Abstract

Wallacea attracts much attention from researchers because it is a meeting point between Asia and Australia with rich biodiversity. Therefore, bioenergy source identification in this region is crucial to better understanding biomass potential and utilization. On the other hand, national bioenergy development usually refers to government policies, including granting permits to use forest land, especially on unproductive land. Thus, balanced utilization of tropical forests as an energy source is required. It must consider several aspects comprehensively, including its function in protecting the surrounding landscape, contributing to food security, and creating economic opportunities for communities around forest areas. This paper addresses biomass utilization in the Wallacea region aligned with Indonesian policy targets for bioenergy generation to achieve the net zero emission target by 2060. The study is carried out by limiting the scope of the area and relying on international databases and the nation’s potential targeting biomass research. In addition, the recent development of conversion technologies is adjusted based on available biomass types, including geographic information systems for potential biomass analysis. The analysis and data synchronization are presented in charts, graphs, and tables. In the early section, the potential of biomass in the Wallacea is explained. The following section discusses several scenarios, routes, and utilization technology options for biomass utilization. Various studies that have been conducted are presented in this section, including machine learning adoptions to model and optimize biomass conversion processes. Furthermore, challenges and opportunities are discussed by looking at various factors, such as accessibility, socio-economics, life cycle assessment, and environmental issues.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Developing a sustainable energy system requires encouraging renewable energy, reducing environmental impact, and high efficiency at competitive costs. The use of renewable energy to diversify the energy mix for achieving the net zero emission target is increasing. Various countries compete in promoting renewable energy and include long-term roadmaps in their energy mix. Biomass is a crucial alternative to renewable energy because it is considered carbon neutral and widely spread evenly worldwide [1]. Carbon neutral is a term to describe the state where the net release of carbon dioxide (CO2) or other greenhouse gases (GHGs) into the atmosphere is zero. It means that the amount of GHGs emitted into the atmosphere is balanced by the amount removed from the atmosphere or prevented from being emitted through various measures, such as reducing emissions, carbon sequestration, or using renewable energy sources. Biomass is a complex compound with components generally consisting of starch, cellulose, hemicellulose, lignin, proteins, and other minerals. Analyzing and considering the different characteristics of each type of biomass can significantly determine the appropriate biomass treatment, including suitable conversion methods [2]. For example, high moisture biomass requires drying as a pretreatment to increase its calorific value. Also, high alkali and alkaline earth metals in the feedstock must be washed before utilization [3]. However, the energy input demand for drying and water washing can significantly reduce the overall efficiency [4].

Based on human intervention, biomass can be categorized into three types: natural plants (aquatic and terrestrial plantations), energy crops, and biomass waste, as depicted in Fig. 1 [2]. Forestry is an example of the first category, where resources can grow naturally and be utilized for human needs. In addition, biomass is grown and dedicated to energy sources such as biofuel production in energy crops. In energy crops, the fuel produced can be solid, liquid, or gas. Furthermore, they can be converted depending on the demand to generate electricity or heat. Finally, biomass waste is advantageous for energy use because it is inexpensive and can reduce the environmental impacts of inappropriate disposals and treatments, such as open burning and landfilling.

Based on the region, biomass can be classified into the tropical, sub-tropical, boreal, and temperate domains. The tropics is the area between the tropic of Cancer (23.5°N) and Capricorn (23.5°S), with complex weather patterns and various environments. The tropical domain covers most global forests, up to 45%, followed by the boreal, temperate and subtropical domains [5]. The temperature in the tropical area tends to be uniform without significant differences except in the highlands. This area has an average temperature of at least 18 °C and receives enough rainwater in its soils [6]. Since most terrestrial biomass is located in the tropical domain, it can become essential to the global carbon cycle and climate change mitigation [7]. Tropical forests are believed to accommodate more than 50% of the world’s biodiversity and store two-thirds of all the carbon in terrestrial plants, making them incredibly valuable [8, 9]. Burning biomass for energy use has been carried out for a long time and can significantly impact atmospheric chemistry and climate [10].

Indonesia is an archipelagic tropical country with abundant and diverse biomass potential. There are many sources of biomass from forests, plantations, and agriculture, which include wood residue, rice husks, corn residue, and special wood plantations [11]. Wallacea, as part of the tropical region, attracts much attention from researchers because it is a meeting point between Asia and Australia and has rich biodiversity [12]. This paper discusses the scenarios for using biomass as an energy source, including the available technologies, especially for the Wallacea region. Constructing feasible technological scenarios and end-products is also important to build sustainable bioenergy-based systems. Furthermore, it is aligned with Indonesian policy targets for bioenergy generation to achieve a carbon–neutral target by 2060. Firstly, the potential of biomass in the Wallacea region needs to be addressed. The following section discusses several scenarios, routes, and utilization technology options for biomass utilization. Various studies that have been conducted are presented in this section, including the adoption of machine learning (ML) to model and optimize biomass conversion processes. Furthermore, challenges and opportunities are discussed by looking at various factors, such as accessibility, socio-economics, life cycle assessment (LCA), and environmental issues.

2 Energy situation and potential resources in Indonesia

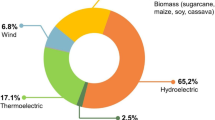

Indonesia’s primary energy supply in 2021 was 225.65 million tonnes of oil equivalent (Mtoe), which was dominated by fossil energy sources, especially coal (36%), followed by oil (32%) and gas (16%), as shown in Fig. 2 [13]. Biomass utilization was estimated at 11% of total energy, equivalent to 23.88 Mtoe, higher than other renewable energy, including hydropower, geothermal, and PV utilization. The national energy mix policy targets a contribution of 31% by 2050 for renewable energy. The Nationally Determined Contribution (NDC) also sets a 29% emission reduction with a contribution of 314 million tonnes (Mt) of reduction in the energy sector [11, 14]. This sector is predicted to generate about 1,669 Mt of CO2 under the business-as-usual (BaU) scenario in 2030 [14]. Adding large coal power plants in recent years will significantly affect the emissions. New coal power plants with a total capacity of 4,800 MW, for example, at least potentially emit 27–32 Mt of CO2 equivalent (CO2-eq) annually if it is not equipped with carbon capture [15].

Four types of renewables are promising in the future but have not been utilized optimally: hydro, solar, wind, and biomass (including biomass waste) energy. Indonesia has the potential for geothermal, hydro (including micro-hydro), biomass, and solar of 29.5, 94.5, 32.7, and 207.9 GW, respectively (Table 1). Although with a total potential of 443.2 GW, the installed renewable energy capacity was only 11.6 GW in 2021 [16]. Mahidin et al. reported that the potential biomass in this country is around 130 Mt, equivalent to 34.4 Mtoe [17]. The biggest proportion is crops, followed by forest and agro-industry residues, as shown in Fig. 3.

Annual biomass potential in Indonesia [17]

An assessment of biomass forest potential for bioenergy purposes has been conducted to understand the potential of Indonesia’s forest biomass resource as a fuel feedstock [18]. The findings are meant to encourage higher biomass utilization in the future and to guide the development of energy and forestry policies. They reported that the potential energy of forest biomass in Indonesia was about 132 PJ, with 50.4% from harvesting residues and 49.6% from wood processing residues. A higher number was reported in another study of 1261 PJ [19]. Differences in approaches for estimation are likely to affect the output. Another study reported the breakdown for each type of biomass, especially for crop waste [20]. The study took into account the area of the plantation and the specific waste per area (t/ha). They reported palm oil waste has a potential of about 32.86 Mt annually, followed by coconut (7.11 Mt), rubber trunk (3.79 Mt), and sugar cane (2.73 Mt). This country produces the largest palm oil in the world, owing to the massive expansion of palm plantations and high global demand [21]. A potential of 40 to 168 GL of bio-methanol could be generated for fuel, according to [22]. It equals half of Indonesia’s current power consumption, potentially reducing emissions by 9 to 38% of the total carbon emitted yearly.

