Abstract

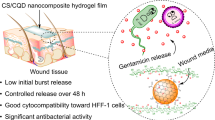

Infectious diseases of skin wound–based bacteria are a considerable issue that often hinders the wound closure, thereby delaying the healing process. The use of wound dressing based-renewable polymers with natural essential oil could overcome the deficiencies of skin wounds. In this work, wound dressings from carboxymethyl cellulose (CMC)/quaternized starch (MS-Q188) in presence antimicrobial cinnamon essential oil (CIEO) nanoemulsion were prepared. Three variable ratios of CIEO (i.e., 1, 3, and 5 wt.%) in nanoemulsion forms were used to fabricate CMC/MS-Q188 bionanocomposites. The resulting bionanocomposites were investigated by XRD, FT-IR, and SEM. The mechanical, hydrophilicity, and barrier properties were evaluated, the outcomes of which demonstrated the tensile properties were achieved. However, the hydrophilicity, water vapor, and oxygen barrier properties were affected when the CIEO nanoemulsion added to the matrix. The migration of polymer components to the skin tissue and cytotoxic effect were investigated by cytotoxicity assays. The outcomes showed that the cell viability was located in the range of ~ 92–100% even at all studied concentrations, indicating there was no cytotoxicity to the cells. The inhibitory effects of CIEO nanoemulsion ratios on different pathogenic microbes were also verified. The developed bionanocomposites open opportunities for their use in smart skin wound dressings and biomedical applications.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The integrity of the people’s health is effectively lied in the skin because of its pivoted role for protecting the human body from exterior hazards, include invade of microorganisms and ultraviolet radiations. As known, the skin tissue is vulnerable to any wound or damage, leading to massive loss of the protective defense mechanism factors against the microbial intrusion and pathogenic organisms. Thereby the human body would badly be affected by these wounds and be chronic, which in turn leads to hinder the wound closure and probably leads to the mortality [1]. Therefore, the growing request for antimicrobial dressing-based renewable materials has extremely emerged because of their efficiently active in prohibiting the growth of a wide range of bacteria species and fungi through interrupting microbial developments, thereby accelerating the wound healing operation [2, 3]. Presently, numerous researches have conducted on wound dressings not only for developing the ideal wound dressings for skin, but to limit the risk related to wound infection which colonized by microbes. Such ideal wound dressings should have certain requirements such as a physical barrier to avoid further adherent to the wounds, antibacterial material to eliminate the microbe infection over the wound zone, cost-effective, absorption system, and environmental conditioner to accelerate wound healing process (i.e., preserve wound hydration and absorb excess extrudates) [4, 5].

Among them, hydrogels-based biodegradable polymeric networks are considered to be a potential candidate because of their unique properties [5, 6]. Wang et al. [7] have developed hydrogel as wound dressings from water-soluble carboxymethyl chitosan (CMCS) crosslinked by 10% genipin. Their results have reported that the physicochemical and biological properties of prepared dressings were achieved. While, Yang et al. [8] have been fabricated highly toughened hydrogels from PVA/nanocellulose in presence lignin-Ag nanoparticles for enhancing antimicrobial activities. Consequently, wound dressing–based hydrogels with porous structure play a crucial role for boosting healthy and timely wound closure by protecting a wound from the surrounding (Tang et al., 2022). Nevertheless, the majority of these hydrogels are prepared by chemically crosslinked which adhere to the wounds in some degree. Mechanical debridement is required to eliminate the dressing, which has the high risk of damaging the newly formed tissue and could cause additional soreness to patients physically, thereby extending the tissue regeneration [6, 9].

Moreover, this may be accompanied by anesthesia which consumes time. To overcome these deficiencies, wound dressing–based renewable polymers can be hybridized by natural essential oils for reducing covalent interactions between the constituents, which in turn leads to the self-removal function. In addition, they gained moisturization and smoothening of the skin. Consequently, this research reported on solving these problems to fabricate highly efficient wound healings from carboxymethyl cellulose (CMC)/quaternized starch by quat-188 in presence antimicrobial natural cinnamon essential oil (CIEO) as a nanoemulsion. These bionanocomposites exhibited herein better biocompatibility, structural, toxicity-free, renewability, and mechanical stability for biomedical applications. Many studies [10,11,12,13] have carried out on modifying or grafting CMC by different biopolymers or biomaterials to enhance the processability and the biocompatibility of CMC, particularly with bone and skin when it used as wound healing. However, most of these reactions are considered to be chemically crosslinked by covalent bonds rather than physical interactions. For this cause, the wound dressing–based CMC/quaternized starch by Q-188 was mixed with CIEO essential oil nanoemulsion to achieve the physicochemical interactions.

Essential oils (EOs) derived from plants have recently been paid the greatest attention in a variety of practical disciplines such as food packaging, pharmaceutical, and cosmetic purposes [14, 15]. This is due to not only they are 100% renewable materials, but they can be used as a promising agent for antimicrobial, anticancer therapy [16], as well as burn healing treatment [17, 18]. Among of these EOs, cinnamon essential oil (CIEO) extracted from bark parts of Ceylon cinnamon (Cinnamomum cassia) has emerged promising impacts against pathogenic microbes and cancer cell diseases [19, 20]. Moreover, the recent studies [21,22,23] have witnessed rapid development of the use of CIEO as an adjunctive therapy in enhancing symptoms of depressive and anxiety disorders. It was found that CIEO essential oil composed of more than 20 constituents; however, the major constituent in the CIEO was cinnamaldehyde, which identified by GC–MS to be ~ 81% of the oil [24], in addition to benzaldehyde (~ 6.70%), cinnamyl ester (~ 6.10%), coumarin (~ 3.20%), camphene (~ 1.70%), and other components. These constituents possess phenolic structure and aldehyde and ketone groups that are notably having positive antimicrobial and antiviral effects [24,25,26]. On the other hand, they can be promoted the noncovalent interactions via the hydrogen bonding linkages. They can also give the moisturizing and smoothing for the skin. Furthermore, another advantage of CIEO is in skin-contact that there is no hazardous when it may be predicated to migrate into skin, thereby becoming a safe component [27].

