: normal phase and reserved phase. In the normal phase, the stationary is a polar adsorbent such as silica. These bonded phases contribute to better elution profiles because they are moderately polar and have a more uniform surface. The mobile phase in this mode includes a non-polar solvent such as hexane that added a more polar modifier, or methylene chloride to control solvent strength and selectivity [247]. On the other hand, HPLC uses mostly reserved phase (RP) as an analytical technique for separating complex mixtures in the chemical, pharmaceutical, and biotechnological industries. RP-HPLC utilizes a non-polar stationary phase and a polar aqueous mobile phase. The mobile phase is usually water mixed with at least one of the water-miscible organic solvents such as acetonitrile, MeOH, EtOH, tetrahydrofuran, and isopropanol, which act as modifiers. The solutes are separated using their hydrophobicity, to which a more hydrophobic solute will be retained on the column longer than a less hydrophobic one [247,248,249]. The selection of the mobile phase compositions, consisting of solvents, buffers, and other additives, will control the interaction degree between the solutes and the stationary phase. For example, acetonitrile is the most popular selection as a modifier due to its low viscosity, which decreases the back pressure, low cut-off wavelength for UV detection, adequate large elution strength, reduced reactivity, and ability to dissolve a wide range of solutes. As alternatives, MeOH or EtOH can be used as a solvent in the mobile phase because they are less toxic, less expensive, and have higher polarity compared to acetonitrile [249]. The introduction of RP columns gains significantly improved HPLC separation for different classes of phenolic compounds, and RP C18 columns are exclusively utilized, followed by C8. The reasons for these references are the relatively high organic content for solute interaction and sufficient chemical stability of the working pH range compared to shorter alkyl chain phases [249, 250]. HPLC is divided into two types: analytical or preparative scale. Analytical HPLC is used for identification, detection, and small-scale preparation. Meanwhile, preparative HPLC is employed to separate and prepare samples [251]. Hence, pure compounds can be obtained by high-performance preparative liquid chromatography. This technique is based on the different physicochemical properties of each component in the crude extract, including ANCs, proanthocyanidins, hydrolyzable tannins, flavonols, flavan-3-ols, flavanones, flavones, and phenolic acids in different plant and food samples [112]. However, the HPLC method has limitations such as with the complex matrixes. An initial preconcentration and purification of the polyphenols from the complex matrixes are therefore crucial before the analysis by HPLC [250].

Also, the chromatographic behavior of the HPLC column will be altered and increased operating pressure under intensive use by the strongly retained materials such as lipids, or hydrophobic proteins. To solve this problem, washing the column with one or a series of strong solvents is essential. Lipids, for example, can be removed by using non-polar solvents such as MeOH, acetonitrile, and tetrahydrofuran. There is no solvents or series of solvent used to strip or remove proteins from the stationary phase. Yet, several solvents, such as acetic acid, (1% v/v in water) or aqueous sodium chloride, sodium phosphate, or sodium sulfate (1–2M) can be applied as eluent or solubilizing agents that strip all adsorbed proteins in HPLC column [252]. In reversed phase column, when a mobile phase does not use buffers or salts, the column can be washed with eluent by the same solvents as that of the mobile phase, only with higher organic solvent concentration [253]. In the case of buffered aqueous mobile phase, using strong solvents immediately is not recommended. A sudden change in the high content of organic solvent might lead to buffer precipitation in the HPLC flowing system and cause plugged frits, plugged connecting tubing, pump seal failure, a scratched piston, or injection valve rotor faults. Therefore, a buffer-free mobile phase, eluent containing the same ratio of water and organic solvent, is used to flush the column then strong solvents are applied to pass through the column [254]. Under the normal phase column, the column is cleaned by using a solution having the same solvents as that of the mobile phase, but in a higher concentration. When polar components adsorb in the column, isopropanol or similar solvents are used to flush them [253].

