Abstract

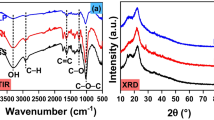

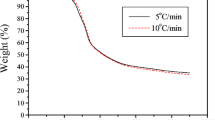

This paper aims to investigate coconut fiber’s thermal behavior and evaluate its potential energy production through kinetic and thermodynamic studies, as well as the potential to produce solid biofuels (briquettes). Structural chemical analysis, proximate analysis, and higher heating value characterized coconut fiber. The thermogravimetric experiments were carried out in an inert atmosphere (N2), varying the heating rates at 5, 10, 15, and 20 K min−1. The kinetic triplet was determined using isoconversional methods and master plot methodology. The pre-exponential factor, enthalpy, entropy, and Gibbs free energy parameters were calculated. The briquettes were made by different particle sizes: mixed particles (without granulometric classification); particles between 0.35 mm and 0.25 mm, and particles lower than 0.25 mm. The coconut fiber briquettes were produced in a compaction system at a temperature of 393.15 K under 15 MPa pressure for 20 min. This study also determined the apparent density, the resistance to diametral compression, and the energy density for coconut fiber briquettes. The pyrolysis reaction was modeled considering the reaction mechanism of as the three-dimensional Jader equation, with global activation energy 129.8 kJ mol−1 and global pre-exponential factor 2.68 × 107 s−1. The enthalpy and entropy values have shown considerable variations due to the conversion, suggesting that the pyrolysis of coconut fiber involves complex reaction mechanisms. The briquetting process enhanced the coconut fibers, and the results have shown that the lower particle size (particles ≤ 0.25 mm) presented better physical–mechanical properties and energy density. It is concluded that coconut fiber has the potential to be turned into biofuels from the thermochemical processes and may be enhanced by the densification process.

Similar content being viewed by others

Data availability

The data that support the findings of this study are openly available on request.

References

(2021) COP 26 in Glasgow. International Journal of Refrigeration 132v-vi. https://doi.org/10.1016/j.ijrefrig.2021.11.029

Adeniyi AG, Otoikhian KS, Ighalo JO, Mohammed IA (2019) Pyrolysis of different fruit peel waste via a thermodynamic model. ABUAD J Eng Res Dev 2:16–24

da Silva Moura A, Demori R, Leão RM et al (2019) The influence of the coconut fiber treated as reinforcement in PHB (polyhydroxybutyrate) composites. Mater Today Commun 18:191–198. https://doi.org/10.1016/j.mtcomm.2018.12.006

Correa MU de (2012) Árvore do conhecimento: coco

Lertwattanaruk P, Suntijitto A (2015) Properties of natural fiber cement materials containing coconut coir and oil palm fibers for residential building applications. Constr Build Mater 94:664–669. https://doi.org/10.1016/j.conbuildmat.2015.07.154

Empresa de Pesquisa Energética - EPE (2019) Balanço Energético Nacional

Bhatnagar A, Tolvanen H, Konttinen J (2020) Potential of stepwise pyrolysis for on-site treatment of agro-residues and enrichment of value-added chemicals. Waste Manage 118:667–676. https://doi.org/10.1016/j.wasman.2020.09.022

Mishra RK, Mohanty K (2020) Kinetic analysis and pyrolysis behaviour of waste biomass towards its bioenergy potential. Biores Technol 311:123480. https://doi.org/10.1016/j.biortech.2020.123480

Setter C, Sanchez Costa KL, Pires de Oliveira TJ, Farinassi Mendes R (2020) The effects of kraft lignin on the physicomechanical quality of briquettes produced with sugarcane bagasse and on the characteristics of the bio-oil obtained via slow pyrolysis. Fuel Process Technol 210:106561. https://doi.org/10.1016/j.fuproc.2020.106561

Saddawi A, Jones JM, Williams A, Wójtowicz MA (2010) Kinetics of the thermal decomposition of biomass. Energy Fuels 24:1274–1282. https://doi.org/10.1021/ef900933k

Maia AAD, de Morais LC (2016) Kinetic parameters of red pepper waste as biomass to solid biofuel. Biores Technol 204:157–163. https://doi.org/10.1016/j.biortech.2015.12.055

Aslan DI, Özoğul B, Ceylan S, Geyikçi F (2018) Thermokinetic analysis and product characterization of Medium Density Fiberboard pyrolysis. Biores Technol 258:105–110. https://doi.org/10.1016/j.biortech.2018.02.126

Yesid Javier, Rueda-Ordóñez Katia, Tannous Edgardo, Olivares-Gómez (2015) An empirical model to obtain the kinetic parameters of lignocellulosic biomass pyrolysis in an independent parallel reactions scheme. Fuel Processing Technology 140222-230 10.1016/j.fuproc.2015.09.001

