Abstract

Sewage sludge (SS) is a residual resulting from wastewater treatment that contains both organic and inorganic materials. Nowadays, SS management is a major issue owing to economic considerations and environmental pressure. It has been reported that the current sludge-to-landfill method would pose potential risks to human health and the environment. The incorporation of sustainable sludge valorization techniques (SVTs) into the SS treatment process could be a promising solution by transforming SS into value-added products, which mitigates the environmental impact of SS disposal. However, the selection of the most optimal process pathway from various SVTs is a challenging task. Hence, this paper proposes a mathematical optimization framework to determine the most sustainable SVT pathway using a single objective function of total annualized cost (TAC) minimization with the consideration of carbon pricing. A case study is conducted to evaluate the performance of the optimized SVT pathway compared to the conventional sludge management practice using different SS sources: (1) domestic sewage sludge and (2) a mixture of industrial sludge and domestic SS. The results reveal that the SVT pathway, which includes anaerobic digestion (AD) and followed by land application, is the most ideal route for domestic SS feed. For mixed SS feed, AD followed by landfilling is preferred due to the presence of hazardous constituents in mixed SS. Sensitivity analysis is performed to study the effect of SS quantity and carbon pricing on the SVT selection. It is expected that this study could provide critical insights into the development of a sustainable SS treatment process.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Sewage sludge (SS) is a by-product of wastewater treatment plants (WWTPs) that comprises primary and secondary sludge. Primary sludge originates from WWTP’s primary treatment, where a primary clarifier or settling tank is used to remove the settleable solids from sewage. These removed settled solids produced from primary treatment are known as primary sludge. After primary treatment, the wastewater still includes high biodegradable organic matters that must be removed to prevent pollution from receiving waterbody. Hence, the activated sludge process is used to reduce biodegradable organic matters of wastewater. The process mixes wastewater with biomass to assimilate the organic matter present in sewage, thus reducing the oxygen demand. The process produces an excess growth of biomass, known as waste-activated sludge or secondary sludge. (Muhammad Yogi [1]. SS can be divided into two categories, which include municipal sludge and industrial sludge. Municipal sludge consists of a high fraction of organic matter and water. In contrast, industrial sludge consists of a higher fraction of inorganic contaminants such as heavy metals [2].

In Malaysia, approximately 500,000 metric tons of mixed SS were produced in 2013, and the amount is expected to increase to 7 million metric tons by 2020 [3]. The ultimate disposal point of SS for most developing countries, including Malaysia, is landfilling. SS is classified as industrial waste and can only be disposed to specified landfill sites in compliance with legislation (Bradley, 2004). However, stricter landfill legislation and high landfill costs impel the plant stakeholders to look for alternative ways to valorize sludge. Besides, the requirement of enormous landfill space and the presence of hazardous or toxic constituents in SS (i.e. grit and sand, organic and inorganic substances, pathogen microbes, heavy metals) that might leach out from landfills and pollute the groundwater network further hinder the application of SS landfilling [4].

It is reported that almost 50% of the sewerage sludge systems in Malaysia used mechanized plants, whereas others still use communal septic tanks, Imhoff tanks, and oxidation ponds [5]. A sewage sludge treatment plant (SSTP) is usually located next to or inside a WWTP to treat the SS before disposing it to a landfill site immediately. In most mechanized plants, SS is first dewatered, followed by the sludge thickening and drying processes, and lastly sent to the landfill site [6]. While SS is often viewed as a waste to be disposed of, it contains a significant amount of organic and nutrient resources that can be recovered and beneficially utilized [7]. The commonly practiced sustainable sludge valorization techniques (SVTs) in Malaysia are anaerobic digestion (AD) and incineration. AD uses anaerobic archaea to break down volatile organic solid in the SS to produce biogas and stabilize SS [5, 8, 9, 10]. Biogas generated from AD can either be used for in-plant heat energy supply or electrical energy generation. Incineration is usually applied for industrial sludge or mixed sewage sludge (a mix of municipal sewage sludge and industrial sludge) to reduce the SS mass and volume by 70 to 90% due to the presence of toxicants and heavy metals [11]. However, the residue remained after incineration, and air pollutants emitted into the atmosphere in gaseous form can be a significant source of ecological degradation [12].

Although various studies have been conducted based on the individual SVT, the research on the process integration between SVTs is relatively scarce. Chai et al. [13] presented a study to estimate and compare the carbon footprint emission of different wastewater treatment technologies and SVTs. The carbon footprints of each technology were calculated based on direct emissions of carbon dioxide (CO2) and nitrogen oxide (N2O) as well as indirect emissions of electricity use. Garrido-Baserba et al. [14] used simulation software to evaluate the economic and global warming potential (GWP) of mesophilic anaerobic digestion (MAD), thermophilic anaerobic digestion (TAD), incineration, gasification, and supercritical water oxidation. Multi-objective optimization was used to assign economic assessment priorities and GWP assessments to identify the most optimum SVT pathway. Supercritical water oxidation was the most suitable option if both criteria were considered equally important. Bianchini et al. [15] evaluated a waste-to-energy plant’s economic viability using process integration to recover waste heat energy for SS drying. The study concluded that SS’s incineration is only economically feasible if industrial waste heats were used for sludge drying. Song et al. [16] conducted a techno-economic analysis of SSTP by considering four pre-defined process pathways which are: (i high concentration AD, followed by dewatering and drying; (ii thermal hydrolysis, followed by high concentration AD, dewatering, and drying; (iii low concentration AD, followed by dewatering and drying, and (iv drying followed by incineration. The investigation results indicated that thermal hydrolysis followed by AD, dewatering, and drying has the optimal energy integration efficiency without natural gas’s external input. Zhou et al. [6] used a multi-criterion decision-making method by considering the environmental, economic, and social aspects as evaluation criteria to determine the optimal SVT pathway. The study evaluated six pre-defined SVTs: lime stabilization, incineration, cement kiln, hydrothermal-pyrolysis, AD followed by composting, and brick manufacturing. It was concluded that AD followed by composting is the ideal solution for sustainable sludge treatment. These studies benefit the industrial stakeholders in assessing the economic and environmental impacts of different SVTs.

