Abstract

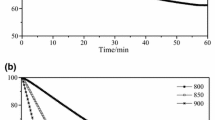

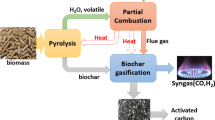

The gasification of agro-industrial residues has been identified as a viable alternative for energy generation, acting simultaneously as a solution for the final disposal of these wastes. Knowing the kinetics of the gasification reaction is crucial to the comprehension of the mechanisms and the phenomena involved in the process, and the development and optimization of industrial gasifiers. Accordingly, this study aims to examine, based on four kinetic models, the CO2 gasification behavior of three biomass chars prepared from apple pomace, spent coffee grounds and sawdust, and to associate the results with differences in the ash composition of the samples. The biochars were obtained from pyrolysis under N2, in a fixed-bed tubular quartz reactor, with an average heating rate of 12 K min−1 and a residence time of 60 min at the final temperature of 873 K. Biochars were isothermally gasified in a thermogravimetric analyzer with CO2, at atmospheric pressure, at temperatures of 1033, 1083 and 1133 K, in the kinetically controlled regime. From the characterization of raw biomasses, it was found that the apple pomace had the highest amount of potassium, and its biochar was the most reactive. Also, it was observed an increase in the gasification rates in the higher conversion region for all biochars. Concerning these reactivity profiles, the inorganic components were more important to the gasification behavior than the biomass lignocellulosic matter. For all biochars, the semi-empirical modified random pore model (MRPM) was the best-fitted model, indicating its suitability to CO2 gasification and confirming the catalytic influence of the inorganic matter in the studied samples. After demineralization, biomass chars presented higher values of activation energy and pre-exponential factor. According to the MRPM model, activation energy values within the range of 161.5–187.2 kJ mol−1 and 232.1–240.2 kJ mol−1, respectively, were obtained for the CO2 gasification of regular biochars and demineralized biochars.

Graphical abstract

Similar content being viewed by others

References

EIA (2019) International Energy Outlook. In: U.S. Energy Inf. Adm. https://www.eia.gov/outlooks/ieo/. Accessed 15 Mar 2020

García R, Pizarro C, Lavín AG, Bueno JL (2012) Characterization of Spanish biomass wastes for energy use. Bioresour Technol 103:249–258. https://doi.org/10.1016/j.biortech.2011.10.004

da Silva JCG, Alves JLF, de Araujo Galdino WV et al (2018) Combustion of pistachio shell: physicochemical characterization and evaluation of kinetic parameters. Environ Sci Pollut Res 25:21420–21429. https://doi.org/10.1007/s11356-017-8945-1

Fermoso J, Stevanov C, Moghtaderi B et al (2009) High-pressure gasification reactivity of biomass chars produced at different temperatures. J Anal Appl Pyrolysis 85:287–293. https://doi.org/10.1016/j.jaap.2008.09.017

Kirkels AF, Verbong GPJ (2011) Biomass gasification: Still promising? A 30-year global overview. Renew Sustain Energy Rev 15:471–481. https://doi.org/10.1016/j.rser.2010.09.046

Fernandes ERK, Marangoni C, Souza O, Sellin N (2013) Thermochemical characterization of banana leaves as a potential energy source. Energy Convers Manag 75:603–608. https://doi.org/10.1016/j.enconman.2013.08.008

Virmond E, De Sena RF, Albrecht W et al (2012) Characterisation of agroindustrial solid residues as biofuels and potential application in thermochemical processes. Waste Manag 32:1952–1961. https://doi.org/10.1016/j.wasman.2012.05.014

Languer MP, Batistella L, Alves JLF et al (2020) Insights into pyrolysis characteristics of Brazilian high-ash sewage sludges using thermogravimetric analysis and bench-scale experiments with GC-MS to evaluate their bioenergy potential. Biomass Bioenerg 138:105614. https://doi.org/10.1016/j.biombioe.2020.105614

Batistella L, Silva V, Suzin RC et al (2015) Gaseous emissions from sewage sludge combustion in a moving bed combustor. Waste Manag 46:430–439. https://doi.org/10.1016/j.wasman.2015.08.039

