Abstract

The research done in this paper is focused on the properties of eight char samples that were produced by a pilot scale reactor: Spirajoule® located in France. This reactor converted different biomass and waste feedstock into three phase’s products: syngas, tars, and chars. In some cases, chars are considered as co-products without added value. However, they present numerous potential applications. Thus, this research is conducted precisely on the characterization of eight chars originating from biomass (waste wood, sawdust, miscanthus wood, and grape marc) and from waste (tires, municipal, and industrial RDF). Four property domains were studied in this research: physicochemical properties (moisture content, pH, skeletal density, and TGA), texture and morphology (SEM/EDX and BET specific surface area), surface chemistry (FTIR), and structure (XRD). Our results showed that the properties of these chars match the properties required in some applications such as soil amendment, catalyst, and water and gas treatment.

Graphical abstract

Similar content being viewed by others

Data availability

All authors confirm that all data and materials as well as software application support their published claims and comply with field standards.

References

Liu Z, Zhang F-S, Wu J (2010) Characterization and application of chars produced from pinewood pyrolysis and hydrothermal treatment. Fuel. 89:510–514. https://doi.org/10.1016/j.fuel.2009.08.042

Nanda S, Dalai AK, Berruti F, Kozinski JA (2016) Biochar as an exceptional bioresource for energy, agronomy, carbon sequestration, activated carbon and specialty materials. Waste Biomass Valor. 7:201–235. https://doi.org/10.1007/s12649-015-9459-z

Debiagi P, Gentile G, Cuoci A, Frassoldati A, Ranzi E, Faravelli T (2018) A predictive model of biochar formation and characterization. Journal of Analytical and Applied Pyrolysis. 134:326–335. https://doi.org/10.1016/j.jaap.2018.06.022

Fryda L, Visser R (2015) Biochar for soil improvement: evaluation of biochar from gasification and slow pyrolysis. Agriculture. 5:1076–1115. https://doi.org/10.3390/agriculture5041076

Oliveira FR, Patel AK, Jaisi DP, Adhikari S, Lu H, Khanal SK (2017) Environmental application of biochar: current status and perspectives. Bioresource Technology. 246:110–122. https://doi.org/10.1016/j.biortech.2017.08.122

Ortiz LR, Torres E, Zalazar D, Zhang H, Rodriguez R, Mazza G (2020) Influence of pyrolysis temperature and bio-waste composition on biochar characteristics. Renewable Energy. 155:837–847. https://doi.org/10.1016/j.renene.2020.03.181

Klasson KT (2017) Biochar characterization and a method for estimating biochar quality from proximate analysis results. Biomass and Bioenergy. 96:50–58. https://doi.org/10.1016/j.biombioe.2016.10.011

Arun J, Gopinath KP, Vigneshwar SS, Swetha A (2020) Sustainable and eco-friendly approach for phosphorus recovery from wastewater by hydrothermally carbonized microalgae: study on spent bio-char as fertilizer. Journal of Water Process Engineering. 38:101567. https://doi.org/10.1016/j.jwpe.2020.101567

Kloss S, Zehetner F, Dellantonio A, Hamid R, Ottner F, Liedtke V, Schwanninger M, Gerzabek MH, Soja G (2012) Characterization of slow pyrolysis biochars: effects of feedstocks and pyrolysis temperature on biochar properties. https://doi.org/10.2134/jeq2011.0070

Verheijen FGA, Mankasingh U, Penizek V, Panzacchi P, Glaser B, Jeffery S, Bastos AC, Tammeorg P, Kern J, Zavalloni C, Zanchettin G, Sakrabani R (2017) Representativeness of European biochar research: part I – field experiments. Journal of Environmental Engineering and Landscape Management. 25:140–151. https://doi.org/10.3846/16486897.2017.1304943

Marris E (2006) Putting the carbon back: black is the new green. Nature. 442:624–626. https://doi.org/10.1038/442624a

