Abstract

A deep eutectic solvent (choline chloride (ChCl)-urea) was chosen to extract flavonoids from Moringa oleifera leaves (FMOL), the condition of extraction was tailor-made, under the optimal extraction conditions (material-to-liquid ratio of 1:60 g/mL, extraction time of 80 min, extraction temperature of 80 °C), the highest extraction efficiency reached 63.2 ± 0.3 mg R/g DW, and nine flavonoids were identified. Then, the biological activities including antioxidant activities, antibacterial activities, and anti-tumor activities were systematically studied. FMOL was superior to positive drugs in terms of antioxidant activity. As to DPPH investigation, the IC50 of FMOL and Vc were 64.1 ± 0.7 and 176.1 ± 2.0 µg/mL; for the ABTS, the IC50 of FMOL and Vc were 9.5 ± 0.3 and 38.2 ± 1.2 µg/mL, the FRAP value of FMOL and Vc were 15.5 ± 0.6 and 10.2 ± 0.4 mg TE/g, and ORAC value of FMOL and Vc were 4687.2 ± 102.8 and 3881.6 ± 98.6 µmol TE/g. The bacteriostatic (MICs were ≤ 1.25 mg/mL) activities of FMOL were much better than propyl p-hydroxybenzoate. Meanwhile, FMOL had comparable inhibitory activity with genistein on tumor cells, IC50 was 307.8 µg/mL, and could effectively induce apoptosis in HCT116. Microcapsules were prepared with xylose-modified soybean protein isolate and gelatin as wall materials; after that, the intestinal release of modified FMOL microcapsules was 86 times of free FMOL. Therefore, this study confirmed that FMOL extracted with ChCl/urea has rich bioactive components, and microencapsulated FMOL has potential application in food industry.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Moringa oleifera is a traditional plant in India, and its flowers, fruits, seeds, leaves, and roots are almost all edible and have high nutritional value [1]. Some studies have reported that Moringa oleifera exhibits growth inhibitory activity against various pathogens [2]. Moringa oleifera leaves (MOL) also contains polysaccharides, polyphenols, water-soluble proteins, and different kinds of flavonoids. Extracts of MOL have potential benefits in the antioxidant, anticancer, and hypoglycemic activities [1]. Flavonoids are one of the main biologically active components of Moringa oleifera. Various solvents such as water [3], methanol/water [4, 5], methanol [6, 7], ethanol [7, 8], ethanol/water [9, 11], n-hexane [12, 13], ethyl acetate [6, 12], and chloroform fraction [13] combined with assisted extraction methods (homogenizer [4], ultrasound [14, 15], microwave [14] and supercritical fluid extraction [16], etc.) have been used for extracting flavonoids from Moringa oleifera leaves.

Traditional organic solvents are the most commonly used to extract flavonoid compounds. But they are volatile, toxic, highly consumed, which largely lead to excessive solvent residue in the extraction and unfriendly to environment. Deep eutectic solvents (DESs) have emerged at the historical moments to address the disadvantage of traditional solvents. DESs have been widely used as catalyst, reaction media, and solvent to extract natural products [17]. As DESs with low raw material price, easy to achieve, low volatility, safe nontoxicity, convenient to store, and lack of byproducts, they have been exploited to extract bioactive substances such as flavonoids [18]. Koutsoukos et al. extracted phenolic and carotenoid compounds from propolis, almond, and red shrimp using DES, prepared by choline chloride/tartaric acid [19]. Cui et al. prepared 12 kinds of DESs to extract flavonoids from sea buckthorn leaves [17]. Yu and Bulone prepared five kinds of choline chloride − based DESs to extract quercetin derivatives from apple pomace [20]. Wu et al. attempted to use 13 kinds of DESs, based choline chloride, betaine, l-proline as hydrogen bond acceptors and malic acid, glycerol, oxalic acid, levulinic acid as hydrogen bond donors with different molar ratios, to extract total phenolic and flavonoid of MOL [21]. The extraction ability of choline chloride/citric acid as DES also has been demonstrated on dried MOL, two of glucosinolates, eight of chlorogenic acids, and twenty of flavonoids have been extracted [22]. Our previous study investigated the extraction rate of FMOL by choline chloride/lactic acid, and the FMOL can be reached 54.8 mg/g DW, which much higher than that of extracted by water and ethanol [23]. Different DESs have various extraction capacities; therefore, it is valuable to attemptable to extract FMOL using deep eutectic solvent and systematic studies on the biological activity of the extracted products.

The flavonoids can be broken down into other compounds with lower bioavailability after gastrointestinal digestion, which may affect by many factors such as pH values, bile salts, and digestive enzymes in the gastrointestinal tract [24]. Therefore, in addition to optimize the efficient extraction of green solvents, it is also necessary to further improve the bioavailability of flavonoids. Microencapsulation as a versatile technique is commonly used for isolation, protection, and controlled delivery of active core materials to enhance the bioavailability and stability of compounds and to improve their controlled release [25, 26]. Soy protein isolate (SPI) and gelatin (GE) are commonly used as wall materials for the preparation of microcapsules. Jia et al. reported that Maillard reaction modification of whey protein and xylooligosaccharide could help to improve the embedding rate and bioavailability [27]. Zhong et al. used a variety of oligosaccharides to modify soybean protein isolate through Maillard reaction as the antioxidant wall material for embedding Lactobacillus casei [28]. In order to improve the bioavailability of FMOL in intestine, xylose-modified soy protein isolate could be used as wall material for microencapsulation of FMOL.

In this study, flavonoids were extracted from the leaves of Moringa oleifera using DES (ChCl/urea). The stirring extraction conditions were optimized, and the flavonoids were isolated from ChCl/urea. The composition of the extracted flavonoids was qualitatively identified. Then, systematically studied the biological activities of the extracted flavonoids, including antioxidant activity, antibacterial activity, and antitumor activity. Moreover, the isolated Moringa oleifera flavonoids were microencapsulated in order to improve its bioavailability in small intestine.

2 Materials and methods

2.1 Reagents and materials

See supplementary materials for materials and reagents.

2.2 Preparation of the DES

The DESs list in Table S1 were prepared according to the report [17] with minor modifications. See supplementary materials for specific operation.

2.3 The extraction of FMOL by DES

The flavonoids from Moringa oleifera leaves (FMOL) were extracted by a simple stirring method, and the extraction rate of flavonoids was determined by ultraviolet spectrophotometry as Wang’s report [29]. The specific method was that 0.25 g dry MOL added to 5 mL DES, stirring at 60 °C, 200 rpm for 60 min. As shown in Table S1, the solvent with the highest extraction rate of FMOL was selected from the six solvents and compared with ethanol and deionized water. Each group of experiments was carried out three times in parallel.

