Abstract

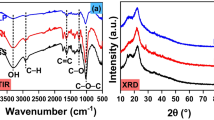

The over reliance on fossil fuels for power generation has resulted in an alarming depletion of petrochemical crude oil reserves, that also is the cause of elevated greenhouse gas effects. Biomass resources are considered potential fuels for the future on account of their renewable and carbon–neutral features. This study presents the physicochemical characteristics and pyrolysis behavior of a novel biomass Ficus natalensis barkcloth (FNB). Physicochemical characterization indicated that the FNB has 74.4% volatile matter contents, a higher heating value (HHV) of 13.8 MJ/kg, and it has 67% cellulose as its main chemical constituent. Thermogravimetric analysis (TGA) showed that major decomposition occurred at the core devolatization (235℃ to 410 ℃) under inert thermal degradation. Model-free and model-fitting kinetic methods were applied to TGA data to compute the kinetics triplet for FNB biomass. The average activation energy (Ea) of the FNB pyrolysis process was determined to be 168 kJ/mol. The compensation effects between pre-exponential factor (A) and Ea detected a rise in collision intensity for the pyrolysis of FNB at high heating rates. The Criado master plot results showed that the pyrolysis of FNB followed first-order reaction (F1) mechanism. The thermodynamic parameters, such as change in enthalpy (ΔH), Gibbs free energy (ΔG), and entropy (ΔS), were also calculated and compared with kinetics parameters to evaluate the evolution of thermal degradation. Physiochemical and thermo-kinetic analysis of FBN revealed its comparable bioenergy potential with established biomasses.

Graphical abstract

Similar content being viewed by others

Data availability

The authors confirm that the data supporting the findings of this study are available within the article [and/or] its supplementary materials.

References

Sajjad Ahmad M, Liu H, Alhumade H et al (2020) A modified DAEM: To study the bioenergy potential of invasive Staghorn Sumac through pyrolysis, ANN, TGA, kinetic modeling, FTIR and GC–MS analysis. Energy Convers Manage 221:113173. https://doi.org/10.1016/j.enconman.2020.113173

Yeo JY, Chin BLF, Tan JK, Loh YS (2019) Comparative studies on the pyrolysis of cellulose, hemicellulose, and lignin based on combined kinetics. J Energy Inst 92:27–37. https://doi.org/10.1016/j.joei.2017.12.003

Singh YD, Mahanta P, Bora U (2017) Comprehensive characterization of lignocellulosic biomass through proximate, ultimate and compositional analysis for bioenergy production. Renewable Energy 103:490–500. https://doi.org/10.1016/j.renene.2016.11.039

Sahoo A, Kumar S, Mohanty K (2021) Kinetic and thermodynamic analysis of Putranjiva roxburghii (putranjiva) and Cassia fistula (amaltas) non-edible oilseeds using thermogravimetric analyzer. Renewable Energy 165:261–277. https://doi.org/10.1016/j.renene.2020.11.011

Mumbach GD, Alves JLF, da Silva JCG et al (2020) Pyrolysis of cocoa shell and its bioenergy potential: evaluating the kinetic triplet, thermodynamic parameters, and evolved gas analysis using TGA-FTIR. Biomass Conversion and Biorefinery. https://doi.org/10.1007/s13399-020-01058-5

Kozłowski RM, Mackiewicz-Talarczyk M, Barriga-Bedoya J (2020) New emerging natural fibres and relevant sources of information. In: Handbook of natural fibres: second edition. pp 747–787

Contributors PE (2015) Ficus natalensis (PROTA). In: PlantUse English,. https://uses.plantnet-project.org/e/index.php?title=Ficus_natalensis_(PROTA)&oldid=196777. Accessed 20 Dec 2020

(2014) Ficus Natalensis Agroforestry System. In: http://www.fao.org/3/a-au287e.pdf. http://www.fao.org/3/a-au287e.pdf. Accessed 20 Dec 2020

Rwawiire S, Tomkova B, Militky J et al (2015) Development of a biocomposite based on green epoxy polymer and natural cellulose fabric (bark cloth) for automotive instrument panel applications. Compos B Eng 81:149–157. https://doi.org/10.1016/j.compositesb.2015.06.021

Rwawiire S, Tomkova B, Militky J et al (2017) Acoustic and thermal properties of a cellulose nonwoven natural fabric (barkcloth). Appl Acoust 116:177–183. https://doi.org/10.1016/j.apacoust.2016.09.027

Mugaanire IT, Wang H, Sun J (2019) Fibrous microcrystalline cellulose from Ficus natalensis barkcloth. European Journal of Wood and Wood Products 77:483–486. https://doi.org/10.1007/s00107-019-01382-2

Farooq A, Jiang S, Farooq A et al (2019) Structure and properties of high quality natural cellulose nano fibrils from a novel material Ficus natalensis barkcloth. J Ind Text. https://doi.org/10.1177/1528083719887533