Lehmann J, Gaunt J, Rondon M (2006) Bio-char sequestration in terrestrial ecosystems – a review. Mitig Adapt Strat Glob Change. 11:403–427. https://doi.org/10.1007/s11027-005-9006-5

Buss W, Graham MC, Shepherd JG, Mašek O (2016) Risks and benefits of marginal biomass-derived biochars for plant growth. Science of The Total Environment. 569–570:496–506. https://doi.org/10.1016/j.scitotenv.2016.06.129

Weber K, Quicker P (2018) Properties of biochar. Fuel. 217:240–261. https://doi.org/10.1016/j.fuel.2017.12.054

Kim P, Johnson A, Edmunds CW, Radosevich M, Vogt F, Rials TG, Labbé N (2011) Surface functionality and carbon structures in lignocellulosic-derived biochars produced by fast pyrolysis. Energy Fuels. 25:4693–4703. https://doi.org/10.1021/ef200915s

Kim KH, Kim J-Y, Cho T-S, Choi JW (2012) Influence of pyrolysis temperature on physicochemical properties of biochar obtained from the fast pyrolysis of pitch pine (Pinus rigida). Bioresource Technology. 118:158–162. https://doi.org/10.1016/j.biortech.2012.04.094

Asadi Zeidabadi Z, Bakhtiari S, Abbaslou H, Ghanizadeh AR (2018) Synthesis, characterization and evaluation of biochar from agricultural waste biomass for use in building materials. Construction and Building Materials. 181:301–308. https://doi.org/10.1016/j.conbuildmat.2018.05.271

Jamradloedluk J, Lertsatitthanakorn C (2014) Characterization and utilization of char derived from fast pyrolysis of plastic wastes. Procedia Engineering. 69:1437–1442. https://doi.org/10.1016/j.proeng.2014.03.139

Long JM, Boyette MD (2017) Analysis of micronized charcoal for use in a liquid fuel slurry. Energies. 10. https://doi.org/10.3390/en10010025

Fuente-Hernández A, Lee R, Béland N, Zamboni I, Lavoie JM (2017) Reduction of furfural to furfuryl alcohol in liquid phase over a biochar-supported platinum catalyst. Energies. 10. https://doi.org/10.3390/en10030286

Klinghoffer, N.B., Castaldi, M.J., Nzihou, A., Klinghoffer, N.B., Castaldi, M.J., Nzihou, A., Properties, C., Perfor, C., Klingho, N.B., Castaldi, M.J., Nzihou, A.: Catalyst properties and catalytic performance of char from biomass gasification To cite this version : HAL Id : hal-01632400 Catalyst Properties and Catalytic Performance of Char from Biomass Gasi fi cation. (2019)

Shen Y (2015) Chars as carbonaceous adsorbents/catalysts for tar elimination during biomass pyrolysis or gasification. Renewable and Sustainable Energy Reviews. 43:281–295

Abu El-Rub Z, Bramer EA, Brem G (2008) Experimental comparison of biomass chars with other catalysts for tar reduction. Fuel. 87:2243–2252. https://doi.org/10.1016/j.fuel.2008.01.004

Gilbert P, Ryu C, Sharifi V, Swithenbank J (2009) Tar reduction in pyrolysis vapours from biomass over a hot char bed. Bioresource Technology. 100:6045–6051. https://doi.org/10.1016/j.biortech.2009.06.041

Hervy M, Weiss-Hortala E, Pham Minh D, Dib H, Villot A, Gérente C, Berhanu S, Chesnaud A, Thorel A, Le Coq L, Nzihou A (2019) Reactivity and deactivation mechanisms of pyrolysis chars from bio-waste during catalytic cracking of tar. Applied Energy. 237:487–499. https://doi.org/10.1016/j.apenergy.2019.01.021

Huber GW, Shabaker JW, Dumesic JA (2003) Raney Ni-Sn catalyst for H2 production from biomass-derived hydrocarbons. Science. 300:2075–2077. https://doi.org/10.1126/science.1085597

