Abstract

Biofuels are a current alternative to promote cleaner energy, minimizing environmental impacts of transport worldwide. One of the sources of these biofuels is cassava starch, which can provide fuel ethanol in the same way as sugarcane. The present study aimed to compare the development of the SAGAC algorithm and other techniques to optimize the cassava starch hydrolysis process. Experimental attempts were made to improve the cassava starch hydrolysis method with the following algorithms: Tabu Search (TS), Simulated Annealing (SA), Genetic Algorithm (GA), and Hybrid Metaheuristic Algorithms (SAG and SAGAC). The algorithms were calibrated and parameterized to generate the values of the variables within their respective domains as follows concentration (6.590 to 23.375 g/L), temperature (28.18 to 61.82 °C), and time (9 to 111 min). Results presented the best conditions for starch hydrolysis at 23.375 g/L, 61.9 °C, and 111 min, where a yield of 84.04% was achieved. Results indicated that the Hybrid Metaheuristic optimization technique SAGAC is more efficient than other optimization techniques and could improve industrial ethanol production from cassava.

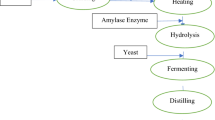

Graphical abstract

Similar content being viewed by others

References

Schmidt JJ, Matthews N (2018) From state to system: financialization and the water-energy-food-climate nexus. Geoforum 91:151–159. https://doi.org/10.1016/j.geoforum.2018.03.001

Schubert S, Gupta J (2013) Comparing global coordination mechanisms on energy, environment, and water. Ecol Soc 18:22. https://doi.org/10.5751/ES-05440-180222

Pereira CLF, Ortega E (2010) Sustainability assessment of large-scale ethanol production from sugarcane. J Clean Prod 18:77–82. https://doi.org/10.1016/j.jclepro.2009.09.007

Giraçol J, Passarini KC, Silva Filho SC, Calarge FA, Tambourgi EB, Santana JCC (2011) Reduction in ecological cost through biofuel production from cooking oils: an ecological solution for the city of Campinas. J Clean Prod 19:1324–1329. https://doi.org/10.1016/j.jclepro.2011.02.015

Ometto AR, Roma WNL (2010) Atmospheric impacts of the life cycle emissions of fuel ethanol in Brazil: based on chemical exergy. J Clean Prod 18:71–76. https://doi.org/10.1016/j.jclepro.2009.09.003

Curvelo-Santana JC, Ehrhardt DD, Tambourgi EB (2010) Optimizing of alcohol production from manioc starch. Food Sci Technol 30(3):613–617. https://doi.org/10.1590/S0101-20612010000300007

Solomon S, Manning M, Marquis M, Qin D (2007) Climate change 2007-the physical science basis: working group I contribution to the fourth assessment report of the IPCC (v. 4). Cambridge University Press.

Chohfi FM, Dupas FA, Lora EES (2021) Balanço, análise de emissão e seqüestro de CO2 na geração de eletricidade excedente no setor sucro-alcooleiro. Encontro de Energia no Meio Rural, 5 . http://www.proceedings.scielo.br/scielo.php?script=sci_arttext&pid=MSC0000000022004000100031&lng=en&nrm=abn

CONAB – Brazilian Supply Company (2020) Perfil sucroalcooleiro safra 2019/20. Available at: https://www.conab.gov.br/info-agro/safras/cana/boletim-da-safra-de-cana-de-acucar/item/download/34870_e1c52a336b53ca05c29824831da3c9e9#:~:text=Etanol%20total%3A%20na%20temporada%202020,em%20rela%C3%A7%C3%A3o%20%C3%A0%20safra%20anterior. Accessed 17 July 2021

Presecki A, Blaževic Z, Vasic-Racki Ð (2013) Complete starch hydrolysis by the synergistic action of amylase and glucoamylase: impact of calcium ions. Bioprocess Biosyst Eng 36:1555–1562. https://doi.org/10.1007/s00449-013-0926-2

Wattanasilp C, Songprakorp R, Nopharatana A, Khompatraporn C (2021) Techno-Cost-benefit analysis of biogas production from industrial cassava starch wastewater in Thailand for optimal utilization with energy storage. Energies 14:416. https://doi.org/10.3390/en14020416