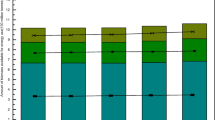

In the electricity generation sector, renewable energy utilization is still limited. A study shows fossil-based fuels are still dominant for the next few decades to meet electricity demand (see Fig. 4) [23]. A massive breakthrough is needed to achieve the government’s decarbonization target, especially for net zero emission in 2060. In the energy sector, efforts have been focused on strategies such as switching to cleaner fuels as alternative approaches to reduce emissions and environmental impacts, including co-firing of coal and biomass and hydrogen energy development. This approach is considered suitable because both can replace hydrocarbon fuels completely. Biomass utilization as a power plant has a potential capacity of 32 GW, spread over many islands [24]. The agricultural and forestry sectors are very promising fuel sources, especially from their waste. Palm oil waste, such as palm kernel shells (PKS), empty fruit bunch (EFB), and palm oil mill effluent (POME), has the greatest potential (more than 10,000 MWe) compared to other biomass wastes, such as rice husk and municipal solid waste [11]. Stich et al. estimated a biomass potential of about 407 TWh annually [25]. Power generation with biomass, in general, can be performed via co-firing with coal. This method is considered promising because of its relatively low cost. However, co-firing has several challenges, primarily related to boiler performance due to the impact of the ash produced. The characteristics of the ash produced can interfere with the performance of boiler heat exchangers. Further investigation is required to ensure co-firing sustainability for the long term [21].

The demand for power generation by type of fuel [23]

3 Biomass potential in the Wallacea region

The Wallacea archipelagic region is the islands in the central part of Indonesia, consisting of Sulawesi, the Nusa Tenggara, Timor Island, and the Maluku Islands, as illustrated in Fig. 5. The area comprises approximately 1680 islands (with Sulawesi as the biggest island), covering an area of 338,000 km2, and is estimated to have a forest area of 141,080 km2 [26, 27]. Wallacea has a drier climate with lower humidity than other parts of Indonesia, except around the Maluku Islands [28]. Mountain forest vegetation is spread around Sulawesi. Closed, tall, and dense plant species characterize the mountain forest biome. Not only mountain forests but there are also mixed forests in the Maluku region, which are equipped with various types of spices, such as cloves, cinnamon, walnuts, and ebony wood [29, 30].

Due to its vital role, various attempts have been made to estimate the potential of a forest. Multiple approaches have been taken to produce accurate data and minimize errors. Forest biomass is an essential variable in calculating the amount of carbon that can be absorbed, including its role as a source of bioenergy. Therefore, an accurate forest biomass estimation is necessary to analyze terrestrial ecosystems’ carbon cycle in large areas [32]. Forest biomass, in general, can be estimated by field calculations and remote sensing methods. The former can produce optimal results for small forests and is not feasible for larger areas considering the cost required, amount of labor load, and time consumed [33]. Remote sensing is needed to estimate the regional scale because this approach requires less manual work and can cover large areas, including inaccessible areas [34]. Sensors can easily acquire data without directly contacting the measured object. Sensors can be divided into passive and active sensors, whereas platforms range from satellites and planes to unmanned aerial vehicles (UAVs) [35].

Simangunsong reported a study that focused on forest residues primarily from natural production forests and industrial forest plantations, as well as wood processing mill residues [18]. Using secondary data, they analyzed the residual factors to determine the potential of biomass as biofuel. However, their investigation did not cover material from early silvicultural thinnings and trees grown in energy plantations due to data availability. A study with remote sensing utilizing UAV-based high-resolution RGB images processed by ML algorithms has been carried out by Kurniawan et al. [9]. The biomass considered were sugar palm, clove, and coconut trees. In addition, a study on mapping Mangrove vegetation has been reported by Rudiastuti et al. [36]. They performed data integration and field study to overview Mangrove vegetation comprehensively. They found Southeast Sulawesi has the largest mangrove forest area with 62,446.4 ha, followed by Central Sulawesi (33,538), North Sulawesi (11,884 ha), South Sulawesi (10,412 ha), Gorontalo (8006 ha), and West Sulawesi (3720 ha).

Furthermore, using Landsat ETM + and MODIS data, tropical rainforests in Sulawesi have been estimated [37]. The up-scaling approach has been developed to identify tropical rainforests and overcome the problem of resolution mismatch between the ground sampling plots and the MODIS data. The study concluded about 48.74 to 612.21 t/ha biomass spread across Sulawesi with a total of about 2408.3 Mt. However, further investigation is needed to determine the potential of biomass utilized in the energy sector. In addition, the raw data of existing biomass needs to be further projected to ensure a sustainable supply. Almulqu and Boonyanuphap studied dynamic ecosystem biomass to accurately estimate the biomass potential in Rote Ndao Regency (East Nusa Tenggara) [38]. The research only focused on common tree species, such as Schleicera oleosa, Dryobalanops aromatic, Mangifera indica, Cordirchotoma torsi, Tamarindus indica, Ficus benyamina, and Vitex parviflora. They highlighted the importance of essential information, such as wood density, to improve the data quality. Research related to biomass potential in the Wallacea region is summarized in Table 2.

In practice, all available biomass cannot be used as an energy source. The safest to use is waste which has no competition with other uses such as material and food, including conservation purposes. Furthermore, most available wastes are not utilized due to collection difficulties and their inherent characteristics. Therefore, minimizing costs and risks can be anticipated by mapping the biomass potential considering conversion methods [2]. The waste is economically preferable with great environmental benefits. However, if an available crop is grown solely for energy, it could lead to environmental destruction. Rhofita et al. [17] offered a framework for biomass waste assessment in Indonesia, as shown in Fig. 6.

The proposed perspective of biomass waste utilization in Indonesia [19]

Indonesia’s representative has presented Sulawesi’s biomass potential for energy use and reported that rice husk (1.11 GW), palm oil waste (0.32 GW), corn waste (0.25 GW), and others could provide 1.9 GW of electricity [11]. Unfortunately, the presented biomass potential is not accompanied by a data collection method. The study conducted by Japan International Cooperation Agency (JICA) revealed a higher biomass potential in the Wallacea region, with about 71 TWh annually, which is dominated by wood waste, rice waste, and corn waste, as depicted in Fig. 7 (accounting for almost 90%) [40]. As a country with the third largest tropical forest, Indonesia has enormous potential for waste forests, including in the Wallacea region. Wood waste usually comes from logging activities, rubber residue, sawdust, wood chips, and plywood waste. With a wider forest area, Sulawesi dominates the total wood waste produced with almost 19.29 TWh annually.

If converted into GW capacity units, the potential of the biomass in each island in the Wallacea region is very high to generate electricity (see Fig. 8). However, conversion to electrical units is intended to help for better understanding and does not mean that all raw biomass wastes must be converted to electricity. For example, Sulawesi has a higher biomass waste potential (of about 5.27 GW) than net electricity capacity in 2025 (estimated based on the government plan [41]). However, the latest report in 2016 stated that the potential for biomass waste in Sulawesi is around 2.5 GW [42]. It is unclear whether the differences in approaches or due to significant deforestation on the island. In addition, several power plants have been demonstrated to co-fire to maximize biomass waste utilization. However, a techno-economic evaluation of co-firing technology and further study of other technological options is needed.

A study on using pellets from sorghum for electricity production has also been carried out for the East Nusa Tenggara region by Wiloso et al. [39]. The capacity of sorghum biomass produced was assumed to be 25% of the marginal land or around 100,000 ha. Their study also analyzed the LCA to evaluate replacing coal fuel with biomass thoroughly. However, the results depend on the assumptions of the data obtained. More intensive trials are also needed to get a technical report on the performance of coal-fired power plants, such as combustion efficiency and the effect of biomass on ash deposits. It was reported that sorghum pellets could result in high slagging or fouling tendencies and threaten the durability of boilers. Based on the annual estimated potential, 8500 GWh of electricity could be generated from biomass yield or reduced emissions of 7.9 Mt of CO2-eq. In addition, West Nusa Tenggara has potential biomass waste, especially from rice husk and corn residues of more than 20,000 TJ/y, including biofuel (from Jatropha Curcas) and biogas [43]. It is equivalent to the energy generation of more than 600 MW of biomass-based plants.