In consideration of the rise in global SS production and the heightened environmental awareness in the community, the development of an economically and environmentally sustainable SS treatment becomes progressively critical. Nevertheless, some limitations are found in the existing research, including the absence of in-depth research on the process integration between different mature SVTs and the development of an end-to-end SS valorization process, i.e., from receiving raw SS to the final disposal of SS. Therefore, this study aims to fill the research gap by proposing a single objective optimization approach that allows process integration between different SVTs to identify the most optimal end-to-end SS valorization process route in terms of economic and environmental metrics. A case study involving the usage of domestic SS and mixed SS (a mixture of domestic SS and industrial sludge) as the feed is presented to evaluate the sustainability performance of the SVT pathway, which is developed using a mixed-integer linear programming (MILP) optimization model with the objective function of total annualized cost (TAC). Note that the SVTs considered in this study comprised different sludge stabilization, phosphorus removal, and sludge disposal methods. Carbon pricing is included in the calculation of TAC to take the GWP of SVTs into account. The superstructure of the optimized SVTs using different SS feeds is presented, and their performance in comparison with the conventional SVT is discussed in this paper. Finally, a sensitivity analysis is conducted to assess the effect of population equivalent (PE) and carbon tax price on the selection of SVTs.

2 Problem statement

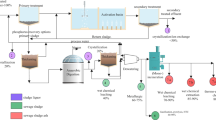

Previous research work from Zhou et al. [6] has evaluated various SVT pathways based on their economic, environmental, and social sustainability performances using a multi-criteria decision-making approach. The study, however, was constrained to six pre-defined SVT process pathways, as shown in Fig. 1. This study limitation rendered multiple SVT process pathways to be disregarded, which can potentially establish a more feasible and environmentally friendlier SS valorization route. Hence, this work tends to improve the flexibility of the proposed superstructure from Zhou et al. by allowing the interconnection between SVTs, as presented in Fig. 2. A single objective function of minimizing TAC is implemented in the optimization model of this study, which constitutes total capital cost (CAPEX), operating cost (OPEX), global warming potential related cost (GWPEX), and revenue gained. The calculating equation for TAC is represented by Eq. (1). The incorporation of GWPEX in the form of carbon taxes or credits into the TAC calculation is essential for taking the GWP of the SVT into the consideration. The charging of carbon taxes indicates that the unit operation would contribute to the carbon emission. Meanwhile, a carbon credit can be claimed if the technology involved removes more carbon than it emits. In Eq. (1), the GWPEX would be a positive value if the payment of carbon taxes is required, but the opposite for carbon credit since it reduces the TAC incurred. The revenue is obtained by selling valuable products from SSTP, such as electricity generated from the CHP system through biogas utilization, where biogas is produced from AD.

adapted from Zhou et al. [6]

Pre-defined SVT process pathway

Figure 2 shows the end-to-end SS valorization process of the SSTP, where the received raw SS \(r\in R\)(e.g., domestic SS and mixed sludge) will undergo several treatment units before disposing of the sludge. The SS sources from WWTP will first be fed to the SS thickening unit \(l\in L\). The thickened sludge will then be sent to the sludge stabilization unit \(k\in K\), and/or nutrient removal unit \(j\in J,\) and/or dewatering unit \(g\in G\). Further treatment \(n\in N\) is required for SS so that it can be finally disposed of through several possible disposal methods \(o\in O\). Note that material and energy recovery technology \(y\in Y\) is included in the SSTP to valorize the energy and by-products generated from sludge stabilization and nutrient removal units. The wastewater from thickening and dewatering units will be directed back to WWTP.

A case study is synthesized and solved in the following sections to demonstrate the developed optimization approach. The case study is modeled based on the WWTP in Jelutong, Penang, which is one of the largest WWTP in Malaysia that serves the wastewater produced by PE of 800,000 [5]. The baseline scenario is simulated to represent the current Malaysian SS valorization method, where the SS will undergo thickening, dewatering, sludge drying, and landfilling. To illustrate the applicability of the proposed optimization framework in addressing a variety of feedstock compositions, two case scenarios are developed in this study. Case 1 uses domestic SS as the feedstock, whereas the SSTP in Case 2 is fed in with a mixed sludge (i.e., a mixture of domestic SS and industrial sludge). It is a common practice to treat both industrial and municipal sewage by mixing them in Malaysia. The only difference between both cases is the composition of sludge feed, whereby SS in Case 2 has higher heavy metal content than Case 1 due to the mixing of industrial sludge. It is assumed that the industrial sludge will constitute 25–50 wt% of the total SS in Case 2. Figure 3 shows the superstructure of the proposed SSTP with the interconnections between multiple SVTs.

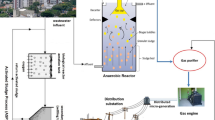

The raw sewage sludge with a mass flow rate of \({m}^{RF}\) firstly sent to the thickener to reduce its water content to 94 vol%. Subsequently, the thickened sludge can be sent to either the sludge stabilization or dewatering unit. For sludge stabilization, the thickened sludge can be treated through mesophilic anaerobic digestion (MAD) or thermophilic anaerobic digestion (TAD) [17]. The biogas produced from the anaerobic digestion (AD) processes is primarily consisting of methane and carbon dioxide [18, 19]. Hence, the biogas can be utilized in a combined heat and power (CHP) system to generate electricity for selling purposes. The anaerobically digested sludge can then be treated in the AIRPREX system or directly sent to the dewatering unit. AIRPREX process is designed as a complete biosolids optimization and phosphorus recovery system that is installed after AD to enhance biological phosphate elimination [20].

In the phosphorus removal process, magnesium salt (MgCl) is added to precipitate the phosphorus present in stabilized sludge to produce struvite [21]. Struvite that is rich in phosphorus can be sold as fertilizer [22]. Note that the treated sludge from the AIRPREX system still needs to be transferred to the dewatering unit. In the dewatering process, the polymer is added to improve the dewaterability of SS. The water removed from SS during thickening and dewatering processes will be directed back to the wastewater treatment plant for secondary treatment. Finally, the dewatered sludge can be sent to the landfill site, incineration unit, or utilized for land application [23]. The drying process is needed before incineration to further reduce SS moisture content to 30 wt%, as the requirement for self-incineration of SS to take place. The incinerated sludge can be used as a feedstock for building materials such as cement manufacturing.

