Abstract

This study investigated the influence of feedstock mixture on the fuel characteristics of briquettes produced from sawdust (SD), cornhusk (CH), and cassava peels (CP) for domestic and industrial applications. The feedstock was each studied singly and mixed in the ratio 30/70, 50/50, and 70/30 with the binder to feedstock ratio of 20:100 by mass for briquette production and characterization. The elemental and proximate analyses were carried out to evaluate fuel properties. The briquette structural arrangement was determined with the Scanning Electron Microscope and Energy Dispersive X-Ray Detector, while the functional groups was obtained from FTIR analyzer. A non-isothermal Coats-Redfern method was carried out to determine the activation energy and pre-exponential factors. The O/C and H/C ratios slightly decrease when the mixing ratio of sawdust with other feedstocks increased. The bonding of the briquette samples was enhanced by blending CH with other feedstocks, thereby improving the structural integrity of the mixed briquettes and closing the gaps and voids within and between particles. The highest infrared transmittance of C–H, OH, C–O, and C=C was found in SD briquette followed by CH and CP while CH briquette contained higher C–C. The activation energy of the briquettes varied between 39.70 and 60.76 kJ/mol. The hypothetical thermal plant analysis of the briquettes shows that mixed CH/CP and CH/SD respectively reduced the potential for CO2 and NO2 emissions. Furthermore, Ca, P, and K played the most significant role in the briquette’s agglomeration. The mixing of feedstocks for briquettes production has great fuel potential for heating applications.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The importance of clean and renewable energy to man cannot be overemphasized. The International Energy outlook (2016) stated that 78% of the total energy requirement of the world will continue to be supplied by fossil fuels until year 2040 [1]. These fossil fuels such as coal, diesel, and petrol, commonly used in meeting several human needs, pose serious threats to the environment with high global warming potential and emissions such as sulfur oxides, nitrogen oxides, carbon monoxide, and total organic compounds [2]; hence, there is a dire need for a viable replacement by biomass for energy applications.

According to FAOSTAT [3], on the average Nigeria produces 60 million tons of cassava tubers and 12 million tons of maize yearly out of which large quantities of wastes including cassava peels and cornhusk are generated. The upgrade of these biomass resources and sawdust to produce high-grade fuels with improved characteristics is the dream of many bioenergy producers and advocates of clean alternative fuel. Unfortunately, these wastes having the potential to absolutely replace fossils have limitations consequence of their low carbon content, heating value, and energy density [4]. These limitations could, however, be improved upon through feedstock mixture and densification [5,6,7,8].

Several researchers have generated briquettes from the mixture of processed agricultural wastes for energy production [9,10,11] and found the products very useful for applications. The admixture of different biomass feedstocks for briquette production was said to yield products with improved thermal qualities and better physical attribute through enhanced adhesion between the feedstock particles [6, 11, 12]. The densification of these processed and mixed agricultural wastes into briquettes is thus necessary for improved handling and end use heating applications [13].

A search of literature on biomass characterization presents a number of research works on the functional groups, morphological transformation, compositional attributes, and elemental modification of some biomass fuel for applications. For instance, Garba et al. [14] studied the compositional and elemental properties of groundnut shell, rice husk, and corncob wastes in their raw form. Lateef and Ogunsuyi [15] studied the surface chemical groups and morphological characterization of Jatropha curcas L. Benavente and Fullana [16] also studied the elemental analysis and Fourier transform infrared spectroscopy of olive mill waste to evaluate the effect of torrefaction on physical and thermal properties of olive mill waste.

Meanwhile, there is dearth of studies on the FTIR spectroscopy, microstructural, thermogravimetric, and elemental distribution of raw briquette blends produced from low valued cassava peels, sawdust, and cornhusk wastes. These analyses are vital for the assessment of the thermal stability, organic and inorganic elemental composition, functional groups, and the degradation levels of the hemicelluloses and cellulose fractions inherent in the briquettes through torrefaction. Moreover, the knowledge of the emission potential and the kinetics of the thermal decomposition of the briquettes can be useful for designing pyrolysis and gasification plant and useful in mathematical modeling of the plant for process condition optimization. This would provide the necessary information as regards the characteristics and performance of briquettes during heating applications.

From the above context, the aim of this present study was to investigate the impact of the admixture of cassava peels (CP), sawdust (SD), and cornhusk (CH) wastes biomass feedstock on the fuel characteristics of briquettes that would be produced by combining them in pairs as CH/CP, CH/SD, and CP/SD at different blending ratios. This study therefore intended to formulate the ideal feedstock blend from these ternary stuffs that would be suitable and viable for domestic and industrial heating applications. This is motivated by the large amount of these agro-wastes generated in the tropics and the drive to turn them to positive use for energy production.

2 Materials and methods

2.1 Sample description

Three different agricultural wastes, cornhusk, cassava peels, and sawdust, were considered the feedstock. The cornhusk sample was acquired at the teaching and research farm, Federal University of Agriculture, Abeokuta, Nigeria. The cassava peel sample was obtained in Fami-Alabata, while sawdust was obtained from Osiele sawmill in Abeokuta, Nigeria. The CH sample was dried to the MC of 8.89% in an oven until it becomes crispy, while the CP and SD were sundried to the MC of 12.57 and 9.91% respectively. The obtained corn husk and cassava peels were grounded in a hammer mill (model HAM-002, Capsfeed Limited, Nigeria) with power rating of 18.5 kW and 2000 kg/h capacity and sieved at the particle size of less than 1.18 mm with Gilson 8 in/200 mm Vibratory Sieve Shaker (model SS-10). The analysis of the sieve is presented in the Appendix. The ground samples of cornhusk, cassava peels, sawdust, and their blends, shown in Fig. 1, were thereafter stored in a desiccator to avoid the absorption of moisture for subsequent experiments.

