Abstract

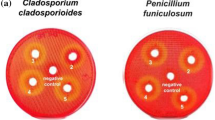

Costs and conversion efficiency associated with cellulase preparations have been identified as factors impeding the development of cellulose hydrolysis–based technologies. Supplementing enzymes to fungal cocktails has been practiced; however, the costs associated offset the benefits of an increase in hydrolysis. This work explores the benefits of using maize bran as a substrate in a sequential fermentation mode to produce β-glucosidase (BGL), intended for augmenting commercial fungal cellulases. Aspergillus tubingensis was grown for BGL production on maize bran in sequential solid-state and submerged fermentation (SsF-SmF). In these experiments, a solid substrate was soaked with a nutrient medium and later with media containing 1% solid substrate. The sequential process was observed to yield a two-fold improvement in BGL production in comparison to traditional methods. The predominance of dispersed mycelia in the sequential process was noted and concluded to be the influencer for improved enzyme secretion. Different substrates were evaluated among which delignified maize bran was found to be the most suitable. The batch fermentation yielded BGL productivity of 400 ± 8.64 CBU/l/day, while the repeated fed-batch mode improved the BGL productivity to 647 ± 13.33 CBU/l/day and 987 ± 12.5 CBU/l/day for 50 and 25% medium replacement, respectively. Supplementing commercial cellulases with the produced BGL was observed to increase cellulose hydrolysis by 20%. This work, therefore, helps explore the potential of maize bran as a substrate for sequential SsF-SmF for BGL production in a cost-effective manner.

Similar content being viewed by others

Abbreviations

- SsF:

-

Solid-state fermentation

- SmF:

-

Submerged fermentation

- BGL:

-

β-Glucosidase

- SLPM:

-

Standard liters per minute

- kDa:

-

Kilodalton

- MB:

-

Maize bran

- CBU:

-

Cellobiose unit

- FPU:

-

Filter paper unit

- CBU/l/day:

-

Cellobiose units per liter per day

References

Zoghlami A, Paës G (2019) Lignocellulosic biomass: understanding recalcitrance and predicting hydrolysis. Front Chem 7:874

Martins LF, Kolling D, Camassola M, Dillon AJP, Ramos LP (2008) Comparison of Penicillium echinulatum and Trichoderma reesei cellulases in relation to their activity against various cellulosic substrates. Biores Technol 99(5):1417–1424

Srivastava N, Rathour R, Jha S, Pandey K, Srivastava M, Thakur VK, ..., Mishra PK (2019) Microbial beta glucosidase enzymes: recent advances in biomass conversation for biofuels application. Biomolecules 9(6):220

Ntana F, Mortensen UH, Sarazin C, Figge R (2020) Aspergillus: a powerful protein production platform. Catalysts 10(9):1064

Wen Z, Liao W, Chen S (2005) Production of cellulase/β-glucosidase by the mixed fungi culture Trichoderma reesei and Aspergillus phoenicis on dairy manure. Process Biochem 40(9):3087–3094

Garbin AP, Garcia NFL, Cavalheiro GF, Silvestre MA, Rodrigues A, Paz MFD, Fonseca GG, Leite RSR (2021) β-glucosidase from thermophilic fungus Thermoascus crustaceus: production and industrial potential. An Acad Bras Cienc 93:e20191349

Tiwari R, Nain PK, Singh S, Adak A, Saritha M, Rana S, ..., Nain L (2015) Cold active holocellulase cocktail from Aspergillus niger SH3: process optimization for production and biomass hydrolysis. J Taiwan Inst Chem Eng 56:57-66

Huang C, Feng Y, Patel G, Xu XQ, Qian J, Liu Q, Kai GY (2021) Production, immobilization and characterization of beta-glucosidase for application in cellulose degradation from a novel Aspergillus versicolor. Int J Biol Macromol 177:437–446

Nanjundaswamy A, Okeke BC (2020) Comprehensive optimization of culture conditions for production of biomass-hydrolyzing enzymes of Trichoderma SG2 in submerged and solid-state fermentation. Appl Biochem Biotechnol 191(1):444–462