Benvenga MAC, Librantz AFH, Santana JCC, Tambourgi EB (2016) Genetic algorithm applied to study of the economic viability of alcohol production from Cassava root from 2002 to 2013. J Clean Prod 113:483–494. https://doi.org/10.1016/j.jclepro.2015.11.051

Selvaraju S, Rajoo B (2018) Process design and optimization of bioethanol production from cassava bagasse using statistical design and genetic algorithm. Prep Biochem Biotechnol 48:834–841. https://doi.org/10.1080/10826068.2018.1514512

Glover F (1989) Tabu Search – Part I. ORSA J Comput (Online) 1:190–206. https://doi.org/10.1287/ijoc.1.3.190

Glover F (1989) Tabu Search – Part II. ORSA J Comput (Online) 2:4–32. https://doi.org/10.1287/ijoc.2.1.4

Paszkowicz W (2009) Genetic Algorithms, a nature-inspired tool: survey of applications in materials science and related fields. Mater Manuf Process 24:174–197. https://doi.org/10.1080/10426910802612270

Kirkpatrick S, Gelatti CD, Vecchi MP (1983) Optimization by simulated annealing. Science, New Series, 220, 671–680. https://science.sciencemag.org/content/220/4598/671

Oysu C, Bingul Z (2009) Application of heuristic and hybrid-GASA algorithms to tool-path optimization problem for minimizing air time during machining. Eng Appl Artif Intell 22:389–396. https://doi.org/10.1016/j.engappai.2008.10.005

Vasan A, Raju KS (2009) Comparative analysis of Simulated Annealing, Simulated Quenching and Genetic Algorithms for optimal reservoir operation. Appl Soft Comput 9:274–281. https://doi.org/10.1016/j.asoc.2007.09.002

Mitchell TM (1997) Machine learning. McGraw-Hill Science, Redmond, EUA, 249–270.

Goldberg DE (1989) Genetic algorithms in search, optimization, and machine learning. Addison-Wesley Pub. Inc., Massachusetts, EUA

Almeida SS, Alves WAL, Araújo SA, Santana JCC, Narain N, Souza RR (2014) Use of simulated annealing in standardization and optimization of the acerola wine production. Food Sci Technol Int 34(2):292–297. https://doi.org/10.1590/fst.2014.0037

Jin C (2011) Software reliability prediction based on support vector regression using a hybrid genetic algorithm and simulated annealing algorithm. IET Software 5(4):398–405. https://doi.org/10.1049/iet-sen.2010.0073

Santana JCC, Araújo AS, Librantz AFH, Tambourgi EB (2010) Optimization of the corn malt drying by use of genetic algorithm. Dry Technol 28:1236–1234. https://doi.org/10.1080/07373937.2010.500439

Benvenga MAC (2012) Comparação de técnicas metaheurísticas de otimização no processo de hidrólise do amido de mandioca para obtenção de álcool, (Masters Dissertation), Universidade Nove de Julho

Librantz AF, Coppini NL, Baptista EA, Araújo SE, Rosa AFC (2010) Genetic algorithm applied to investigate cutting process parameters influence on workpiece price formation. Mater. Manuf. Process, 26:3, 550–557. https://www.tandfonline.com/doi/abs/https://doi.org/10.1080/10426914.2010.512817

Sivamani S, Baskar R (2018) Process design and optimization of bioethanol production from cassava bagasse using statistical design and genetic algorithm. Prep Biochem Biotechnol 48(9):834–841. https://doi.org/10.1080/10826068.2018.1514512

Adeleye TM, Kareem SO, Bankole MO, Atanda O, Adeogun AI (2020) Ethanol production from cassava starch by protoplast fusants of Wickerhamomycesanomalus and Galactomycescandidum. EJBAS 7(1):67–81. https://doi.org/10.1080/2314808X.2020.1746884

Field CBC, Michalak AM (2015) Water, climate, energy, food: Inseparable & indispensable, 114(3):7–17. https://www.jstor.org/stable/24711226

Raymond ABD (2020) Aligning competing risks? Global food security as a trade-offs-based approach to risk and food policy. Sci Technol Soc 25:19–37. https://doi.org/10.1177/0971721819889917