Several assumptions are made to simplify the problem addressed. First, the maintenance costs, piping cost, electricity grid construction of SSTP, transportation cost of sewage sludge, and labor cost are excluded. Besides, the heat integration between the selected SVTs is not considered in this study. For instance, the heat generated from CHP will not be used to heat the anaerobic reactor. It is also assumed that the energy losses along the electrical transmission lines from CHP to the electrical substation are negligible. Although the variation in SS feedstock flow rate and composition is usual in real cases, a steady-state condition is assumed in this study whereby the SS flow rate and composition remain constant. The conversion rate of Euro to RM is assumed to be 1:4.69. The SSTP is assumed to have an operating life of 20 years, with 7920 operating hours per annum.

3 Research methodology

The research methodology is divided into three sections. In the first and second sections, the mass and energy balances of the sewage sludge are formulated. The third section includes the formulation of the variables present in the objective function Eq. (1), i.e., CAPEX, OPEX, revenue, and GWPEX.

3.1 Composition of raw sludge feed and mass balances for SVTs

Raw sludge (RS) feed in Malaysia has a dry solid content of 0.05 by weight [24]. The PE of RS is scaled to 800,000, whereby the average SS produced per capita in the conventional activated sludge process is estimated to be 40 g dry solids/inhabitant/day, with a dry solid concentration of 3 wt% [25]. Hence, the daily SS production is equivalent to 32,000 kg dry solids/day or 1,066,667 kg SS/day. The SS compositions for domestic and mixed sludge are provided in Tables 1 and 2. Note that the domestic sludge may contain a minor amount of heavy metals as shown in Table 2, which can be originated from urban run-off or galvanized pipes in the WWTP. However, it is within the national waste treatment and disposal guideline limits in Malaysia. By contrast, the heavy metal content of mixed SS (e.g., Cd and Zn) exceeds the guideline limits, which can impact human health and would cause various types of cancer [26].

The mass balance calculations for all SVT units, i.e., thickening, sludge stabilization, nutrient removal, dewatering, further treatment, SS disposal, and material and energy recovery technologies are summarized in Supplementary Materials Section A.

3.2 CAPEX, OPEX, revenue and GWPEX

This section discusses the computation of CAPEX and OPEX of individual unit operations as well as the revenue gained from the operation of SSTP. Besides, the GWPEX of the unit operations is estimated to determine the carbon taxes charged or carbon credits given for SSTP operation. The lifetime of SSTP is assumed to be 20 years, and the total annualized cost is calculated by using an annualizing factor (AF) of 0.1598/year. Note that for GWPEX the carbon tax is charged with the price of 7 Euro/ ton of CO2 or RM 0.03283/ kg of CO2 as a penalty for contributing to global warming. A similar price of carbon credit (7 Euro/ton of CO2 reduced) is given, if the SVT units exhibit negative carbon emissions.

3.2.1 Sludge thickening

Since the wastewater generated from the sludge thickening process will be directed to WWTP, the GWP of the thickening unit is negligible. The OPEX of thickening is assumed to be 5% of its CAPEX. The CAPEX of the thickening unit can be calculated using Eq. (2) [29].

3.2.2 Sludge stabilization

The formulation of both sludge stabilization technology options, i.e., MAD and TAD, is presented in this section. Note that the CAPEX estimated is based on the cost prices reported in 2016. Hence, the result obtained is adjusted using the ratio of the price index. The price index in 2016 and 2019 are \({PI}_{2016}\) = 499.6 and \({P}_{2019}\) = 607.5, respectively. Since there is fugitive emission of biogas from AD, carbon taxes will be charged accordingly. Likewise, the OPEX of the sludge stabilization unit is assumed to be 5% of its CAPEX.

Given that the MAD process involves two anaerobic digesters, the total CAPEX of MAD can be calculated as:

As TAD only requires one anaerobic digester, the total CAPEX of TAD can be estimated as:

where, RT is retention time, \(s.f.\) is the safety factor (1.1).

The GWP of both AD can be represented by:

where, \(GW{P}^{BG}\) is GWP of biogas equivalent to CO2 (25 kg CO2/ kg biogas).

3.2.3 Energy and material recovery

The electricity generated through energy recovered from CHP system is the main profit source in SSTP. It is assumed that a feed-in-tariff \((FiT)\) of RM 0.3184/kWh will be provided by the Sustainable Energy Development Authority (SEDA) Malaysia. The annual operating hour \(\left({Y}^{h}\right)\) of WWTP is assumed to be 7920 h or 330 days. It is assumed that the electricity generation in the CHP system will contribute to a GWP reduction \(\left(GW{P}_{ele}\right)\) of 0.9 \(\mathrm{kg} {\mathrm{CO}}_{2}/\mathrm{kWh}\). The unit cost of \({U}^{CHP}\) is RM 12,374.8/kW. Similarly, the CAPEX obtained is adjusted using the ratio of the price index, where the price index in 2013 and 2019 are given as 567 and 608, respectively.

The struvite produced from the phosphorus recovery unit is sold at the price \(\left({U}^{AP}\right)\) of RM 258/ton. The phosphorus recovery process requires MgCl to form struvite at a dosing rate of 1828 kg MgCl for 418,000 tons of SS, where the unit price of MgCl \(({U}^{MgCl})\) is RM 352/ tons. Since struvite sold can be used to substitute manufactured fertilizer, it is assumed that the GWP of the phosphorus recovery unit is negative, as it contributes to carbon reduction. Given that Eq. (16) is a non-linear equation, a piecewise linearization is performed to linearize Eq. (16) as shown in Supplementary Material Figure B.1.

where, \(Li{t}^{AP,Eq}\) is the literature capital cost of phosphorus recovery unit \((RM \mathrm{6,097,000})\).