In the current work, the influence of CIEO essential oil addition to CMC/quaternized starch by Q-188 was investigated with the aim to produce highly efficient antimicrobial wound dressings with self-removal capability to meet eco-friendly purposes. Hence, morphology, mechanical properties, hydrophilicity, water vapor/gas permeability, cytotoxicity, and antimicrobial activities were evaluated. The proposed mechanism for the chemical reactions of quaternized starch, CMC, and CIEO essential oil was also studied.

2 Materials and experimental techniques

2.1 Materials

Carboxy methylcellulose (CMC) was supplied from Sigma Aldrich, Cairo-Egypt. Maize starch (MS) consisting of amyl pectin with traces of amylase and moisture content of 12–13.8% was obtained from National Company for Maize Products (NCMP), Cairo-Egypt. (3-Chloro-2-hydroxypropyl) trimethylammonium chloride (60%), under commercial name Quat-188 (Q188), was purchased from Sigma-Aldrich, Cairo-Egypt. Citric acid extra-pure and Tween 20 were offered from SDFCL, India. Cinnamon essential oil (CIEO) with 100% pure therapeutic grade was brought from oil recovery unit, National Research Centre, Giza-Egypt. All other reagents such as sodium hydroxide (NaOH), distilled water (DW), acetone, and ethanol (EtOH) were directly used as received without extra purification.

2.2 Synthesis of quaternized starch by Q188

Herein, quaternization of starch by Q188 was synthesized according to the previous procedure in literature [28] with further modifications. About 16 g of Q188 was mixed with sodium hydroxide solution at Q188/ NaOH ratio 3:1 using a material to liquor ratio 1:4. The half amount of NaOH solution was added to Q188. Meanwhile, the other half of NaOH was added to 20-g starch pre-slurred in water (starch to liquor ratio 1:2). Q188/NaOH solution was added to starch/NaOH, and the reaction content was maintained in water bath with continuous stirring at 70 °C for 2 h. At the end of the reaction, the mixture was neutralized to be at pH 7 using 1 N HCl. The prepared quaternized starch (MS-Q188) was precipitated by EtOH and washed several times with EtOH /DW 80/20, followed by acetone. The obtained precipitation was finally dried at 40 °C.

2.3 Synthesis of cinnamon essential oil nanoemulsion

Oil-in-water nanoemulsion was prepared using cinnamon oil (5% v/v), 1.25 ml of tween 20 (i.e., nonionic surfactant), and DW. Initially, coarse emulsion was formed by adding 46.25 ml of deionized water to organic phase containing 2.5-ml cinnamon essential oil and surfactant, was mixing and stirring via a magnetic stirrer at 500 rpm for 10 min, then the emulsion was heating at 60 °C for 6 h then stirring, using (Daihan Scientific Homogenizer) at 25,000 rpm for 10 min. The obtained CIEO nanoemulsion was kept in normal conditions for late use [29].

2.4 Fabrication of CMC/Q188-CIEO bionanocomposites

The CMC/MS-Q188-CIEO bionanocomposites were fabricated as the following process. Firstly, 3 g of CMC was transferred into a 250-mL flask, and 100-ml DW added to it. The temperature was maintained at 70 °C with stirring to form a homogeneous viscous solution (3 wt.%). In another beaker, MS-Q188 (3 wt.%) was dissolved in hot DW at 60 °C. A blend of CMC/MS-Q188 was obtained by mixing the two polymer solutions (50%: 50% wt./wt.). Separately, citric acid was added as crosslinker (10% wt./wt. based on polymer blend) to polymer solution with continuous mechanical stirring. Afterward, the mixture was cured at 150 °C for 10 min to create the cross-linked blend. Then, the solution was left to cool down till room temperature followed by addition of glycerol (3 wt.%) and cinnamon oil nanoemulsion (CIEO) in variable proportions of (i.e., 1, 3, and 5%) to polymer blend. The prepared suspension was casted into transparent rounded glass Petri dishes and left at normal conditions for solvent evaporation and film formation (Fig. 1). The investigated bionanocomposites were coded as CMC/MS-Q188-xCIEO, where x refers to the cinnamon essential oil nanoemulsion (CIEO) proportion in the nanocomposite.

2.5 X-ray diffraction analysis

The structure and the morphology of bionanocomposite films were investigated by using a Philips X-ray diffractometer (PW 1930 generator, PW 1820 goniometer, Netherlands) equipped with Cu Kα radiation (45 kV, 40 mA, and λ = 0.15418 nm). The data were scanned over a 2Ө range from 10 to 80° with step size of 0.05 and at a counting time per step 2 s/step, and at a sampling width of 0.010°.

2.6 Scanning electron microscopy analysis

The morphology of the prepared bionanocomposites was assessed via scanning electron microscopy (SEM, Model Quanta FEG 250, FEI Company). The specimens were first cryo-fractured in liquid nitrogen, and the fractured cross-section was gold-coated agar by automatic sputter coater before the examination to avoid electrostatic charging during the observation. The acceleration voltage (5–10 kV) and the electron beam spot size (3–3.5) were closely chosen for optimizing the quality of the images. Moreover, the FT-IR analysis in transmission mode for raw maize starch, pure Q188 and synthesized MS-Q188 and ATR-FT-IR for fabricated bionanocomposites were carried out using IR Affinity-1S, Shimadzu-Japan, respectively.

2.7 Characterization of CIEO nanoemulsion

The droplet size distribution of cinnamon essential oil nanoemulsion was determined using DLS and a Zeta sizer (Nano ZS model ZEN 3600, Malvern, UK) at a fixed scattering angle of 173° and a temperature of 25 °C, the droplet size distribution of cinnamon essential oil (CIEO) nanoemulsion was measured. In order to eliminate the viscosity generated by the ingredients and, additionally, to minimize the multiple scattering effect, the generated emulsion was diluted with milli-Q (Millipore corporation) double distilled water prior to the experiment. Also, to investigate the morphology of the cinnamon essential oil (CIEO) nanoemulsion, transmission electron microscopy (TEM, Model: JEOL-JEM-1400) was used. One drop of the produced nanoemulsion was placed on a copper grid and negatively stained with phosphortungstic acid to facilitate TEM examinations.