2.2 Production of briquettes

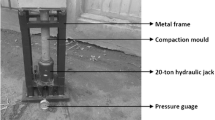

A piston type briquetting machine designed and fabricated by the authors was used to produce cylindrical briquette with a diameter of 50 mm and a height of 100 mm from cornhusk, cassava peels, sawdust, and their binary blends at different ratios. The details of its specifications and operation can be seen in Akogun and Waheed [17]. The double constituent mixture consisted of 30/70, 50/50, and 70/30 by weight ratio of two agricultural wastes each from cornhusk, cassava peels, and sawdust. The ratios were chosen to study the relative effect of feedstock quantity on the fuel properties of the briquettes. The feedstocks were blended uniformly with water and cassava starch which serves as the binder at the binder to feedstock ratio of 1:5 by mass. After feedstock mixing, the blends were weighed, using the electronic digital weighing balance HD series (HUAZHI, China) model HD-B30000 which has a maximum weighing capacity of 3 kg and accuracy of \(\pm\) 0.1 g, before pouring it into the molds. The mixture in the mold was compressed at the ambient temperature and pressure of 15 MPa and 5-min dwell time. The briquettes were ejected gently and sun-dried for 3 weeks to reduce the moisture content below 12%wb which is the recommended moisture content for safe storage of briquettes to prevent biodegradation, spontaneous combustion, and bacteria attack [18, 19]. This briquetting process was carried out according to the procedure of Obi and Okongwu [20] and Kpalo et al. [9]. The fuel characteristics of the produced sun-dried briquettes were analyzed for scanning electron microscopy, thermogravimetric analysis, Energy Dispersive X-ray Spectrum, proximate, elemental analysis such as carbon, hydrogen, sulfur, nitrogen, and oxygen content, and Fourier Transform Infrared Spectroscopy, in line with standard procedures. The CO2 and NO2 emissions potential was estimated from the briquette samples using a hypothetical 1 MW power plant.

2.3 Briquette characteristics

S3Chemical characterization

Proximate analysis such as the fixed carbon, moisture content, volatile matter content, and ash content of the samples was studied according to the procedure of Akogun et al. [6]. The Flash 2000 CHNS/O Elemental Analyzer (Thermo Fisher Scientific, USA; Serial No. 2009.F0002) was used for the determination of the carbon, hydrogen, and nitrogen content present in each briquette sample according to ASTM D3176-15 [21]. The oxygen content was obtained using Eq. (1).

Moreover, the trace elements and ash chemical constituents in fuel samples were analyzed with Energy Dispersive X-ray Spectrum (EDS) according to the procedure of Jyothsna et al. [22] and Adegoke et al. [23]. The higher calorific values of samples were obtained using oxygen bomb calorimeter XRY-1A model (Wincom, Hunan, China) in line with ASTM E711-87 [24] standard.

2.4 Structural characterization

The structural arrangement of the briquette samples was determined using Tescan Vega 3 Scanning Electron Microscope coupled with an Oxford Energy Dispersive X-Ray Detector (Czech Republic) model 51-XMX1010. The microscope was operated with an acceleration voltage of 20 kV, beam intensity of 17 W/m2, and the scanning speed of 10 \(\mathrm{\mu s}\)/pixel using Secondary Electron Detector (SED). The samples were first carbon coated with Agar Turbo Carbon Coater to improve their conductivity. Here, two-sided carbon tape was fixed to a SEM sample stub while the briquette powder was sprinkled onto the surface. A carbon coating was applied at 100 A, and the sample was examined in the SEM chamber. A SEM micrograph of each briquette samples in powdered form was generated.

The functional groups that present the surface chemistry of the raw briquettes were obtained from FTIR analyzer, PerkinElmer Frontier FTIR Spectrometer 3. In this study, dried and ground briquette sample (about 0.7 mg) was mixed with potassium bromide (about 70 mg) that was previously oven-dried to reduce interferences from water. Each spectrum was recorded in the wavenumber range from 4000 to 500 cm−1 with a resolution of 2 cm−1. The response of the fuel to its fraction of volatile components was studied by monitoring the weight change or mass loss that occurs as the sample is heated at constant rate using a thermogravimetric analyzer (TGA) Model SDT Q600 V20.9 Build 20 Universal V4.5A (TA Instruments, New Castle, DE, USA; Nbr 961001.901). That is, the changes in mass in response to the increase in temperature, through slow pyrolysis and combustion, are recorded. The TGA dries the samples at 105 °C during the first phase to ensure that the moisture in the samples is acceptable before dynamic runs with constant heating rate can begin. The briquette sample of 5 mg was heated at 35 °C on a 1-min hold time and ramped up to 1000 °C at the heating rate and nitrogen flow of 12.5 °C min−1 and 20 mL min−1 respectively in line with Bai et al. [25]. All tests were carried out three times, and the average results presented.

2.5 Kinetic theory

There are several coal-fired thermal engines in use whose operations and performance are constrained by the combustion properties of coal [11]. The determination of kinetic parameters from biomass fuel system is therefore essential to give adequate information for the design and optimization of the combustion system for heating applications. A non-isothermal evaluation, called the Coats-Redfern method, was carried out to determine the activation energy in line with Coats and Redfern [26]. The samples are decomposed by thermal degradation during the process of combustion. The rate of conversion is described by the kinetic equation expressed as

where \(dX/dt\), k(T), and \(f(X)\) are the fuel conversion, rate of conversion, reaction rate constant which is temperature dependent, and the function of the reaction mechanism, respectively.