Vyazovkin S, Burnham AK, Criado JM et al (2011) ICTAC Kinetics Committee recommendations for performing kinetic computations on thermal analysis data. Thermochim Acta 520:1–19. https://doi.org/10.1016/j.tca.2011.03.034

Várhegyi G, Czégény Z, Jakab E et al (2009) Tobacco pyrolysis. Kinetic evaluation of thermogravimetric–mass spectrometric experiments. J Anal Appl Pyrol 86:310–322. https://doi.org/10.1016/j.jaap.2009.08.008

Lopes FCR, Tannous K (2020) Coconut fiber pyrolysis decomposition kinetics applying single- and multi-step reaction models. Thermochim Acta 691:178714. https://doi.org/10.1016/j.tca.2020.178714

Chen J, Wang Y, Lang X et al (2017) Evaluation of agricultural residues pyrolysis under non-isothermal conditions: thermal behaviors, kinetics, and thermodynamics. Biores Technol 241:340–348. https://doi.org/10.1016/j.biortech.2017.05.036

Singh RK, Pandey D, Patil T, Sawarkar AN (2020) Pyrolysis of banana leaves biomass: physico-chemical characterization, thermal decomposition behavior, kinetic and thermodynamic analyses. Bioresource Technol 310:123464

Simão BL, Júnior JAS, Chagas BME et al (2018) Pyrolysis of Spirulina maxima: kinetic modeling and selectivity for aromatic hydrocarbons. Algal Res 32:221–232. https://doi.org/10.1016/j.algal.2018.04.007

White JE, Catallo WJ, Legendre BL (2011) Biomass pyrolysis kinetics: a comparative critical review with relevant agricultural residue case studies. J Anal Appl Pyrol 91:1–33

Açıkalın K (2021) Determination of kinetic triplet, thermal degradation behaviour and thermodynamic properties for pyrolysis of a lignocellulosic biomass. Bioresource Technol 125438

Yang I, Cooke-Willis M, Song B, Hall P (2021) Densification of torrefied Pinus radiata sawdust as a solid biofuel: effect of key variables on the durability and hydrophobicity of briquettes. Fuel Process Technol 214:106719. https://doi.org/10.1016/j.fuproc.2020.106719

Ajimotokan HA, Ibitoye SE, Odusote JK et al (2019) Physico-mechanical properties of composite briquettes from corncob and rice husk. J Bioresour Bioprod 4:159–165. https://doi.org/10.12162/jbb.v4i3.004

Cabrales H, Arzola N, Araque O (2020) The effects of moisture content, fiber length and compaction time on African oil palm empty fruit bunches briquette quality parameters. Heliyon 6:e05607. https://doi.org/10.1016/j.heliyon.2020.e05607

Afra E, Abyaz A, Saraeyan A (2021) The production of bagasse biofuel briquettes and the evaluation of natural binders (LNFC, NFC, and lignin) effects on their technical parameters. J Clean Prod 278:123543. https://doi.org/10.1016/j.jclepro.2020.123543

Setter C, Ataíde CH, Mendes RF, de Oliveira TJP (2021) Influence of particle size on the physico-mechanical and energy properties of briquettes produced with coffee husks. Environ Sci Pollut Res 28:8215–8223. https://doi.org/10.1007/s11356-020-11124-0

ASTM (2013) D1762–84, Standard test method for chemical analysis of wood charcoal, ASTM

TAPPI T. (2007) 204 cm-97. Solvent extractives of wood and pulp. 12

Gomide JL, Demuner BJ (1986) Determinação do teor de lignina em material lenhoso: método Klason modificado. O papel 47:36–38

Goldschimid O (1971) Ultraviolet spectra. In: Sarkanen KV, Ludwig CH Lignins: occurrence, formation, structure and reactions. John Wiley Interprice, New York

Cardoso CR, Oliveira TJP, Santana Junior JA, Ataíde CH (2013) Physical characterization of sweet sorghum bagasse, tobacco residue, soy hull and fiber sorghum bagasse particles: density, particle size and shape distributions. Powder Technol 245:105–114. https://doi.org/10.1016/j.powtec.2013.04.029

Uzun BB, Yaman E (2017) Pyrolysis kinetics of walnut shell and waste polyolefins using thermogravimetric analysis. J Energy Inst 90:825–837

Li H, Li L, Zhang R et al (2014) Fractional pyrolysis of Cyanobacteria from water blooms over HZSM-5 for high quality bio-oil production. J Energy Chem 23:732–741