2.8 Mechanical properties

The tensile properties in terms of tensile stress and tensile strain at break for bionanocomposite films were determined using an Instron 34SC-5 universal tensile testing machine, UK, equipped with a load cell of 5 kN and a crosshead speed of 10 mm min−1, according to ASTM D 882–18. The dumbbell specimens were die-cut from the casted biocomposite films. Prior to testing, all specimens were conditioned at a temperature of 23 ± 2 °C and 50 ± 5% relative humidity for at least 24 h. The average and standard uncertainty of three parallel trails for each sample was recorded.

2.9 Hydrophilicity assessment

The hydrophilicity of bionanocomposites films was metered by water contact angle (WCA) measurements. The test for all samples was conducted by depositing different water droplets on the surface of specimens using an OCA20-programmed and software-controlled video-based contact angle meter (Data Physics Instruments GmbH, Filder- Stadt, Germany). The WCA values were acquired after the deposition during the first few seconds at 25 °C and 58% RH.

2.10 Barrier properties

By making use of a GBPI W303 (B) water vapor permeability analyzer, the water vapor transmission rate (WVTR) was distinguished using the cup method. The WVTR was considered in terms of the amount of water vapor that has moved in a unit time across the unit area under specific humidity (4–10%) and temperature (38 °C) conditions as per the standards of ASTM D1653 and ASTM E96. Moreover, the rate of transmission of gas GTR (O2) was obtained by means of an N530 B Gas Permeability Analyzer (China), as per the standards followed by ASTM D1434-82 (2003).

2.11 Cytotoxicity assays

Cytotoxic impact on human tumor cell lines in terms of cell viability was estimated by the mitochondrial dependent reduction of yellow MTT (3-(4,5-dimethylthiazol-2-yl)-2,5-diphenyl tetrazolium bromide) to purple formazan [30, 31]. All the following experiments were also performed in a sterile area using a laminar flow biosafety cabinet class II (Manufactured by: Labconco). In brief, cells were suspended in DMEM medium, 1% antibiotic–antimycotic mixture (10,000U/ml potassium penicillin, 10,000 μg/ml streptomycin sulfate, and 25 μg/ml amphotericin B) and 1% l-glutamine and 5% fetal bovine serum at 37 °C under 5% CO2 using CO2 incubator (Sartorius Stedim, Biotech, Göttingen, Germany). Viable cells were batch cultured for 10 days, then seeded at concentration of 10 × 103 cells/well in fresh complete growth medium in 96-well plastic plates at 37 °C for 24 h under 5% CO2 either alone (negative control) or with different concentrations of drugs to give a final concentration of (500, 250, 125, 62.5, 31.25, 15.625 μg/ml).

After 48 h of incubation, medium was aspirated, 20 μl MTT salt (2.5 μg/ml) were added to each well and incubated for further 4 h at 37 °C under 5% CO2. To stop the reaction and dissolving the formed crystals, 200μL of 10% sodium dodecyl sulfate (SDS) in 0.01 M HCL was added to each well and incubated overnight at 37 °C. A positive control which composed of 100 μg/ml was used as a known cytotoxic natural agent which gives 100% lethality under the same conditions [32]. The absorbance was then measured using a microplate multi-well reader (Bio-Rad Laboratories Inc., model 3350, Hercules, CA, USA) at 595 nm and a reference wavelength of 620 nm.

2.12 Pathogenic strains tests

Pathogenic strains were collected from the Dairy department at National Research Centre, Egypt for example (Staphylococcus aureus ATCC 6538; Bacillus cereus B-3711; Escherichia coli ATCC 8739; and Salmonella typhimurium ATCC 14,028). Tested bacterial strains were incubated in nutrient broth at 35 °C/24 h until noticeable turbidity became 0.5 “McFarland” standard solution. The antimicrobial assessment of the fabricated bionanocomposites (that contained different concentrations of CIEO essential oil) was carried out via the disc diffusion along with as described in our previous article [33] and recommended (BSAC 2007). Where 20 μL of the various tested strains was spread on the surface of the plates comprising Mueller–Hinton agar medium using sterile cotton swabs and the plates were reset at 37 °C for 2 h to saturate with bacterial strains. The CMC/MS-Q188-CIEO bionanocomposites films samples cut in the diameter 0.5 cm and put on the surface of agar medium. The tested plates were incubated at 37 °C/24 h. After the incubation time, the outcomes and the diameter of growth inhibition zones were metered in millimeter, and the mean values were registered.

2.13 Statistical analysis

All experiment outcomes were expressed as an average ± standard uncertainty. The data were analyzed by one-way or single factor analysis of variance (ANOVA design) in order to compare the differences between the sample means according to ISO GUIDE 35–2017. This analysis is used to determine the probability level (p value) and associated F-distribution for the mean values of independent groups for each CIEO concentration.

3 Results and discussion

3.1 Evaluation droplet size distribution and morphology of cinnamon essential oil nanoemulsion

The prepared nanoemulsion via cinnamon oil was designed in two stages. The oil phase, which comprised cinnamon oil and Tween 80 as a surfactant, was first made into a coarse emulsion by adding distilled water (1:3 v/v), which was then subjected to ultrasonic emulsification to generate a nanoemulsion. Figure 2a displays the nanoemulsion droplet size dispersion. The average droplet size is 48 nm, and the droplet size ranges from 5 to 100 nm, as shown in Fig. 2a. Additional information about the nanoemulsion droplets morphology and structure were provided by TEM analysis. It was found that the spherical shape of the nanoemulsion droplets for CIEO nanoemulsion was noticed as demonstrated in Fig. 2b. This outcome was confirmed by DLS studies. Additionally, the TEM image of CIEO nanoemulsion showed that a roughly spherical-shaped CIEO nanoemulsion was observed, confirming the formation of spherical particles with irregular sizes from 28 to 50 nm in the nanoemulsion.