The conversion is determined using

where \({M}_{0}\) denotes the initial mass of the fuel, \({M}_{T}\) the mass at temperature T, and \({M}_{R}\) the residual mass at the end of heating process, all in mg.

The rate constant k that is temperature dependent was determined using the Arrhenius relation

where A is the pre-exponential factor (min−1), \({E}_{a},\) the activation energy (kJ mol−1), R, the universal gas constant, 8.314 (JK−1 mol−1), and T, the absolute temperature (K).

Thermogravimetric analysis was used to conduct a linear heating program in non-isothermal kinetics. Inserting Eq. (4) and \(\upbeta =dT/dt\) which is defined as the constant rate of heating in Eq. (2) yields

The solid reaction mechanism was described with Coats-Redfern method, assuming a reaction of order n and the reaction model \(f\left(X\right)={(1-X)}^{n}\). In line with Lu et al. [27], the application of variable separation and integration gives Eq. (6).

where \(g\left(X\right)\) is the integral conversion function. The righthand side term of Eq. (6) is same as that of Eq. (7).

Applying logarithms to both sides of Eq. (7) yields

It should be noted that in most reactions, \({E}_{a}/RT\gg 1,\) and this implies that the term \(2RT/{E}_{a}\) is close to zero so that the term \(\left(1-2RT/{E}_{a}\right)\) reduces to unity as shown in Eqs. (10) and (11).

The activation energy, (\({E}_{a})\), is determined by plotting \(In \left[\left(-In(1-X)\right)/{T}^{2}\right]\) for \(n=1\) or \(In \left[\left(1-In({1-X)}^{1-n})\right)/{T}^{2}(1-n)\right]\) for \(n\ne 1\) against \(1/T\) which yields a straight line graph having a slope of \({-E}_{a}/R.\)

2.6 Emission potential of the briquettes

The emissions obtained from the combustion of single and mixed briquettes from cornhusk, sawdust and cassava peel wastes were estimated from their elemental characteristics and gross higher calorific value. A hypothetical biomass fired power plant of capacity, P (J/s), would produce 3600P energy unit in 1 h. The potential carbon (IV) oxide and nitrogen (IV) oxide emissions are derived as follows:

The quantity of biomass fuel, Mf (kg/h), to generate 3600P is obtained as

where HCV (J/kg) is the fuel higher calorific value.

The mass of CO2, \({M}_{CO2}\) (kg/h) that would be produced,

where 12 and 44 are the molar mass of C and CO2 respectively.

The mass of N2, \({M}_{N2}\) (kg/h) that would be produced,

where 14 and 46 are the molar mass of N and NO2 respectively. The percentage carbon and nitrogen contents of the fuel are denoted by C% and N% respectively.

3 Results and discussion

3.1 Proximate analysis

Information on the proximate, elemental, higher calorific value and atomic ratio of briquette are vital for fuel combustion in coal thermal plants and should therefore be adequately investigated during process design. The feedstock mixing is considered during the process parameter selection because certain elements in some fuels could be toxic to the environment if their compositions are high, but their harm could be reduced by mixing them with other environmentally friendly fuels. Feedstock mixing is therefore one of the major parameters that help to improve biofuel quality in terms of their properties. The suitability of the briquettes from agricultural wastes including the CH, SD, and CP and their blends was studied in this work. Table 1 shows the proximate analysis in terms of the MC, AC, VM, and FC for the single and mixed briquette samples from the CH, CP, and SD. For the single briquette samples, the MC, AC, VM, and FC were found to vary between \(8.50\pm 0.08\)-\(10.10\pm 0.08\)%, \(1.65\pm 0.08\)-\(9.85\pm 0.07\)%, \(62.70\pm 0.99\)-\(72.60\pm 1.63\)%, and \(17.35\pm 0.24\)-\(18.25\pm 0.43\)%, respectively. The SD displayed higher VM, the CP gave higher AC and MC while the CH exhibited higher FC. The results obtained in this study show an inverse relationship between the FC and VM. That is, when the FC increased, the VM decreased showing that the FC of a fuel is dependent on the values of the VM and AC. This result is consistent with the findings of Kumar et al. [28] in their study of the fuel properties of composite briquettes from dry leaves. A maximum ash content \(\le\) 10% and a minimum value \(\le\) 6% were recommended by ISO 17225-7 [29] standard for solid biomass. Sample B met the maximum ash content requirement, while the other briquette samples met the minimum values. The briquettes produced from the CH, SD, CP, and their blends would therefore not pollute the environment. Low ash concentration is most preferable for an efficient combustion system because it will not cause slagging. It is therefore anticipated that the briquettes produced from samples A-L except sample B would perform well in heating applications based on their ash content. The significance of the low ash content obtained in this study is that the briquettes can be good fuel for gasifiers and other thermal applications. The values of the moisture content obtained in this study are less than 12%wb which is consistent with the SS 18 71 20 [18] and DIN 51731 [19] standard for the moisture content of briquettes (i.e., \(MC\le 12\%wb)\). This is a safe moisture content to prevent biological decomposition of the briquette samples during storage and steam formation which could lead to explosion during combustion.

The moisture content obtained in this work compared well with that of Rezanian et al. [30] (66.27–80.3%) for water hyacinth and empty fruit bunches and Kpalo et al. [9] (74.67–79.30%) for blends of corncob and oil palm trunk bark. Higher VM is a sign of the readiness of the briquettes to ignite during combustion, and greater mass loss might be experienced during carbonization when the VM is high. It also shows that more energy is taken when the volatiles are burnt off before the release of heat energy [31]. After mixing, it was observed that the VM in samples D-L reduced except in samples G and H while the FC increased significantly. This indicates that samples D-L would combust with an increase burning rate while the amount of gaseous emission and smoky flames would also increase than those for samples G and H. This trend was in line with the results of Chungcharoen and Srisang [32] who observed that briquettes with higher VM experienced better combustion but with smoky blaze. Therefore, lower value of volatile matter presents briquettes of high-quality value thus making sample L (CP/SD—70/30) the most suitable for use based on this quality index.