Ferreira-Leitão V, Gottschalk LMF, Ferrara MA et al (2010) Biomass Residues in Brazil: Availability and Potential Uses. Waste and Biomass Valorization 1:65–76. https://doi.org/10.1007/s12649-010-9008-8

Alves JLF, da Silva JCG, Languer MP et al (2020) Assessing the bioenergy potential of high-ash anaerobic sewage sludge using pyrolysis kinetics and thermodynamics to design a sustainable integrated biorefinery. Biomass Convers Biorefinery. https://doi.org/10.1007/s13399-020-01023-2

Virmond E, Albrecht W, Althoff CA et al (2021) Gaseous emissions from co-combustion of biosolids from the meat processing industry with wood. Environ Prog Sustain Energy 2018:1–14. https://doi.org/10.1002/ep.13633

Min F, Zhang M, Zhang Y et al (2011) An experimental investigation into the gasification reactivity and structure of agricultural waste chars. J Anal Appl Pyrolysis 92:250–257. https://doi.org/10.1016/j.jaap.2011.06.005

Nowicki L, Antecka A, Bedyk T et al (2011) The kinetics of gasification of char derived from sewage sludge. J Therm Anal Calorim 104:693–700. https://doi.org/10.1007/s10973-010-1032-1

Domenico MD, Collazzo GC, Pacioni TR et al (2019) Gasification of Brazilian coal-chars with CO 2: effect of samples’ properties on reactivity and kinetic modeling. Chem Eng Commun 206:158–168. https://doi.org/10.1080/00986445.2018.1477763

Guizani C, Escudero Sanz FJ, Salvador S (2013) The gasification reactivity of high-heating-rate chars in single and mixed atmospheres of H2O and CO2. Fuel 108:812–823. https://doi.org/10.1016/j.fuel.2013.02.027

Ahmed II, Gupta AK (2011) Kinetics of woodchips char gasification with steam and carbon dioxide. Appl Energy 88:1613–1619. https://doi.org/10.1016/j.apenergy.2010.11.007

Mermoud F, Salvador S, Van de Steene L, Golfie F (2006) Influence of the pyrolysis heating rate on the steam gasification rate of large wood char particles. Fuel 85:1473–1482. https://doi.org/10.1016/j.fuel.2005.12.004

Cetin E, Moghtaderi B, Gupta R, Wall TF (2004) Influence of pyrolysis conditions on the structure and gasification reactivity of biomass chars. Fuel 83:2139–2150. https://doi.org/10.1016/j.fuel.2004.05.008

Luo S, Xiao B, Hu Z et al (2010) Influence of particle size on pyrolysis and gasification performance of municipal solid waste in a fixed bed reactor. Bioresour Technol 101:6517–6520. https://doi.org/10.1016/j.biortech.2010.03.060

Cetin E, Moghtaderi B, Gupta R, Wall TF (2005) Biomass gasification kinetics: influences of pressure and char structure. Combust Sci Technol 177:765–791. https://doi.org/10.1080/00102200590917266

Domenico MD, Amorim SM, Collazzo GC et al (2019) Coal gasification in the presence of lithium orthosilicate. Part 1: Reaction kinetics. Chem Eng Res Des 141:529–539. https://doi.org/10.1016/j.cherd.2018.11.011

Duman G, Uddin MA, Yanik J (2014) The effect of char properties on gasification reactivity. Fuel Process Technol 118:75–81. https://doi.org/10.1016/j.fuproc.2013.08.006

Suzuki T, Nakajima H, Ikenaga N et al (2011) Effect of mineral matters in biomass on the gasification rate of their chars. Biomass Convers Biorefinery 1:17–28. https://doi.org/10.1007/s13399-011-0006-2

Dupont C, Nocquet T, Da Costa JA, Verne-Tournon C (2011) Kinetic modelling of steam gasification of various woody biomass chars: Influence of inorganic elements. Bioresour Technol 102:9743–9748. https://doi.org/10.1016/j.biortech.2011.07.016

Zhang Y, Ashizawa M, Kajitani S, Miura K (2008) Proposal of a semi-empirical kinetic model to reconcile with gasification reactivity profiles of biomass chars. Fuel 87:475–481. https://doi.org/10.1016/j.fuel.2007.04.026