3.2.4 Dewatering

The dewatering process consumes polymer at a rate of 1.5 tons based on the literature capacity \(\left(Li{t}^{DW,Poly}\right)\). The unit price of polymer \({U}^{poly}\) is RM 18,760/ton. Since the dewatering process only generates wastewater that is directed back to WWTP, the GWP of the dewatering process can be assumed to be negligible. Note that there is no revenue generated in the dewatering unit. Since the dewatering unit can receive the influent stream from either thickening, AD, or phosphorus recovery, the cost calculation for the dewatering unit can be expressed as follows [30]:

3.2.5 Landfilling

For landfilling option, since the transportation costs are not considered in this study, hence the calculation will only include the GWP of landfilling \((GW{P}^{LF})\). Note that the GWP of non-digested sludge landfilling is obtained from Liu et al. [31] as \(1898 \mathrm{kg C}{\mathrm{O}}_{2}/\mathrm{ton}\) and the GWP of digested sludge landfilling is from Hobson and Martinsen, [32] as \(474 \mathrm{kg C}{\mathrm{O}}_{2}/\mathrm{ton}\). The high GWP value from landfilling of non-digested sludge is due to the fugitive emissions of CH4 produced from anaerobic decomposition of sludge in the underground, especially when the sludge is not stabilized and contains a high concentration of pathogens [33].

3.2.6 Land application

SS quality is an important decision factor for land application as the dewatered sludge will be used as a fertilizer to provide nutrients to agricultural land. Land applications using dewatered sludge are cost-effective as the transportation costs are excluded [34]. In this study, two constraints are applied to the land application pathway. First, the RS needs to be domestic and cannot be mixed with any industrial sludge due to the presence of heavy metals. Second, the sludge must undergo AD to reduce its pathogen content to the acceptable limit [35]. Note that the GWP of land application SS is obtained from Liu et al. [31], i.e., \(73\mathrm{ kg C}{\mathrm{O}}_{2}/\mathrm{ton}\).

3.2.7 Drying

It is assumed that the sludge drying takes place by evaporating the SS through natural convection, hence no carbon emissions are released from the sludge drying process. The CAPEX of the sludge drying process is estimated using Eq. (28) [36]. As Eq. (28) is a non-linear equation, a piecewise linearization approach is used to linearize Eq. (28), as shown in Supplementary Material Eq. (B.2) and (B.3).

3.2.8 Incineration

The CAPEX and OPEX of the incineration unit as shown in Eq. (30) and (31) are derived from Ashwekar et al. [37]. The carbon emissions released from digested and non-digested sludge during incineration (\(GW{P}^{INC}\)) are assumed to be \(898 \mathrm{kg C}{\mathrm{O}}_{2}/\mathrm{ton}\) and \(499.4 \mathrm{kg C}{\mathrm{O}}_{2}/\mathrm{ton}\), respectively [31].

3.2.9 Ash disposal

The incinerator bottom ash can either be landfilled or used as a raw material for the manufacturing of bricks. Note that landfilling of ash has negligible GWP. On the other hand, the utilization of ash for brick manufacturing shows negative GWP, where = \(GW{P}^{BM}-3.7 \mathrm{kg C}{\mathrm{O}}_{2}/\mathrm{ton}\).

3.2.10 Total annualized cost

TAC is determined based on the CAPEX, OPEX, revenue gained, and carbon taxes charged. There are two revenue sources in the SSTP, which are the sales of electricity generated and the sales of struvite as the fertilizer. The latter is applicable only if the phosphorus recovery pathway is selected. The net electricity and heat generation from the SSTP are expressed as Eqs. (34) and (35). The total revenue, CAPEX, OPEX, and GWP of the SSTP are calculated using Eqs. (36)–(39).

Binary term b indicates the selection of SVT for the SS treatment pathway. SVTs are represented by variable z, where \(z \in Z\) can be computed as: \(z=\left\{\mathrm{1,2}, \dots 11\right\}\), corresponding to superscripts {TH, MAD, TAD, CHP, AP, DW, LF, LA, DR, INC, BM} (the definition of the superscripts can refer to Nomenclature). Since the product of a binary term and a continuous variable is a non-linear equation, the equation linearization is performed as shown in Supplementary Materials Section D.

Finally, the objective function of minimizing the TAC of SSTP is set for synthesizing an optimal SVT process pathway through the proposed optimization framework. The objective function used is shown in Eq. (40).

4 Results and discussion

In this section, the optimization results of SSTP are firstly discussed for both case scenarios: (1) domestic and (2) mixed SS. A sensitivity analysis is then performed to study the effect of carbon tax price and PE on the selection of SVTs.

4.1 Optimization results and analysis

The proposed SSTP is formulated as a mixed-integer linear programming (MILP) model and solved using the LINGO v18.0 global solver. The modeling equations used to present the optimization results are shown in Sect. 4. Note that some of the equations contain bilinear terms. Hence, a piecewise linear approximation technique is applied to linearize these bilinear terms for model solving. The constraints for the linearization of bilinear terms are shown in Supplementary Materials Section C. The model has 264 variables and 99 integers and is solved using 8 GB RAM, 64-bits Operating System Windows 10 within 0.49 s. The baseline scenario that simulates the conventional SS treatment practice in Malaysia is illustrated in Fig. 4a, whereby the raw SS will undergo thickening, dewatering, and landfilling. The simulation results for Cases 1 and 2 are presented in Figs. 4b and c. By comparing the SSTP model between the baseline scenario and Cases 1 and 2, it is noticed that an additional sludge stabilization unit is included in the SSTP of Cases 1 and 2. The sludge stabilization method selected in both cases is TAD, and the biogas produced from TAD is sent to the CHP system for energy recovery and generation. TAD is preferred over MAD as it exhibits a higher biogas yield and organic loading rate as well as lower hydraulic time, which ultimately reduces TAD reactor volume, and a lower CAPEX can be attained [39].