Van Soest PJ, Robertson JB, Lewis BA (1991) Methods for dietary fiber, neutral detergent fiber, and nonstarch polysaccharides in relation to animal nutrition. J Dairy Sci 74:3583–3597. https://doi.org/10.3168/jds.S0022-0302(91)78551-2

Opfermann JR, Kaisersberger E, Flammersheim HJ (2002) Model-free analysis of thermoanalytical data-advantages and limitations. Thermochim Acta 391:119–127. https://doi.org/10.1016/S0040-6031(02)00169-7

Vyazovkin S, Burnham AK, Criado JM et al (2011) ICTAC Kinetics Committee recommendations for performing kinetic computations on thermal analysis data. Thermochim Acta 520:1–19. https://doi.org/10.1016/j.tca.2011.03.034

Pratap A, Lilly Shanker Rao T, Lad KN, Dhurandhar HD (2007) Isoconversional vs. Model fitting methods. J Therm Anal Calorim 89:399–405. https://doi.org/10.1007/s10973-006-8160-7

Collazzo GC, Broetto CC, Perondi D et al (2017) A detailed non-isothermal kinetic study of elephant grass pyrolysis from different models. Appl Therm Eng 110:1200–1211. https://doi.org/10.1016/j.applthermaleng.2016.09.012

Varma AK, Singh S, Rathore AK, et al (2020) Investigation of kinetic and thermodynamic parameters for pyrolysis of peanut shell using thermogravimetric analysis. Biomass Conversion and Biorefinery. https://doi.org/10.1007/s13399-020-00972-y

Criado JM (1978) Kinetic analysis of DTG data from master curves. Thermochimica Acta 24:186–189. https://doi.org/10.1016/0040-6031(78)85151-X

Kaur R, Gera P, Jha MK, Bhaskar T (2018) Pyrolysis kinetics and thermodynamic parameters of castor (Ricinus communis) residue using thermogravimetric analysis. Biores Technol 250:422–428. https://doi.org/10.1016/j.biortech.2017.11.077

Ashraf M, Ramzan N, Khan RU, Durrani AK (2021) Analysis of mixed cattle manure: Kinetics and thermodynamic comparison of pyrolysis and combustion processes. Case Studies in Thermal Engineering 26:101078. https://doi.org/10.1016/j.csite.2021.101078

Wen S, Yan Y, Liu J et al (2019) Pyrolysis performance, kinetic, thermodynamic, product and joint optimization analyses of incense sticks in N2 and CO2 atmospheres. Renewable Energy 141:814–827. https://doi.org/10.1016/j.renene.2019.04.040

Alves JLF, da Silva JCG, da Silva Filho VF et al (2019) Kinetics and thermodynamics parameters evaluation of pyrolysis of invasive aquatic macrophytes to determine their bioenergy potentials. Biomass Bioenerg 121:28–40. https://doi.org/10.1016/j.biombioe.2018.12.015

Siddiqi H, Bal M, Kumari U, Meikap BC (2020) In-depth physiochemical characterization and detailed thermo-kinetic study of biomass wastes to analyze its energy potential. Renewable Energy 148:756–771. https://doi.org/10.1016/j.renene.2019.10.162

Xu F, Yu J, Tesso T et al (2013) Qualitative and quantitative analysis of lignocellulosic biomass using infrared techniques: a mini-review. Appl Energy 104:801–809. https://doi.org/10.1016/j.apenergy.2012.12.019

Hihu Muigai H, Choudhury BJ, Kalita P, Moholkar VS (2021) Physico–chemical characterization and pyrolysis kinetics of Eichhornia Crassipes, Thevetia Peruviana, and Saccharum Officinarum. Fuel 289:119949. https://doi.org/10.1016/j.fuel.2020.119949

Sobek S, Werle S (2020) Isoconversional determination of the apparent reaction models governing pyrolysis of wood, straw and sewage sludge, with an approach to rate modelling. Renewable Energy 161:972–987. https://doi.org/10.1016/j.renene.2020.07.112

López-González D, Fernandez-Lopez M, Valverde JL, Sanchez-Silva L (2013) Thermogravimetric-mass spectrometric analysis on combustion of lignocellulosic biomass. Biores Technol 143:562–574. https://doi.org/10.1016/j.biortech.2013.06.052

Chen Z, Zhu Q, Wang X et al (2015) Pyrolysis behaviors and kinetic studies on Eucalyptus residues using thermogravimetric analysis. Energy Convers Manage 105:251–259. https://doi.org/10.1016/j.enconman.2015.07.077

Syed S, Qudaih R, Talab I, Janajreh I (2011) Kinetics of pyrolysis and combustion of oil shale sample from thermogravimetric data. Fuel 90:1631–1637. https://doi.org/10.1016/j.fuel.2010.10.033

Sobek S, Werle S (2020) Kinetic modelling of waste wood devolatilization during pyrolysis based on thermogravimetric data and solar pyrolysis reactor performance. Fuel 261:116459. https://doi.org/10.1016/j.fuel.2019.116459