3.2 X-ray diffraction and FT-IR analysis

XRD thermograms were confirmed the fabrication of CMC/MS-Q188 nanocomposites in presence variable concentrations of CIEO ranging from 1 to 5 wt.%. The outcomes were plotted in (Figure 3a). It can be observed that the diffraction peak for CMC/MS-Q188 appeared at 2ϴ ~ 19.50° with a small shift to lower 2ϴ position when compared to pristine CMC (i.e., 2ϴ = 20.40°) [34], evidencing the existence of a cationic moiety into the backbone of CMC polymer. Nevertheless, by increasing the CIEO proportion (i.e., from 1 to 5%) in the CMC/MS-Q188 blend, new diffraction peaks were appeared at ~ 5.51°, 8.15°, 10.67°, and 13.16°, meanwhile their intensities increase with increasing the proportion of CIEO. These characteristic peaks may be attributed to CIEO nanoemulsion, indicating the formation of new networks in the CMC/MS-Q188 matrix.

The quaternization of the maize starch by Q188 (MS-Q188) and then with CMC in presence of variable ratios of CIEO nanoemulsion was supported by FT-IR spectra as illustrated in Figure 3b–c. In Figure 3b, spectra corresponding to raw maize starch and pure Q188 were also provided for comparison with cationized MS-Q188. Both spectra for raw starch and pure Q188 showed a broad absorption band at ~ 3450–3190 cm−1 that can be assigned to stretching vibration of -O–H groups and single absorption band at 1640 cm−1 was notable for the intramolecular H-bond hydroxyl group [28, 35]. However, after cationization of hybrid starch by Q188, new absorption peaks were observed at ~ 1475 cm−1 which assigned to -C-N stretching and also at ~ 2075 cm−1 that were absent in raw starch spectrum, evidencing the merge of cationic moiety into the backbone of the investigated starch. On the other hand, Figure 3c demonstrated the ATR-FT-IR spectra for CMC/MS-Q188 blend and the bionanocomposites based on the concentration of the CIEO essential oil in the blend ranging from 1 to 5%. From the figure, it was clearly noticed that the broad band appeared at ~ 3295 cm−1 assignable to stretching frequency of hydroxyl groups in CMC/MS-Q188 blend.

The position of this band was shifted into higher wavenumber (i.e., ~ at 3460 cm−1) when adding CIEO nanoemulsion to the bland. Meanwhile, an intensified band observed at ~ 1085 cm−1 especially for CMC/MS-Q188-5 CIEO bionanocomposite which was probably due to the glycosidic linkage (-C–O–C- stretching) and the bending vibration of -C–OH. All of them indicate the possible good interactions between the functional groups of CIEO and the CMC/MS-Q188 segments which can be related to the increase of the peak intensity because of the higher CIEO concentration. This outcome is consistent with contact angle measurements herein and agrees with that reported elsewhere [36]. Interestingly, it was also found that characteristic band at ~ 1731 cm−1 observed for -C = O group of CMC and its intensity increased with increasing the content of CIEO in the biopolymer film, in addition to a strong band at ~ 1670 cm−1 for -C = C- group in case of 5% of CIEO.

This confirms that a few unreacted CIEO components (i.e., cinnamaldehyde as major constituents in the oil) might be existed and easily linked with water molecules, therefore reducing the contact angle value for the bionanocomposite film. Meanwhile, the peak well of the hydroxyl for CMC/MS-Q188 became narrow with inserting MS-Q188 to CMC when compared to MS-Q188 itself. This outcome proves the consumption of -OH groups during the process, indicating the chemical interaction of hydroxy groups in MS-Q188 was expected to react with functional sites in CMC to form new carboxylic group (-COO) [37] as displayed in (Fig. 1). On contrast, the increased intensity of the hydroxyl peak of CMC/MS-Q188-5 CIEO at ~ 3460 cm−1 when compared to other nanocomposite films, indicating that the new hydroxyl group’s formation towards the reaction of CMC with CIEO essential oil as depicted in Figure 3c and was consistent with (Fig. 1).

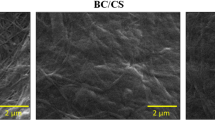

3.3 SEM analysis

SEM images can provide enjoyable information about the biocompatibility of CMC and MS-Q188 in absence and presence of CIEO essential oil. Figure 4 illustrates the SEM micrographs of CMC/MS-Q188 blend and its bionanocomposite films with variable ratios of CIEO essential oil. The micrograph for blank sample (absence of oil) demonstrated that a partial aggregation from MS-Q188 particles was noticed, indicating that the addition of hybrid starch was insufficient to promote the interfacial adhesion with CMC. Thereby affecting the tensile properties of the CMC/MS-Q188 blend when compared to CMC solely (i.e., ~ 50 MPa) [37]. However, the insertion of 1 wt.% of CIEO to the blend shown better compatibility between CMC and hybrid starch and became completely miscible with the absence of clear aggregation. This corroborates CIEO role in the improvement of the biocompatibility of the CMC/MS-Q188 blend. Correspondingly, on further increment of the CIEO ratio to 5 wt.%, a rough surface with few voids was observed (see the arrows in Fig. 4). This might be due to the plasticizer impact resulting in an excess of essential oil in the blend, which in turn facilitate the movement of polymer molecules, thereby decreasing the adhesion force of the polymer matrix [14, 38]. This result agrees with that obtained by mechanical and barrier properties herein.

3.4 Mechanical properties

The mechanical properties including the tensile stress and tensile strain at break were conducted to point out the influence of variable ratios of CIEO nanoemulsion addition on the tensile properties at room temperature and at 50 ± 5% relative humidity of CMC/MS-Q188 polymer blend. As presented in (Fig. 5), the blend exhibited a quite tensile strength (~ 13.30 N/mm2) and tensile strain at break (~ 7.80%). However, after adding 1 wt. % of CIEO, a notable change for both tensile parameters, was occurred and it rose to ~ 15.70 N/mm2 and ~ 12.80%, respectively. Maybe the reason behind the achievement in these properties was due to the biocompatibility between the components, which in turn leads to the possible crosslinking throughout the interfacial bonding between the functional sites of CIEO and CMC/MS-Q188 matrix (Fig. 1).

