Abstract

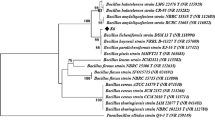

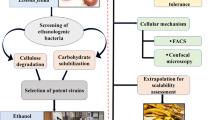

Due to its flexible properties, bacterial nanocellulose (BNC) has been attracting tremendous attention. In this study, BNC was produced by Acetobacter xylinum ATCC2376 and a local isolate, namely, Bacillus cereus MMS1. The production of BNC was done by utilising pineapple peel extract (PPE) (wastes discarded after cutting the fruit) as the alternative carbon source substituting the commercial D-glucose (control) in Hestrin–Schramm (HS) medium under agitated conditions. This research is aimed to investigate the synthesis of BNC by an isolated bacterial strain from termite’s gut using an agro-industrial waste which is the pineapple peel extract. Six bacterial strains, namely, F8, F5, M1, M6, H7 and H11, were screened and identified for potential BNC producer. The selected bacterial strain was identified as Bacillus cereus MMS1 using 16S rRNA nucleotide sequences. Then, the production of BNC was done by B. cereus MMS1 using pineapple peel extract, while A. xylinum ATCC2376 acted as a control. The BNC production in this study was attained at 2% (w/v) glucose concentration, 12 days of incubation period and 150 rpm agitation speed which was 5.83 g/L by A. xylinum ATCC2376 in HS medium using commercial glucose as carbon source. Meanwhile, 4.42 g/L and 2 g/L of BNC were produced by B. cereus MMS1 after 12 days of incubation with an initial concentration of 2% (w/v) using commercial glucose and pineapple peel extract, respectively.

Similar content being viewed by others

Data availability

The datasets generated during and/or analysed during the current study are available in the manuscript itself.

References

Jozala AF, Pértile RAN, dos Santos CA, de Carvalho Santos-Ebinuma V, Seckler MM, Gama FM, Pessoa A (2014) Bacterial cellulose production by Gluconacetobacter xylinus by employing alternative culture media. Appl Microbiol Biotechnol 99(3):1181–1190

Gao M, Li J, Bao Z, Hu M, Nian R, Feng D, Zhang H (2019) A natural in situ fabrication method of functional bacterial cellulose using a microorganism. Nat Commun 10(1):1–10

Shoseyov O, Kam D, Ben Shalom T, Shtein Z, Vinkler S, Posen Y (2019) Nanocellulose composite biomaterials in industry and medicine. Biol-Inspired Syst 12:693–784

Jozala AF, de Lencastre-Novaes LC, Lopes AM, de Carvalho Santos-Ebinuma V, Mazzola PG, Pessoa-Jr A, Chaud MV (2016) Bacterial nanocellulose production and application: a 10-year overview. Appl Microbiol Biotechnol 100(5):2063–2072

Thomas P, Duolikun T, Rumjit NP, Moosavi S, Lai CW, Johan MRB, Fen LB (2020) Comprehensive review on nanocellulose: recent developments, challenges and future prospects. J Mech Behav Biomed Mater 110:103884

Revin V, Liyaskina E, Nazarkina M, Bogatyreva A, Shchankin M (2018) Cost-effective production of bacterial cellulose using acidic food industry by-products. Braz J Microbiol 49:151–159

Yu X, Atalla RH (1996) Production of cellulose II by Acetobacter xylinum in the presence of 2, 6-dichlorobenzonitrile. Int J Biol Macromol 19(2):145–146

Hidayah N, Abdul F (2019) Profitability of pineapple production (Ananas comosus) among smallholders in Malaysia. Int J Recent Technol Eng 8(4):4202–4207

Sukruansuwan V, Napathorn SC (2018) Use of agro-industrial residue from the canned pineapple industry for polyhydroxybutyrate production by Cupriavidus necator strain A-04. Biotechnol Biofuels 11(1):1–15

Ruslan NA, Aris NFM, Othman N, Saili AR, Muhamad MZ, Aziz NNH (2017) A preliminary study on sustainable management of pineapple waste: perspective of smallholders. Int J Acad Res Bus Soc Sci 7(6):1–7