Biomass waste can be used directly or indirectly as fuel. Charcoal, rice husk, twigs, and dry leaves briquettes are examples of biomass fuels that can be used directly as heating or power sources [44]. The heating value of biomass fuel varies depending on the source. The use of biomass can make a significant contribution to waste management, fuel security, and climate change. In rural areas, especially in developing countries, biomass from wood, leaves, rice husks, and straw is the primary fuel for heating and cooking. Several solutions are offered to reduce the impact of the direct burning of biomass on the environment and health, one of which is better conversion technology using biomass stove technology [45]. Biomass stove technology can increase the efficiency of burning biomass and reduce pollution emissions significantly, thereby preventing the negative impacts of using biomass on family health. The National Electricity Company (PLN) has planned to use biomass for power generation and is targeting a total of 45 MW (5 locations) in Maluku starting in 2024. In Sulawesi, 50 MW of biomass power generation was also prepared, as well as 9.8 MW in Gorontalo and about 10 MW in Nusa Tenggara [41]. Apart from being utilized for dedicated biomass power generation, the existing potential can be used for co-firing in coal power plants. Around 19 GW of coal power plants in Indonesia have the potential to be co-fired. More than 500 MW of coal power plants in the Wallace region have been planned to be co-fired with biomass, and, up to now, they have been successfully demonstrated in three locations. East Nusa Tenggara has also established a 1 MW gasification system from biomass.

4 Energy conversion scenarios, routes, and technologies for tropical biomass

4.1 Tropical biomass conversion technologies

Biomass waste generally consists of cellulose, hemicellulose, lignin (aromatic polymer), and extractives (in small amounts). Because it is resistant to hydrolysis, complex cellulose must be pretreated to break into simple sugars before fermentation to produce biofuel. Hemicellulose, a complex polysaccharide produced from various five- and six-carbon sugars, is weaker than cellulose. Hemicellulose hydrolysis is simpler than cellulose hydrolysis because of the amorphous nature of its structure and the involvement of a smaller number of hydrogen bonds [46]. Hemicellulose is easily degraded into simple sugars, unlike strong and crystalline cellulose. Cellulosic biomass contains lignin, a group of complex organic polymers that provide the cell wall’s mechanical strength. Lignin can be used for biofuel production or converted into energy through a thermochemical process [2]. Table 3 estimates the chemical composition of several different biomass wastes [47,48,49,50].

Technological advances to harness the energy contained in biomass are growing dramatically. Appropriate procedures are used to increase the collected biomass waste (depending on circumstances). Size reduction, compaction, drying [51], and torrefaction are required before being converted using the primary technologies. The main pathways of biomass conversion to energy can be categorized into thermochemical and biochemical conversions, as illustrated in Fig. 9. The thermochemical approach involves heat and chemical processes to obtain primary products from biomass waste, such as direct combustion, gasification, pyrolysis, and more advanced method using thermochemical cycles. In addition, the biochemical conversion uses microorganisms to decompose and convert raw fuel with gaseous or liquid fuels as products: anaerobic digestion, fermentation, and photobiological hydrogen production. The biofuel products can be varied depending on microorganisms’ selection; hydrogen [52], biogas/methane [53, 54], ethanol, acetone, butanol, organic acids, butanediol, isobutanol, xylitol, mannitol, and xanthan gum. Biochemical conversion methods are preferred because of their simplicity and do not require dry input materials as required in thermal conversion [53]. In addition, the final product can be used directly or stored before being distributed to final users.

Although potentially very high, biomass utilization still faces many technical and non-technical challenges. The government provides several prioritized programs and guides related to bioenergy, including (1) the utilization of waste as a source of electricity generation, (2) biofuel programs, and (3) waste utilization from agriculture, plantation, and forest land, as well as degraded land. Based on this program, the biomass potential in Wallacea can be simplified, as depicted in Fig. 9. Although biomass waste can be converted through various methods, the condition of the raw material itself may influence the selection of the most suitable technology.

The use of biodiesel nationally continues to grow in terms of quality, volume, mix, and the number of stakeholders (producers and consumers). Biodiesel products in Indonesia refer to first-generation biodiesel, which is produced through a transesterification reaction using methanol and an alkaline catalyst, such as sodium methylate (Na-methylate), sodium hydroxide (NaOH), or potassium hydroxide (KOH). In this process, biodiesel is the main product, with glycerol as a by-product. Biodiesel has reached B30, a mixture of 30 vol% fatty acid methyl ester (FAME) in automotive diesel oil. Furthermore, a matrix related to feedstock and its utilization technology has been proposed, as listed in Table 4 [24]. Almost all of the existing biomass waste can be utilized as a source of bioethanol raw materials through pyrolysis or cellulosic bioethanol. In addition to producing biofuels, using biomass to generate power is also a promising technology option. The gasification route is also an attractive option besides direct combustion to produce steam to drive turbines. The National Electricity General Plan (RUKN) states that PLN plans to implement co-firing to their 52 units of coal power plants. Co-firing is a thermochemical conversion method by substituting coal at a specific ratio with biomass materials such as wood pellets, PKS, and sawdust. In 2024, it is estimated that the total co-firing capacity at PLN’s power plants will reach 18 GW. The co-firing plan is intended to support renewable energy development without constructing new generators. Compared to conversion with other methods, co-firing has several characteristics, such as low costs, ignition acceleration [55], no need to build a new power plant, and reduced coal utilization, but it requires a sufficient biomass supply. A co-firing trial on the 26 coal power plants has demonstrated up to a 5% biomass ratio, including in the Wallacea region.

Applying co-firing biomass in a circulating fluidized bed (CFB) or pulverized coal boilers could reduce combustion efficiency [56, 57]. In other words, a larger fuel mass is required to produce the same energy output. Alfian et al. [58] investigated the effect of co-firing coal with wood chip biomass (up to 30%) on the performance of coal feeder and draught plants of 50 MW circulating fluidized bed. They reported that biomass co-firing could increase the feeder and draught plant’s auxiliary power consumption and the net plant heat rate (NPHR). This co-firing technology can be used on various power plant scales from 100 to 3000 MW. However, pretreatments, such as drying and pulverizing, may be required depending on the characteristics of the boiler [59].

A report issued by Economic Research Institute for ASEAN and East Asia (ERIA) discussed the challenges during biomass fuel combustion in the CFB boiler, especially for tropical biomass (see Fig. 10). However, this CFB boiler is designed to tolerate various fuel types and accommodate biomass that cannot be used in pulverized boilers. Even though they have a relatively lower tendency, CFB boilers also have the potential to have ash-related problems such as slagging, fouling, and corrosion due to biomass mixture in the combustion [60]. Hariana et al. [21] studied combustion performance, including slagging-fouling behavior during coal co-firing with EFB and frond. They found that co-firing 25% biomass with bituminous coal potentially increases the probability of slagging, confirmed by lowered ash melting temperatures, deposition, and sticky material in the boiler probe. Instead of drying, pretreatment through hydrothermal treatment is claimed to improve raw biomass quality significantly [61,62,63,64]. It is a pressurized thermal conversion process conducted under supercritical water conditions between 150 and 350 °C. The improved biomass fuel can then be co-fired with coal to produce better combustion performance and lower emissions [65, 66]. Practically, additional energy is required for continuous operation, so it is feared that it will reduce the overall efficiency.

The adaptability of fuel for CFB boiler [67]

In several simulated case study scenarios, palm oil waste as a co-firing material (with a ratio of 25%) can reduce emission intensity (g/kWh) to 20% lower than dedicated coal [67]. If biomass utilization is increased to 50% in the boiler, the reduction is quite linear, with a 44% reduction in CO2 emissions. However, raising the biomass ratio from 25 to 50% is expected to slightly decrease the overall efficiency from 34 to 32% (based on lower heating value).

Pyrolysis is another option for converting biomass waste into useful products. This method can be divided into flash, fast, and slow/conventional, as summarized in Table 5. Flash pyrolysis is carried out at temperatures of about 700–1000 °C with very short residence times and higher heating rates, generating gas, liquid/bio-oil, and a small amount of biochar. It generates bio-oil at moderate temperatures with a 0.5–2 s residence time. Fast pyrolysis is more developed than flash and slow pyrolysis because it can produce higher efficiency and related environmental issues [68]. The compositions of the bio-oil, gas, and charcoal yields are 70–75, 13, and 12%, respectively. This process requires heat which can be obtained from the gas or solid fuel produced. Bio-oil has the potential to act as an intermediary before being upgraded and fractionated to produce higher-quality fuels. Furthermore, wider applications, such as transportation fuel, require a feasibility assessment.