On further increase of CIEO content from 3 to 5 wt. %, the tensile stress value crucially decreased to ~ 8.60 N/mm2(by ~ 35%) and 3.90 N/mm2 (by ~ 71%), respectively, when compared to CMC/MS-Q188 blend, but it is still sufficient to be acceptable in wound healing applications. Also, the tensile strain at break declined to ~ 2.40% in case of bionanocomposite film having 5 wt.% of essential oil. This might be due to plasticizer impact resulting in an excess of CIEO oil within the polymer matrix (i.e., bearing CHO groups) which in turn increase the free volume available by chains mobility and exigent less energy to break the composite chains during the test, leading to increase the film ductility to brittle transition stage [37]. This outcome agrees with that obtained by WCA and permeability measurements. Accordingly, it can be concluded that the concentration at 1 wt.% CIEO in the polymer blend was preferable to give high tensile properties compared to the others.

3.5 Hydrophilicity evaluation for bionanocomposite films

WCA measurements of fabricated samples with variable contents of CIEO essential oil nanoemulsion, in terms of hydrophilicity, play a pivot role in wound dressing and scar inhibition. In order to assess the influence of CIEO oil in CMC biopolymer films on the surface wettability or hydrophilicity, WCA values and the representative pictures of WCA measurements using DW as probe liquid were given in (Fig. 6). It was obvious from the figure that WCA value for CMC/MS-Q188 blank was 98° attesting the lowest wettability [39]. However, WCA values drastically reduced from 79.10 to 31.30° when increasing the CIEO proportion in the matrix from 1 to 5%, respectively. The reason for this was that an increase in the hydrophilic character of the bionanocomposite was taken place because of the inclusion of the CIEO, which could be induced to gain more water droplets with the film constituents at the surface, which in turn contributes to increase the WCA value.

Thus, the wettable wound dressing cannot only absorb the tissue exudates from the wound region to limit the microbial infection hazard, but can also preserve the moisture to boost the swelling behavior, therefore improving the wound dressing performance [40]. This outcome is consistent with that reported elsewhere for both quaternized silicone and chitosan as a wound healing material [41]. Further, Winter et al. have reported that by maintaining the wound environment moist, it has improved the healing and fast-curing of the wound compared to keeping the wound environment dry [42]. These data revealed that the fabricated bionanocomposite films are strongly promising alternatives to classical cotton-based wound dressings.

3.6 Barrier properties

Table 1 illustrates the data obtained for OTR and WVTR for fabricated CMC/MS-Q188-CIEO bionanocomposites having variable ratios of CIEO essential oil. The accomplished values displayed that the permeability of OTR increased by adding CIEO nanoemulsion in the fabricated CMC/MS-Q188-CIEO bionanocomposites even at any concentration. As given in the table, the OTR for the CMC/MS-Q188 blend (with no CIEO nanoemulsion) was 29 cm3 m−2 24 h−1 Pa−1 attesting the relative hydrophobic nature of the film and then increased to 35 cm3 m−2 24 h−1 Pa−1 with using 1 wt.% of CIEO content in the blend. Moreover, when adding 3 and 5 wt.% CIEO nanoemulsion in the CMC/MS-Q188 matrix, the OTR values were gradually increased by increasing the CIEO from 37 to 70 cm3 m−2 24 h−1 Pa−1, respectively. Generally, it is the principle necessary of wound dressing, as the presence of oxygen aids new cells to regenerate and accelerate the wound healing process [43].

Similarly, by conducting the WVTR instrument to evaluate the permeability performance for the fabricated CMC/MS-Q188-CIEO bionanocomposites using different proportions of CIEO. It was also noticed that the WVTR values gradually increased by increasing the loadings of CIEO from 1 to 5 wt.%. The WVTR values were 945 g/(m2 day) for CMC/MS-Q188 blend and 1150 g/(m2 day) for CMC/MS-Q188-1 CIEO sample. When increasing the CIEO content to 3% and 5% in the blend, WVTR value was 1211 and 1371 g/(m2 day), respectively. The key reason for the reduction of OTR and WVTR values with addition of CIEO concentration to the matrix is the plasticizer effect of the essential oil which in turn boosts to the polymer chains relaxation and interfacial debonding between the components in biopolymer matrix, therefore increasing the permeability property. This result agrees with that reported by WCA measurements.

3.7 Cytotoxicity assays

The cytotoxicity assessment of human tumor cell lines was verified by determining the percentage cell viability and IC50 values using the MTT assay as displayed in Figure 7a–b. The investigated samples were tested at different concentrations ranging from 500 to 15.625 μg/ml under incubation at 37 °C/5% CO2 for 48 h. As illustrated in Figure 7a, the cell viability was located in the range of 92–100% even at all studied concentrations. This confirms that prepared samples either with or without CIEO essential oil, as well as their dilutions, did not exhibit cytotoxicity to the cells. Moreover, it was found from ANOVA analysis that F calculated (i.e., 0.50029) < F critical (i.e., 3.68232) and P value (i.e., 0.61611) > 0.05 indicating the experimental results are located in the valid area, and there is a common point in the data population; therefore, data homogeneity between the different groups were achieved.

This finding is consistent with that verified in literature’s elsewhere [15]. Moreover, Serini et al. [44] reported that the material can be exhibited a significant toxicity when cell viability value was less than 50% compared to the control cells. Cell viability was above 90% in the most of our data cases wherein cytotoxicity was determined, demonstrating the high safety of these biomaterials and their potential as candidates for smart wound dressings. Adding CIEO essential oil to the matrix may consistently result in a reduction in the IC50 value (Figure 7b). Maybe the aldehyde groups in CIEO, especially at the highest oil ratio, were the cause of that decrease in IC50 value, which could have had a noticeable impact on cell proliferation [40, 45].