3.2 Elemental analysis

The main elemental constituents of briquettes are carbon, nitrogen, hydrogen, oxygen, and sulfur. The elemental compositions of the single and mixed briquettes (samples A–L) are presented in Table 2. The carbon content determines the efficiency of a fuel for combustion and is an important parameter that presents any biomass usage for fuel purposes. The carbon content of the mixed samples (G–L) is higher than those for samples A and B but less than that of sample C. The carbon content for the mixed briquettes was the weighted average value of the individual single fuel briquettes blended. The higher value of carbon content in sample C could be due to the better fuel quality of SD briquettes than those of the CH and CP briquettes in terms of their higher calorific values and fixed carbon contents [33]. The mixed and unmixed feedstocks examined in this work are beneficial for combustion and heating applications because of their high carbon constituents. Carbon transforms to and is released mainly to the atmosphere as carbon (IV) oxide during combustion. Moreover, the higher calorific value of a fuel is reduced at low carbon value and high oxygen value [34]. The oxygen contents decreased in the mixed briquette samples compared to the unmixed, except in samples D–F (cornhusk and cassava peels briquette samples). This indicates that mixing SD with the other feedstocks significantly reduced the presence of oxygen content in the briquettes. Moreover, samples mixed with high percentage of the SD present the lowest content of nitrogen and would favor low NO2 emissions during combustion. Generally, the total carbon and hydrogen contents of lignin rich fuel are higher than 50% [35]. It has also been established that briquettes with high carbon content and low oxygen content are appropriate for energy applications [36].

3.3 Atomic ratio

Meanwhile, the ratios of H/C and O/C account for the suitability and efficiency of a fuel during combustion. Briquettes having low O/C and H/C atomic ratios will give less smoke, less CO2, and low moisture when burned, leading to increased combustion efficiency [37]. The O/C and H/C atomic ratios of samples A–L are presented in Table 2.

There was a reduction in the O/C and H/C atomic ratios with the increase in the mixing ratio of sawdust with other feedstocks as could be seen for the samples G, H, K, and L. These samples have higher value of carbon compared to other mixed briquette samples. The ratios of H/C and O/C obtained in this study ranged between 1.58–1.73 and 0.84–1.11 respectively. These are within the standard values for raw biomass which are in the range of 1.2–2.0 for H/C ratio and 0.04–0.8 for O/C ratio [11, 38, 39].

3.4 Higher calorific value

The CH, CP, and SD gave HCV of 12,270, 12,870, and 14,700 kJ/kg, respectively. The higher calorific value for SD was higher than that of the CP and CH briquettes implying that SD contained higher energy potential when compared with the CH and CP. The higher calorific values obtained for the blended briquettes were mostly the weighted average values of those for their root biomass and ranged between 12,410 kJ/kg (sample D) and 14,010 kJ/kg (sample J). The maximum heating value for the biomass blends is close to the ISO 17225-7 [29] recommended minimum requirement of 14,500 kJ/kg. The mixing of CH, CP, and SD feedstocks can be beneficial for improving the heating value of single agricultural biomass for fuel applications.

3.5 EDS analysis

The results presented so far have shown that mixing of the feedstock improves their briquette’s fuel quality and combustion properties. The Energy Dispersive X-ray Spectrum presented in Figure 2 shows that the briquettes from cassava peels, corn husk, sawdust, and their blends have varying ash chemical constituents. The major inorganic mineral compositions of the briquettes are Si, Ca, and K. The average K, Si, Ca, P, Fe, S, and Al concentration in the mixed briquettes was seen to have either increase or decrease than they were for the individual briquettes.

This agreed with the findings of Smith et al. [40] that the composition of these biomass changes when two or more biomasses are mixed. The mixing could result in the increase or a decrease in the constituents of the feedstock. The present results show that the concentration of K in the CP and CH was 1.3 but was 0.6 and 0.9 in the CH/SD (30/70) and CH/CP (30/70) briquettes, respectively due to mixing. A decrease in the inorganic mineral concentration of P (0.1) was, however, noticed in all the briquette samples when compared to the average inorganic constituents in the CH/CP (50/50). Moreover, the concentration of the inorganic ash composition in some of the mixed briquettes studied was close to that of the individual CP and CH briquettes. However, the composition of Si in the mixed briquettes of CH/CP (50/50) and CH/CP (70/30) was outrageously higher than the values of the individual feedstocks studied.

The EDS analysis of the various briquette samples shows that Si, Ca, and K are the major briquette agglomeration elements that play the most significant role during thermal process. The choice of a briquette for a given application depends on the operational requirements or use as each of these elements has its environmental and energy impact on the surroundings and the system.