Ketnawa S, Chaiwut P, Rawdkuen S (2012) Pineapple wastes: a potential source for bromelain extraction. Food Bioprod Process 90(3):385–391

Santoso SP, Lin SP, Wang TY, Ting Y, Hsieh CW, Yu RC, Cheng KC (2021) Atmospheric cold plasma-assisted pineapple peel waste hydrolysate detoxification for the production of bacterial cellulose. Int J Biol Macromol 175:526–534

Hussain Z, Sajjad W, Khan T, Wahid F (2019) Production of bacterial cellulose from industrial wastes: a review. Cellulose 26(5):2895–2911

Castro C, Zuluaga R, Putaux JL, Caro G, Mondragon I, Gañán P (2011) Structural characterization of bacterial cellulose produced by Gluconacetobacter swingsii sp. from Colombian agroindustrial wastes. Carbohydr Polym 84(1):96–102

Kumbhar JV, Rajwade JM, Paknikar KM (2015) Fruit peels support higher yield and superior quality bacterial cellulose production. Appl Microbiol Biotechnol 99(16):6677–6691

Anwar B, Bundjali B, Sunarya Y, Arcana I (2021) Properties of bacterial cellulose and its nanocrystalline obtained from pineapple peel waste juice. Fibers Polym 22(5):1228–1236

Voon WWY, Muhialdin BJ, Yusof NL, Rukayadi Y, Hussin AM (2019) Bio-cellulose production by Beijerinckia fluminensis WAUPM53 and Gluconacetobacter xylinus 0416 in sago by-product medium. Appl Biochem Biotechnol 187(1):211–220

Hong F, Wei B, Chen L (2015) Preliminary study on biosynthesis of bacterial nanocellulose tubes in a novel double-silicone-tube bioreactor for potential vascular prosthesis. Biomed Res Int 2015:1–9

Jain A, Jain R, Jain S (2020) Determination of blood creatinine. Basic Tech Biochem, Microbiol Mol Biol, 201–203.

Budaeva VV, Gismatulina YA, Mironova GF, Skiba EA, Gladysheva EK, Kashcheyeva EI, Sakovich GV (2019) Bacterial nanocellulose nitrates. Nanomater 9(12):1–12

Chandrasekaran PT, Bari NK, Sinha S (2017) Enhanced bacterial cellulose production from Gluconobacter xylinus using super optimal broth. Cellulose 24(10):4367–4381

Hestrin S, Schramm M (1954) Synthesis of cellulose by Acetobacter xylinum II: preparation of freeze-dried cells capable of polymerizing glucose to cellulose. Biochem J 58(2):345–352

Lestari P, Elfrida N, Suryani A, Suryadi Y (2014) Study on the production of bacterial cellulose from Acetobacter xylinum using agro-waste. Jordan J Biol Sci 147(1570):1–6

Rangaswamy BE, Vanitha KP, Hungund BS (2015) Microbial cellulose production from bacteria isolated from rotten fruit. Int J Polym Sci 2015:8

Sari AM, Budianto FA, Nursiwi A, Sanjaya AP, Utami R, Zaman MZ (2021) Study of Acetobacter xylinum FNCC 0001 fermentation kinetics using artificial media containing various carbon and nitrogen concentrations. IOP Conf Ser: Earth Environ Sci 828(1):012004

Rolfe MD, Rice CJ, Lucchini S, Pin C, Thompson A, Cameron AD, Hinton JC (2012) Lag phase is a distinct growth phase that prepares bacteria for exponential growth and involves transient metal accumulation. J Bacteriol 194(3):686–701

Costa AF, Almeida FC, Vinhas GM, Sarubbo LA (2017) Production of bacterial cellulose by Gluconacetobacter hansenii using corn steep liquor as nutrient sources. Front Microbiol 8:2027

Ogrizek L, Lamovšek J, Čuš F, Leskovšek M, Gorjanc M (2021) Properties of bacterial cellulose produced using white and red grape bagasse as a nutrient source. Processes 9(7):1088