Umeki K, Namioka T, Yoshikawa K (2012) The effect of steam on pyrolysis and char reactions behavior during rice straw gasification. Fuel Process Technol 94:53–60. https://doi.org/10.1016/j.fuproc.2011.09.023

Yuan S, Chen X, Li J, Wang F (2011) CO 2 Gasification Kinetics of Biomass Char Derived from High-Temperature Rapid Pyrolysis. Energy Fuels 25:2314–2321. https://doi.org/10.1021/ef200051z

Ahmed II, Gupta AK (2012) Sugarcane bagasse gasification: Global reaction mechanism of syngas evolution. Appl Energy 91:75–81. https://doi.org/10.1016/j.apenergy.2011.07.001

Pacioni TR, Soares D, Di DM et al (2016) Bio-syngas production from agro-industrial biomass residues by steam gasification. Waste Manag 58:221–229. https://doi.org/10.1016/j.wasman.2016.08.021

ASTM (2007) E1755–01: standard test method for ash in biomass. In: Annual book of ASTM standards. ASTM International, West Conshohocken, pp 1–3. https://doi.org/10.1520/E1755-01R07

Nowakowski DJ, Jones JM (2008) Uncatalysed and potassium-catalysed pyrolysis of the cell-wall constituents of biomass and their model compounds. J Anal Appl Pyrolysis 83:12–25. https://doi.org/10.1016/j.jaap.2008.05.007

Sofekun OA, Doraiswamy LK (1996) High-Temperature Oxidation of Zinc Sulfide: Kinetic Modeling under Conditions of Strict Kinetic Control. Ind Eng Chem Res 35:3163–3170. https://doi.org/10.1021/ie960013e

Alves JLF, Da Silva JCG, Sena RF de et al (2018) CO2 gasification of biochars prepared from agroindustrial waste: a kinetic study. In: 26th European Biomass Conference and Exhibition Proceedings, pp 769–777. https://doi.org/10.5071/26thEUBCE2018-2CV.4.20

Ye DP, Agnew JB, Zhang DK (1998) Gasification of a South Australian low-rank coal with carbon dioxide and steam: kinetics and reactivity studies. Fuel 77:1209–1219. https://doi.org/10.1016/S0016-2361(98)00014-3

Fermoso J, Arias B, Pevida C et al (2008) Kinetic models comparison for steam gasification of different nature fuel chars. J Therm Anal Calorim 91:779–786. https://doi.org/10.1007/s10973-007-8623-5

Szekely J, Evans JW (1971) A structural model for gas-solid reactions with a moving boundary-II. Chem Eng Sci 26:1901–1913. https://doi.org/10.1016/0009-2509(71)86033-5

Gavals GR (1980) A random capillary model with application to char gasification at chemically controlled rates. AIChE J 26:577–585. https://doi.org/10.1002/aic.690260408

Bhatia SK, Perlmutter DD (1980) A random pore model for fluid-solid reactions: I. Isothermal, kinetic control. AIChE J 26:379–386. https://doi.org/10.1002/aic.690260308

Seo DK, Lee SK, Kang MW et al (2010) Gasification reactivity of biomass chars with CO2. Biomass Bioenerg 34:1946–1953. https://doi.org/10.1016/j.biombioe.2010.08.008

Gil MV, Fermoso J, Pevida C et al (2010) Intrinsic char reactivity of plastic waste (PET) during CO2 gasification. Fuel Process Technol 91:1776–1781. https://doi.org/10.1016/j.fuproc.2010.07.019

Raghunathan K, Yang RYK (1989) Unification of coal gasification data and its applications. Ind Eng Chem Res 28:518–523. https://doi.org/10.1021/ie00089a003

Liu H, Luo C, Kaneko M et al (2003) Unification of gasification kinetics of char in CO2 at elevated temperatures with a modified random pore model. Energy Fuels 17:961–970. https://doi.org/10.1021/ef020231m

Lahijani P, Zainal ZA, Mohamed AR, Mohammadi M (2013) Ash of palm empty fruit bunch as a natural catalyst for promoting the CO2 gasification reactivity of biomass char. Bioresour Technol 132:351–355. https://doi.org/10.1016/j.biortech.2012.10.092