Vyazovkin S, Chrissafis K, Di Lorenzo ML et al (2014) ICTAC Kinetics Committee recommendations for collecting experimental thermal analysis data for kinetic computations. Thermochim Acta 590:1–23

de Carvalho VS, Tannous K (2017) Thermal decomposition kinetics modeling of energy cane Saccharum robustum. Thermochim Acta 657:56–65

Aslan DI, Parthasarathy P, Goldfarb JL, Ceylan S (2017) Pyrolysis reaction models of waste tires: application of master-plots method for energy conversion via devolatilization. Waste Manage 68:405–411

Sánchez-Jiménez PE, Pérez-Maqueda LA, Perejón A, Criado JM (2013) Limitations of model-fitting methods for kinetic analysis: polystyrene thermal degradation. Resour Conserv Recycl 74:75–81. https://doi.org/10.1016/j.resconrec.2013.02.014

Cai J, Xu D, Dong Z et al (2018) Processing thermogravimetric analysis data for isoconversional kinetic analysis of lignocellulosic biomass pyrolysis: case study of corn stalk. Renew Sustain Energy Rev 82:2705–2715. https://doi.org/10.1016/j.rser.2017.09.113

Vyazovkin S, Burnham AK, Criado JM et al (2011) ICTAC Kinetics commitee recommendations for performing kinetic computations on thermal analysis data. Thermochim Acta 520:1–19. https://doi.org/10.1016/j.tca.2011.03.034

Janković B (2008) Kinetic analysis of the nonisothermal decomposition of potassium metabisulfite using the model-fitting and isoconversional (model-free) methods. Chem Eng J 139:128–135. https://doi.org/10.1016/j.cej.2007.07.085

Evans MG, Polanyi M (1935) Some applications of the transition state method to the calculation of reaction velocities, especially in solution. Trans Faraday Soc 31:875–894

Eyring H (1935) The activated complex in chemical reactions. J Chem Phys 3:107–115

ASTM E711–87 (2004) Standard test method for gross calorific value of refuse-derived fuel by the bomb calorimeter. Annual Book of ASTM Standards

Hansted ALS, Nakashima GT, Martins MP et al (2016) Comparative analyses of fast growing species in different moisture content for high quality solid fuel production. Fuel 184:180–184. https://doi.org/10.1016/j.fuel.2016.06.071

Yang X, Wang H, Strong PJ et al (2017) Thermal properties of biochars derived from waste biomass generated by agricultural and forestry sectors. Energies 10:469

Siddiqi H, Bal M, Kumari U, Meikap BC (2020) In-depth physiochemical characterization and detailed thermo-kinetic study of biomass wastes to analyze its energy potential. Renew Energy 148:756–771. https://doi.org/10.1016/j.renene.2019.10.162

Choudhury ND, Chutia RS, Bhaskar T, Kataki R (2014) Pyrolysis of jute dust: effect of reaction parameters and analysis of products. J Mater Cycles Waste Manag 16:449–459. https://doi.org/10.1007/s10163-014-0268-4

Eriksson S, Prior M (1990) The briquetting of agricultural wastes for fuel. Food and Agriculture Organization of the United Nations

Chen Z, Hu M, Zhu X et al (2015) Characteristics and kinetic study on pyrolysis of five lignocellulosic biomass via thermogravimetric analysis. Biores Technol 192:441–450. https://doi.org/10.1016/j.biortech.2015.05.062

Kaur R, Gera P, Jha MK, Bhaskar T (2018) Pyrolysis kinetics and thermodynamic parameters of castor (Ricinus communis) residue using thermogravimetric analysis. Biores Technol 250:422–428. https://doi.org/10.1016/j.biortech.2017.11.077

Tahir MH, Çakman G, Goldfarb JL et al (2019) Demonstrating the suitability of canola residue biomass to biofuel conversion via pyrolysis through reaction kinetics, thermodynamics and evolved gas analyses. Biores Technol 279:67–73. https://doi.org/10.1016/j.biortech.2019.01.106

Dhyani V, Kumar J, Bhaskar T (2017) Thermal decomposition kinetics of sorghum straw via thermogravimetric analysis. Biores Technol 245:1122–1129. https://doi.org/10.1016/j.biortech.2017.08.189

McKendry P (2002) Energy production from biomass (part 1): overview of biomass. Biores Technol 83:37–46. https://doi.org/10.1016/S0960-8524(01)00118-3

Sait HH, Hussain A, Salema AA, Ani FN (2012) Pyrolysis and combustion kinetics of date palm biomass using thermogravimetric analysis. Biores Technol 118:382–389. https://doi.org/10.1016/j.biortech.2012.04.081