From Figs. 4b and c, it is noticeable that only the AD process is selected for sludge valorization but not other SVT technologies such as the AIRPREX system and incineration, regardless of the type of SS feed. Considering the limited phosphorus content of SS as shown in Table 1, the revenue gained from selling struvite products is not sufficient to defray the expenses for installing and operating the AIRPREX system, thus rendering it to be economically infeasible. Hence, a direct land application using the dewatered phosphorus-containing SS would be a more viable option compared to the implementation of the phosphorus recovery process. SS incineration is also not preferred in this case due to the high moisture content of SS even after dewatering. While the installation of an additional drying unit can solve the problem; however, it is not ideal from an economic perspective. Ashwekar et al. [37] reported that incineration would contribute to significant carbon emissions, hence requiring sophisticated air emission control equipment to mitigate the environmental impact of the incineration process. This further hinders the application of the incineration process to eliminate the sludge and for brick manufacturing using ashes.

Though both Cases 1 and 2 show similar sludge valorization approaches, the SS disposal methods selected are completely different. Case 2 chooses the same disposal approach as the baseline scenario, i.e., landfilling. However, in Case 1, the dewatered sludge is sent for land application. The selection of final disposal methods is highly dependent on the sludge quality, especially its heavy metal contents. Therefore, landfilling is a more appropriate option for Case 2 due to the high concentration of heavy metals in the mixed sludge that exceeds the Malaysian guideline limits for land application [28].

For domestic SS feed, the selected SVT pathway from this study coincides with the research findings from Zhou et al. [6], where the AD followed by land application is considered the most optimal sludge valorization and disposal pathway from both economic and environmental perspectives. Zhou et al. solved this multi-attribute decision-making problem using a combination of the analytic hierarchy process (AHP) and Vlsekriterijumska Optimizacija I Kompromisno Resenje (VIKOR) method, which assesses the ranking of the different pre-defined SVT pathways to evaluate the compromise solution. On the other hand, this study modified the problem by allowing the development of other feasible pathways and analyzed it using a unique single-objective mathematical optimization framework. The agreement between the result of both studies that utilize different optimization approaches indicate that the implementation of AD technology and proper land application is the most important among all SVTs to realize sustainable sludge management. This outcome also reveals the feasibility of the proposed framework to solve the complicated multi-criteria decision-making problem by simplifying it into a single-objective optimization problem, which can be more time effective without compromising the solution validity.

The calculated TAC for each case scenario is tabulated in Table 3. The TAC for the baseline scenario is estimated to be RM 691,072, which is mainly contributed by the charging of carbon taxes (96% of TAC, or equivalent to RM 661,948) due to SS landfilling. It is reported that the landfilling of non-digested sludge would result in a high amount of greenhouse gas (GHG) emissions as a consequence of organic matter decomposition in SS [31]. The TAC for Case 1 and Case 2 are RM 323,774/year and RM 461,444/year, respectively. Compared to the baseline scenario, the implementation of the proposed SVT pathway for Cases 1 and 2 saves about 53% and 33% of TAC, respectively. Despite the high CAPEX for the optimized SSTP (RM 4,945,638/year) due to the installation of TAD and CHP systems, the selling of electricity generated from the CHP system (RM 4,388,630/year of revenue) in the optimized SSTP can offset the expensive CAPEX requirement. Besides, it is worth mentioning that the proposed SVT pathway has negative GWP regardless of SS feed type. The negative GWP indicates that the optimized SS treatment processes do not generate extra GHG; instead, they minimize the GHG emissions as a result of biogas utilization to displace fossil fuels for electricity generation. The results obtained are in agreement with the study conducted by Daniel-Gromke et al. [40] where negative GWP (\(-49 \mathrm{kg C}{\mathrm{O}}_{2}\) equivalent per ton of bio-waste) can be achieved if AD is implemented. Owing to the negative GWP, carbon credits are provided to the proposed SSTP operation instead of being charged with a substantial amount of carbon tax. This explains the better economic feasibility of the proposed SSTP compared to conventional SS treatment processes.

The difference in TAC between Cases 1 and 2 is due to the selection of the final disposal method. As previously stated, landfilling is selected in Case 2 instead of land application owing to the high heavy metal concentration of the mixed sludge. Methane, the most efficient gas to greenhouse emissions, is produced when the landfilled SS is left to decay anaerobically. On the other hand, the dewatered SS in Case 1 is utilized as a fertilizer or soil improver, where organic matters in SS are absorbed by plants rather than being decomposed anaerobically [31]. Hence, higher carbon credits are provided for the SSTP operation of Case 1 compared to Case 2. The result indicates that despite the optimized SSTP can treat both domestic and mixed SS efficiently with the same amount of revenue obtained, an additional cost is required when treating mixed SS due to the less ideal SS disposal approach taken with consideration of the environmental conservation and ecosystem balance. Nevertheless, it can be deduced that the proposed SVT pathway is more sustainable than the conventional SS treatment route based on economic and environmental perspectives.

The relative sizes of the selected SVT unit operation CAPEX and OPEX for Cases 1 and 2 are shown in Fig. 5. The installation of the CHP system for heat and electricity generation contributes the most CAPEX and OPEX to SSTP operation, i.e., 60.87% of CAPEX and 59.54% of OPEX. The second highest CAPEX and OPEX contributor is the TAD unit as the anaerobic digesters are expensive and high utility costs are required to control the heat-sensitive AD process. Note that the CAPEX and OPEX of thickening and dewatering units are negligible compared to other unit operations based on the cost breakdown from Fig. 5.

Although the AD unit constitutes a great proportion of CAPEX and OPEX, the application of AD systems with biogas capture and utilization technologies is necessary for the development of a sustainable SS treatment process38. Without the installation of the AD systems, the landfilling or land application of SS that consists of fermentable organic matters would result in GHG emissions due to anaerobic decomposition in the underground. During the AD process, the biogas produced with methane as its primary gas constituent needs to be captured to prevent it from escaping to the atmosphere. As elucidated in this study, the collected biogas can be valorized to substitute fossil fuel for electricity generation, which is an important revenue operation for SSTP operation and also further diminishes the GHG emissions to the environment. In light of the importance of AD in addressing climate change issues and potentially generating additional incomes, it is recommended to install an AD system before the dewatering unit instead of directly sending the SS for dewatering as conventionally practiced in the SSTPs in Malaysia.

4.2 Sensitivity analysis

The sensitivity analysis is conducted based on Case 1 to study the effect of PE and the carbon pricing on the selection of the SVT process pathway.