ChCl/urea (1:2, mol/mol) was selected as extraction solvent; the effects of material-to-liquid ratio (1:10–1:80 g/mL), extraction time (20–120 min), and temperature (40–90 °C) on the extraction rate were further studied at the stirring velocity of 200 rpm.

2.4 Experiment of response surface methodology

On the basis of single factor experiment, the extraction process was optimized by Box-Behnken design (BBD) with three factors and three levels by using the Design-Expert 8.0.6 statistical software. The experimental scheme was shown in Table S2, and Table S3 for factor level table. The variables were coded as − 1, 0, and + 1 levels respectively, in which the material-to-liquid ratio (X1) were 1:70, 1:80, and 1:90 g/mL, the extraction duration (X2) were 70, 80, and 90 min, and the extraction temperature (X3) were 70, 80, and 90 °C. Taking the extraction rate of total flavonoids in FMOL (Y1) as the response variable, 17 groups of experiments were designed.

2.5 Detection and identification of FMOL components

An ultra-performance liquid chromatography orbital ion trap mass spectrometry (UPLC-Q-Orbitrap MS) platform was used for the qualitative study. See supplementary materials for specific operation.

2.6 Antioxidant activities

2.6.1 DPPH free radical scavenging activity

The DPPH radical scavenging rate of the sample was determined as previous report [23]. See supplementary material for specific operation.

2.6.2 ABTS free radical scavenging activity

The clearance rate of ABTS+ free radicals was determined according to the previous report [23]. See supplementary material for specific operation.

2.6.3 Iron reducing antioxidant capacity (FRAP)

FRAP capability of FMOL was determined by previous report [23]. See supplementary material for specific operation.

2.6.4 Oxygen Free Radical Absorption Capacity (ORAC)

The oxygen radical absorbance capacity (ORAC) was evaluated by comparison with Trolox using the method [30]. See supplementary material for specific operation.

2.7 Antimicrobial activity

The inhibition zone was determined by the filter paper agar diffusion method. Added 300 µL of test bacteria suspension (1.5 × 106 CFU/mL) to agar medium, took 6 mm diameter sterile filter paper with sterile forceps and stuck it, dropped 10 µL of sample to be tested, cultured upside down in 37 °C incubator for 24 h, and measured and counted the diameter of a bacteriostatic circle.

The minimum inhibitory concentration (MIC) has been determined. 5 µL sample was mixed with 195 µL of test bacterial suspension (1.5 × 106 CFU/mL) and incubated at 37 °C for 24 h. The OD was measured at 610 nm with multifunctional microplate reader. The positive control was propyl hydroxybenzoate, and the negative control was DMSO. All tests were performed in triplicate.

2.8 Antiproliferative activity assay

2.8.1 Antitumor cell activity

The inhibition rate of tumor cells was determined by the MTT method. Three types of tumor cells with higher inhibition rates were selected from human breast cancer cells (MCF-7), human colon cancer cells (HCT116), human cervical cancer cells (HeLa), human lung cancer cells (A549), human liver cancer cells (Hep G-2), and mouse melanoma cells (B16), and their IC50 were calculated. See supplementary material for specific operation. Cell inhibition rate (%) = (ODcontrol − ODsample)/ODcontrol × 100%. All tests were performed in sextuplicate.

Acridine orange (AO) staining experiment: 1 mL/well cell suspension (5 × 105 cells/mL) was added into each cell culture plate, and cultured in 5% CO2 at 37 °C for 24 h. Then each well was added 1 mL FMOL sample (diluted with culture medium) and further incubated for 3 h. After the incubation, each sample was stained with 20 µL AO fluorescent dye solution (5 µg/mL) for 0.5 h, and then washed with PBS for 3 times, after that 1 mL of culture medium was added to each well. Then, the samples were observed under a fluorescence inverted microscope or laser confocal microscope.

2.8.2 The effect of FMOL on apoptosis

The apoptosis experiment was determined according to the reported method with slightly modified [31]. See supplementary material for specific operation.

2.9 Preparation of microcapsules

Xylose (xyl) was selected to modify soybean protein isolate (SPI) by Maillard reaction [27], and FMOL microcapsules were prepared by combining gelatin (GE) as crosslinking agent with modified SPI by composite coagulation method [28]. Microcapsule embedding rate (EE) = A − A0/A × 100, where A is the content of FMOL in microcapsules, A0 is the surface flavonoids attachment of FMOL microcapsules.

The factors of microcapsule preparation included exploring the effects of different wall material concentration, core-wall ratio, emulsifying power, and emulsifying time on microcapsule embedding rate and morphology. The specific was shown in supplementary material.

2.10 Characterization of FMOL microcapsules

The characterization methods of microcapsules were shown in supplementary material, include Fourier transform infrared spectroscopy (FT-IR), X-ray diffraction (XRD) [32], and scanning electron microscope (SEM) [33].

2.11 In vitro digestion of FMOL microcapsules

The simulated in vitro digestion of FMOL microcapsules was investigated and the general procedure was followed Brodkorb’s study [34]. The simulated oral digestive juice, gastric digestive juice, and small intestinal digestive juice were shown in Table S4 and preheated at 37 °C before use. The digestive stabilities of FMOL or FMOL microcapsules in different digestive stages, that is, bioavailability, were studied by simulating the digestion of oral, gastric, and intestinal fluids. The release rate of flavonoids (%) = C/C0 × 100, where C was the content of flavonoids in the solution after in vitro digestion, and C0 is the content of flavonoids in the coating extract before in vitro digestion.

2.12 Statistical analysis

The data were processed with Origin 2019, and the final results were expressed as the mean ± standard deviation of three values (n = 3). The Design-Expert 8.0.6 (STAT ease Inc., Minneapolis, Minnesota, USA) was used for response surface methodology (RSM) as an optimization tool. The IC50 results were statistically analyzed using GraphPad prism version 8.0 (GraphPad Software Inc., La Jolla, CA), and the significance level was 5%.

3 Results and discussions

3.1 The screening of DES

Six deep eutectic solvents were selected as extraction solvents. Figure 1(a) compares the extraction rate of flavonoids between six DESs (composed of choline chloride and various hydrogen bond donors) and traditional solvents. The extraction rates of FMOL conducted with DESs were all higher than those obtained with ethanol and DI water. DESs composed of diverse hydrogen bond donors and choline chloride had different extraction effects on FMOL. This could be attributed to the different physical and chemical properties of various DESs, including solubility, viscosity, and polarity, which could affect the extraction efficiency of FMOL [35]. The DES prepared by ChCl/urea had the highest rate for FMOL extraction in the investigated solvents.