Fast pyrolysis has been commonly used for industrial combustion. Some tropical biomasses, including ogbono wood, mango wood, neem wood, ogbono shell, ogirisi wood, and tropical almond wood, were studied for biofuel production through pyrolysis [69]. The highest bio-oil yield of 66 wt% was obtained from neem wood. The efficiency could be increased by combining bio-oil yield of about 80% and biochar combustion for heat sources [70]. Improved reactor and operational conditions may lead to higher bio-oil production. However, it may also be challenging to identify precise reasons that cause variations in the amount of bio-oil produced from these species because so many variables might affect them, including process temperature, heating rate, the composition of biomass, and residence time [71, 72]. A study on the case of tropical biomass in developing countries reported that fast and slow pyrolysises are quite effective in reducing CO2 emissions at a moderate cost. Gasification tends to be high-cost unless aided by high carbon and electricity costs [73].

The main thermochemical conversion methods for biomass conversion include combustion, gasification, and pyrolysis. Apart from that, there is also a chemical looping method that is still in development. These processes are inherently related to one another. An overall summary of these conversions is tabulated in Table 6. It should be noted that carbon capture can be added to the back end of conventional biomass thermochemical conversion processes to capture CO2 for a net CO2-negative process [74].

Unlike combustion and pyrolysis, gasification is a partial oxidation process with complex chemical reactions at a high-temperature range of 500–1300 °C. In this process, a gasifying agent such as water, steam, or oxygen is generally used to produce a mixture of syngas (H2, CO, CH4) and CO2, H2O, N2, and light hydrocarbons. The utilization of gasification to convert biomass waste, such as rice husk [82] and wheat straw [83], has been reported. The gas produced can be used in power plants and processed into H2, dimethyl ether (DME), methanol, ethanol, or other fuels. Gasification can also be combined with an integrated system to produce higher efficiency, called the integrated gasification combined cycle (IGCC). Among the common problems faced by the gasification process is the production of tar and unwanted contaminants, such as alkaline compounds, increasing the cost of purification. A gasification reactor’s performance can be influenced by the type and design of the gasification reactor/gasifier, biomass composition, temperature, catalyst, and gasification agent. Gasification technologies can be classified into types: fixed or moving bed, fluidized bed, and entrained flow, as shown in Fig. 12. Compared to the other gasifier, a fluidized bed has numerous benefits such as uniform heat transfer, high biomass-to-gas conversion rates, and flexibility for large-scale production [84, 85]. Even though it might be suitable for coal on a large scale, using an entrained gasifier for biomass waste is not applicable due to its high moisture content and required fine particles [84, 86].

4.2 Advanced methods for optimization

An approach using a mathematical model is needed to solve problems that involve high complexity, non-linear parameters, and high-dimensional, including those related to the design of thermal conversion processes, optimization, and intensification [87]. As depicted in Fig. 11, models can be used to determine optimal operating conditions, including various possible outputs for a system. Models can also enable real-time process control and optimization and forecast critical process performance parameters [88]. Among these strategies, ML has recently attracted considerable attention to optimizing biomass conversion processes, yield prediction, real-time monitoring, and process control, where artificial neural networks (ANN) have been the most commonly used algorithms [89]. The ANN is frequently employed to solve complex non-linear problems for biomass conversion via thermochemical or biochemical processes. Other ML approaches, such as support vector machine (SVM), decision tree (DT), random forest (RF), extreme gradient boosting (XGBoost), and adaptive-network-based fuzzy inference system (ANFIS), are also widely employed.

Using ML in biomass utilization, presented by Muzammil et al. [89]

Lijian et al. [90] developed a model to predict several parameters during hydrothermal treatment using biomass wastes such as algae and food waste. The dataset is a compilation of 18 published papers, considering several features, including elemental composition, temperature, and other operating conditions. They found that nitrogen content, solid content, and temperature are the most critical factors in determining some output properties. In addition, Mohammadreza et al. [91] compared ML methodologies for predicting the kinetics of hydrothermal carbonization of selective biomass. They found that when the reaction kinetics were fast, the ML models differed from the experimental data. However, it is generally inferred that the ML techniques are suitable for interpolating and extrapolating the kinetics of the hydrothermal carbonization process. Gopirajan et al. [92] also concluded that an ML-driven optimization approach is better suited for a process that involves many parameters, such as the hydrothermal liquefaction of biomass.

Li et al. [93] used ML to understand, predict, interpret, and optimize biomass gasification using information obtained from raw material conditions and gasifier specifications. The results revealed that the gradient boosting regression (GBR) model predicted the compositions of three-phase products and syngas well. Higher H2 yield could be achieved under several conditions, such as high temperatures (> 800 °C), higher carbon, and lower nitrogen contents. ML-based models were developed for co-pyrolysis biomass to generate biofuel and biochar [94]. The models were trained, tested, and validated using hundreds of biochar and bio-oil data to predict yields of biomass pyrolysis. The authors also offered some analysis techniques to understand the effect of different parameters, thus providing excellent insight into this topic. Huang et al. [95] also used big data and ML to maximize char yield and higher heating value from biomass or other solids pyrolysis. They found that the developed polynomial regressions could accurately predict the desired outputs if the inputs are well known. The gradient boosting model also performed well with high accuracy based on pyrolysis feedstock and operation conditions. In addition, coal-biomass co-pyrolysis models were also studied using collected experimental results from the literature [96]. The data involved 30 biomass and 28 coal samples, such as corn stalks, husks, white pine, and wood waste. The solid fuel compositions were collected and analyzed, including experiment parameters such as the heating rate and the coal-biomass ratio. Among the results, temperature conditions are the most determining factor during co-pyrolysis, followed by mixture ratio, fuel characteristics, and heating value.

ML is also widely used to predict and solve complex biochemical conversion problems. The ANN, DT, SVM, and other approaches have been used to perform scientific tasks in methane, bio-oil, hydrogen, or ethanol productions via biochemical conversion. Based on a NARX-BP hybrid neural network, Xiao et al. [97] developed methane production using two-stage models involving microbial electrolysis cells and in-situ biogas upgrading. The results suggested two-stage approach performs better than the traditional one-stage model in predicting methane production. ANN method could also achieve a high level among different ML methods in modeling and could support long-term prediction and optimal performance for complex biochemical conversion.

Estimation of biogas and methane production from treating potato starch processing wastewater was developed using three-layered feedforward backpropagation ANN (BP-ANN) and multiple non-linear regression (MnLR) [98]. At several parameters, optimized methanation of 65–75% was achieved. BP-ANN showed better performance than the MnLR method since it could accommodate control of the anaerobic digestion process. Furthermore, a fermentative hydrogen production model has been developed using the ANN approach [99]. Sugarcane vinasse was utilized as raw materials during anaerobic fermentation, and some parameters were employed, such as fermentation time and volatile fatty acids (VFA) production. The model could predict H2 yield with high accuracy with R2 > 0.987. The authors also suggested that employing a model based on acetate and butyrate is recommended for complex or mixed cultures. Althuri et al. [100] optimized bioethanol production from lignocellulosic biomass using co-fermentation. A non-isothermal simultaneous pretreatment and saccharification were also performed. AI-ANN was employed in optimization modeling, adopting process parameters such as temperature, residence time, strain ratio, and substrate loading. In conclusion, every modeling and optimization approach developed has advantages and disadvantages. Using only one evaluation criterion to pick the best ML model is insufficient because each study has different objectives and methodologies. ML and optimization algorithms have advantages over conventional approaches in terms of precision and accuracy and potentially boost the use of biomass as an energy source in the future.

5 Challenges and opportunities

Currently, sustainable renewable energy development in the Wallacea region faces specific challenges from both technical and regulatory perspectives, such as economic, social, and environmental. Several points need to be highlighted, including the following:

-

Renewable electricity is relatively more expensive than conventional power plants (coal). However, as the production and introduction of renewable energy increase massively, the cost of renewable electricity decreases gradually, reaching a competitive level with fossil fuels;

-

Intermittent power plants (solar and wind) require energy storage to maintain the stability of the power supply and balance of the whole electrical grid;

-

Power plants with the least cost and good capacity factor, such as hydro and geothermal, are generally located in conservation areas far from power load, so they take a relatively long time to build due to licensing constraints, geographical constraints, and the potential for landslides;

-

Developing biomass and biogas for generating power requires a guaranteed feedstock supply over time.