Sueyasu T, Oike T, Mori A, Kudo S, Norinaga K, Hayashi J (2012) Simultaneous steam reforming of tar and steam gasification of char from the pyrolysis of potassium-loaded woody biomass. Energy Fuels. 26:199–208. https://doi.org/10.1021/ef201166a

Arun J, Gopinath KP, SundarRajan P, Malolan R, Adithya S, Sai Jayaraman R, Srinivaasan Ajay P (2020) Hydrothermal liquefaction of Scenedesmus obliquus using a novel catalyst derived from clam shells: solid residue as catalyst for hydrogen production. Bioresource Technology. 310:123443. https://doi.org/10.1016/j.biortech.2020.123443

Inyang MI, Gao B, Yao Y, Xue Y, Zimmerman A, Mosa A, Pullammanappallil P, Ok YS, Cao X (2016) A review of biochar as a low-cost adsorbent for aqueous heavy metal removal. Critical Reviews in Environmental Science and Technology. 46:406–433. https://doi.org/10.1080/10643389.2015.1096880

Park J-H, Ok YS, Kim S-H, Cho J-S, Heo J-S, Delaune RD, Seo D-C (2016) Competitive adsorption of heavy metals onto sesame straw biochar in aqueous solutions. Chemosphere. 142:77–83. https://doi.org/10.1016/j.chemosphere.2015.05.093

Yang Y, Sheng G (2003) Pesticide adsorptivity of aged particulate matter arising from crop residue burns. J. Agric. Food Chem. 51:5047–5051. https://doi.org/10.1021/jf0345301

Xiao F, Pignatello JJ (2016) Effects of post-pyrolysis air oxidation of biomass chars on adsorption of neutral and ionizable compounds. Environ. Sci. Technol. 50:6276–6283. https://doi.org/10.1021/acs.est.6b00362

Rasheed A, Sana S, Kashif S-R, Umer Z, Khatoon M (2017) To evaluate the efficiency of char and biochar for waste water treatment. Resources, Recycling and Waste Management 2

Arun J, Varshini P, Prithvinath PK, Priyadarshini V, Gopinath KP (2018) Enrichment of bio-oil after hydrothermal liquefaction (HTL) of microalgae C. vulgaris grown in wastewater: bio-char and post HTL wastewater utilization studies. Bioresource Technology 261:182–187. https://doi.org/10.1016/j.biortech.2018.04.029

Hervy, M.: Valorisation de chars issus de pyrogazéification de biomasse pour la purification de syngas : lien entre propriétés physico-chimiques, procédé de fonctionnalisation et efficacité du traitement. (2017)

Helleur R, Popovic N, Ikura M, Stanciulescu M, Liu D (2001) Characterization and potential applications of pyrolytic char from ablative pyrolysis of used tires. Journal of Analytical and Applied Pyrolysis. 58–59:813–824. https://doi.org/10.1016/S0165-2370(00)00207-2

Hwang IH, Matsuto T, Tanaka N, Sasaki Y, Tanaami K (2007) Characterization of char derived from various types of solid wastes from the standpoint of fuel recovery and pretreatment before landfilling. Waste Management. 27:1155–1166. https://doi.org/10.1016/j.wasman.2006.05.013

Daouk E, Sani R, Pham Minh D, Nzihou A (2018) Thermo-conversion of solid recovered fuels under inert and oxidative atmospheres: gas composition and chlorine distribution. Fuel. 225:54–61. https://doi.org/10.1016/j.fuel.2018.03.136

Ghani WAWAK, Mohd A, da Silva G, Bachmann RT, Taufiq-Yap YH, Rashid U, Al-Muhtaseb AH (2013) Biochar production from waste rubber-wood-sawdust and its potential use in C sequestration: chemical and physical characterization. Industrial Crops and Products. 44:18–24. https://doi.org/10.1016/j.indcrop.2012.10.017