Tabal A, Barakat A, Aboulkas A, El Harfi K (2021) Pyrolysis of ficus nitida wood: determination of kinetic and thermodynamic parameters. Fuel 283:119253. https://doi.org/10.1016/j.fuel.2020.119253

Ma Z, Wang J, Yang Y et al (2018) Comparison of the thermal degradation behaviors and kinetics of palm oil waste under nitrogen and air atmosphere in TGA-FTIR with a complementary use of model-free and model-fitting approaches. J Anal Appl Pyrol 134:12–24. https://doi.org/10.1016/j.jaap.2018.04.002

Epesse Misse S, Brillard A, Mayandyshev P, et al (2020) Comparative pyrolysis, combustion, and kinetic modeling of twelve Cameroonian woody biomass. Biomass Conversion and Biorefinery. https://doi.org/10.1007/s13399-020-00808-9

Hameed S, Sharma A, Pareek V et al (2019) A review on biomass pyrolysis models: kinetic, network and mechanistic models. Biomass Bioenerg 123:104–122. https://doi.org/10.1016/j.biombioe.2019.02.008

Wang S, Guo X, Wang K, Luo Z (2011) Influence of the interaction of components on the pyrolysis behavior of biomass. J Anal Appl Pyrol 91:183–189. https://doi.org/10.1016/j.jaap.2011.02.006

Rathore NS, Pawar A, Panwar NL (2021) Kinetic analysis and thermal degradation study on wheat straw and its biochar from vacuum pyrolysis under non-isothermal condition. Biomass Conversion and Biorefinery. https://doi.org/10.1007/s13399-021-01360-w

Jiang H, Wang J, Wu S et al (2010) Pyrolysis kinetics of phenol-formaldehyde resin by non-isothermal thermogravimetry. Carbon 48:352–358. https://doi.org/10.1016/j.carbon.2009.09.036

Damartzis T, Vamvuka D, Sfakiotakis S, Zabaniotou A (2011) Thermal degradation studies and kinetic modeling of cardoon (Cynara cardunculus) pyrolysis using thermogravimetric analysis (TGA). Biores Technol 102:6230–6238. https://doi.org/10.1016/j.biortech.2011.02.060

Mehmood MA, Ye G, Luo H et al (2017) Pyrolysis and kinetic analyses of Camel grass (Cymbopogon schoenanthus) for bioenergy. Biores Technol 228:18–24. https://doi.org/10.1016/j.biortech.2016.12.096

Ahmad MS, Mehmood MA, Al Ayed OS et al (2017) Kinetic analyses and pyrolytic behavior of Para grass (Urochloa mutica) for its bioenergy potential. Biores Technol 224:708–713. https://doi.org/10.1016/j.biortech.2016.10.090

Alhumade H, Ahmad MS, Mauri E et al (2021) Investigating the bioenergy potential of invasive Reed Canary (Phalaris arundinacea) through thermal and kinetic analyses. Biomass Conversion and Biorefinery. https://doi.org/10.1007/s13399-021-01664-x

Chen R, Li Q, Xu X et al (2020) Combustion characteristics, kinetics and thermodynamics of Pinus Sylvestris pine needle via non-isothermal thermogravimetry coupled with model-free and model-fitting methods. Case Studies in Thermal Engineering 22:100756. https://doi.org/10.1016/j.csite.2020.100756

Khawam A, Flanagan DR (2006) Solid-state kinetic models: basics and mathematical fundamentals. J Phys Chem B 110:17315–17328. https://doi.org/10.1021/jp062746a

Almazrouei M, Janajreh I (2020) Model-fitting approach to kinetic analysis of non-isothermal pyrolysis of pure and crude glycerol. Renewable Energy 145:1693–1708. https://doi.org/10.1016/j.renene.2019.07.095

Fernandez-Lopez M, Pedrosa-Castro GJ, Valverde JL, Sanchez-Silva L (2016) Kinetic analysis of manure pyrolysis and combustion processes. Waste Manage 58:230–240. https://doi.org/10.1016/j.wasman.2016.08.027

Naqvi SR, Tariq R, Hameed Z et al (2019) Pyrolysis of high ash sewage sludge: Kinetics and thermodynamic analysis using Coats-Redfern method. Renewable Energy 131:854–860. https://doi.org/10.1016/j.renene.2018.07.094

K., A. Vuppaladadiyam, M. Zhao MZM and AFS, (2019) Microalgae as renewable fuel resource: a comparative study on thermogravimetric and kinetic behavior of four microalgae. Sustainable Energy Fuels 3:1283–1296. https://doi.org/10.1039/C9SE00114J

Funding

The author(s) revealed the following financial support for the publication of this manuscript: the whole project was held by “National Key R&D Program of China (2018YFC2000900)” and “Suzhou Science and Technology Project (ZXL2018134).”

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Farooq, A., Ashraf, M., Aslam, Z. et al. Pyrolytic conversion of a novel biomass Ficus natalensis barkcloth: physiochemical and thermo-kinetic analysis. Biomass Conv. Bioref. 13, 11671–11685 (2023). https://doi.org/10.1007/s13399-021-01964-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-01964-2