The massive use of biomass requires a continuous supply. On a regional scale, information is needed regarding how much biomass can be utilized. As shown in Fig. 12, not all the total biomass waste can be used for energy. This estimate also needs to consider future projections, providing short-, mid-, and long-term estimates [101]. Although forestry and biomass industries offer relatively cheap and easy access, field measurement may still be required to calculate the recoverable biomass accurately. Even though it is abundant, if it is not easily accessible, it will increase recovery costs due to location constraints and tenure/land management constraints [102]. Location constraints are challenges in collecting and distributing biomass from harvesting to processing locations. Location-related costs are also determined by distance, mode of transportation, and terrain encountered. A study reports energy consumption while transporting biomass, assuming that one truck can transport 5 t of biomass with 3 km/L of fuel [103]. From the calculation, it is obtained that to distribute a distance of 30 km, 75 MJ/t of dry biomass energy is needed. This value is considered relatively small compared to the energy required in the drying process. In addition to location factors, social, political, and cultural conditions will influence the decision-making process related to the use of biomass because it involves land ownership/land rights.

In the economic aspect, the assessment shows that converting biomass residues into wood pellets will increase the country’s forest resources’ value and government revenues from natural resource assets. The economic value of forest biomass is approximately 5.6 USD/t, including wood residues [18]. The cost of producing wood pellets is estimated to be around 103.0 USD/t or 5.7 USD/GJ, lower than other countries such as Finland, Germany, Norway, Sweden, and the United States [18, 104]. In addition, converting crop residues into wood pellets will also support Indonesia’s poverty alleviation strategy and other socio-economic benefits for rural communities, especially those who live on the edge of the forest and are vulnerable to poverty. The development of national bioenergy projects by 2050 will provide broad economic benefits, including creating jobs and avoiding environmental costs [11]. According to a cost and benefit analysis, the total economic benefits gained are 55 billion USD, including 12 billion USD from resilient job creation. Currently, in the Wallace region, 3 million people are living below the poverty line, according to Indonesia Statistics. Although the link between energy and poverty alleviation can be direct or indirect, the benefits of developing biomass for energy in poor areas are undeniable.

Furthermore, LCA for biomass utilization in the energy sector has been widely reported, including in tropical regions. Aberilla et al. [105] reported the LCA of the environmental sustainability of agricultural waste for power generation at a small scale in rural areas. The LCA evaluation has been performed following ISO14040/44. They concluded biomass conversion via anaerobic digestion is the best option based on 14 out of 18 impacts. The results also suggest that gasification has up to 12 times lower impacts per kWh than combustion to generate electricity. In addition, a review of the LCA study on biomass thermochemical conversion is reported, involving various technologies: combustion, co-combustion, pyrolysis, gasification, and liquefaction [106]. The work was mainly focused on lignocellulosic biomass to produce high-value end products such as power, biofuel, solid fuel, and chemical products. The reported LCA evaluation is commonly limited and divided into three main phases, from cultivation to plant demolition and recycling, as shown in Fig. 13. The author concluded it is important to investigate the co-generation process via multiple routes.

Three main phases for the LCA [106]

Unsustainable biomass utilization due to excessive harvesting and consumption on a centralized or large system can lead to forest degradation, reduced biodiversity, and soil degradation [107]. In addition, other indirect impacts can arise, such as flooding, wastewater issues, and long-term health impacts due to direct burning. On a large scale, biomass energy is considered carbon–neutral but not nutrient neutral since extracted biomass contains nitrogen and other nutrients, not solely the cycle of carbon [108]. So far, LCA studies have tended to ignore this point, but in large-scale utilization, a more careful evaluation is needed to minimize environmental impacts. Biomass energy utilization can intersect and compete with urbanization, forests, and crops due to the massive use of land [108]. Palm oil expansion is responsible for Indonesia and Malaysia’s 1.5% annual deforestation rate [109]. In the thermochemical method, considerable impacts should also be addressed, including GHGs emissions, fly/bottom ash generation, water pollution, hazards due to prolonged exposure to toxic materials, and unintentional incidentals with the high-temperature operation.

6 Conclusion

As a meeting point between Asia and Australia with rich biodiversity, Wallacea has attracted much attention from researchers. Studies regarding the potential of those bio-resources and their utilization are vital to achieving sustainable biomass utilization in the area. This work addresses biomass utilization in the Wallacea region aligned with Indonesian policy targets for bioenergy generation to reach the net zero emission target by 2060. Some essential points from the study can be concluded as follows:

-

As a country with the third largest tropical forest, Indonesia has enormous potential for waste forests, including in the Wallacea region. Biomass waste comes from logging activities, such as rubber residue, sawdust, wood chips, and plywood waste. A study reveals biomass potential in the Wallacia region with about 71 TWh, dominated by wood, rice, and corn.

-

Although potentially very high, biomass utilization is still relatively low. It still faces many technical and non-technical challenges. The government provides several prioritized programs and guides related to bioenergy, including (1) the utilization of waste as a source of electricity generation, (2) biofuel programs, and (3) waste utilization from agriculture, plantation, and forest land, as well as degraded land.

-

In addition, ML and optimization algorithms can be used and have advantages over conventional approaches in terms of precision and accuracy and potentially boost the use of biomass. This approach can solve problems that involve high complexity, non-linear parameters, and high-dimensional, including those related to the design of conversion processes, optimization, and intensification. They can also assist policymakers in optimum long-term planning considering energy/price forecast, demand projection, and emission-cost optimization based on selected conversion technologies.

Data availability

Data used in this work are presented in this paper.

References

Tumuluru JS (2018) Effect of pellet die diameter on density and durability of pellets made from high moisture woody and herbaceous biomass. Carbon Resour Convers 1:44–54. https://doi.org/10.1016/J.CRCON.2018.06.002

Darmawan A, Aziz M (2022) An overview of biomass waste utilization. Innovative Energy Conversion from Biomass Waste. Elsevier, pp 1–23. https://doi.org/10.1016/B978-0-323-85477-1.00007-5

Wang X, Hu Z, Ma J, Yi L, Li J, Cheng Y et al (2023) Effect of semi-continuous water washing on the combustion behaviors of agricultural organic solid waste. Carbon Resour Convers 6:58–64. https://doi.org/10.1016/J.CRCON.2022.12.003

Aziz M, Fushimi C, Kansha Y, Mochidzuki K, Kaneko S, Tsutsumi A et al (2011) Innovative energy-efficient biomass drying based on self-heat recuperation technology. Chem Eng Technol 34:1095–1103. https://doi.org/10.1002/CEAT.201100065

FAO (2020) Global Forest Resources Assessment. Main report, Rome. https://doi.org/10.4060/ca8753en

Nicholas ID (1988) Plantings in tropical and subtropical areas. Agric Ecosyst Environ 22:465–482

Ghosh SM, Behera MD (2018) Aboveground biomass estimation using multi-sensor data synergy and machine learning algorithms in a dense tropical forest. Appl Geogr 96:29–40. https://doi.org/10.1016/J.APGEOG.2018.05.011

Cuni-Sanchez A, Sullivan MJP, Platts PJ, Lewis SL, Marchant R, Imani G et al (2021) High aboveground carbon stock of African tropical montane forests. Nature 596(7873):536–542. https://doi.org/10.1038/s41586-021-03728-4

Kurniawan IF, Aneiba A, Hussain A, Idrissi M, Dunggio I, Asyhari AT (2022) Large-scale Tree Detection through UAV-based Remote Sensing in Indonesia: Wallacea Case Study Proceedings - 2022 8th International Conference on Information Management. ICIM 2022:110–5

Ludwig J, Marufu LT, Huber B, Andreae MO, Helas G (2003) Domestic combustion of biomass fuels in developing countries: a major source of atmospheric pollutants. J Atmos Chem 44:23–37. https://doi.org/10.1023/A:1022159910667

Economic Research Institute for ASEAN and East Asia (2022) Forecast of biomass demand potential in Indonesia: seeking a business model for wood pellets. Report, Jakarta

Purnomo GA, Mitchell KJ, O’connor S, Kealy S, Taufik L, Schiller S et al (2021) Mitogenomes reveal two major influxes of Papuan ancestry across wallacea following the last glacial maximum and austronesian contact. Genes 12:965. https://doi.org/10.3390/GENES12070965

Ministry of Energy and Mineral Resources (2022) Handbook of Energy & Economy Statistics of Indonesia 2021. Jakarta