7.4 High-speed counter-current chromatography

High-speed counter-current chromatography (HSCCC) is an alternative to liquid chromatography. It is a liquid–liquid extraction without the support of any solid that eliminates the irreversible adsorption of compounds onto the solid support matrix. HSCCC is considered a potent candidate for large-scale production, with high recovery and high efficiency, which can improve the loading capacity of samples. The impurities of the desired fraction would be removed, and the yield of purified polyphenols increases after purification. HSCCC can be operated in various phases and modes: normal phases, reserve phase, pH zone refining, dual mode, gradient mode, and recycling mode [255, 256]. According to Degenhardt et al. [257], methyl tert-butyl ether (MTBE)/n-butanol/acetonitrile/water 2:2:1:5 v/v/v/v acidified with 0.1% TFA was employed as eluent to isolate ANCs from red cabbage, black currant, black chokeberry, and roselle. In addition, HSCCC can be applied to separate monomeric catechins, their galloylated esters, and caffeine from tea and other polyphenols from food like procyanidins, phenolic acids, and flavonol glycosides using MTBE/acetonitrile/0.1% aqueous TFA (2:2:3, v/v/v) [258].

8 Challenges and prospects in bioactive compounds extraction

This review provides an adequate understanding of different advanced extraction methodologies used to separate/extract bioactive compounds widely solicited as colorants and antibacterial agents. As a result, Table 6 provides a summary of the different extraction techniques of phytochemicals from plants, presenting details on the conditions, merits, and demerits of each method. In terms of natural products extraction, particularly bioactive compounds from innovative technologies, six principles have been proposed: (1) selection of varieties and use of the plant resources; (2) use of alternative solvents, mainly water or agro-solvents; (3) decrease of energy consumption by advanced extraction technologies; (4) produce co-products instead of wastes, consisting of bio-and agro-refining industry; (5) decrease unit operations and favor safe, robust, and controlled process; (6) target for non-denatured and biodegradable extracts in the absence of contaminants. When choosing a suitable extraction technology, one should follow those principles to connect with the biorefinery concept [259]. Indeed, the use of plant-derived colorants and antimicrobial agents has been perceived as having health-promoting benefits and coloring qualities. However, in the textile field, the major problem of its natural colorants and antimicrobial agents encountered is inadequate availability because of the matters in the collection, prices, compounds’ characteristics, and especially standardized methods of their production [260]. By applying the biorefinery concept, the evaluations of extraction efficiency, economic feasibility, and environmental perspectives are crucial to designing an appropriate extraction process for eco-textile products. Several extraction strategies have been conducted over the years, concerning properties such as sources of matrix, chemical structures, solubility, and chemical properties of both raw materials and solvents used, as well as the conditions during the procedure such as pH, temperature, and extraction time [108].

The manuscript also demonstrates that the utilization of green solvent with auxiliaries under pressurized conditions is the key factor in designing a novel extraction process. Under the advancement of technology, combinations like ultrasound-assisted DES extraction are more effective than a single method. The supplement of enzymes, including cellulose and pectinase for the extraction process such as ultrasound processing, is broadly used to recover ANCs from grape skin and raspberry wine residues. From another perspective, solvent utilization is under investigation to eliminate hazards using non-toxic chemicals and improve the yield of bioactive compounds, and energy consumption. For instance, DESs are promising alternatives to organic solvents [273]. Likewise, the addition of ultrasound-assisted technology allows the tannin extraction process to save 34% energy and 34% water, improving the feasibility of scaling up the extraction process in the industry [274]. As a highlight of solvent selection, the employment of Hansen Solubility Parameters is known as a tool to investigate the solubility parameter theory, to narrow the choice of the most sufficient green solvents to isolate bioactive compounds [275, 276].

Therefore, these advanced techniques encourage the idea that it may be possible to develop chemicals with improved safety profiles, utilizing safe solvents auxiliaries, design for energy efficiency, and degradation prevention [108]. However, scaling up the extraction methods for industry also faces many demerits and complexities such as limited recovery, the degradation of phenolic compounds, equipment cost, and maintenance feasibility. Importantly, energy and solvent consumption can be mentioned as essential subjects [277, 278]. For instance, in the SF extraction process, many factors such as extractors, reactors, CO2 reservoirs, heat exchangers, piping, valves, and operations automation to reduce manpower costs need to be appropriately considered. These units add significant costs, increasing the total investment cost of building a pilot or industrial-scale SF extraction. Moreover, the cleaning section should receive attention due to its time consumption in large-scale operations [279]. Accordingly, the need for scaling up should be integrated with the application of environmental assessment tools (life cycle assessment, etc.) and economic studies to propose safer and cleaner alternatives to more ordinary processes [259]. Consequently, more data from relevant materials and resources to emissions and wastes can be collected to study the potency of different bioactive compound extraction processes for diverse applications [280].

9 Conclusion