3.6 Fourier transform infrared spectroscopy (FTIR) analysis

The functional groups of the briquette samples in accordance with the value of their wavelength and percentage transmittance were obtained from FTIR analysis. The infrared (IR) spectra of the briquette fuels are presented in Fig. 3A–D. Table 3 presents the possible compounds, functional groups, and the FTIR signal for the briquettes examined. The listing shows that the briquettes comprised alkene, aromatics, esters, ketone, and alcohol with varied functional groups such as C–C ranging from (700–400 cm−1), C–O (1050 cm−1), C=C (1632 cm−1), C=O stretching carbonyl and ketone (1722 cm−1), C–H stretching (2860–2970 cm−1), and OH ranging from 3600–3000 cm−1 [41, 42]. In Fig. 3A, the first infrared peak that occurred at 3329 cm−1 could be attributed to the hydroxyl (O–H) groups present in all the briquette samples. The highest infrared transmittance of OH, C=C, C–H, and C–O was found in the SD briquette followed by the CH and then CP, while the CH briquettes contained higher C–C. The effect of the feedstock mixing on the briquettes is shown in Fig. 3B–D. The IR transmittance for different functional groups especially for C–O stretching became sharper and more visible when the composition of cassava peels was increased (Fig. 3B, D). For the CH/SD (50/50) mixing ratio, the C–O stretching and C–H bending overlap the entire wavelength of the CH/SD (70/30) and CH/SD (30/70) as shown in Fig. 3C. The transmittance of the C–H stretching and C=C (aromatic) bending was found in the range of 97–100% followed by the OH stretching for all the IR spectra. The transmittance of the C–H stretching (2850–2921 cm−1), C=C, and C–O stretching on the other hand were lower. The transmittance of the C–H, C–C, C–O, and C=O stretching between the infrared band of 1018 and 1737 cm−1 is typical of the C–O–C asymmetrical stretching present in the lignin, cellulose, and hemicellulose [43]. Zhong et al. [44] remarked that coal particles formed rigid and strong briquettes because of the oxygen bridges which are attributed to the large functional groups containing oxygen and the C=C group. The spectral analysis of the briquette samples studied illustrates that the feedstock mixing slightly influenced the functional group peaks intensity.

3.7 SEM analysis

The integrity of the internal structure of the briquettes samples was studied by SEM to visualize the voids and gaps between particles. Figure 4 shows different gaps and voids between particles of the mixed and unmixed briquette samples at 100× magnification. It could be seen that briquettes from the CP, SD, CH/CP (70/30), and CH/SD (30/70) (Fig. 4B,C,F,J) present a dense and an agglomerated plate structure which indicates poor bonding and disintegrated internal structure. The bond of the polymers was enhanced for the briquette samples: the CH, CH/CP (30/70), CH/SD (30/70), CH/SD (50/50), and mixed SD and CP samples at varying composition (Fig. 4A,D,G,H,I,K,L). This is evident through the rough surface, improved structural integrity of the unmixed briquettes, and the closed gaps and voids within and between particles. These observations could be related to the biomass constituents such as hemicellulose, cellulose, and lignin of the feedstocks considered for briquette production. The strong impact of the feedstock mixture and binder in briquetting is reflected through the stacking of some of the mixed particles.

This stacking tendency helps the flow of the binder through the increase in the adhesive forces between the adjoining particles [45]. The cassava starch binder yielded mechanically more durable briquettes due to the enhanced flow of the binder. The roughness, agglomerated blocks, voids, and gaps in the briquette samples could be eliminated if these fuels were subjected to thermochemical transformation.

3.8 Thermogravimetric (TG) analysis

The TG weight loss against temperature curve obtained during the pyrolysis process for each briquette samples through the non-isothermal experiment is shown in Fig. 5. The thermal degradation process of the briquette sample is in 3 steps viz: dehydration, devolatilization, and carbonization [46]. These three steps are clearly demonstrated by the TG curves and are described as follows: the first step which involved the loss of water and low molecular weight volatiles occurs between room temperature and 190 \(^\circ{\rm C}\). The second stage involving the devolatilization phase of lignin, hemicelluloses, and cellulose ranged from 190 to 450 \(^\circ{\rm C}\). The breakdown of hemicelluloses and lignin was followed by the cellulose released volatile organic compounds. The second step ended with char formation consisting of the mixture of ash and fixed carbon obtained from the rest of the lignin degradation. There is an appreciable loss in weight during this stage. The third stage, dominated by the breakdown of lignin and carbonaceous solids with insignificant weight loss, occurs at temperatures above 450 \(^\circ{\rm C}\). It corresponds to the char oxidation when oxygen was injected. This step ends when ash only was obtained. It can be seen in Fig. 5a that the SD degraded faster than the CH and CP. The increase in the proportion of the SD in CH/SD and CP/SD briquettes hastened their degradation.

At the heating rate of 12.5 \(\mathrm{^\circ{\rm C} }/\mathrm{min}\), the heating of the particles of the briquettes ensued more gradually, thereby providing better heat transfer to the inside of and between particles. The CP briquettes have the lowest weight loss (i.e., highest residual weight), followed by the CH and SD, in that order. Consequently, the temperature that would be required to pyrolyze the CP to obtain the same weight loss with the other briquettes having higher weight loss such as the CH and SD briquettes would be greater. There was a decrease in the residual weight of the CH/SD and CP/SD briquettes with the increase in the proportion of the SD as can be seen in Fig. 5c, d. Generally, the weight loss could be increased, and the time required to reach the pyrolysis temperature reduced with the increase in the heating rates as observed by Quan et al. [47].

3.9 Reaction kinetics

The experimental data of TGA for the mixed and unmixed briquettes were used to plot fitting curves of G(\(X\)) defined as \(In \left[\left(-In(1-X)\right)/{T}^{2}\right]\) against \(1/T\) to generate a linear regression line to estimate the activation energy in line with Coats-Redfern method. A sample plot for 100% CH, CP, and SD is presented in Fig. 6 for temperature in the range 190 to 390 \(^\circ{\rm C}\). The activation energies, Ea, and pre-exponential factors, A, for all the samples (A–L) are presented in Table 4. The Ea varies within the range of 39.70 (which is for CP) and 60.76 (for SD), and ln(A) within 5.52 (for SD) and 9.17 (for CP). The values of these parameters for the other briquette blends fall in between these ranges. The CP was the most reactive among the samples. The R2 values of the briquettes obtained in this study are above 0.94, which shows good correlation of the data. The values of the activation energy and logarithms of the pre-exponential factor of 47.62 and 7.60 respectively obtained in this work for the raw CH are in close agreement with 48.47 and 6.56 obtained by Toptas et al. [48] for the raw corn stalk. Also, the value of the activation energy of 60.76 for the SD is close to 63.88 obtained by Lu et al. [27] for 75/25 coal/biomass blend. The activation energies for all the samples are slightly below 56.10 for lignite obtained by Samaksaman and Manatura [49]. These values would increase if the samples were subjected to some thermochemical pretreatment such as torrefaction or pyrolysis as observed in the work of Toptas et al. [48], Gao et al. [50], and Samaksaman and Manatura [49].