Zhang Y, Rao Y, Zhou M (2007) GASA Hybrid algorithm applied in airline crew rostering system. Tsinghua SciTechnol 12. https://doi.org/10.1016/S1007-0214(07)70120-7

Adeboye BS, Adewole BZ, Adedoja AM, Obayopo SO, Asere AA, Kayode O, Idris MO, Okediran IK (2021) Optimization and modeling of process parameters on the yield of enhanced pyrolysis oil during co-pyrolysis of cassava peel with polystyrene. Environ Challenges 5:100347. https://doi.org/10.1016/j.envc.2021.100347

Khunnonkwao P, Jantama SS, Jantama K, Joannis-Cassan C, Taillandier P (2021) Sequential coupling of enzymatic hydrolysis and fermentation platform for high yield and economical production of 2, 3-butanediol from cassava by metabolically engineered Klebsiella oxytoca. J Chem Technol Biotechnol 96(5):1292–1301. https://doi.org/10.1002/jctb.6643

Awoyale AA, Lokhat D (2021) Hybridization of selected nigerian lignocellulosic biomass feedstocks for bioethanol production: modeling and optimization of pretreatment and fermentation process parameters using response surface methodology. J Oleo Sci ess21038. https://doi.org/10.5650/jos.ess21038

Biswas R, Teller PJ, Khan MU, Ahring BK (2020) molecules, sugar production from hybrid poplar sawdust: optimization of enzymatic hydrolysis and wet explosion pretreatment, https://doi.org/10.3390/molecules25153396, https://www.mdpi.com/1420-3049/25/15/3396

Lü H, Zhou J, Liu J, Lü C, Lian F, Li Y (2019) Optimization of hydrothermal pretreatment for co-utilization of xylose and glucose of cassava anaerobic residue for producing ethanol. Chin J Chem Eng 27(4):920–927. https://doi.org/10.1016/j.cjche.2018.08.025

Geng N-N, Zhang Y, Sun Y-X, Jiang YJ (2016) Optimization of sustainable biofuel network based on hybrid genetic algorithm. Civil Engineering and Urban Planning IV - Proceedings of the 4th International Conference on Civil Engineering and Urban Planning, CEUP 2015. https://doi.org/10.1201/b19880-168

Yingling B, Zongcheng Y, Honglin W, Li C (2011) Optimization of bioethanol production during simultaneous saccharification and fermentation in very high-gravity cassava mash. Antonie Van Leeuwenhoek 99(2):329–339. https://doi.org/10.1007/s10482-010-9494-5

Aztatzi-Pluma D, Figueroa-Gerstenmaier S, Padierna LC, Vázquez-Núñez E, Molina-Guerrero CE (2020) Kinetic parameter determination for depolymerization of biomass by inverse modeling and metaheuristics. Processes 8:836. https://doi.org/10.3390/pr8070836

Molina C, Sánchez A, Serafín-Muñoz A, Folch-Mallol J (2014) Optimization of Enzymatic Saccharification of wheat straw in a micro-scale system by response surface methodology, Revista Mexicana de Ingeniería Química. 13:765–778. www.rmiq.org.

Acknowledgements

The first author thanks the PROSUP/CAPES program and the Universidade Paulista (UNIP) for the doctoral scholarship.

Author information

Authors and Affiliations

Contributions

Conceptualization, Benvenga M. A. C.; methodology, Benvenga M.A.C.; software development, validation, and data curation, Benvenga M.A.C.; writing, review, and editing, Benvenga M.A.C. and Nääs I.A.; supervision, Nääs I.A.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• We propose minimizing the use of natural resources when producing ethanol.

• The process optimization makes ethanol costs decrease.

• Optimizing ethanol production from cassava might broaden the use of sustainable fuel.

Appendix

Appendix

Rights and permissions

About this article

Cite this article

C., B.M.A., A., N.I. Optimization of hydrolysis of cassava starch for biofuel production using a Hybrid Metaheuristic Algorithm. Biomass Conv. Bioref. 14, 2141–2153 (2024). https://doi.org/10.1007/s13399-022-02912-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-02912-4