Daria M, Krzysztof L, Jakub M (2020) Characteristics of biodegradable textiles used in environmental engineering: a comprehensive review. J Clean Prod 268:122129. https://doi.org/10.1016/j.jclepro.2020.122129

Mian I, Li X, Jian Y et al (2019) Kinetic study of biomass pellet pyrolysis by using distributed activation energy model and Coats Redfern methods and their comparison. Biores Technol 294:122099. https://doi.org/10.1016/j.biortech.2019.122099

Chen W-H, Eng CF, Lin Y-Y, Bach Q-V (2020) Independent parallel pyrolysis kinetics of cellulose, hemicelluloses and lignin at various heating rates analyzed by evolutionary computation. Energy Convers Manage 221:113165. https://doi.org/10.1016/j.enconman.2020.113165

Hu M, Chen Z, Wang S et al (2016) Thermogravimetric kinetics of lignocellulosic biomass slow pyrolysis using distributed activation energy model, Fraser-Suzuki deconvolution, and iso-conversional method. Energy Convers Manage 118:1–11. https://doi.org/10.1016/j.enconman.2016.03.058

de GodoisBaroni É, Tannous K, Rueda-Ordóñez YJ, Tinoco-Navarro LK (2016) The applicability of isoconversional models in estimating the kinetic parameters of biomass pyrolysis. J Therm Anal Calorim 123:909–917. https://doi.org/10.1007/s10973-015-4707-9

Ceylan S, Topçu Y (2014) Pyrolysis kinetics of hazelnut husk using thermogravimetric analysis. Biores Technol 156:182–188. https://doi.org/10.1016/j.biortech.2014.01.040

Singh RK, Patil T, Sawarkar AN (2020) Pyrolysis of garlic husk biomass: physico-chemical characterization, thermodynamic and kinetic analyses. Bioresour Technol Rep 12:100558. https://doi.org/10.1016/j.biteb.2020.100558

Sobek S, Werle S (2020) Kinetic modelling of waste wood devolatilization during pyrolysis based on thermogravimetric data and solar pyrolysis reactor performance. Fuel 261:116459. https://doi.org/10.1016/j.fuel.2019.116459

Wang J, Zhang M, Chen M et al (2006) Catalytic effects of six inorganic compounds on pyrolysis of three kinds of biomass. Thermochim Acta 444:110–114

Hameed S, Sharma A, Pareek V et al (2019) A review on biomass pyrolysis models: Kinetic, network and mechanistic models. Biomass Bioenerg 123:104–122

Cardoso CR, Miranda MR, Santos KG, Ataíde CH (2011) Determination of kinetic parameters and analytical pyrolysis of tobacco waste and sorghum bagasse. J Anal Appl Pyrol 92:392–400

Liu R, Liu G, Yousaf B et al (2022) Novel investigation of pyrolysis mechanisms and kinetics for functional groups in biomass matrix. Renew Sustain Energy Rev 153:111761

Leng E, Guo Y, Chen J et al (2022) A comprehensive review on lignin pyrolysis: mechanism, modeling and the effects of inherent metals in biomass. Fuel 309:122102

Blasi CD (2008) Modeling chemical and physical processes of wood and biomass pyrolysis. Prog Energy Combust Sci 34:47–90. https://doi.org/10.1016/j.pecs.2006.12.001

Vlaev LT, Georgieva VG, Genieva SD (2007) Products and kinetics of non-isothermal decomposition of vanadium(IV) oxide compounds. J Therm Anal Calorim 88:805–812. https://doi.org/10.1007/s10973-005-7149-y

Mallick D, Poddar MK, Mahanta P, Moholkar VS (2018) Discernment of synergism in pyrolysis of biomass blends using thermogravimetric analysis. Biores Technol 261:294–305. https://doi.org/10.1016/j.biortech.2018.04.011

Ahmad MS, Mehmood MA, Ayed OSA et al (2017) Kinetic analyses and pyrolytic behavior of Para grass (Urochloa mutica) for its bioenergy potential. Biores Technol 224:708–713. https://doi.org/10.1016/j.biortech.2016.10.090

Mehmood MA, Ye G, Luo H et al (2017) Pyrolysis and kinetic analyses of Camel grass ( Cymbopogon schoenanthus ) for bioenergy. Biores Technol 228:18–24. https://doi.org/10.1016/j.biortech.2016.12.096

Santos VO, Queiroz LS, Araujo RO et al (2020) Pyrolysis of acai seed biomass: kinetics and thermodynamic parameters using thermogravimetric analysis. Bioresour Technol Rep 12:100553. https://doi.org/10.1016/j.biteb.2020.100553