3.10 Emission potential of the briquettes

Equations (12)–(16) were used to determine the CO2 and NO2 emissions that would be generated by a 1-MW hypothetical power plant running on the briquette samples A–L by using their carbon and nitrogen contents presented in Table 2. The results of the emission potential of briquettes from cornhusk, sawdust, cassava peels, and their blends are presented in Table 5. The feedstock blend with the highest weight of CO2 per hour is CH/SD (30/70) (427.28 kg), and the lowest is CH/CP (70/30) (350.44 kg). The briquette samples: CH/SD (30/70), CH/SD (50/50), and CP/SD (70/30) yielded a higher amount of carbon (IV) oxide than the unmixed briquettes. The weight of nitrogen (IV) oxide of briquettes from cornhusk, cassava peels, and sawdust per hour were 5.69 kg, 10.85 kg, and 1.61 kg respectively. Cassava peel briquette will release higher amount of nitrogen (IV) oxide emission, followed by cornhusk and sawdust. Although the nitrous oxide emission was moderate, the potential for its formation largely depends on the amount of the CP composition present in briquette samples and the power plant operating conditions.

4 Conclusion

The use of cornhusk, cassava peels, sawdust, and their blends as fuel is a sustainable option in solving global warming and fuel shortage. This work has studied the fuel characteristics of CH, CP, SD briquettes, and their blends. The results show that the fuel properties of the CH and CP briquettes were enhanced by their blend with the SD. The CP/SD (70/30) briquettes displayed lowest volatile matter, the CH/SD (30/70) briquettes gave lower ash content and moisture content while the CP/SD (30/70) briquettes displayed higher fixed carbon. The higher calorific value of CP/SD (30/70) briquette was higher than those of other briquette blends, showing that this blend contained higher energy potential when compared with the CH and CP briquettes. The high ash content of 9.85% in cassava peel briquette requires appropriate reduction to minimal levels by varying the amount of cassava peels in CH/CP and CP/SD briquettes. For briquette samples CH/CP (30/70), CH/SD (30/70, 50/50), and mixed SD and CP samples at varying composition, the bonding of the polymers was enhanced, having a rough surface, and improving the structural integrity of the briquettes and closing the gaps and voids within and between particles. The concentration of K in CP and CH was 1.3 but was reduced to 0.6 and 0.9 in CH/SD (30/70) and CH/CP (30/70) respectively due to mixing. The highest infrared transmittance of OH, C–H, C=C, and C–O were found in the SD briquette followed by the CH and then by CP while the CH briquette contained higher C–C. During the TG analysis, the residual weight of the CH/SD and CP/SD briquettes decreases with the increase in the proportion of the SD. The pollution potential of CH/CP blends is in a better range for fuel, because they would emit lower amounts of CO2 and NO2. The overall results show that the CP/SD briquette with 30/70 mixture ratio has optimum performance in terms of the higher heating value, low ash and moisture contents, and emissions. The results of this work thus established that the use of the feedstock mixing from lignocellulosic source such as cassava peel, corn husk, and sawdust wastes can be a sustainable solution to enhance their fuel characteristics, and they could be used for co-combustion in domestic and industrial applications. Also, their utilization would help to mitigate against pollution and emission control and stimulate economic advantage.

Data availability

Data are available from the corresponding author on request.

Abbreviations

- AC:

-

Ash content

- CH :

-

Cornhusk

- CP:

-

Cassava peel

- HCV:

-

Higher calorific value

- FC:

-

Fixed carbon content

- MC:

-

Moisture content

- SD:

-

Saw dust

- VM:

-

Volatile matter

References

Mohammed IY, Abakr YA, Yusup S, Kazi FK (2017) Valorization of Napier grass via intermediate pyrolysis: optimization using response surface methodology and pyrolysis products characterization. J Clean Prod 142:1848–1866. https://doi.org/10.1016/j.jclepro.2016.11.099

Akhtar J, Imran M, Ali AM, Nawaz Z, Muhammad A, Butt RK, Jillani MS, Naeem HA (2021) Torrefaction and thermochemical properties of agriculture residues. Ener 14:4218. https://doi.org/10.3390/en14144218

FAOSTAT (2022) Food and Agriculture Organization of the United Nations—Statistics Division. Crop Production. Available online: https://www.fao.org/faostat/en/#data/QCL (accessed on 4 July 2022).