4.2.1 Population equivalent

Note that the amount of SS in this study is quantified in the form of population equivalent (PE). Since the population size is expected to continuously rise in the future, it is imperative to evaluate the impact of SS feed quantity on the economic feasibility of the selected SVT pathway through the proposed optimization framework. The effect of PE on the TAC for the selection of the SVT process route is studied through the alteration of PE by − 50%, − 20%, + 20%, and + 50%. As displayed in Fig. 6a, the TAC of optimized SSTP increases linearly with increasing PE. It is because higher CAPEX and OPEX are required for the installation of larger equipment for SVTs’ unit operation to accommodate the greater amount of SS feed. Despite increasing the PE up to 50%, the SVT pathway selected remains the same, i.e., thickening, TAD, dewatering, and land application. This indicates the importance of the TAD unit in optimizing the economic feasibility of the SSTP, as it helps to reduce the TAC by creating profit through biogas production for generating electricity and minimizing the GWP of the SS treatment process.

4.2.2 Carbon pricing

Carbon pricing policies have been imposed in most developing countries such as the European Union as an approach to tackle climate change. Although Malaysia does not implement a carbon pricing policy at the current state, the Malaysian government announced that it will be introduced soon to attain carbon neutrality in the future. Therefore, it is of interest to analyze the effect of carbon pricing policy on the selection of optimal SVT pathways based on TAC. Likewise, the GWPEX are varied by − 100%, − 50%, + 50%, and + 100% to conduct the sensitivity analysis. Based on Fig. 6b, the TAC rises with the increasing carbon prices, until it reaches its maximum at − 62% change in the carbon prices. Note that the further increasing carbon prices would result in the substitution of the SVT pathway, as the TAC starts to drop significantly after reaching the maximum point. When there is no or low carbon pricing imposed, the selected SVT pathway for Case 1 is similar to the baseline scenario, i.e., sludge thickening, followed by dewatering and landfilling. By contrast, TAD is included in the optimized SVT pathway and land application is chosen as the final disposal method when the carbon prices increase from − 62%.

In the case where carbon prices are adjusted from − 100% to \(-\) 62%, the TAC increases with carbon prices due to the higher carbon taxes incurred for landfilling. The TAD process is not selected under this circumstance because the carbon credit provided from electricity generation using biogas produced through the TAD process is less appealing, since it could not counterbalance the high CAPEX and OPEX for TAD operation. However, the installation of the TAD process, as well as the implementation of land application, become promising at a higher carbon pricing, as more carbon credit can be obtained to reduce the TAC incurred.

5 Conclusion

The SVT pathway is optimized using a MILP model with the objective function to minimize TAC incurred, where the TAC is constituted by CAPEX, OPEX, revenue as well as GWPEX for SSTP operation. A case study based on three different scenarios is performed, whereby the baseline scenario represents the conventional sludge treatment and disposal practices in Malaysia. Cases 1 and 2 demonstrate the optimized SVT pathway via the proposed optimization framework using domestic SS and mixed SS (a mixture of domestic and industrial sludge) as the feedstock, respectively. The results from the optimization framework suggest the implementation of TAD for both Cases 1 and 2, where the biogas produced is utilized for electricity generation to maximize revenue gained and reduce GHG emissions. However, landfilling is selected over the land application in Case 2 due to the high concentration of heavy metals in mixed SS, which is not suitable for land application in concern of environmental conservation. The sensitivity analysis is conducted to study the effect of PE and carbon prices on the SVT pathway selection. The results from sensitivity analysis indicate that the carbon pricing would affect the optimized SVT pathway selection, where TAD is preferred at a higher carbon pricing owing to high carbon credits that minimize the TAC. The outcomes of this study could provide valuable insights into the development of a flexible SVT process route that considers both economic and environmental aspects. However, the current optimization model only takes account of GWP, where other environmental performance criteria such as fossil depletion and freshwater eutrophication are not included in the study. Therefore, future work can consider the application of the life cycle assessment on the different SVT options to obtain further insights into the environmental aspects connected to each optimized solution.

Abbreviations

- r :

-

{r,…,R} Is a set of raw feed sludge

- l :

-

\(\{l, \dots , L\}\) Is a set of thickening technologies

- k :

-

\(\{k, \dots , K\}\) Is a set of sludge stabilization technologies

- j :

-

\(\{j, \dots , K\}\) Is a set of nutrient removal technologies

- g :

-

\(\{g, \dots , G\}\) Is a set of dewatering technologies

- z :

-

\(\{z, \dots , Z\}\) Is a set of sludge valorization methods

- BGY:

-

Biogas yield (Nm3/kg)

- FiT:

-

Feed-in-tariff rate (RM/kWh)

- \(Li{t}^{cap}\) :

-

Literature capacity (population eq.)

- MW:

-

Molecular weight (kg/kmol)

- P:

-

Pressure (Pa)

- PI:

-

Price index

- R:

-

Gas constant (m3·Pa/(K·mol))

- \({Y}^{h}\) :

-

Annual operating hours (h)

- \(\upepsilon\) :

-

Efficiency of equipment

- \(b\) :

-

Binary number

- EG:

-

Energy generation (kJ/d)

- HC:

-

Heat consumption (kJ/d)

- HG:

-

Heat generation (kJ/d)

- \(m\) :

-

Mass flow rate (kg/d)

- RT:

-

Retention time (day)

- T:

-

Temperature (°C)

- U:

-

Cost unit (RM/unit)

- V:

-

Volumetric flow rate (m3/d)

- \(x\) :

-

Mass fraction

- \(\rho\) :

-

Density (kg/m3)

- \(\upsilon\) :

-

Volume fraction

- AD:

-

Anaerobic digestion

- AP:

-

Phosphorus recovery

- BG:

-

Biogas

- BM:

-

Building material

- CAPEX:

-

Capital expenditure

- CHP:

-

Combined heat and power

- DM:

-

Disposal method

- DR:

-

Drying

- DW:

-

Dewatering

- FG:

-

Fugitive emission

- GWP:

-

Global warming potential

- GWPEX:

-

Global warming potential related cost

- INC:

-

Incineration

- LA:

-

Land application

- LF:

-

Landfilling

- MAD:

-

Mesophilic anaerobic digestion

- MILP:

-

Mixed-integer linear programming

- OPEX:

-

Operating expenditure

- PE:

-

Population equivalent

- Ph:

-

Phosphorus

- Poly:

-

Polymer

- REV:

-

Revenue

- RS:

-

Raw sludge

- S:

-

Sludge stream

- S.f.:

-

Safety factor

- SS:

-

Sewage sludge

- SSTP:

-

Sewage sludge treatment plant

- SVT:

-

Sludge valorization technique

- TAD:

-

Thermophilic anaerobic digestion

- TH:

-

Thickener

- VS:

-

Volatile solid

- WW:

-

Wastewater stream

- WWTP:

-

Wastewater treatment plant

References

Muhhamad Yogi Angga, Siregar H (2014) Optimization of the treatment and disposal of sewage sludge in the ATO of Como: options and scenarios assessment. Implement Sci 39(1):1–24. https://doi.org/10.13140/2.1.2760.6088

Kem J, Heinzmann B, Markus B (2008) (PDF) Recycling and biotechnology for bioenergy production: principles and applications. Agricultural Engineering International. https://www.researchgate.net/publication/228613904_Recycling_and_Assessment_of_Struvite_Phosphorus_from_Sewage_Sludge. Accessed 23 June 2020

Nor MAM, Hamed ASA, Ali FH, Khim OK (2015) (PDF) Properties and performance of water treatment sludge (WTS)-clay bricks. Jurnal Teknologi. https://www.researchgate.net/publication/289503677_Properties_and_performance_of_water_treatment_sludge_WTS-clay_bricks. Accessed 23 June 2020

Urra J, Alkorta I, Mijangos I, Epelde L, Garbisu C (2019) Application of sewage sludge to agricultural soil increases the abundance of antibiotic resistance genes without altering the composition of prokaryotic communities. Sci Total Environ 647:1410–1420. https://doi.org/10.1016/j.scitotenv.2018.08.092

Hanum F, Yuan LC, Kamahara H, Aziz HA, Atsuta Y, Yamada T, Daimon H (2019) Treatment of sewage sludge using anaerobic digestion in Malaysia: current state and challenges. In Frontiers in Energy Research (Vol. 7, Issue MAR). Frontiers Media S.A. https://doi.org/10.3389/fenrg.2019.00019

Zhou G, Gu Y, Yuan H, Gong Y, Wu Y (2020) Selecting sustainable technologies for disposal of municipal sewage sludge using a multi-criterion decision-making method: a case study from China. Resources, Conservation and Recycling, 161(December 2019), 104881. https://doi.org/10.1016/j.resconrec.2020.104881

Fijalkowski K, Rorat A, Grobelak A, Kacprzak MJ (2017) The presence of contaminations in sewage sludge – the current situation. J Environ Manage 203(Pt 3):1126–1136. https://doi.org/10.1016/j.jenvman.2017.05.068

Anukam A, Mohammadi A, Naqvi M, Granström K (2019) A review of the chemistry of anaerobic digestion: methods of accelerating and optimizing process efficiency. Processes 7(8):504. https://doi.org/10.3390/pr7080504

Nakashimada Y, Ohshima Y, Minami H, Yabu H, Namba Y, Nishio N (2008) Ammonia-methane two-stage anaerobic digestion of dehydrated waste-activated sludge. Appl Microbiol Biotechnol 79(6):1061–1069. https://doi.org/10.1007/s00253-008-1501-7

Van Pham D, Takeshi F, Hoang Minh G, Pham Phu ST (2020) Comparison between single and two-stage anaerobic digestion of vegetable waste: kinetics of methanogenesis and carbon flow. Waste and Biomass Valorization 11(11):6095–6103. https://doi.org/10.1007/s12649-019-00861-0

Đurđević D, Blecich P, Jurić Ž (2019) Energy recovery from sewage sludge: the case study of Croatia. Energies 12(10):1927. https://doi.org/10.3390/en12101927

Gherghel A, Teodosiu C, Gisi SD (2019) A review on wastewater sludge valorisation and its challenges in the context of circular economy. J Clean Prod 228:244–263. https://doi.org/10.1016/j.jclepro.2019.04.240

Chai C, Zhang D, Yu Y, Feng Y, Wong MS (2015) Carbon footprint analyses of mainstream wastewater treatment technologies under different sludge treatment scenarios in China. Water (Switzerland) 7(3):918–938. https://doi.org/10.3390/w7030918

Garrido-Baserba M, Molinos-Senante M, Abelleira-Pereira JM, Fdez-Güelfo LA, Poch M, Hernández-Sancho F (2015) Selecting sewage sludge treatment alternatives in modern wastewater treatment plants using environmental decision support systems. J Clean Prod 107:410–419. https://doi.org/10.1016/j.jclepro.2014.11.021

Bianchini A, Bonfiglioli L, Pellegrini M, Saccani C (2015) Sewage sludge drying process integration with a waste-to-energy power plant. Waste Manage 42:159–165. https://doi.org/10.1016/j.wasman.2015.04.020

Song C, Li R, Zhao Y, Li R, Ma D, Kansha Y (2019) Assessment of four sewage sludge treatment routes with efficient biogas utilization and heat integration. Process Saf Environ Prot 126:205–213. https://doi.org/10.1016/j.psep.2019.04.007

Gebreeyessus GD, Jenicek P (2016) Thermophilic versus mesophilic anaerobic digestion of sewage sludge: a comparative review. In Bioengineering (Vol. 3, Issue 2). MDPI AG. https://doi.org/10.3390/bioengineering3020015

Rivero M, Solera R, Perez M (2014) Anaerobic mesophilic co-digestion of sewage sludge with glycerol: enhanced biohydrogen production. Int J Hydrogen Energy 39(6):2481–2488. https://doi.org/10.1016/j.ijhydene.2013.12.006

Xie S, Hai FI, Zhan X, Guo W, Ngo HH, Price WE, Nghiem LD (2016) Anaerobic co-digestion: a critical review of mathematical modelling for performance optimization. In Bioresource Technology 222:498–512. https://doi.org/10.1016/j.biortech.2016.10.015