Sambodo MT, Yuliana CI, Hidayat S, Novandra R, Handoyo FW, Farandy AR et al (2022) Breaking barriers to low-carbon development in Indonesia: deployment of renewable energy. Heliyon 8:e09304. https://doi.org/10.1016/J.HELIYON.2022.E09304

IESR (Institute for Essential Services Reform) (2022) Indonesia Energy Transition Outlook 2022. Jakarta

IESR (2021) Indonesia Energy Transition Outlook 2021: Tracking Progress of Energy Transition in Indonesia. Jakarta

Zaki M, Mamat R, Susanto H (2020) Potential and utilization of biomass for heat energy in Indonesia: a review. Int J Sci Technol Res 9:331–344

Simangunsong BCH, Sitanggang VJ, Manurung EGT, Rahmadi A, Moore GA, Aye L et al (2017) Potential forest biomass resource as feedstock for bioenergy and its economic value in Indonesia. For Policy Econ 81:10–17. https://doi.org/10.1016/J.FORPOL.2017.03.022

Rhofita EI, Rachmat R, Meyer M, Montastruc L (2022) Mapping analysis of biomass residue valorization as the future green energy generation in Indonesia. J Clean Prod 354:131667. https://doi.org/10.1016/J.JCLEPRO.2022.131667

ERIA (2022) Forecast of biomass demand potential in Indonesia seeking a business model for wood pellets. Jakarta

Hariana, Prabowo, Hilmawan E, Milky Kuswa F, Darmawan A, Aziz M (2022) A comprehensive evaluation of cofiring biomass with coal and slagging-fouling tendency in pulverized coal-fired boilers. Ain Shams Eng J 14:101499. https://doi.org/10.1016/j.asej.2022.102001

Suntana AS, Vogt KA, Turnblom EC, Upadhye R (2009) Bio-methanol potential in Indonesia: forest biomass as a source of bio-energy that reduces carbon emissions. Appl Energy 86:S215–S221. https://doi.org/10.1016/J.APENERGY.2009.05.028

Economic Research Institute for ASEAN and East Asia (2020) Energy Outlook and Energy Saving Potential in East Asia 2020. Jakarta

NEDO (2020) Study of Biomass Potential for Energy Use in Indonesia. Bangkok

Stich J, Ramachandran S, Hamacher T, Stimming U (2017) Techno-economic estimation of the power generation potential from biomass residues in Southeast Asia. Energy 135:930–942. https://doi.org/10.1016/J.ENERGY.2017.06.162

Lohman DJ, de Bruyn M, Page T, von Rintelen K, Hall R, Ng PKL et al (2011) Biogeography of the Indo-Australian archipelago. Annu Rev Ecol Evol Syst 42:205–226. https://doi.org/10.1146/ANNUREV-ECOLSYS-102710-145001

Voigt M, Supriatna J, Deere NJ, Kastanya A, Mitchell SL, Rosa IMD et al (2021) Emerging threats from deforestation and forest fragmentation in the Wallacea centre of endemism. Environ Res Lett 16:094048. https://doi.org/10.1088/1748-9326/AC15CD

Hamilton R, Stevenson J, Li B, Bijaksana S (2019) A 16,000-year record of climate, vegetation and fire from Wallacean lowland tropical forests. Quat Sci Rev 224:105929. https://doi.org/10.1016/J.QUASCIREV.2019.105929

Ariane Cosiaux (2014) Local uses of tree species and contribution of mixed tree gardens to livelihoods in saleman: village near Manusela National Park, Seram Island, Maluku (Indonesia). Cifor, Bogor Barat. https://doi.org/10.17528/CIFOR/004857

Widyani R, Nilamcaya M, Iftitah D (2022) The benefits of indonesian spices for livestock health as a legacy of our ancestors local wisdom. IOP Conf Ser Earth Environ Sci 1020:012032. https://doi.org/10.1088/1755-1315/1020/1/012032

Ariefrahman (2014) Subregions in the biogeography of the Wallacea region. https://en.wikipedia.org/wiki/Wallacea. Accessed 25 Jan 2023

Lu D, Batistella M, Moran E (2005) Satellite estimation of aboveground biomass and impacts of forest stand structure. Photogramm Eng Remote Sensing 71:967–974. https://doi.org/10.14358/PERS.71.8.967

Li Y, Li M, Li C, Liu Z (2020) Forest aboveground biomass estimation using Landsat 8 and Sentinel-1A data with machine learning algorithms. Sci Rep 10:1–12. https://doi.org/10.1038/s41598-020-67024-3

Turton AE, Augustin NH, Mitchard ETA (2022) Improving estimates and change detection of forest above-ground biomass using statistical methods. Remote Sens 14:4911. https://doi.org/10.3390/rs14194911

Lechner AM, Foody GM, Boyd DS (2020) Applications in remote sensing to forest ecology and management. One Earth 2:405–412. https://doi.org/10.1016/J.ONEEAR.2020.05.001

Rudiastuti AW, Yuwono DM, Niendyawati, Pramono GH, Rahmanto BD (2016) Overview of national thematic data integration (an experience on one map mangrove Sulawesi). IOP Conf Ser Earth Environ Sci 47:012012. https://doi.org/10.1088/1755-1315/47/1/012012

Propastin P (2013) Large-scale mapping of aboveground biomass of tropical rainforest in Sulawesi, Indonesia, using Landsat ETM+ and MODIS data. 50:633–651. https://doi.org/10.1080/15481603.2013.850305

Almulqu AA, Boonyanuphap J (2018) Aboveground biomass in tropical dry forest at Rote Ndao Regency, East Nusa Tenggara Province, Indonesia. 26:9–62

Wiloso EI, Setiawan AAR, Prasetia H, Muryanto Wiloso AR, Subyakto, et al (2020) Production of sorghum pellets for electricity generation in Indonesia: a life cycle assessment. Biofuel Res J 7:1178–94. https://doi.org/10.18331/BRJ2020.7.3.2

JICA (2000) Situation of Renewable Energy. Jakarta

National Electricity Company (2021) Rencana Usaha Penyediaan Tenaga Listrik (RUPTL) 2021–2030. Jakarta

Budhijanto W, Ariyanto T, Cahyono RB (2019) Bioenergy potential from agricultural residues and industrial wastes in Indonesia. Journal of Smart Processing 8:253–259. https://doi.org/10.7791/jspmee.8.253

Saladin Islami M, Mochamad A, Almitra DL (2020) Renewables cities and regions roadmap initial status. Initial Status Report of Deep-Dive Region Initial Status Report of Deep-Dive Region: West Nusa Tenggara Province. Jakarta

Pusat Studi Energi (2011) Biofuel Dari Biomassa. https://pse.ugm.ac.id/biofuel-dari-biomassa/. Accessed 21 Dec 2022

Haryana A (2019) Development of biomass energy usage in the household sector and its impact on LPG subsidy expenses and poor family health. Jakarta

Alawad I, Ibrahim H (2022) Pretreatment of agricultural lignocellulosic biomass for fermentable sugar: opportunities, challenges, and future trends. Biomass Convers Biorefinery 2022(1):1–29. https://doi.org/10.1007/S13399-022-02981-5

Chang SH (2014) An overview of empty fruit bunch from oil palm as feedstock for bio-oil production. Biomass Bioenergy 62:174–181. https://doi.org/10.1016/J.BIOMBIOE.2014.01.002

Ahmad ZS (2016) Characterization of meranti wood sawdust and removal of lignin content using pre-treatment process. Nat Conf Postgrad Res 598–606

Jackson MG (1977) Review article: The alkali treatment of straws. Anim Feed Sci Technol 2:105–130. https://doi.org/10.1016/0377-8401(77)90013-X

Hu G, Heitmann JA, Rojas OJ (2008) Feedstock pretreatment strategies for producing ethanol from wood, bark, and forest residues. Bioresources 3:270–294. https://doi.org/10.15376/biores.3.1.270-294

de Holanda PV, Lima RM, Costa ABS, de Sousa RC (2023) Drying of poultry manure for biomass applications in the combustion. Biomass Convers Biorefin 1:1–11. https://doi.org/10.1007/S13399-023-04001-6/FIGURES/4