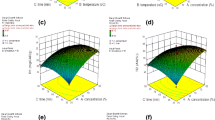

a Screening and comparison of extraction solvents. Extraction rate of flavonoids using ChCl/urea under different b material-to-liquid ratios, c extraction times, and d extraction temperatures. Response surface diagram of interaction, e A: material-to-liquid ratio and B: extraction time, f A: material-to-liquid ratio and C: extraction temperature, g B: extraction time and C: extraction temperature, h comparison of extraction rate before and after optimization

3.2 The effects of different conditions on the FMOL extraction rate

The control variable method was used to study three single factors. As Fig. 1(b) shows, with the material-to-liquid ratio of 1:10 to 1:80 g/mL, the extraction rate of FMOL increased from 34.0 ± 0.5 to 51.7 ± 0.2 mg R/g DW, while the extraction rates of the material-to-liquid ratio were 1:60 and 1:80 g/mL; the rates have little difference, namely 50.7 ± 0.9 and 51.7 ± 0.2 mg R/g DW, respectively, showing that the extraction approached to platform stage, so the best material-to-liquid ratio was regarded as 1:60 g/mL. Such a result could contribute to that when the material-to-liquid ratio was too low, the MOL powder was not fully dispersed and mixed insufficiently with the DES, leading to an insufficient dissolution of flavonoids. However, an excessively high material-to-liquid ratio would cause the solvent to absorb a certain amount of heat and increase the viscosity, which is averse to the breaking of MOL cell’s wall, decreasing mass transfer, and results in low extraction rate of flavonoids. In the meantime, it could also cause solvent waste and problems of subsequent test treatment [36]. Therefore, MOL powder’s optimal material-to-liquid ratio to ChCl/urea solvent was considered to be 1:60 g/mL.

Under the material-to-liquid ratio of 1:60 g/mL, the effect of extraction time on the extraction rate of flavonoids was studied. As Fig. 1(c) depicts, with extraction time increasing from 20 to 120 min, the extraction rate of flavonoids increased from 29.4 ± 0.04 to 56.1 ± 1.3 mg R/g DW. When the extraction time reached 80 min, the highest extraction rate (60.6 ± 0.9 mg R/g DW) was obtained, but when the extraction time was increased continuously to 120 min, the extraction rate decreased to 56.1 ± 1.3 mg R/g DW. This could be allied to the extraction time being too long and thus the flavonoids being destroyed.

Then, the optimal extraction temperature of MOL powder extracted with ChCl/urea was further investigated under the as-obtained optimum material-to-liquid ratio and extraction time. As shown in Fig. 1(d), as the temperature improved from 20 to 80 °C, the extraction rate increased from 27.1 ± 0.3 to 61.7 ± 0.8 mg R/g DW. In comparison, when the temperature was increased continuously to 90 °C, the extraction rate descended to 53.6 ± 2.1 mg R/g DW. This may be owing to when the extraction temperature was too low, the molecular movement was slow and led to a low dissolution, diffusion, and penetration rate, which goes against to the dissolution of flavonoids. High temperature could reduce the viscosity of DES, increase the diffusion coefficient and improve the extraction efficiency. However, high temperature could lead to the structure damage of flavonoids, resulting in a reduction in the extraction rate.

The variance analysis was conducted on the test data, and the bias regression coefficients of each factor were tested. The analysis of variance results is summarized in Table S5. The larger the F value, the greater the influence. It could be seen that the order of factors affecting the content of flavonoids was B (extraction time) > C (extraction temperature) > A (material-to-liquid ratio).

The P value of this model was < 0.01, extremely significant, and the P′ value of lack of fit was 0.0967 > 0.01, not significant, indicating that the regression equation fit well and could predict the content of flavonoids under different extraction conditions. The correlation coefficient R2 of the correction model was 0.9804, and the correction determination coefficient Radj2 was 0.9551, indicating that the fitting of the equation was good. The model could explain the change of 98.04% response value. Therefore, this model could analyze the real changes in response values and determine the optimal extraction process conditions.

To further investigate the interaction of relevant variables and determine the best advantage, a response surface graph was drawn using the Design-Expert 8.0.6 software for visual analysis. The results were consistent with the results of mathematical model analysis in Fig. 1(e)–(g), which could better understand the interaction between the two variables and its optimal range [35].

Model verification: The optimal extraction conditions, including material-to-liquid ratio, extraction time, and temperature, were 1:79 g/mL, 70 min, and 83 °C. Under these conditions, the predicted flavonoid content in MOL was 63.3 ± 0.1 mg R/g DW. The experimental results showed that the measure value of total flavonoids in MOL was 63.2 ± 0.3 mg R/g DW, and the error was only 0.1 mg R/g DW. Furthermore, it can be seen from Fig. 1(h) that the extraction rate of flavonoids after optimization was 63.2 ± 0.3 mg mg R/g DW, which was 1.7 and 2.6 times to that of before optimization (38.0 ± 0.9 mg R/g DW) and ethanol extraction (24.3 ± 0.8 mg R/g DW). The optimized value was significantly higher than the screening value (38.0 ± 0.9 mg R/g DW), indicating that the extraction conditions of FMOL were successfully optimized via this model. Additionally, the optimal extraction rate of FMOL (63.2 ± 0.3 mg R/g DW) extracted by ChCl/urea from Moringa oleifera leaves was much higher than that of those extracted with other solvents, such as the extract yields extracted with 50% aqueous ethanol solution (29.5 ± 0.3 mg/g DW) [11], methanol (35.19 mg/g DW) [37], l-proline/ethylene glycol (30.93 mg GAE/g DW) [38], and l-proline/glycerol (29.8 mg GAE/g DW) [21].

3.3 Identification of FMOL

The composition of flavonoids extracted with ChCl/urea was identified using LC–MS, the results were presented in Fig. 2 and Table S6. Nine of flavonoids were identified, including hyperoside, vitexin, quercetin, cynaroside, quercetin 3-β-d glucoside, kaempferol, taxifolin, luteolin, and fisetin; the MS diagram of the nine flavonoids could be seen from Fig. S5–S13, in which hyperoside, vitexin, quercetin, cynaroside, quercetin 3-β-d glucoside, kaempferol, luteolin, and taxifolin have been reported in Moringa oleifera leaves extracted by hot water [22], ethanol [9], methanol or methanol/water [30, 39], choline chloride/lactic acid [23], 20% ammonium sulfate and ethanol [22], choline chloride/citric acid [22], l-proline/levulinic [21], and l-proline/glycerol [21], and fisetin has been reported in Moringa oleifera leaves for the first time.