Yoshida H, Li Z, Forstner G, Goel R (2019) Full scale implementation of airprex phosphorus recovery and the development of a mechanistic process model in GPS-X™. 91st Annual Water Environment Federation Technical Exhibition and Conference. WEFTEC 2018:5308–5316. https://doi.org/10.2175/193864718825138745

Kabbe, C. (2013) Sustainable sewage sludge management fostering phopshorus recovery. EasyMining Germany. https://www.researchgate.net/publication/279954144_Sustainable_sewage_sludge_management_fostering_phopshorus_recovery

D. Vries, S., Postma, R., van Scholl, L., Blom-Zandstra, G., Verhagen, J., & Harms, I. (2016) Economic feasibility and climate benefits of using struvite from the Netherlands as a phosphate (P) fertilizer in West Africa. International Journal of Innovative Technology and Exploring Engineering (IJITEE), 9(4). https://doi.org/10.18174/417821

Arisily, A. T., Sara, E. A., & Ali, H. (2020) Methodology for optimizing sewage sludge treatment, valorization and disposal methods. application to the Marrakech (Morocco) wastewater treatment plant 306. International Journal of Innovative Technology and Exploring Engineering (IJITEE), 9(4). https://doi.org/10.35940/ijitee.C8172.029420

Abbas, A. H., Ibrahim, A. B. A., Nor, M. F. M., & Aris, M. S. (2011) Characterization of Malaysian domestic sewage sludge for conversion into fuels for energy recovery plants. 2011 National postgraduate conference - energy and sustainability: exploring the innovative minds, NPC 2011. https://doi.org/10.1109/NatPC.2011.6136402

Tambo, N., Kobayashi, M., Thebault, P., & Haubry, A. (1982) Sludge treatment and disposal. In Water Supply (Vol. 1, Issue 2 /3). https://doi.org/10.2166/9781780402130

Genchi, G., Sinicropi, M. S., Lauria, G., Carocci, A., & Catalano, A. (2020) The effects of cadmium toxicity. In International Journal of Environmental Research and Public Health (Vol. 17, Issue 11). MDPI AG. https://doi.org/10.3390/ijerph17113782

Rosenani A, Kala D, Ishak CF (2008) (PDF) Characterization of Malaysian sewage sludge and nitrogen mineralization in three soils treated with sewage sludge. Malaysian Journal of Soil Science. https://www.researchgate.net/publication/237559217_Characterization_of_M laysian_sewage_sludge_and_nitrogen_mineralization_in_three_soils_treated_with_sewag _sludge. Accessed 23 June 2020

Bradley, R. M., & Dhanagunan, G. R. (2004) Sewage sludge management in Malaysia. In International Journal of Water (Vol. 2, Issue 4, pp. 267–283). Inderscience Publishers. https://doi.org/10.1504/IJW.2004.005526

Sharrer M, Rishel K, Taylor A, Vinci BJ, Summerfelt ST (2010) The cost and effectiveness of solids thickening technologies for treating backwash and recovering nutrients from intensive aquaculture systems. Biores Technol 101:6630–6641. https://doi.org/10.1016/j.biortech.2010.03.101

Li W, Li L, Qiu G (2017) Energy consumption and economic cost of typical wastewater treatment systems in Shenzhen, China. J Clean Prod 163:S374–S378. https://doi.org/10.1016/j.jclepro.2015.12.109

Liu B, Wei Q, Zhang B, Bi J (2013) Life cycle GHG emissions of sewage sludge treatment and disposal options in Tai Lake Watershed, China. Sci Total Environ 447:361–369. https://doi.org/10.1016/j.scitotenv.2013.01.019

Hobson, J., & Martinsen, T. (2001) CH4 and N2O emissions from waste water handling. Good Practice Guidance and Uncertainty Management in National Greenhouse Gas Inventories

O’kelly, B. C. (2005) Sewage sludge to landfill: some pertinent engineering properties. J Air Waste Manag Assoc 55(6):765–771. https://doi.org/10.1080/10473289.2005.10464670

Singh RP, Agrawal M (2008) Potential benefits and risks of land application of sewage sludge. Waste Manage 28(2):347–358. https://doi.org/10.1016/j.wasman.2006.12.010

Elmi A, Al-Khaldy A, AlOlayan M (2020) Sewage sludge land application: balancing act between agronomic benefits and environmental concerns. J Clean Prod 250:119512. https://doi.org/10.1016/j.jclepro.2019.119512

Mills N, Pearce P, Farrow J, Thorpe RB, Kirkby NF (2014) Environmental & economic life cycle assessment of current & future sewage sludge to energy technologies. Waste Manage 34:185–195. https://doi.org/10.1016/j.wasman.2013.08.024

Ashwekar P, Jiang Y, Pan H, Pratson L (2017) Feasibility study of energy recovery by incineration-a case study of the triangle wastewater treatment plant. Master of Science, Duke University

Khanal, S. K. (2008) Anaerobic biotechnology for bioenergy production. In S. K. Khanal (Ed.), Anaerobic biotechnology for bioenergy production: principles and applications. Wiley-Blackwell. https://doi.org/10.1002/9780813804545

Labatut RA, Angenent LT, Scott NR (2014) Conventional mesophilic vs. thermophilic anaerobic digestion: a trade-off between performance and stability? Water Res 53:249–258. https://doi.org/10.1016/j.watres.2014.01.035

Daniel-Gromke J, Liebetrau J, Denysenko V, Krebs C (2015) Digestion of bio-waste - GHG emissions and mitigation potential. Energy, Sustainability and Society 5(1):1–12. https://doi.org/10.1186/s13705-014-0032-6

Funding

Open Access funding enabled and organized by CAUL and its Member Institutions

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Woo, D.C.Y., Goh, Q.H., Poh, P.E. et al. A technoeconomic analysis of sewage sludge valorization for carbon emission reduction. Biomass Conv. Bioref. 13, 13591–13604 (2023). https://doi.org/10.1007/s13399-022-02922-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-02922-2