3.8 Antibacterial activity for bionanocomposites

Table 2 shows the antibacterial effects of designated of the fabricated CMC/MS-Q188-CIEO bionanocomposites containing different ratios (1, 3, and 5%) of the fabricated CIEO nanoemulsion when examined against Gram-positive bacteria (S. aureus and B. cereus) and Gram-negative bacteria (E. coli, and S. typhmirum). The diameter of clear inhibition zone was significantly increased when CIEO essential oil incorporated into CMC/MS-Q188 matrix and the inhibition zone ranged from 14 to 35 mm against tested strains. Furthermore, the clear inhibition zone meaningfully improved by adding different loadings of CIEO nanoemulsion. In the case of using Staphylococcus aureus strain, the inhibition zone was verified from 14 to 20 mm when using different concentrations of investigated CIEO.

Also, the inhibition zone significantly improved for Bacillus cereus in the range of 23 to 28 mm. In case of using Gram-negative bacteria such as Escherichia coli and Salmonella typhimurium, the inhibition zone was increased by increasing the ratio of CIEO essential oil in the CMC/MS-Q188 bionanocomposites from 21 to 30 mm.

Furthermore, the obtained outcomes establish that the addition of CIEO essential oil to CMC/MS-Q188 blend showed strong antimicrobial properties against Gram-positive and Gram-negative bacteria strains, due to the CIEO nanoemulsion constituents that possess phenolic structure and aldehyde and ketone groups that are notably having positive antimicrobial and antiviral effects [20, 25, 26]. Consequently, the outcomes reveal excellent possibility of utilizing these toxicity-free bionanocomposites based natural CIEO essential oil for potential wound healing and tissue engineering applications.

4 Conclusions

In the present work, high-efficient and toxicity-free wound dressing materials were fabricated from CMC/quaternized starch in presence antibacterial natural CIEO nanoemulsion by solution casting route. This technique was developed for enhancing the removal wound dressing biomaterial via physicochemical linkages by adding antimicrobial natural CIEO nanoemulsion. The chemical structure of hybrid starch by Q188 and the bionanocomposites were characterized by FT-IR spectroscopy and XRD patterns. SEM micrographs demonstrated that the biocompatibility between CMC and hybrid starch was achieved with inserting CIEO nanoemulsion, especially at 1 wt.% of the oil. Whereas high CIEO nanoemulsion concentration (i.e., 5 wt.%) in the blend may induce to form the aggregation structure. The fabricated CMC/MS-Q188-CIEO bionanocomposites showed desirable tensile properties even at high essential oil concentrations when compared to wound dressing materials based-hydrogels. However, the obtained outcomes from hydrophilicity and barrier properties were proven that the physicochemical interactions between CMC and hybrid starch in presence CIEO essential oil were achieved. Where high CIEO content in the polymer blend can drive to form noncovalent interactions via the hydrogen bonds. Moreover, the cytotoxicity assays displayed that the cell viability was located in the range of ~ 92–100% even at all studied concentrations, confirming the toxicity-free of these materials to the cells. CMC/MS-Q188 bionanocomposite–based CIEO essential oil were exhibited strong antibacterial activities against different pathogenic bacteria (Gram-positive and Gram-negative bacteria), when compared to the blank sample (CMC/MS-Q188). Therefore, our research reveals that these renewable bionanocomposites from CMC/MS-Q188-CIEO exhibited a strong antimicrobial activity with toxicity-free and can be serving as smart wound dressings for advanced wound care.

Data availability

The datasets used and/or analyzed during the current study available from the corresponding author on reasonable request.

References

Mohebali A, Abdouss M, Taromi FA (2020) Afshar Taromi, Fabrication of biocompatible antibacterial nanowafers based on HNT/PVA nanocomposites loaded with minocycline for burn wound dressing. Mater Sci Eng C 110:110685. https://doi.org/10.1016/j.msec.2020.110685

Edwards R, Harding KG (2004) Bacteria and wound healing. Curr Opin Infect Dis 17:91–96. https://doi.org/10.1097/00001432-200404000-00004

Omar A, Wright JB, Schultz G, Burrell R, Nadworny P (2017) Microbial biofilms and chronic wounds. Microorganisms 5:1–15. https://doi.org/10.3390/microorganisms5010009

Singh B, Dhiman A (2016) Design of acacia gum-carbopol-cross-linked-polyvinylimidazole hydrogel wound dressings for antibiotic/anesthetic drug delivery. Ind Eng Chem Res 55:9176–9188. https://doi.org/10.1021/acs.iecr.6b01963

Zhang Y, Jiang M, Zhang Y, Cao Q, Wang X, Han Y, Sun G, Li Y, Zhou J (2019) Novel lignin–chitosan–PVA composite hydrogel for wound dressing. Mater Sci Eng C 104:110002. https://doi.org/10.1016/j.msec.2019.110002

Xu W, Song Q, Xu JF, Serpe MJ, Zhang X (2017) Supramolecular hydrogels fabricated from supramonomers: a novel wound dressing material. ACS Appl Mater Interfaces 9:11368–11372. https://doi.org/10.1021/acsami.7b02850

Wang D, Zhang N, Meng G, He J, Wu F (2020) The effect of form of carboxymethyl-chitosan dressings on biological properties in wound healing. Colloids Surfaces B Biointerfaces 194:111191. https://doi.org/10.1016/j.colsurfb.2020.111191

Yang W, Xu F, Ma X, Guo J, Li C, Shen S, Puglia D, Chen J, Xu P, Kenny J, Ma P (2021) Highly-toughened PVA/nanocellulose hydrogels with anti-oxidative and antibacterial properties triggered by lignin-Ag nanoparticles. Mater Sci Eng C 129:112385. https://doi.org/10.1016/j.msec.2021.112385