Further analysis of the extracted products obtained with different solvents revealed various flavonoids. Table S7 shows part of the reported results of extracted flavonoids, indicated that the DES is a good solvent for the extraction of natural products. Different DESs could sometimes obtain various extracted products, and new compounds from Moringa oleifera leaves.

3.4 Bioactivity of FMOL

3.4.1 Antioxidant activities

DPPH free radical scavenging activity of FMOL

Flavonoids from Moringa oleifera have a significant antioxidant capacity related to its immune enhancement activity [40], anti-inflammatory activities [41], antioxidant activities [23], and anticancer activities [1]. Previous studies showed that the determination of antioxidant activity depended on the reaction mechanism, and a variety of tests must be combined to accurately assess the antioxidant capacity of samples [42]. In this study, DPPH, ABTS, FRAP, and ORAC methods were used to assess the antioxidant activity of FMOL samples reliably.

The DPPH radical scavenging ability of the samples was determined. As Fig. 3(a) depicts, it was gratifying that the FMOL extracted with ChCl/urea showed excellent DPPH radical scavenging activity, superior to Vc in the range of 12.5–800 µg/mL. The scavenging rate was 81.4% ± 1.1 at 800 µg/mL. The IC50 of Vc and FMOL values were 170.6 ± 2.0 and 64.1 ± 0.7 µg/mL, respectively. FMOL samples’ DPPH free radical scavenging activity was more than twice as high as Vc. The satisfactory DPPH scavenging activity of FMOL was found to be far better than those of many flavonoid extracts from plants, such as Moringa oleifera leaf extract (149.8 μg/mL) [43], and hawthorn samples (80 µg/mL and 120 µg/mL) [30].

a DPPH radical scavenging activities of Vc and FMOL; b ABTS radical scavenging activities of Vc and FMOL. c Inhibition of FMOL on various tumor cells, d inhibitory activity of FMOL/genistein at different concentrations on B16 cells, e inhibitory activity of FMOL/genistein at different concentrations on HCT116 cells, f inhibitory activity of FMOL/genistein at different concentrations on Hep G-2 cells

ABTS free radical scavenging activity of FMOL

ABTS free radical solution had high absorption at 734 nm when FMOL was added to ABTS free radical solution, the absorbance at 734 nm decreased, that is, ABTS free radicals were removed by FMOL, indicating that FMOL had the activity of scavenging free radicals [44]. As Fig. 3(b) shows, the scavenging activity of FMOL extracted with ChCl/urea was much better than that of Vc at low concentrations (12.5 ~ 50 µg/mL). In contrast, the scavenging activity of FMOL was equal to that of Vc at high concentrations (100 ~ 400 µg/mL). FMOL exhibits higher activity in scavenging free radicals even at low concentrations, further demonstrating the excellent antioxidant capacity of the as-obtained FMOL. In the meantime, the IC50 of FMOL was 9.5 ± 0.3 µg/mL, which was much better than Vc (38.2 ± 1.2 µg/mL).

Ferric reducing antioxidant power (FRAP) of FMOL

It is important to estimate the total antioxidant activity by diverse methods for the total antioxidant potential of any food matrix, so the FRAP of FMOL was also studied.

The FRAP of FMOL extracted with ChCl/urea was measured, the value obtained was 15.5 ± 0.6 mg TE/g (Table 1), and the corresponding value of the positive control Vc was 10.2 ± 0.4 mg TE/g. Rocchetti et al. investigated the FRAP of flavonoid samples from Moringa oleifera leaves extracted by ethyl acetate, and the corresponding value was 13.77 mg TE/g [4]. The FRAP of FMOL extracted with ChCl/urea (15.5 ± 0.6 mg TE/g) was not only higher than that of Vc (10.2 ± 0.4 mg TE/g) but also superior to that of flavonoids extracted via ethyl acetate (13.77 mg TE/g), indicating that the DES-extracted FMOL has outstanding ferric reducing antioxidant capacity.

Oxygen Free Radical Absorption Capacity (ORAC) of FMOL

The ORAC was measured and the results was shown in Table 1; the value was 4687.2 ± 102.8 µmol TE/g, superior to that of the positive control Vc (3881.6 ± 98.6 µmol TE/g). Recently, the ORAC values of flavonoids extracted from Moringa oleifera leaves using water /methanol (20:80, v/v) and water/ ethanol (20:80, v/v) were 108.1 µmol TE/g and 3560.5 µmol TE/g [45], respectively, far below the ORAC value of FMOL (4687.2 ± 102.8 µmol TE/g), which undoubtedly demonstrated that the flavonoids extracted by DES have superior antioxidant activity than those extracted by the traditional solvent.

Through the above comprehensive evaluation of the antioxidant capacity of FMOL by the DPPH, ABTS, FRAP, and ORAC, the excellent antioxidant capacity of FMOL extracted via ChCl/urea was demonstrated better than Vc.

3.4.2 Antimicrobial activity

With the abuse of antibiotics, plants have attracted considerable attention as a potential source of antibacterial drugs [40]. Bacterial growth inhibition is one of methods to study antimicrobial activity assessment, which is low cost and can provide meaningful effect within a short period of time. Therefore, it was of great significance to explore the inhibitory effect of FMOL on different bacteria.

The experimental results in Table 2 and Fig. S1 show that the diameter of the inhibition zone produced by FMOL at a concentration of 2.5 mg/mL (15.6 ± 0.4–18.7 ± 0.6 mm) was even more significant than that of the positive drug at 10 mg/mL (13.6 ± 0.4–15.2 ± 1.3 mm), which indicates that the inhibitory effects of FMOL on five bacteria were better than that of propyl p-hydroxybenzoate (the positive control). The inhibitory effect on Proteus common was showing best among the investigated bacteria.

To further explore the antimicrobial capacity of FMOL extracted with ChCl/urea, the minimum inhibitory concentration (MIC) was investigated by the above five bacteria. As shown in Table 2, the MICs of FMOL to E. coli, Staphylococcus aureus, Bacillus subtilis, and Pseudomonas aeruginosa were 1.25 mg/mL and to Proteus common was 0.625 mg/mL. The MIC values of the positive drug (propyl p-hydroxybenzoate) were twice to that of FMOL, further revealing the strong bacteriostatic ability of the as-prepared FMOL. In addition, the MIC results were consistent with the inhibitory zone experiment results.

3.4.3 Antiproliferative activity

Epidemiological studies have shown that various parts of Moringa oleifera have beneficial effects on health, and the leaves are potential source of antitumor activity [39]. Biological evaluation of FMOL was performed with an in vitro antitumor MTT assay via six types of tumor cells (MCF-7, HCT116, HeLa, A549, B16, Hep G-2).