Frassatto PAC, Casciatori FP, Thoméo JC, Gomes E, Boscolo M, da Silva R (2021) β-Glucosidase production by Trichoderma reesei and Thermoascus aurantiacus by solid state cultivation and application of enzymatic cocktail for saccharification of sugarcane bagasse. Biomass Convers Biorefin 11(2):503–513

de Oliveira Rodrigues P, dos Santos BV, Costa L, Henrique MA, Pasquini D, Baffi MA (2017) Xylanase and β-glucosidase production by Aspergillus fumigatus using commercial and lignocellulosic substrates submitted to chemical pre-treatments. Ind Crops Prod 95:453–459

Dias LM, Dos Santos BV, Albuquerque CJB, Baeta BEL, Pasquini D, Baffi MA (2018) Biomass sorghum as a novel substrate in solid-state fermentation for the production of hemicellulases and cellulases by Aspergillus niger and A. fumigatus. J Appl Microbiol 124(3):708–718

Sørensen A, Andersen JJ, Ahring BK, Teller PJ, Lübeck M (2014) Screening of carbon sources for beta-glucosidase production by Aspergillus saccharolyticus. Int Biodeterior Biodegradation 93:78–83

Visvanathan C, Trankler J, Joseph K, Chiemchaisri C, Basnayake BFA, Gongming Z (2004) Municipal solid waste management in Asia. Asian regional research program on environmental technology (ARRPET). Asian Institute of Technology publications. ISBN, 974, 417–258

Ramamoorthy NK, Sambavi TR, Renganathan S (2019) A study on cellulase production from a mixture of lignocellulosic wastes. Process Biochem 83:148–158

Varotkar P, Tumane PM, Wasnik DD (2016) Bioconversion of waste paper into bio-ethanol by co-culture of fungi isolated from lignocellulosic waste. Int J Pure Appl Biosci 4(4):264–274

Saeed F, Hussain M, Arshad MS, Afzaal M, Munir H, Imran M, ..., Anjum FM (2021) Functional and nutraceutical properties of maize bran cell wall non-starch polysaccharides. Int J Food Prop 24(1):233-248

Singh RS, Chauhan K, Jindal A (2018) Response surface optimization of solid-state fermentation for inulinase production from Penicillium oxalicum using corn bran. J Food Sci Technol 55(7):2533–2540

Singhania RR, Patel AK, Pandey A, Ganansounou E (2017) Genetic modification: a tool for enhancing beta-glucosidase production for biofuel application. Biores Technol 245:1352–1361

Vasconcellos VM, Tardioli PW, Giordano RLC, Farinas CS (2015) Production efficiency versus thermostability of (hemi) cellulolytic enzymatic cocktails from different cultivation systems. Process Biochem 50(11):1701–1709

Cunha FM, Esperanca MN, Zangirolami TC, Badino AC, Farinas CS (2012) Sequential solid-state and submerged cultivation of Aspergillus niger on sugarcane bagasse for the production of cellulase. Biores Technol 112:270–274

López-Gómez JP, Venus J (2021) Potential role of sequential solid-state and submerged-liquid fermentations in a circular bioeconomy. Fermentation 7(2):76

Florencio C, Cunha FM, Badino AC, Farinas CS, Ximenes E, Ladisch MR (2016) Secretome analysis of Trichoderma reesei and Aspergillus niger cultivated by submerged and sequential fermentation processes: enzyme production for sugarcane bagasse hydrolysis. Enzyme Microb Technol 90:53–60

An Q, Wu XJ, Han ML, Cui BK, He SH, Dai YC, Si J (2016) Sequential solid-state and submerged cultivation of the white rot fungus Pleurotus ostreatus on biomass and the activity of lignocellulolytic enzymes. BioResources 11(4):8791–8805

Mandels M, Weber J (1969) The production of cellulases. In Cellulases and their applications. Advan Chem Ser 95:391–414

Updegraff DM (1969) Semimicro determination of cellulose in biological materials. Anal Biochem 32(3):420–424

Rapp P, Grote E, Wagner F (1981) Formation and location of 1,4-β-glucanases and 1,4-β-glucosidases from Penicillium janthinellum. Appl Environ Microbiol 41(4):857–866

Ahamed A, Vermette P (2008) Culture-based strategies to enhance cellulase enzyme production from Trichoderma reesei RUT-C30 in bioreactor culture conditions. Biochem Eng J 40(3):399–407

Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D, Crocker DLAP (2008) Determination of structural carbohydrates and lignin in biomass. Lab Anal Proced 1617(1):1–16

Ghose TK (1987) Measurement of cellulase activities. Pure Appl Chem 59(2):257–268

Bradford MM (1976) A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal Biochem 72(1–2):248–254

Mitteer DR, Greer BD, Fisher WW, Cohrs VL (2018) Teaching behavior technicians to create publication-quality, single-case design graphs in GraphPad Prism 7. J Appl Behav Anal 51(4):998–1010

Pandey A, Selvakumar P, Soccol CR, Nigam P (1999) Solid state fermentation for the production of industrial enzymes. Curr Sci 149–162

Gowthaman MK, Krishna C, Moo-Young M (2001) Fungal solid-state fermentation—an overview. Appl Mycol Biotechnol 1:305–352

Bansal N, Tewari R, Soni R, Soni SK (2012) Production of cellulases from Aspergillus niger NS-2 in solid state fermentation on agricultural and kitchen waste residues. Waste Manage 32(7):1341–1346

Hendriks ATWM, Zeeman G (2009) Pretreatments to enhance the digestibility of lignocellulosic biomass. Biores Technol 100(1):10–18

Salihu A, Abbas O, Sallau AB, Alam MZ (2015) Agricultural residues for cellulolytic enzyme production by Aspergillus niger: effects of pretreatment. 3 Biotech 5(6):1101–1106

Veiter L, Rajamanickam V, Herwig C (2018) The filamentous fungal pellet—relationship between morphology and productivity. Appl Microbiol Biotechnol 102(7):2997–3006

Grimm LH, Kelly S, Krull R, Hempel DC (2005) Morphology and productivity of filamentous fungi. Appl Microbiol Biotechnol 69(4):375–384

Peberdy JF (1994) Protein secretion in filamentous fungi—trying to understand a highly productive black box. Trends Biotechnol 12(2):50–57

Ahamed A, Vermette P (2009) Effect of culture medium composition on Trichoderma reesei’s morphology and cellulase production. Biores Technol 100(23):5979–5987

Farkas V (1979) Biosynthesis of cell walls of fungi. Microbiol Rev 43(2):117–144

Florencio C, Cunha FM, Badino AC, Farinas CS (2015) Validation of a novel sequential cultivation method for the production of enzymatic cocktails from Trichoderma strains. Appl Biochem Biotechnol 175(3):1389–1402

Domingues FC, Queiroz JA, Cabral JMS, Fonseca LP (2000) The influence of culture conditions on mycelial structure and cellulase production by Trichoderma reesei Rut C-30. Enzyme Microb Technol 26(5–6):394–401

Johansen CL, Coolen L, Hunik JH (1998) Influence of morphology on product formation in Aspergillus awamori during submerged fermentations. Biotechnol Prog 14(2):233–240

Jiménez-Tobon GA, Penninckx MJ, Lejeune R (1997) The relationship between pellet size and production of Mn(II) peroxidase by Phanerochaete chrysosporium in submerged culture. Enzyme Microb Technol 21(7):537–542

Wyman CE (1994) Ethanol from lignocellulosic biomass: technology, economics, and opportunities. Biores Technol 50(1):3–15

Zhang L, Liu Y, Niu X, Liu Y, Liao W (2012) Effects of acid and alkali treated lignocellulosic materials on cellulase/xylanase production by Trichoderma reesei Rut C-30 and corresponding enzymatic hydrolysis. Biomass Bioenerg 37:16–24

Abdella A, Mazeed TES, El-Baz AF, Yang ST (2016) Production of β-glucosidase from wheat bran and glycerol by Aspergillus niger in stirred tank and rotating fibrous bed bioreactors. Process Biochem 51(10):1331–1337

Howell MJ, Wilke CR (1978) Process development studies for the production of β-glucosidase from Aspergillus phoenicis (No. LBL-7867). Lawrence Berkeley National Lab.(LBNL), Berkeley, CA (United States)

Gibbs PA, Seviour RJ, Schmid F (2000) Growth of filamentous fungi in submerged culture: problems and possible solutions. Crit Rev Biotechnol 20(1):17–48