Ibeto CN, Enoch P, Alum OL (2017) Impact of torrefaction on fuel emissions and properties of lignite and their blends with biowastes. J Chem Soc Nig 42(2):15–21

Akande OM, Olorunnisola AO (2018) Potential of briquetting as a waste management option for handling market-generated vegetable waste in Port Harcourt. Nigeria. Recycl 3(2):1–14. https://doi.org/10.3390/recycling3020011

Akogun OA, Waheed MA, Ismaila SO, Dairo OU (2020) Co-briquetting characteristics of cassava peel with sawdust at different torrefaction pretreatment conditions. Ener Sour Part A: Recov Utiliz Environ Eff 1–19. https://doi.org/10.1080/15567036.2020.1752333

Akogun OA, Waheed MA, Ismaila SO, Dairo OU (2022) Physical and combustion indices of thermally treated cornhusk and sawdust briquettes for heating applications in Nigeria. J Nat Fib 19(4):1201–1216. https://doi.org/10.1080/15440478.2020.1764445

Iftikhar M, Asghar A, Ramzan N, Sajjadi B, Chen W (2019) Biomass densification: effect of cow dung on the physicochemical properties of wheat straw and rice husk based biomass pellets. Biom Bioener 122:1–16. https://doi.org/10.1016/j.biombioe.2019.01.005

Kpalo SY, Zainuddin MF, Manaf LA, Roslan AM (2020) Evaluation of hybrid briquettes from corncob and oil palm trunk bark in a domestic cooking application for rural communities in Nigeria. J Clean Prod 284:124745. https://doi.org/10.1016/j.jclepro.2020.124745

Bamisaye A, ·Rapheal IA (2021) Effect of binder type on the NaOH‑treated briquettes produced from banana leaves. Biom Conv Bioref. https://doi.org/10.1007/s13399-021-01771-9

Waheed MA, Akogun OA, Enweremadu CC (2022) An overview of torrefied bioresource briquettes: quality influencing parameters, enhancement through torrefaction and applications. Bioresou Bioproc 9:122. https://doi.org/10.1186/s40643-022-00608-1

Ajimotokan HA, Ibitoye SE, Odusote JK, Adesoye OA, Omoniyi PO (2019) Physico-mechanical properties of composite briquettes from corncob and rice husk. J Bioresou Bioprod 4(3):159–165. https://doi.org/10.12162/jbb.v4i3.004

Waheed MA, Akogun OA (2020) Quality enhancement of briquette from cornhusk and cassava peel blends for co-firing in coal thermal plant. Int J Ener Res 45(2):1867–1878. https://doi.org/10.1002/er.5865

Garba MU, Gambo SU, Musa U, Tauheed K, Alhassan M, Adeniyi OD (2018) Impact of torrefaction on fuel property of tropical biomass feedstocks. Biof 9(3):369–377. https://doi.org/10.1080/17597269.2016.1271629

Lateef FA, Ogunsuyi HO (2021) Jatropha curcas L biomass transformation via torrefaction: surface chemical groups and morphological characterization. Cur Res Gr Sustain Chem 4:100142. https://doi.org/10.1016/j.crgsc.2021.100142

Benavente V, Fullana A (2015) Torrefaction of olive mill waste. Biom Bioener 73:186–194. https://doi.org/10.1016/j.biombioe.2014.12.020

Akogun OA, Waheed MA (2022) Development and performance evaluation of a piston type hydraulically operated briquetting machine with replaceable moulds. Agric Engrg Int CIGR EJ 24(1):113–126

SS 187120 (1998) Biofuels and peat, fuel pellets. Classification. Swedish Standards Institution, Stockholm, Sweden

DIN 51731 (1996) Testing of solid fuels, compressed untreated wood. Requirements and Testing. Deutsches Institut für Normung, Berlin, Germany

Obi OF, Okongwu KC (2016) Characterization of fuel briquettesmade from a blend of rice husk and palm oil mill sludge Biomass Conv. Bioref. https://doi.org/10.1007/s13399-016-0206-x

ASTM D3176–15 (2015) Standard practice for ultimate analysis of coal and coke. ASTM Int., West Conshohocken, PA

Jyothsna S, Manjula G, Sateesh S, Nageswara AS (2020) Qualitative elemental analysis of selected potential anti-asthmatic medicinal plant taxa using EDXRF technique. Heliyon 6(2):e03260. https://doi.org/10.1016/j.heliyon.2020.e03260

Adegoke IA, Ige AR, Bamisaye A, Elinge CM, Olubunmi OA (2022) Effect of alkaline delignification on physico-chemical and combustion properties of bean chaff briquette. Asian J Trop Biotechnol 19:20–27

ASTM E711-87 (2012) American Society for Testing and Materials—standard test method for gross higher calorific value of refuse-derived fuel by the bomb calorimeter

Bai X, Wang G, Gong C, Yu Y, Liu W, Wang D (2017) Co-pelletizing characteristics of torrefied wheat straw with peanut shell. Bioresour Technol 233:373–381. https://doi.org/10.1016/j.biortech.2017.02.091

Coats AW, Redfern JP (1964) Kinetic parameters from thermogravimetric data. Nat 201(4914):68–69. https://doi.org/10.1038/201068a0

Lu KM, Lee WJ, Chen WH, Lin TC (2013) Thermogravimetric analysis and kinetics of co-pyrolysis of raw/torrefied wood and coal blends. App Ener 105:57–65. https://doi.org/10.1016/j.apenergy.2012.12.050

Kumar TTA, Mech N, Ramesh ST, Gandhimathi R (2022) Evaluation of composite briquettes from dry leaves in energy applications for agrarian communities in India. J Clean Prod 350:131312. https://doi.org/10.1016/j.jclepro.2022.131312

ISO 17225–7 (2021) Solid Biofuels-Fuel specifications and classes-Part 7: Graded Non-woody briquettes. ISO, Geneva, Switzerland

Rezania S, Md Din MF, Kamaruddin SF, Taib SM, Singh L, Yong EL, Dahalan FA (2016) Evaluation of water hyacinth (Eichhornia crassipes) as a potential raw material source for briquette production. Energy 111:768–773. https://doi.org/10.1016/j.energy.2016.06.026

Onukak I, Mohammed-Dabo I, Ameh A, Okoduwa S, Fasanya O (2017) Production and characterization of biomass briquettes from tannery solid waste. Recyc 2(4):1–19. https://doi.org/10.3390/recycling2040017