According to the MTT experimental results in Fig. 3(c), FMOL showed relatively high inhibitory activity against B16, HCT116, and Hep G-2 cells. Different concentrations of FMOL were used to the three kinds of cells to obtain different cell inhibitory activities, as shown in Fig. 3(d)–(f). The IC50 was for the inhibition rates of the three kinds of cells. The results displayed that the IC50 of FMOL on B16, HCT116, and Hep G-2 cells were 415.0 ± 3.3, 307.8 ± 5.8, and 349.6 ± 8.1 µg/mL, respectively. The IC50 of genistein (the positive control) on B16, HCT116, and Hep G-2 cells were 398.2 ± 10.1, 281.7 ± 4.2, and 335.8 ± 6.7 µg/mL, respectively. Based on the results of the IC50 of antitumor proliferation in the three kinds of cells, FMOL had the best inhibitory effect on HCT116 cells, and it was slightly lower than that of genistein. Recently, Yang et al. revealed that peanut extract has a strong antiproliferative effect on HCT116 cells, with IC50 of 1.39 ~ 9.33 mg dry extract/mL [46], far higher than that of as-extracted FMOL, which indicated that FMOL has a considerable inhibitory effect on tumor cells.

An acridine orange (AO) staining experiment has been performed for FMOL to verify the results from the MTT assay. The overlap effect of AO staining results for B16 (Fig. S2), HCT116 (Fig. S3), and Hep G-2 cells (Fig. S4) became more evident with increasing FMOL concentration, and its variation effect was consistent with the IC50 results. This result indicated that the pH value in cells increased under the action of FMOL, and it was speculated that FMOL had a similar effect on alkaline lysosomes [47]. Figure 4 (a)–(d) shows confocal laser imaging of HCT116 cells stained with AO after 3 h of treatment with FMOL. The overlapping effect of AO staining revealed dose-dependent effect on cell viability for the as-extracted FMOL; furthermore, HCT116 cells exhibited increasing detached and dead cells with the increasing dosage of FMOL, indicating the excellent antiproliferative activity of FMOL extracted with ChCl/urea.

Confocal laser imaging of HCT116 cells stained with acridine orange after 3 h of a cells without sample treatment, b–d the cells treated with different concentrations of FMOL were extracted by ChCl/urea: b 50 µg/mL, c 100 µg/mL, d 200 µg/mL. Under different treatments: e cells without sample treatment, f–h the cells treated with different concentrations of FMOL: f 100 µg/mL, g 500 µg/mL, h 1000 µg/mL, i Genistein (1000 µg/mL), induced HCT116 cell apoptosis for 24 h, and j the proportions of apoptosis cells

In order to further demonstrate the bioactivity of FMOL on the tumor cells, the effect of FMOL on cellular apoptosis was investigated. HCT116 cells were treated with FMOL at varying concentrations for 24 h by employing an Annexin V-FITC/PI assay. As shown in Fig. 4(e)–(j), incubation with FMOL and genistein drastically increased the proportion of apoptotic cells compared with the control group. After treatment with FMOL, the proportions of early apoptotic cells were 1.8% at 100 µg/mL, 5.1% at 500 µg/mL, and 6.0% at 1000 µg/mL, respectively, whereas the corresponding proportions of late apoptotic cells reached 4.6%, 9.4%, and 11.2%, respectively. These results illustrated that FMOL significantly induced cellular apoptosis in a dose-dependent manner and thus could effectively induce apoptosis in HCT116 cells.

3.5 Characterization of FMOL microcapsules

The preparation process is shown in Fig. 5(a). As depicts in Fig. S14, the optimal wall material concentration, core-wall ratio, and stirring rate and time were of 1.8% SPI-3.6% xyl and 1.0% GE, 1:6, 500 rpm, and 15 min, under which conditions, the embedding rate of FMOL could reach 66.5%, and the FMOL microcapsule particle size distribution was shown in Fig. S15, 94% of the FMOL microcapsule diameter were < 100 µm, observing the morphology of FMOL microcapsule through microscope and SEM. The microscope diagram of wet microcapsule is shown in Fig. 5(b), and the SEM results are shown in Fig. 5(c)–(d). The morphology of microcapsules showed a certain bonding block, there was no obvious particle dispersion state, and only a few cystic protrusions could be seen in the sample. The reason for this phenomenon may be that some residual wall material polymers did not form microcapsules during the preparation of microcapsules, or the water loss during the freeze drying process after the preparation of microcapsules may cause the adhesion on the surface of film-forming wall materials, resulting in agglomeration and shrinkage of microcapsules [28].

Then, the FMOL microcapsules were characterized. It can be seen from Fig. 5(e) that the characteristic absorption of amide C = O stretching and amide II bands (N–H and C–N) in protein was around 1650 and 1540 cm−1, and the characteristic absorption of carbohydrates (including C–C and C–O stretching vibration and C–H bending) was mainly concentrated at 1180–953 cm−1 [28]. Herein, the peak enhancement of wave number 1650 cm−1 and the peak attenuation of 1540 cm−1 probably be the result of glycosylation between SPI and xylose. FMOL microcapsules contained the characteristic peaks of SPI, xyl, GE, and FMOL in the range of 500–4000 cm−1, and two characteristic peaks of FMOL (about 3440 cm−1 and 2950 cm−1) could be found in the infrared spectrum of FMOL microcapsules. Therefore, it could be seen that the wall material had been wrapped into FMOL to form FMOL microcapsules.

In general, crystalline materials exhibit spikes, while amorphous products exhibit wider peaks. As shown in Fig. 5 (f), in the XRD patterns of all materials, a characteristic diffraction peak appears at about 20°. However, xylose, as a crystalline substance, showed many peaks between 10 and 80°, but the characteristic peaks of xylose after maillard reaction did not appear in the characteristic peaks of FMOL microcapsules. The reason may be that xylose could carry out maillard reaction efficiently at 80 °C and 30 min, which completely changed its structure [32].

3.6 In vitro digestion of FMOL microcapsules

Microcapsules have been widely used in the field of food, and many of microencapsulation of food bioactive substances are to release active ingredients in the digestive system in a way of effective digestion and absorption, and give play to their physiological and health effects.

Table 3 shows that the flavonoid release and bioavailability of free FMOL, modified FMOL microcapsules, and unmodified FMOL microcapsules in the simulated oral, gastric, and intestinal stages. The results showed that the bioavailability of modified FMOL microcapsules increased 9.1% and unmodified FMOL microcapsules increased 2.4% compared with the free FMOL. Therefore, the application of modified microcapsules of FMOL could improve the bioavailability of Moringa flavonoids.