Casabar JT, Unpaprom Y, Ramaraj R (2019) Fermentation of pineapple fruit peel wastes for bioethanol production. Biomass Convers Biorefinery 9(4):761–765

Hajar N, Zainal S, Nadzirah KZ, Roha AS, Atikah O, Elida TT (2012) Physicochemical properties analysis of three indexes pineapple (Ananas Comosus) peel extract variety N36. APCBEE Proc 4:115–121

Ban-Koffi L, Han YW (1990) Alcohol production from pineapple waste. World J Microbiol Biotechnol 6(3):281–284

Nurtjahtja K (2020) The effect of Acetobacter xylinum starter in waste liquid pineapple peel on the properties of nata de pina. Int J Ecophysiol 2(02):86–91

Matsutani M, Ito K, Azuma Y, Ogino H, Shirai M, Yakushi T, Matsushita K (2015) Adaptive mutation related to cellulose producibility in Komagataeibacter medellinensis (Gluconacetobacter xylinus) NBRC 3288. Appl Microbiol Biotechnol 99(17):7229–7240

Ross P, Mayer R, Benziman M (1991) Cellulose biosynthesis and function in bacteria. Microbiol Rev 55(1):35–58

Wang J, Tavakoli J, Tang Y (2019) Bacterial cellulose production, properties and applications with different culture methods – a review. Carbohyd Polym 219:63–76

Jacek P, Ryngajłło M, Bielecki S (2019) Structural changes of bacterial nanocellulose pellicles induced by genetic modification of Komagataeibacter hansenii ATCC 23769. Appl Microbiol Biotechnol 103(13):5339–5353

Kouda T, Yano H, Yoshinaga F, Kaminoyama M, Kamiwano M (1996) Characterization of non-Newtonian behavior during mixing of bacterial cellulose in a bioreactor. J Ferment Bioeng 82(4):382–386

Saichana N, Matsushita K, Adachi O, Frébort I, Frebortova J (2015) Acetic acid bacteria: a group of bacteria with versatile biotechnological applications. Biotechnol Adv 33(6):1260–1271

El-Saied H, Basta AH, Gobran RH (2004) Research progress in friendly environmental technology for the production of cellulose products (bacterial cellulose and its application). Polym-Plast Technol Eng 43(3):797–820

Rani MU, Appaiah A (2011) Optimization of culture conditions for bacterial cellulose production from Gluconacetobacterhansenii UAC09. Ann Microbiol 61(4):781–787

Molina-Ramírez C, Castro M, Osorio M, Torres-Taborda M, Gómez B, Zuluaga R, Castro C (2017) Effect of different carbon sources on bacterial nanocellulose production and structure using the low pH resistant strain Komagataeibactermedellinensis. Mater 10(6):639

Lin SP, Kuo TC, Wang HT, Ting Y, Hsieh CW, Chen YK, Cheng KC (2020) Enhanced bioethanol production using atmospheric cold plasma-assisted detoxification of sugarcane bagasse hydrolysate. Biores Technol 313:123704

Acknowledgements

The authors would like to express their gratitude to AlafPutra Biowealth Sdn Bhd, Kota Tinggi, Johor, for the collaboration and supply of samples.

Funding

This research was funded by the Universiti Putra Malaysia under Putra Grant Scheme (UPM/700–2/1/Geran Putra — 959700).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Adriana Connie Lee, data collection and data analysis; Adriana Connie Lee and Suraini Abd-Aziz, data collection, data analysis and interpretation and drafting the article. Adriana Connie Lee, Madihah Md Salleh, Mohamad Faizal Ibrahim, Ezyana Kamal Bahrin and Suraini Abd-Aziz, conception or design of the work, critical revision of the article and final approval of the version to be published. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

All the authors have read and understood the editorial policies for publication in Bioresources and Bioprocessing.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lee, A.C., Salleh, M.M., Ibrahim, M.F. et al. Pineapple peel as alternative substrate for bacterial nanocellulose production. Biomass Conv. Bioref. 14, 5541–5549 (2024). https://doi.org/10.1007/s13399-022-03169-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-03169-7