Zhang X, Li C, Qu J, Guo Q, Huang K (2019) Cotton stalk activated carbon-supported Co–Ce–B nanoparticles as efficient catalysts for hydrogen generation through hydrolysis of sodium borohydride. Carbon Resour Convers 2:225–232. https://doi.org/10.1016/J.CRCON.2019.11.001

Al Afif R, Pfeifer C (2022) Biochemical methane potential of three-phase olive mill solid waste: influence of temperature and supplemental enzymes. Carbon Resour Convers 5:248–54. https://doi.org/10.1016/J.CRCON.2022.07.002

Al Afif R, Pfeifer C (2021) Enhancement of methane yield from cotton stalks by mechanical pre-treatment. Carbon Resour Convers 4:164–8. https://doi.org/10.1016/J.CRCON.2021.04.003

Matveeva AG, Patrakov YF, Sechin AI, Plyusnin PE, Kuznetsov AV, Podgorbunskikh EM et al (2023) Co-milling as a synergy factor for co-firing. A case study of wood/coal blends. Carbon Resour Convers 6:51–7. https://doi.org/10.1016/J.CRCON.2022.11.001

Peters J, May J, Ströhle J, Epple B (2020) Flexibility of CFB combustion: an investigation of Co-combustion with biomass and RDF at part load in pilot scale. Energies 13:4665. https://doi.org/10.3390/EN13184665

Wang X, Rahman ZU, Lv Z, Zhu Y, Ruan R, Deng S et al (2021) Experimental study and design of biomass co-firing in a full-scale coal-fired furnace with storage pulverizing system. Agronomy 11:810. https://doi.org/10.3390/AGRONOMY11040810

Reza AM, Susetyo MA, Juangsa FB (2021) Biomass Co-firing Effect on Coal Feeder and Draught Plant for 50 MW Class CFB Boiler Type CFPP. Proceedings 113–118. https://doi.org/10.1109/ICT-PEP53949.2021.9601047

McKendry P (2002) Energy production from biomass (part 2): conversion technologies. Bioresour Technol 83:47–54. https://doi.org/10.1016/S0960-8524(01)00119-5

Ke X, Zhang Y, Liu X, Wu Y, Huang Z, Zhang M et al (2022) Development of biomass-fired circulating fluidized bed boiler with high steam parameters based on theoretical analysis and industrial practices. J Energy Inst 105:415–423. https://doi.org/10.1016/J.JOEI.2022.10.011

Areeprasert C, Chanyavanich P, Ma D, Shen Y, Yoshikawa K (2017) Effect of hydrothermal treatment on co-combustion of paper sludge with coal: thermal behavior, NO emissions, and slagging/fouling tendency. Biofuels 8:187–196. https://doi.org/10.1080/17597269.2016.1215071

Novianti S, Nurdiawati A, Zaini IN, Sumida H, Yoshikawa K (2016) Hydrothermal treatment of palm oil empty fruit bunches: an investigation of the solid fuel and liquid organic fertilizer applications. Biofuels 7:627–636. https://doi.org/10.1080/17597269.2016.1174019

Ruksathamcharoen S, Chuenyam T, Ajiwibowo MW, Yoshikawa K (2019) Thermogravimetric analysis of combustion characteristics and kinetics of hydrothermally treated and washed empty fruit bunch. Biofuels 12:977–986. https://doi.org/10.1080/17597269.2018.1564482

Kim HJ, Park C, Nepal R, Oh SC (2021) Hydrothermal Treatment of Empty Fruit Bunches to Enhance Fuel Characteristics. Energies 14:1467. https://doi.org/10.3390/EN14051467

Parshetti GK, Quek A, Betha R, Balasubramanian R (2014) TGA–FTIR investigation of co-combustion characteristics of blends of hydrothermally carbonized oil palm biomass (EFB) and coal. Fuel Process Technol 118:228–234. https://doi.org/10.1016/J.FUPROC.2013.09.010

Darmawan A, Budianto D, Aziz M, Tokimatsu K (2017) Retrofitting existing coal power plants through cofiring with hydrothermally treated empty fruit bunch and a novel integrated system. Appl Energy 204:1138–1147. https://doi.org/10.1016/j.apenergy.2017.03.122

Economic Research Institute for ASEAN and East Asia (2018) Study on the Biomass Coal Co-Combustion. Jakarta

Terry LM, Li C, Chew JJ, Aqsha A, How BS, Loy ACM et al (2021) Bio-oil production from pyrolysis of oil palm biomass and the upgrading technologies: a review. Carbon Resour Convers 4:239–250. https://doi.org/10.1016/j.crcon.2021.10.002

Okoroigwe Edmund C, Li Z (2015) Bio-oil yield potential of some tropical woody biomass. J Energ South Afr 26:33–41

Vuppaladadiyam AK, Vuppaladadiyam SSV, Awasthi A, Sahoo A, Rehman S, Pant KK et al (2022) Biomass pyrolysis: A review on recent advancements and green hydrogen production. Bioresour Technol 364:128087. https://doi.org/10.1016/J.BIORTECH.2022.128087

Jha S, Nanda S, Acharya B, Dalai AK (2022) A review of thermochemical conversion of waste biomass to biofuels. Energies 15:6352. https://doi.org/10.3390/en15176352

Azeez AM, Meier D, Odermatturgen, Willner T (2010) Fast pyrolysis of African and European lignocellulosic biomasses using Py-GC/MS and fluidized bed reactor. J Anal Appl Pyrolysis 24:2078–2085. https://doi.org/10.1021/ef9012856

Snyder BF, Brian Snyder CF (2019) Costs of biomass pyrolysis as a negative emission technology: a case study. Int J Energy Res 43:1232–1244. https://doi.org/10.1002/ER.4361

Zhao M, Park A-HA, Zhao X, Hui Zhou AB, Singh VSCD, Zhao MAB et al (2017) Biomass-based chemical looping technologies: the good, the bad and the future. Energy Environ Sci 10:1885. https://doi.org/10.1039/c6ee03718f

Vassilev SV, Baxter D, Andersen LK, Vassileva CG (2013) An overview of the composition and application of biomass ash. Part 1. Phase–mineral and chemical composition and classification. Fuel 105:40–76. https://doi.org/10.1016/J.FUEL.2012.09.041

Kobayashi N, Fan LS (2011) Biomass direct chemical looping process: a perspective. Biomass Bioenergy 35:1252–1262. https://doi.org/10.1016/J.BIOMBIOE.2010.12.019

Gerbens-Leenes W, Hoekstra AY, van der Meer TH (2009) The water footprint of bioenergy. Proc Natl Acad Sci USA 106:10219–10223. https://doi.org/10.1073/PNAS.0812619106/SUPPL_FILE/0812619106SI.PDF

Kirtay E (2011) Recent advances in production of hydrogen from biomass. Energy Convers Manag 52:1778–1789. https://doi.org/10.1016/J.ENCONMAN.2010.11.010

Basu P (2013) Biomass gasification and pyrolysis: practical design and theory. Biomass Gasification Pyrolysis, 2nd edn. Academic Press. https://doi.org/10.1016/C2009-0-20099-7

Walling E, Babin A, Vaneeckhaute C (2019) Nutrient and carbon recovery from organic wastes. Springer, Biorefinery 351–373. https://doi.org/10.1007/978-3-030-10961-5_14

Darmawan A, Aziz M (2022) Process and products of biomass conversion technology. Innovative Energy Conversion from Biomass Waste. Elsevier pp 25–60. https://doi.org/10.1016/B978-0-323-85477-1.00004-X

Tuan PD, Minh Quan L, Nhi VT, Huong HM, Phung LTK, Feng D (2022) Enrichment of hydrogen in product gas from a pilot-scale rice husk updraft gasification system. Carbon Resour Convers 5:231–239. https://doi.org/10.1016/J.CRCON.2022.07.003

Wang X, Chen Q, Zhu H, Chen X, Yu G (2023) In-situ study on structure evolution and gasification reactivity of biomass char with K and Ca catalysts at carbon dioxide atmosphere. Carbon Resour Convers 6:27–33. https://doi.org/10.1016/J.CRCON.2022.10.002

Chan YH, Cheah KW, How BS, Loy ACM, Shahbaz M, Singh HKG et al (2019) An overview of biomass thermochemical conversion technologies in Malaysia. Sci Total Environ 680:105–123. https://doi.org/10.1016/J.SCITOTENV.2019.04.211