The bioavailability of free FMOL and microencapsulated FMOL have been investigated; the release amounts of FMOL, unmodified FMOL microcapsules, and modified FMOL microcapsules in different simulated digestion stages were further analyzed. Figure 5(g) depicts that the release amounts of free FMOL, unmodified FMOL microcapsules, and modified FMOL microcapsules in simulated oral digestion stages were 57.2%, 26.3%, and 24.0%, respectively. In the simulated gastric digestion stage, the release amounts were 29.9%, 31.9%, and 33.0%, respectively. In the simulated intestinal digestion stage, the release rates were 0.5%, 32.8%, and 39.4%, respectively. The experimental results showed that the oral release of FMOL was twice of microcapsules, which was not conducive to the embedding protection of flavonoids. There was little difference in the release of the three samples in the simulated gastric digestion stage. The release of unmodified FMOL microcapsules was 49.0 ± 0.5 μg/mL; the release rate was 32.8%, which was 70 times to that of free FMOL. In the simulated intestinal digestion stage, the release of free FMOL was only 0.7 ± 0.3 μg/mL; the release rate was only 0.5%. The release amount of modified FMOL microcapsule was 60.2 ± 0.6 μg/mL; the release rate was 39.4%, which greatly increased the intestinal release of free FMOL (about 86 times). The intestinal release rate of modified FMOL microcapsules was about 6.6% higher than that of unmodified FMOL microcapsules. Therefore, the microencapsulation of FMOL was conducive to protect the slow release of FMOL in the process of digestion, and the microcapsule prepared by soybean protein isolate modified by xylose could further retard the release of FMOL in the intestine.

4 Conclusion

Different DESs were investigated to extract FMOL, and ChCl/urea was found to be the best DES for obtaining FMOL, with an optimized extractive effect (63.2 ± 0.3 mg R/g DW). Nine flavonoids were identified by LC–MS and luteolin was previously unreported from Moringa oleifera leaves. Then, its antioxidant, antibacterial, and antitumor activities were systematically studied. FMOL was superior to positive drugs in antioxidant activity (DPPH free radical scavenging, ABTS free radical scavenging, FRAP, ORAC) and antibacterial activity in vitro. The FMOL extracted with ChCl/urea had exciting antineoplastic activity and was comparable with that of the positive control. The FMOL has certain antitumor activity, and the overlap effect of AO staining and cell apoptosis results revealed a dose-dependent effect on cell viability for the as-extracted FMOL. The microencapsulation has enhanced the slow release rate of FMOL, the release amounts of FMOL, unmodified FMOL microcapsules, and modified FMOL microcapsules were 0.7 ± 0.3, 60.2 ± 0.6, and 49.0 ± 0.5 µg/mL respectively. The intestinal release of unmodified FMOL microcapsules and modified FMOL microcapsules were 70 and 86 times of that of free FMOL. Therefore, the microencapsulation can improve the bioavailability of FMOL. In conclusion, FMOL extracted by ChCl/urea has excellent biological activity, and its microencapsulation is helpful to FMOL slower release, which could broad the application prospects of FMOL in food or pharmaceutical industry.

References

Dhakad AK, Ikram M, Sharma S, Khan S, Pandey VV, Singh A (2019) Biological, nutritional, and therapeutic significance of Moringa oleifera Lam. Phytother Res 33(11):2870–2903. https://doi.org/10.1002/ptr.6475

Alzaabi MM, Hamdy R, Ashmawy NS, Hamoda AM, Alkhayat F, Khademi NN, . . . Soliman SSM (2022) Flavonoids are promising safe therapy against COVID-19. Phytochem Rev 21(1): 291–312. https://doi.org/10.1007/s11101-021-09759-z

Olvera Aguirre G, Mendoza Taco MM, Moo Huchin VM, Lee Rangel HA, Roque Jiménez JA, Gómez Vázquez A, . . . Chay Canul AJ (2022) Effect of extraction type on bioactive compounds and antioxidant activity of Moringa oleifera Lam. leaves. Agriculture 12(9): 1462. https://doi.org/10.3390/agriculture12091462

Rocchetti G, Pagnossa JP, Blasi F, Cossignani L, Piccoli RH, Zengin G, . . . Lucini L (2020) Phenolic profiling and in vitro bioactivity of Moringa oleifera leaves as affected by different extraction solvents. Food Res Int 127: 108712. https://doi.org/10.1016/j.foodres.2019.108712

Aldossary HM, Alqurashi RM (2021) In vitro antioxidant and antimicrobial activity of Moringa oleifera leaf as a natural food preservative in chicken burgers. Emir J Food Agr 33(6):450–457. https://doi.org/10.9755/ejfa.2021.v33.i6.2711

Adeyi AO, Mustapha KK, Ajisebiola BS, Adeyi OE, Metibemu DS, Okonji RE (2021) Inhibition of Echis ocellatus venom metalloprotease by flavonoid-rich ethyl acetate sub-fraction of Moringa oleifera (Lam.) leaves: in vitro and in silico approaches. Toxin Rev 41(2): 476–486. https://doi.org/10.1080/15569543.2021.1893334

Bennour N, Mighri H, Eljani H, Zammouri T, Akrout A (2020) Effect of solvent evaporation method on phenolic compounds and the antioxidant activity of Moringa oleifera cultivated in Southern Tunisia. S Afr J Bot 129:181–190. https://doi.org/10.1016/j.sajb.2019.05.005

Albarri R, Şahin S (2022) A green method for the extraction of Moringa oleifera leaves: evaluation of several in vitro assays for bioactive properties. Biomass Convers Bioref. https://doi.org/10.1007/s13399-022-02690-z

Chigurupati S, Al-Murikhy A, Almahmoud SA, Almoshari Y, Saber Ahmed A, Vijayabalan S, . . . Raj Palanimuthu V (2022) Molecular docking of phenolic compounds and screening of antioxidant and antidiabetic potential of Moringa oleifera ethanolic leaves extract from Qassim region, Saudi Arabia. Saudi J Biol Sci 29(2): 854–859. https://doi.org/10.1016/j.sjbs.2021.10.021

Silva LMP, Inacio MRC, Silva G, Silva J, Luz J, Almeida MDG, . . . Zucolotto SM (2022) The first optimization process from cultivation to flavonoid-rich extract from Moringa oleifera Lam. leaves in Brazil. Foods 11(10): 1452. https://doi.org/10.3390/foods11101452

Kashaninejad M, Blanco B, Benito Román O, Beltrán S, Niknam SM, Sanz MT (2021) Maximizing the freeze-dried extract yield by considering the solvent retention index: extraction kinetics and characterization of Moringa oleifera leaves extracts. Food Bioprod Process 130:132–142. https://doi.org/10.1016/j.fbp.2021.09.008