Tahir MH, Mahmood MA, Çakman G, Ceylan S (2020) Pyrolysis of oil extracted safflower seeds: product evaluation, kinetic and thermodynamic studies. Biores Technol 314:123699. https://doi.org/10.1016/j.biortech.2020.123699

Soria-Verdugo A, Goos E, García-Hernando N, Riedel U (2018) Analyzing the pyrolysis kinetics of several microalgae species by various differential and integral isoconversional kinetic methods and the Distributed Activation Energy Model. Algal Res 32:11–29

Kaliyan N, Morey RV (2009) Factors affecting strength and durability of densified biomass products. Biomass Bioenerg 33:337–359. https://doi.org/10.1016/j.biombioe.2008.08.005

Tumuluru JS, Wright CT, Hess JR, Kenney KL (2011) A review of biomass densification systems to develop uniform feedstock commodities for bioenergy application. Biofuels Bioprod Bioref 5:683–707. https://doi.org/10.1002/bbb.324

Ndindeng SA, Mbassi JEG, Mbacham WF et al (2015) Quality optimization in briquettes made from rice milling by-products. Energy Sustain Dev 29:24–31. https://doi.org/10.1016/j.esd.2015.09.003

Granado MPP, Suhogusoff YVM, Santos LRO et al (2021) Effects of pressure densification on strength and properties of cassava waste briquettes. Renew Energy 167:306–312. https://doi.org/10.1016/j.renene.2020.11.087

Missagia B, Guerrero C, Narra S et al (2011) Physicomechanical properties of rice husk pellets for energy generation. Energy Fuels 25:5786–5790

de Nazaret Cardenas-Rodriguez H, Martins R, Oliveira LEL et al (2021) Analysis on the use of briquettes as an alternative to improve the generation of thermal energy in the locality of Aripuana-Brazil. Energies 14:6355

Lubwama M, Yiga VA, Muhairwe F, Kihedu J (2020) Physical and combustion properties of agricultural residue bio-char bio-composite briquettes as sustainable domestic energy sources. Renew Energy 148:1002–1016. https://doi.org/10.1016/j.renene.2019.10.085

Lubwama M, Yiga VA (2018) Characteristics of briquettes developed from rice and coffee husks for domestic cooking applications in Uganda. Renew Energy 118:43–55. https://doi.org/10.1016/j.renene.2017.11.003

Trubetskaya A, Leahy JJ, Yazhenskikh E et al (2019) Characterization of woodstove briquettes from torrefied biomass and coal. Energy 171:853–865. https://doi.org/10.1016/j.energy.2019.01.064

Salema AA, Afzal MT, Bennamoun L (2017) Pyrolysis of corn stalk biomass briquettes in a scaled-up microwave technology. Biores Technol 233:353–362. https://doi.org/10.1016/j.biortech.2017.02.113

Setter C, Silva FTM, Assis MR et al (2020) Slow pyrolysis of coffee husk briquettes: characterization of the solid and liquid fractions. Fuel 261:116420. https://doi.org/10.1016/j.fuel.2019.116420

Felfli FF, Mesa P JM, Rocha JD et al (2011) Biomass briquetting and its perspectives in Brazil. Biomass Bioenerg 35:236–242. https://doi.org/10.1016/j.biombioe.2010.08.011

Acknowledgements

The authors acknowledge the Brazilian institutions CAPES (Federal Agency for the Support and Improvement of Higher Education), CNPq (National Council for Scientific and Technological Development) and FAPEMIG (Minas Gerais State Research Foundation) for their support of this research.

Funding

This study was supported by Brazilian institutions CAPES (Federal Agency for the Support and Improvement of Higher Education), CNPq (National Council for Scientific and Technological Development), and FAPEMIG (Minas Gerais State Research Foundation).

Author information

Authors and Affiliations

Contributions

Letícia Maciel Sant’Ana Simões: investigation, data curation, and roles/writing—original draft. Carine Setter: investigation, methodology, data curation, roles/writing—original draft, and writing—review and editing. Nádia Guimarães Sousa: data curation and visualization. Cássia Regina Cardoso: data curation, visualization, and writing—review and editing. Tiago José Pires De Oliveira: conceptualization, data curation, investigation, methodology, resources, supervision, and writing—review and editing.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

We declared that this manuscript does not involve researching about humans or animals.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Simões, L.M.S., Setter, C., Sousa, N.G. et al. Biomass to biofuel densification of coconut fibers: kinetic triplet and thermodynamic evaluation. Biomass Conv. Bioref. 14, 631–648 (2024). https://doi.org/10.1007/s13399-022-02393-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-02393-5