Senthilkumar C, Kannan PR, Balashanmugam P, Raghunandhakumar S, Sathiamurthi P, Sivakumar S, Arockiarajam A, Mary SA, Madhan B (2022) Collagen - Annona polysaccharide scaffolds with tetrahydrocurcumin loaded microspheres for antimicrobial wound dressing. Carbohydr Polym 3:100204. https://doi.org/10.1016/j.carpta.2022.100204

Basu P, Narendrakumar U, Arunachalam R, Devi S, Manjubala I (2018) Characterization and evaluation of carboxymethyl cellulose-based films for healing of full-thickness wounds in normal and diabetic rats. ACS Omega 3:12622–12632. https://doi.org/10.1021/acsomega.8b02015

Kim GH, Im JN, Kim TH, Lee GD, Youk JH, Doh SJ (2018) Preparation and characterization of calcium carboxymethyl cellulose/chitosan blend nonwovens for hemostatic agents. Text Res J 88:1902–1911. https://doi.org/10.1177/0040517517712101

El-Sayed S, Mahmoud KH, Fatah AA, Hassen A (2011) DSC, TGA and dielectric properties of carboxymethyl cellulose/polyvinyl alcohol blends. Phys B Condens Matter 406:4068–4076. https://doi.org/10.1016/j.physb.2011.07.050

Izadiyan Z, Shameli K, Teow SY, Yusefi M, Kia P, Rasouli E, Tareq MA (2021) Anticancer activity of 5-fluorouracil-loaded nanoemulsions containing Fe3O /Au core-shell nanoparticles. J Mol Struct 1245:131075. https://doi.org/10.1016/j.molstruc.2021.131075

Moustafa H, El-Sayed SM, Youssef AM (2021) Synergistic impact of cumin essential oil on enhancing of UV-blocking and antibacterial activity of biodegradable poly (butylene adipate-co-terephthalate)/clay platelets nanocomposites. J Thermoplast Compos Mater. https://doi.org/10.1177/0892705721989771

Ardekani NT, Khorram M, Zomorodian K, Yazdanpanah S, Veisi H, Veisi H (2019) Evaluation of electrospun poly (vinyl alcohol)-based nanofiber mats incorporated with Zataria multiflora essential oil as potential wound dressing. Int J Biol Macromol 125:743–750. https://doi.org/10.1016/j.ijbiomac.2018.12.085

Meghani N, Patel P, Kansara K, Ranjan S, Dasgupta N, Ramalingam C, Kumar A (2018) Formulation of vitamin D encapsulated cinnamon oil nanoemulsion: Its potential anti-cancerous activity in human alveolar carcinoma cells. Colloids Surf B 166:349–357. https://doi.org/10.1016/j.colsurfb.2018.03.041

Hoogewerf CJ, Hop MJ, Nieuwenhuis MK, Oen IM, Middelkoop E, Van Baar ME (2020) Topical treatment for facial burns. Cochrane Database Syst Rev (7). https://doi.org/10.1002/14651858.CD008058.pub3

Ali M, Jahromi M, Zangabad PS, Moosavi SM, Zangabad KS, Ghamarypour A, Aref AR, Hamblin MR, Education US, Education US (2018) Nanomedicine and advanced technologies for burns: preventing infection and facilitating wound healing. Adv Drug Deliv Rev 123:33–64. https://doi.org/10.1016/j.addr.2017.08.001.Nanomedicine

Kumar M, Mahmood S, Mandal UK (2022) An updated account on formulations and strategies for the treatment of burn infection - a review. Curr Pharm Des 28(18):1480–1492. https://doi.org/10.2174/1381612828666220519145859 (PMID: 35598231)

Perng DS, Tsai YH, Cherng J, Kuo CW, Shiao CC, Cherng JM (2016) Discovery of a novel anti-cancer agent targeting both topoisomerase I and II in hepatocellular carcinoma Hep 3B cells in vitro and in vivo: Cinnamomum verum component 2-methoxycinnamaldehyde. J Drug Target 24:624–634. https://doi.org/10.3109/1061186X.2015.1132221

Sohrabi R, Pazgoohan N, Seresht HR, Amin B (2017) Repeated systemic administration of hanIran. J Basic Med Sci 20:708–714. https://doi.org/10.22038/ijbms.2017.8841

Amani F, Azadi A, Rezaei A, Kharazmi MS, Jafari SM (2022) Preparation of soluble complex carriers from aloe vera mucilage/gelatin for cinnamon essential oil: Characterization and antibacterial activity. J Food Eng 334:111160. https://doi.org/10.1016/j.jfoodeng.2022.111160

Zhou L, Fu J, Bian L, Chang T, Zhang C (2022) Preparation of a novel curdlan/bacterial cellulose/cinnamon essential oil blending film for food packaging application. Int J Biol Macromol 212(May):211–219. https://doi.org/10.1016/j.ijbiomac.2022.05.137

de Moraes Filho LEPT, de Andrade MF, de Freitas LF, Palha MDLAPF, Vinhas GM (2022) Development and characterization of poly (butylene adipate-co-terephthalate)(PBAT) antimicrobial films with clove and cinnamon essential oils. J Food Process Preserv 46(4):e16489. https://doi.org/10.1111/jfpp.16489

Pradhan D, Biswasroy P, Kumar Naik P, Ghosh G, Rath G (2020) A review of current interventions for COVID-19 prevention. Arch Med Res 5:363–374. https://doi.org/10.1016/j.arcmed.2020.04.020

El-Wakil AEAA, Moustafa H, Youssef AM (2020) Antimicrobial low-density polyethylene/low-density polyethylene-grafted acrylic acid biocomposites based on rice bran with tea tree oil for food packaging applications. J Thermoplast Compos Mater. https://doi.org/10.1177/0892705720925140

Rieger KA, Schiffman JD (2014) Electrospinning an essential oil: cinnamaldehyde enhances the antimicrobial efficacy of chitosan/poly(ethylene oxide) nanofibers. Carbohyd Polym 113:561–568. https://doi.org/10.1016/j.carbpol.2014.06.075