Shahbaz M, AlNouss A, Ghiat I, Mckay G, Mackey H, Elkhalifa S et al (2021) A comprehensive review of biomass based thermochemical conversion technologies integrated with CO2 capture and utilisation within BECCS networks. Resour Conserv Recycl 173:105734. https://doi.org/10.1016/J.RESCONREC.2021.105734

Liu S, Xing Y, Chen H, Tang P, Jiang J, Tang S et al (2017) Sustainable reactors for biomass conversion using pyrolysis and fermentation. Encyclopedia of Sustainable Technologies. Elsevier pp 541–552. https://doi.org/10.1016/B978-0-12-409548-9.10245-3

Wang Z, Peng X, Xia A, Shah AA, Huang Y, Zhu X et al (2022) The role of machine learning to boost the bioenergy and biofuels conversion. Bioresour Technol 343:126099. https://doi.org/10.1016/J.BIORTECH.2021.126099

Hameed S, Sharma A, Pareek V, Wu H, Yu Y (2019) A review on biomass pyrolysis models: Kinetic, network and mechanistic models. Biomass Bioenergy 123:104–122. https://doi.org/10.1016/J.BIOMBIOE.2019.02.008

Khan M, Raza Naqvi S, Ullah Z, Ali Ammar Taqvi S, Nouman Aslam Khan M, Farooq W et al (2023) Applications of machine learning in thermochemical conversion of biomass-a review. Fuel 332:126055. https://doi.org/10.1016/J.FUEL.2022.126055

Leng L, Zhang W, Liu T, Zhan H, Li J, Yang L et al (2022) Machine learning predicting wastewater properties of the aqueous phase derived from hydrothermal treatment of biomass. Bioresour Technol 358:127348. https://doi.org/10.1016/J.BIORTECH.2022.127348

Aghaaminiha M, Mehrani R, Reza T, Sharma S (2021) Comparison of machine learning methodologies for predicting kinetics of hydrothermal carbonization of selective biomass. Biomass Convers Biorefin 1:1–10. https://doi.org/10.1007/S13399-021-01858-3/FIGURES/8

Gopirajan PV, Gopinath KP, Sivaranjani G, Arun J (2023) Optimization of hydrothermal liquefaction process through machine learning approach: process conditions and oil yield. Biomass Convers Biorefin 13:1213–1222. https://doi.org/10.1007/S13399-020-01233-8/TABLES/1

Li J, Li L, Tong YW, Wang X (2022) Understanding and optimizing the gasification of biomass waste with machine learning. Green Chem Eng. https://doi.org/10.1016/J.GCE.2022.05.006

Alabdrabalnabi A, Gautam R, Mani Sarathy S (2022) Machine learning to predict biochar and bio-oil yields from co-pyrolysis of biomass and plastics. Fuel 328:125303. https://doi.org/10.1016/J.FUEL.2022.125303

Huang Z, Manzo M, Xia C, Cai L, Zhang Y, Liu Z et al (2022) Effects of waste-based pyrolysis as heating source: meta-analyze of char yield and machine learning analysis. Fuel 318:123578. https://doi.org/10.1016/J.FUEL.2022.123578

Wei H, Luo K, Xing J, Fan J (2022) Predicting co-pyrolysis of coal and biomass using machine learning approaches. Fuel 310:122248. https://doi.org/10.1016/J.FUEL.2021.122248

Xiao J, Liu C, Ju B, Xu H, Sun D, Dang Y (2021) Estimation of in-situ biogas upgrading in microbial electrolysis cells via direct electron transfer: two-stage machine learning modeling based on a NARX-BP hybrid neural network. Bioresour Technol 330:124965. https://doi.org/10.1016/J.BIORTECH.2021.124965

Antwi P, Li J, Boadi PO, Meng J, Shi E, Deng K et al (2017) Estimation of biogas and methane yields in an UASB treating potato starch processing wastewater with backpropagation artificial neural network. Bioresour Technol 228:106–115. https://doi.org/10.1016/J.BIORTECH.2016.12.045

Sydney EB, Duarte ER, Martinez Burgos WJ, de Carvalho JC, Larroche C, Soccol CR (2020) Development of short chain fatty acid-based artificial neuron network tools applied to biohydrogen production. Int J Hydrogen Energ 45:5175–5181. https://doi.org/10.1016/J.IJHYDENE.2019.10.128

Althuri A, Gujjala LKS, Banerjee R (2017) Partially consolidated bioprocessing of mixed lignocellulosic feedstocks for ethanol production. Bioresour Technol 245:530–539. https://doi.org/10.1016/J.BIORTECH.2017.08.140

Oneil E, Lippke B (2009) Eastern Washington biomass accessibility. Seattle, Washington

Rosillo-Calle F, de Groot PL, Hemstock S, Woods J (2015) The biomass assessment handbook. Earthscan, London

The Japan Institute of Energy (2008) Panduan untuk Produksi dan Pemanfaatan Biomassa. Tokyo

Trømborg E, Ranta T, Schweinle J, Solberg B, Skjevrak G, Tiffany DG (2013) Economic sustainability for wood pellets production - a comparative study between Finland, Germany, Norway, Sweden and the US. Biomass Bioenerg 57:68–77. https://doi.org/10.1016/j.biombioe.2013.01.030

Aberilla JM, Gallego-Schmid A, Azapagic A (2019) Environmental sustainability of small-scale biomass power technologies for agricultural communities in developing countries. Renew Energy 141:493–506. https://doi.org/10.1016/j.renene.2019.04.036

Patel M, Zhang X, Kumar A (2016) Techno-economic and life cycle assessment on lignocellulosic biomass thermochemical conversion technologies: a review. Renew Sustain Energy Rev 53:1486–1499. https://doi.org/10.1016/J.RSER.2015.09.070

Ashter SA (2018) Environmental impact of biomass conversion. Technology and Applications of Polymers Derived from Biomass. Elsevier pp 249–259. https://doi.org/10.1016/b978-0-323-51115-5.00013-x

Abbasi T, Abbasi SA (2010) Biomass energy and the environmental impacts associated with its production and utilization. Renew Sustain Energy Rev 14:919–937. https://doi.org/10.1016/j.rser.2009.11.006

Hooijer A, Silvius M, Wösten H, Page S (2006) PEAT-CO2, assessment of CO2 emissions from drained peatlands in SE Asia. Delft Hydraulics report Q3943

Acknowledgements

This work was supported by the British Council COP26 Trilateral Research Initiative grant under the project “Scaling-up Indonesian Bioenergy Potential through Assessment of Wallacea’s Plant Species: Data-Driven Energy Harvesting and Community-Centred Approach” and “Consolidating Data-Driven Wallacea’s Forest Bioenergy Utilisation Route via Stakeholder Empowerment for Sustainable Forest Ecosystem.” TA acknowledged the support from the GB Sasakawa Foundation that facilitated the visit to The University of Tokyo.

Funding

Open access funding provided by The University of Tokyo. The British Council COP26 Trilateral Research Initiative grant under the project “Scaling-up Indonesian Bioenergy Potential through Assessment of Wallacea’s Plant Species: Data-Driven Energy Harvesting and Community-Centred Approach” and “Consolidating Data-Driven Wallacea’s Forest Bioenergy Utilisation Route via Stakeholder Empowerment for Sustainable Forest Ecosystem.”

Author information

Authors and Affiliations

Contributions

AD: Conceptualization, writing, editing, Methodology. TA: Conceptualization, Supervision, Funding acquisition. ID: Methodology, writing, editing. S: Data curation, writing, editing. MA: Conceptualization, Supervision, writing, editing.

Corresponding author

Ethics declarations

Ethical approval

This article does not contain any studies with human participants or animals performed by the author.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• Wallacea is a meeting point between Asia and Australia with rich biodiversity.

• Biomass utilization in the Wallacea should be aligned with the national bioenergy policy.

• Biomass potential and suitable conversion technologies have been discussed.

• A matrix related to biomass feedstock and its utilization technology was proposed.

• Machine learning and optimization algorithms can be used to boost biomass use.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Darmawan, A., Asyhari, T., Dunggio, I. et al. Energy harvesting from tropical biomasses in Wallacea region: scenarios, technologies, and perspectives. Biomass Conv. Bioref. (2023). https://doi.org/10.1007/s13399-023-04223-8

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-023-04223-8