Han X, Song W, Liu G, Li Z, Yang P, Qu Y (2017) Improving cellulase productivity of Penicillium oxalicum RE-10 by repeated fed-batch fermentation strategy. Biores Technol 227:155–163

Decker C, Visser J, Schreier P (2001) β-Glucosidase multiplicity from Aspergillus tubingensis CBS 643.92: purification and characterization of four β-glucosidases and their differentiation with respect to substrate specificity, glucose inhibition, and acid tolerance. Appl Microbiol Biotechnol 55(2):157–163

Prajapati BP, Suryawanshi RK, Agrawal S, Ghosh M, Kango N (2018) Characterization of cellulase from Aspergillus tubingensis NKBP-55 for generation of fermentable sugars from agricultural residues. Biores Technol 250:733–740

Rawat R, Kumar S, Chadha BS, Kumar D, Oberoi HS (2015) An acidothermophilic functionally active novel GH12 family endoglucanase from Aspergillus niger HO: purification, characterization and molecular interaction studies. Antonie Van Leeuwenhoek 107(1):103–117

Cunha FM, Vasconcellos VM, Florencio C, Badino AC, Farinas CS (2017) On-site production of enzymatic cocktails using a non-conventional fermentation method with agro-industrial residues as renewable feedstocks. Waste Biomass Valorization 8(2):517–526

Adsul M, Sandhu SK, Singhania RR, Gupta R, Puri SK, Mathur A (2020) Designing a cellulolytic enzyme cocktail for the efficient and economical conversion of lignocellulosic biomass to biofuels. Enzyme Microb Technol 133:109442

Rajasree KP, Mathew GM, Pandey A, Sukumaran RK (2013) Highly glucose tolerant β-glucosidase from Aspergillus unguis: NII 08123 for enhanced hydrolysis of biomass. J Ind Microbiol Biotechnol 40(9):967–975

Tiwari R, Singh PK, Singh S, Nain PK, Nain L, Shukla P (2017) Bioprospecting of novel thermostable β-glucosidase from Bacillus subtilis RA10 and its application in biomass hydrolysis. Biotechnol Biofuels 10(1):1–18

da Costa SG, Pereira OL, Teixeira-Ferreira A, Valente RH, de Rezende ST, Guimarães VM, Genta FA (2018) Penicillium citrinum UFV1 β-glucosidases: purification, characterization, and application for biomass saccharification. Biotechnol Biofuels 11(1):1–19

KoolothValappil P, Rajasree KP, Abraham A, Christopher M, Sukumaran RK (2019) Characterization of a glucose tolerant β-glucosidase from Aspergillus unguis with high potential as a blend-in for biomass hydrolyzing enzyme cocktails. Biotech Lett 41(10):1201–1211

Kao MR, Kuo HW, Lee CC, Huang KY, Huang TY, Li CW, ..., Ho THD (2019) Chaetomella raphigera β-glucosidase D2-BGL has intriguing structural features and a high substrate affinity that renders it an efficient cellulase supplement for lignocellulosic biomass hydrolysis. Biotechnol Biofuels 12(1):1-18

Acknowledgements

The work was supported in part by TEQIP-III, DBT-ICT Centre for Energy Biosciences, and Gencrest LLP Pvt. Ltd. The DBT-ICT Centre for Energy Biosciences is duly acknowledged for providing the infrastructure and facilities for the research work. The authors are grateful to both Privi Organics Pvt. Limited, Navi Mumbai, India, and Indian Glycols Limited, Uttarakhand, India, for providing biomass samples and to Gencrest LLP Pvt. Ltd. for the enzyme samples used in the study.

Author information

Authors and Affiliations

Contributions

SS and AAO conceptualized the study, and AAO facilitated funds for conducting the work. TM and SS designed the experiments, and TM conducted the experiments. Data analysis was conducted by TM, SS, and AAO. TM wrote the manuscript. TM, SS, and AAO critically reviewed and edited the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Mule, T.A., Sawant, S.S. & Odaneth, A.A. Maize bran as a potential substrate for production of β-glucosidase. Biomass Conv. Bioref. 14, 4029–4039 (2024). https://doi.org/10.1007/s13399-022-02747-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-02747-z