Chungcharoen T, Srisang N (2020) Preparation and characterization of fuel briquettes made from dual agricultural waste: cashew nut shells and areca nuts. J Clean Prod 256:120434. https://doi.org/10.1016/j.jclepro.2020.120434

Akogun OA, Waheed MA (2022) Development and performance evaluation of a piston type hydraulically operated briquetting machine with replaceable moulds. Agric Engr Int CIGR J. 24(1):113-127. http://www.cigrjournal.org

Sait HH, Hussain A, Salema AA, Ani FN (2012) Pyrolysis and combustion kinetics of date palm biomass using thermogravimetric analysis. Biores Techn 118:382–9. https://doi.org/10.1016/j.biortech.2012.04.081

Senneca O, Chirone R, Salatino P, Nappi L (2007) Patterns and kinetics of pyrolysis of tobacco under inert and oxidative conditions. J Analy App Pyro 79:227–233. https://doi.org/10.1016/j.jaap.2006.12.011

Pimenidou P, Dupont V (2012) Characterisation of palm empty fruit bunch (PEFB) and pinewood bio-oils and kinetics of their thermal degradation. Biores Techn 109:198–205. https://doi.org/10.1016/j.biortech.2012.01.020

Abdullah H, Wu H (2009) Biochar as a Fuel: 1. Properties and grindability of biochars produced from the pyrolysis of mallee wood under slow-heating conditions. Ener Fuels 23:4174–4181. https://doi.org/10.1021/ef900494t

Chen WH, Lin BJ, Lin YY, Chu YS, Ubando AT, Show PL, On HC, Chang JS, Ho SH, Culaba AB, Pétrissans A, Pétrissans M (2021) Progress in biomass torrefaction: principles, applications and challenges. Progr Ener Comb Sc 82:100887. https://doi.org/10.1016/j.pecs.2020.100887

Nunes LJR, Matias JCO (2020) Biomass torrefaction as a key driver for the sustainable development and decarbonization of energy production. Sustainabl 12(3):922. https://doi.org/10.3390/su12030922

Smith AM, Singh S, Ross AB (2016) Fate of inorganic material during hydrothermal carbonisation of biomass: influence of feedstock on combustion behaviour of hydrochar. Fuel 169:135–145. https://doi.org/10.1016/j.fuel.2015.12.006

Yang H, Yan R, Chen H, Lee DH, Liang DT, Zheng C (2006) Mechanism of palm oil waste pyrolysis in a packed bed. Ener Fu 20:1321–1328. https://doi.org/10.1021/ef0600311

Kim YH, Lee SM, Lee HW, Lee JW (2012) Physical and chemical characteristics of products from the torrefaction of yellow poplar (Liriodendron tulipifera). Biores Technol 116:120–125. https://doi.org/10.1016/j.biortech.2012.04.033

Kayiwa R, Kasedde H, Lubwama M, Kirabira JB (2021) Mesoporous activated carbon yielded from pre-leached cassava peels. Bioresour Bioprocess 8:53. https://doi.org/10.1186/s40643-021-00407-0

Zhong Q, Yang Y, Li Q, Xu B, Jiang T (2017) Coal tar pitch and molasses blended binder for production of formed coal briquettes from high volatile coal. Fu Proc Technol 157:12–19. https://doi.org/10.1016/j.fuproc.2016.11.005

Ahna BJ, Chang H, Lee SM, Choi DH, Cho ST, Han G, Yang I (2014) Effect of binders on the durability of wood pellets fabricated from Larix kaemferi C. and Liriodendron tulipifera L. sawdust. Renew Ener 62:18e23. https://doi.org/10.1016/j.renene.2013.06.038

Setter C, Silva FTM, Assis MR, Ataíde CH, Trugilho PF, Oliveira TJP (2020) Slow pyrolysis of coffee husk briquettes: characterization of the solid and liquid fractions. Fuel 261:116420. https://doi.org/10.1016/j.fuel.2019.116420

Quan C, Li A, Gao N (2009) Thermogravimetric analysis and kinetic study on large particles of printed circuit board wastes. Was Mgt 29:2353–2360. https://doi.org/10.1016/j.wasman.2009.03.020

Toptas A, Yildirim Y, Duman G, Yanik J (2015) Combustion behavior of different kinds of torrefied biomass and their blends with lignite. Biores Techn 177:328–336. https://doi.org/10.1016/j.biortech.2014.11.072

Samaksaman U, Manatura K (2021) Co-combustion characteristics and kinetics behavior of torrefied sugarcane bagasse and lignite. Int J Renew Ener Develop 10(4):737–746

Gao M, Li S, Sun C (2004) Thermal degradation of wood in air and nitrogen treated with basic nitrogen compounds and phosphoric acid. Comb Sci Techn 176(12):2057–2070. https://doi.org/10.1080/00102200490514840

Acknowledgements

Waheed, M. A. acknowledged the University of South Africa for the Visiting Research Support Programme Grant and the Federal University of Agriculture, Abeokuta, Nigeria, for his release.

Funding

Open access funding provided by University of South Africa.

Author information

Authors and Affiliations

Contributions

M. A. W.: conceptualization and project design, methodology, writing, editing and review. O. A. A.: methodology, writing, editing, and review. C. C. E.: conceptualization and project design, editing and project administration.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Waheed, M.A., Akogun, O.A. & Enweremadu, C.C. Influence of feedstock mixtures on the fuel characteristics of blended cornhusk, cassava peels, and sawdust briquettes. Biomass Conv. Bioref. 13, 16211–16226 (2023). https://doi.org/10.1007/s13399-023-04039-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-023-04039-6