Haroen U, Syafwan, Kurniawan K, Budiansyah A (2022) Determination of nutrient content, beta-carotene, and antioxidant activity of Moringa oleifera extraction using organic solution. J Adv Vet Anim Res 9(2):246–254. https://doi.org/10.5455/javar.2022.i590

Do BH, Hoang NS, Nguyen TPT, Ho NQC, Le TL, Doan CC (2021) Phenolic extraction of Moringa Oleifera leaves induces caspase-dependent and caspase-independent apoptosis through the generation of reactive oxygen species and the activation of intrinsic mitochondrial pathway in human melanoma cells. Nutr Cancer 73(5):869–888. https://doi.org/10.1080/01635581.2020.1776885

Albarri R, Şahin S (2022) Monitoring the recovery of bioactive molecules from Moringa oleifera leaves: microwave treatment vs ultrasound treatment. Biomass Convers Bioref. https://doi.org/10.1007/s13399-021-02232-z

Yerena Prieto BJ, Gonzalez Gonzalez M, Vázquez Espinosa M, González Peredo AV, García Alvarado MÁ, Palma M, . . . Barbero, G. F., (2022). Optimization of an ultrasound-assisted extraction method applied to the extraction of flavonoids from Moringa Leaves (Moringa oleífera Lam.). Agron 12(2): 261–273. https://doi.org/10.3390/agronomy12020261

Yerena Prieto BJ, Gonzalez Gonzalez M, García Alvarado MÁ, Casas L, Palma M, del Carmen Rodríguez Jimenes G, . . . Cejudo Bastante C (2022) Evaluation of the effect of different co-solvent mixtures on the supercritical CO2 extraction of the phenolic compounds present in Moringa oleifera Lam. Leaves. Agron 12(6): 1450-1462. https://doi.org/10.3390/agronomy12061450

Cui Q, Liu JZ, Wang LT, Kang YF, Meng Y, Jiao J, Fu YJ (2018) Sustainable deep eutectic solvents preparation and their efficiency in extraction and enrichment of main bioactive flavonoids from Sea buckthorn leaves. J Clean Prod 184:826–835. https://doi.org/10.1016/j.jclepro.2018.02.295

Duan L, Dou LL, Guo L, Li P, Liu EH (2016) Comprehensive evaluation of deep eutectic solvents in extraction of bioactive natural products. ACS Sustain Chem Eng 4(4):2405–2411. https://doi.org/10.1021/acssuschemeng.6b00091

Koutsoukos S, Tsiaka T, Tzani A, Zoumpoulakis P, Detsi A (2019) Choline chloride and tartaric acid, a natural deep eutectic solvent for the efficient extraction of phenolic and carotenoid compounds. J Clean Prod 241:118384. https://doi.org/10.1016/j.jclepro.2019.118384

Yu L, Bulone V (2021) De-glycosylation and enhanced bioactivity of flavonoids from apple pomace during extraction with deep eutectic solvents. Green Chem 23(18):7199–7209. https://doi.org/10.1039/d1gc01928g

Wu L, Li L, Chen S, Wang L, Lin X (2020) Deep eutectic solvent-based ultrasonic-assisted extraction of phenolic compounds from Moringa oleifera L. leaves: optimization, comparison and antioxidant activity. Sep Purif Technol 247:117014. https://doi.org/10.1016/j.seppur.2020.117014

Hamany Djande CY, Piater LA, Steenkamp PA, Madala NE, Dubery IA (2018) Differential extraction of phytochemicals from the multipurpose tree, Moringa oleifera, using green extraction solvents. S Afr J of Bot 115:81–89. https://doi.org/10.1016/j.sajb.2018.01.009

Wang YY, Peng C, Zhang Y, Wang ZR, Chen YM, Dong JF, . . . Wei P (2022) Optimization, identification and bioactivity of flavonoids extracted from Moringa oleifera leaves by deep eutectic solvent. Food Biosci 47: 101687. https://doi.org/10.1016/j.fbio.2022.101687

Peanparkdee M, Borompichaichartkul C, Iwamoto S (2021) Bioaccessibility and antioxidant activity of phenolic acids, flavonoids, and anthocyanins of encapsulated Thai rice bran extracts during in vitro gastrointestinal digestion. Food Chem 361:130161. https://doi.org/10.1016/j.foodchem.2021.130161

George TT, Oyenihi AB, Rautenbach F, Obilana AO (2021) Characterization of Moringa oleifera leaf powder extract encapsulated in maltodextrin and/or gum arabic coatings. Foods 10(12):3044–3062. https://doi.org/10.3390/foods10123044

Lopez Polo J, Monasterio A, Cantero Lopez P, Osorio FA (2021) Combining edible coatings technology and nanoencapsulation for food application: a brief review with an emphasis on nanoliposomes. Food Res Int 145:110402. https://doi.org/10.1016/j.foodres.2021.110402

Jia C, Cao D, Ji S, Lin W, Zhang X, Muhoza B (2020) Whey protein isolate conjugated with xylo-oligosaccharides via maillard reaction: characterization, antioxidant capacity, and application for lycopene microencapsulation. LWT-Food Sci Technol 118:108837. https://doi.org/10.1016/j.lwt.2019.108837

Zhong S-R, Li M-F, Zhang Z-H, Zong M-H, Wu X-L, Lou W-Y (2021) Novel antioxidative wall materials for Lactobacillus casei microencapsulation via the maillard reaction between the soy protein isolate and prebiotic oligosaccharides. J Agric Food Chem 69(46):13744–13753. https://doi.org/10.1021/acs.jafc.1c02907

Wang Y, Duan X, Ren G, Liu Y (2019) Comparative study on the flavonoids extraction rate and antioxidant activity of onions treated by three different drying methods. Dry Technol 37(2):245–252. https://doi.org/10.1080/07373937.2018.1482907

Li M, Chen X, Deng J, Ouyang D, Wang D, Liang Y, . . . Sun Y (2020) Effect of thermal processing on free and bound phenolic compounds and antioxidant activities of hawthorn. Food Chem 332: 127429. https://doi.org/10.1016/j.foodchem.2020.127429

Wu CJ, Wu JQ, Hu Y, Pu S, Lin Y, Zeng Z, . . . Chen WH (2021) Design, synthesis and biological evaluation of indole-based 1,2,4 triazolo 4,3-a pyridine derivatives as novel microtubule polymerization inhibitors. Eur J Med Chem 223: 113629. https://doi.org/10.1016/j.ejmech.2021.113629

Meng FB, Li JJ, Zhang Q, Li YC, Liu DY, Chen WJ, Zhang Y (2021) Complex wall materials of polysaccharide and protein effectively protected numb-taste substance degradation of Zanthoxylum bungeanum. J Sci Food Agri 101(11):4605–4612. https://doi.org/10.1002/jsfa.11103