Hebeish A, Higazy A, El-Shafei A, Sharaf S (2010) Synthesis of carboxymethyl cellulose (CMC) and starch-based hybrids and their applications in flocculation and sizing. Carbohydr Polym 79:60–69. https://doi.org/10.1016/j.carbpol.2009.07.022

El-Sayed SM, El-Sayed HS (2021) Antimicrobial nanoemulsion formulation based on thyme (Thymus vulgaris) essential oil for UF labneh preservation. J Market Res 10:1029–1041

Mitra I, Mukherjee S, Reddy Venkata PB, Dasgupta S, Jagadeesh Bose CK, Mukherjee S, Linert W, Moi SC (2016) Benzimidazole based Pt(II) complexes with better normal cell viability than cisplatin: synthesis, substitution behavior, cytotoxicity, DNA binding and DFT study. RSC Adv 6:76600–76613. https://doi.org/10.1039/c6ra17788c

El-Baz FK, Hussein RA, Mahmoud K, Abdo SM (2018) Cytotoxic activity of carotenoid rich fractions from Haematococcus pluvialis and Dunaliella salina microalgae and the identification of the phytoconstituents using LC-DAD/ESI-MS. Phyther Res 32:298–304. https://doi.org/10.1002/ptr.5976

Thabrew MI, Hughes RD, Mcfarlane IG (1997) Screening of hepatoprotective plant components using a HepG2 cell cytotoxicity assay. J Pharm Pharmacol 49:1132–1135. https://doi.org/10.1111/j.2042-7158.1997.tb06055.x

El-Sayed HS, El-Sayed SM, Mabrouk AM, Nawwar GA, Youssef AM (2021) Development of eco-friendly probiotic edible coatings based on chitosan, alginate and carboxymethyl cellulose for improving the shelf life of UF soft cheese.". J Polym Environ 29(6):1941–1953

Abdel-Galil A, Ali HE, Atta A, Balboul MR (2014) Influence of nanostructured TiO 2 additives on some physical characteristics of carboxymethyl cellulose (CMC). J Radiat Res Appl Sci 7:36–43. https://doi.org/10.1016/j.jrras.2013.11.004

Ibrahim MM, Moustafa H, El Rahman ENA, Mehanny S, Hemida MH, El-Kashif E (2020) Reinforcement of starch based biodegradable composite using Nile rose residues. J Mater Res Technol 9:6160–6171. https://doi.org/10.1016/j.jmrt.2020.04.018

Dong R, Guo B (2021) Smart wound dressings for wound healing. Nano Today 41:101290. https://doi.org/10.1016/j.nantod.2021.101290

Tavares KM, de Campos A, Luchesi BR, Resende AA, de Oliveira JE, Marconcini JM (2020) Effect of carboxymethyl cellulose concentration on mechanical and water vapor barrier properties of corn starch films. Carbohydr Polym 246:116521. https://doi.org/10.1016/j.carbpol.2020.116521

Moustafa H, Darwish NA, Youssef AM (2022) Rational formulations of sustainable polyurethane/chitin/rosin composites reinforced with ZnO-doped-SiO2 nanoparticles for green packaging applications. Food Chemistry 371:131193. https://doi.org/10.1016/j.foodchem.2021.131193

Ramírez C, Gallegos I, Ihl M, Bifani V (2012) Study of contact angle, wettability and water vapor permeability in carboxymethylcellulose (CMC) based film with murta leaves (Ugni molinae Turcz) extract. J Food Eng 109:424–429. https://doi.org/10.1016/j.jfoodeng.2011.11.005

Yu X, Cheng C, Peng X, Zhang K, Yu X (2022) A self-healing and injectable oxidized quaternized guar gum/carboxymethyl chitosan hydrogel with efficient hemostatic and antibacterial properties for wound dressing. Colloids Surfaces B Biointerfaces 209:112207. https://doi.org/10.1016/j.colsurfb.2021.112207

Gao Z, Su C, Wang C, Zhang Y, Wang C, Yan H, Hou G (2021) Antibacterial and hemostatic bilayered electrospun nanofibrous wound dressings based on quaternized silicone and quaternized chitosan for wound healing. Eur Polym J 159:110733. https://doi.org/10.1016/j.eurpolymj.2021.110733

Rogrers RPSJ, © (1962) Nature Publishing Group. Nat Int J Sci 196:1048–1050

Singh B, Dhiman A (2016) Design of acacia gum-carbopol-cross-linked-polyvinylimidazole hydrogel wound dressings for antibiotic/anesthetic drug delivery. Ind Eng Chem Res 55(34):9176–9188. https://doi.org/10.1021/acs.iecr.6b01963

Serini S, Cassano R, Facchinetti E, Amendola G, Trombino S, Calviello G (2019) Anti-irritant and anti-inflammatory effects of DHA encapsulated in resveratrol-based solid lipid nanoparticles in human keratinocytes. Nutrients 11:1–17. https://doi.org/10.3390/nu11061400

Yusefi M, Soon MLK, Teow SY, Monchouguy EI, Neerooa BNHM, Izadiyan Z, Shameli K (2022) Fabrication of cellulose nanocrystals as potential anticancer drug delivery systems for colorectal cancer treatment. Int J Biol Macromol 199:372–385. https://doi.org/10.1016/j.ijbiomac.2021.12.189

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB). The authors wish to gratefully acknowledge the National Research Centre (NRC), Egypt for supporting the current work through; Project No: 12010304.

Author information

Authors and Affiliations

Contributions

Hesham Moustafa, Hanaa E. Nasr, and Ahmed M. Youssef: conceptualization, formal analysis, investigation, methodology, resources, supervision, validation, writing — original draft, writing — review and editing.

Corresponding authors

Ethics declarations

Ethics approval

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Moustafa, H., Nasr, H.E. & Youssef, A.M. Development of antibacterial carboxymethyl cellulose/quaternized starch bionanocomposites based on cinnamon essential oil nanoemulsion for wound healing applications. Biomass Conv. Bioref. (2022). https://doi.org/10.1007/s13399-022-03403-2

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-022-03403-2