Marquez-Montesinos F, Cordero T, Rodrı́guez-Mirasol J, Rodrı́guez JJ, (2002) CO2 and steam gasification of a grapefruit skin char. Fuel 81:423–429. https://doi.org/10.1016/S0016-2361(01)00174-0

Di BC, Galgano A, Branca C (2019) Exothermic Events of Nut Shell and Fruit Stone Pyrolysis. ACS Sustain Chem Eng 7:9035–9049. https://doi.org/10.1021/acssuschemeng.9b01474

Jeguirim M, Limousy L, Dutournie P (2014) Pyrolysis kinetics and physicochemical properties of agropellets produced from spent ground coffee blended with conventional biomass. Chem Eng Res Des 92:1876–1882. https://doi.org/10.1016/j.cherd.2014.04.018

Alves J, da Trindade E, da Silva J et al (2020) Lignocellulosic residues from the Brazilian juice processing industry as novel sustainable sources for bioenergy production: preliminary assessment using physicochemical characteristics. J Braz Chem Soc 31:1939–1948. https://doi.org/10.21577/0103-5053.20200094

Olugbade T, Ojo O, Mohammed T (2019) Influence of binders on combustion properties of biomass briquettes: a recent review. BioEnergy Res 12:241–259. https://doi.org/10.1007/s12155-019-09973-w

Olugbade TO, Ojo OT (2020) Biomass torrefaction for the production of high-grade solid biofuels: a review. BioEnergy Res 13:999–1015. https://doi.org/10.1007/s12155-020-10138-3

Olugbade TO, Ojo OT (2021) Binderless briquetting technology for lignite briquettes: a review. Energy, Ecol Environ 6:69–79. https://doi.org/10.1007/s40974-020-00165-3

Huang J, Qiao Y, Wei X et al (2019) Effect of torrefaction on steam gasification of starchy food waste. Fuel 253:1556–1564. https://doi.org/10.1016/j.fuel.2019.05.142

Chen Q, Zhou J, Liu B et al (2011) Influence of torrefaction pretreatment on biomass gasification technology. Chinese Sci Bull 56:1449–1456. https://doi.org/10.1007/s11434-010-4292-z

Asadullah M, Zhang S, Min Z et al (2010) Effects of biomass char structure on its gasification reactivity. Bioresour Technol 101:7935–7943. https://doi.org/10.1016/j.biortech.2010.05.048

Vassilev SV, Baxter D, Andersen LK, Vassileva CG (2010) An overview of the chemical composition of biomass. Fuel 89:913–933. https://doi.org/10.1016/j.fuel.2009.10.022

Bhat A, Ram Bheemarasetti JV, Rajeswara Rao T (2001) Kinetics of rice husk char gasification. Energy Convers Manag 42:2061–2069. https://doi.org/10.1016/S0196-8904(00)00173-4

Zhang L, Huang J, Fang Y, Wang Y (2006) Gasification Reactivity and Kinetics of Typical Chinese Anthracite Chars with Steam and CO 2. Energy Fuels 20:1201–1210. https://doi.org/10.1021/ef050343o

Tangsathitkulchai C, Junpirom S, Katesa J (2013) Comparison of kinetic models for co2 gasification of coconut-shell chars: carbonization temperature effects on char reactivity and porous properties of produced activated carbons. Eng J 17:13–28. https://doi.org/10.4186/ej.2013.17.1.13

Zhu W, Song W, Lin W (2008) Catalytic gasification of char from co-pyrolysis of coal and biomass. Fuel Process Technol 89:890–896. https://doi.org/10.1016/j.fuproc.2008.03.001

Acknowledgements

The authors would like to thank the National Council for Scientific and Technological Development (CNPq/Brazil Process 458412/2014-7 and 303742/2017-8) and National Council for the Improvement of Higher Education (CAPES) for their financial support, the LCME-UFSC for technical support during electron microscopy work, and the Albrecht Equipamentos Industriais Ltda for providing the samples used in this study.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pacioni, T.R., Soares, D., Di Domenico, M. et al. Kinetic modeling of CO2 gasification of biochars prepared from Brazilian agro-industrial residues: effect of biomass indigenous mineral content. Biomass Conv. Bioref. 13, 6675–6688 (2023). https://doi.org/10.1007/s13399-021-01671-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-01671-y