Shao P, Xuan S, Wu W, Qu L (2019) Encapsulation efficiency and controlled release of Ganoderma lucidum polysaccharide microcapsules by spray drying using different combinations of wall materials. Int J Biol Macromol 125:962–969. https://doi.org/10.1016/j.ijbiomac.2018.12.153

Brodkorb A, Egger L, Alminger M, Alvito P, Assuncao R, Ballance S, . . . Recio I (2019) INFOGEST static in vitro simulation of gastrointestinal food digestion. Nat Protoc 14(4): 991–1014. https://doi.org/10.1038/s41596-018-0119-1

Mansur AR, Song NE, Jang HW, Lim TG, Yoo M, Nam TG (2019) Optimizing the ultrasound-assisted deep eutectic solvent extraction of flavonoids in common buckwheat sprouts. Food Chem 293:438–445. https://doi.org/10.1016/j.foodchem.2019.05.003

Rajha HN, Darra NE, Hobaika Z, Boussetta N, Vorobiev E, Maroun RG, Louka N (2014) Extraction of total phenolic compounds, flavonoids, anthocyanins and tannins from grape byproducts by response surface methodology. Influence of solid-liquid ratio, particle size, time, temperature and solvent mixtures on the optimization process. Pol J Food Nutr Sci 05(04):397–409. https://doi.org/10.4236/fns.2014.54048

Rocchetti G, Blasi F, Montesano D, Ghisoni S, Marcotullio MC, Sabatini S, . . . Lucini L (2019) Impact of conventional/non-conventional extraction methods on the untargeted phenolic profile of Moringa oleifera leaves. Food Res Int 115: 319–327. https://doi.org/10.1016/j.foodres.2018.11.046

Zhu H, Zhang J, Li C, Liu S, Wang L (2020) Morinda citrifolia L. leaves extracts obtained by traditional and eco-friendly extraction solvents: relation between phenolic compositions and biological properties by multivariate analysis. Ind Crop Prod 153. https://doi.org/10.1016/j.indcrop.2020.112586

Coppin JP, Xu Y, Chen H, Pan M.-H, Ho C.-T, Juliani R, . . . Wu Q (2013) Determination of flavonoids by LC/MS and anti-inflammatory activity in Moringa oleifera. J Func Foods 5(4): 1892–1899. https://doi.org/10.1016/j.jff.2013.09.010

Li C, Dong Z, Zhang B, Huang Q, Liu G, Fu X (2020) Structural characterization and immune enhancement activity of a novel polysaccharide from Moringa oleifera leaves. Carbohyd Polym 234:115897. https://doi.org/10.1016/j.carbpol.2020.115897

Lizbeth Martinez-Gonzalez C, Martinez L, Martinez Ortiz EJ, Eva Gonzalez Trujano M, Deciga Campos M, Ventura Martinez R, Diaz Reval I (2017) Moringa oleifera, a species with potential analgesic and anti-inflammatory activities. Biomed Pharmacother 87:482–488. https://doi.org/10.1016/j.biopha.2016.12.107

Zhao DR, Jiang YS, Sun JY, Li HH, Luo XL, Zhao MM (2019) Anti-inflammatory mechanism Involved in 4-ethylguaiacol-mediated inhibition of LPS-induced inflammation in THP-1 cells. J Agric Food Chem 67(4):1230–1243. https://doi.org/10.1021/acs.jafc.8b06263

Guillén Román CJ, Guevara González RG, Rocha- Guzmán NE, Mercado-Luna A, Pérez Pérez MCI (2018) Effect of nitrogen privation on the phenolics contents, antioxidant and antibacterial activities in Moringa oleifera leaves. Ind Crop Prod 114:45–51. https://doi.org/10.1016/j.indcrop.2018.01.048

Maduwanthi SDT, Marapana R (2021) Total phenolics, flavonoids and antioxidant activity following simulated gastro-intestinal digestion and dialysis of banana (Musa acuminata, AAB) as affected by induced ripening agents. Food Chem 339:127909. https://doi.org/10.1016/j.foodchem.2020.127909

Oldoni TLC, Merlin N, Bicas TC, Prasniewski A, Carpes ST, Ascari J, . . . Thome G (2021) Antihyperglycemic activity of crude extract and isolation of phenolic compounds with antioxidant activity from Moringa oleifera Lam. leaves grown in Southern Brazil. Food Res Int 141: 110082. https://doi.org/10.1016/j.foodres.2020.110082

Yang QQ, Kim G, Farha AK, Luo Q, Corke H (2020) Phenolic profile, antioxidant and antiproliferative activities of diverse peanut cultivars. J Food Meas Charact 14(5):2361–2369. https://doi.org/10.1007/s11694-020-00483-4

Yu XH, Hong XQ, Mao QC, Chen WH (2019) Biological effects and activity optimization of small-molecule, drug-like synthetic anion transporters. Eur J Med Chem 184:111782. https://doi.org/10.1016/j.ejmech.2019.111782

Funding

This work was supported by Guangdong Basic and Applied Basic Research Foundation (No. 2020A1515110427, 2022A1515010009, 2020A1515110406), the Youth Innovation Project of Guangdong Province University (No. 2020KQNCX088), the National Natural Science Foundation of China (No. 21802019), Science and Technology Program of Jiangmen City (JZ202210), Graduate Education Innovation Program of Wuyi University (YJS-SF JD-22–04), the Characteristics Innovation Project of Guangdong Province University (No. 2019KTSCX185), COVID-19 Epidemic Prevention and Control Project (No. 2020FKZX02), and the Science and Technology Program of Jiangmen (No. 2020030101110005138).

Author information

Authors and Affiliations

Contributions

Ping Wei: conceptualization, investigation, formal analysis, writing—original draft, writing—editing. Yue Zhang: methodology, investigation, data treatment, formal analysis. Yao-Ying Wang: methodology, software, investigation, writing—original draft. Jin-Feng Dong: formal analysis, validation. Bi-Ni Liao: writing—editing. Zhi-Cheng Su: formal analysis. Wu Li: writing—editing. Ju-Cai Xu: writing—editing. Wen-Yong Lou: writing—editing. Hui-Hui Su: writing—editing. Chao Peng: project administration, funding acquisition, supervision, writing—review.

Corresponding author

Ethics declarations

Ethical approval

With no need for ethical approval.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wei, P., Zhang, Y., Wang, YY. et al. Efficient extraction, excellent activity, and microencapsulation of flavonoids from Moringa oleifera leaves extracted by deep eutectic solvent. Biomass Conv. Bioref. 13, 15095–15109 (2023). https://doi.org/10.1007/s13399-023-03877-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-023-03877-8