Sette P, Fernandez A, Soria J, Rodriguez R, Salvatori D, Mazza G (2020) Integral valorization of fruit waste from wine and cider industries. Journal of Cleaner Production. 242:118486. https://doi.org/10.1016/j.jclepro.2019.118486

Luo S, Xiao B, Hu Z, Liu S (2010) Effect of particle size on pyrolysis of single-component municipal solid waste in fixed bed reactor. International Journal of Hydrogen Energy. 35:93–97. https://doi.org/10.1016/j.ijhydene.2009.10.048

Ma W, Hoffmann G, Schirmer M, Chen G, Rotter VS (2010) Chlorine characterization and thermal behavior in MSW and RDF. Journal of Hazardous Materials. 178:489–498. https://doi.org/10.1016/j.jhazmat.2010.01.108

Swagathnath G, Rangabhashiyam S, Murugan S, Balasubramanian P (2019) Influence of biochar application on growth of Oryza sativa and its associated soil microbial ecology. Biomass Conv. Bioref. 9:341–352. https://doi.org/10.1007/s13399-018-0365-z

Xu X, Zhao Y, Sima J, Zhao L, Mašek O, Cao X (2017) Indispensable role of biochar-inherent mineral constituents in its environmental applications: a review. Bioresource Technology. 241:887–899. https://doi.org/10.1016/j.biortech.2017.06.023

Yuan J-H, Xu R-K, Zhang H (2011) The forms of alkalis in the biochar produced from crop residues at different temperatures. Bioresource Technology. 102:3488–3497. https://doi.org/10.1016/j.biortech.2010.11.018

Ulusal A, Apaydın Varol E, Bruckman VJ, Uzun BB (2020) Opportunity for sustainable biomass valorization to produce biochar for improving soil characteristics. Biomass Conv. Bioref. https://doi.org/10.1007/s13399-020-00923-7

Carter S, Shackley S, Sohi S, Suy BT, Haefele S (2013) The impact of biochar application on soil properties and plant growth of pot grown lettuce (Lactuca sativa) and cabbage (Brassica chinensis). Agronomy. 3:404–418. https://doi.org/10.3390/agronomy3020404

Brewer CE, Chuang VJ, Masiello CA, Gonnermann H, Gao X, Dugan B, Driver LE, Panzacchi P, Zygourakis K, Davies CA (2014) New approaches to measuring biochar density and porosity. Biomass and Bioenergy. 66:176–185. https://doi.org/10.1016/j.biombioe.2014.03.059

Zhao C, Liu X, Chen A, Chen J, Lv W, Liu X (2020) Characteristics evaluation of bio-char produced by pyrolysis from waste hazelnut shell at various temperatures. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects 0:1–11. https://doi.org/10.1080/15567036.2020.1754530

Kastanaki E, Vamvuka D (2006) A comparative reactivity and kinetic study on the combustion of coal–biomass char blends. Fuel. 85:1186–1193. https://doi.org/10.1016/j.fuel.2005.11.004

Meng F, Xiao K, Li X, Wang H, Wang G, Lu L (2020) Characteristics of chars prepared by low-temperature co-pyrolysis of lignite and biomass. Combustion Science and Technology. 192:513–530. https://doi.org/10.1080/00102202.2019.1576654

Nair RR, Mondal MM, Weichgrebe D (2020) Biochar from co-pyrolysis of urban organic wastes—investigation of carbon sink potential using ATR-FTIR and TGA. Biomass Conv. Bioref. https://doi.org/10.1007/s13399-020-01000-9

Jindo K, Mizumoto H, Sawada Y, Sanchez-Monedero MA, Sonoki T (2014) Physical and chemical characterization of biochars derived from different agricultural residues. Biogeosciences. 11:6613–6621. https://doi.org/10.5194/bg-11-6613-2014

Wang M, Zhang L, Li A, Irfan M, Du Y, Di W (2019) Comparative pyrolysis behaviors of tire tread and side wall from waste tire and characterization of the resulting chars. Journal of Environmental Management. 232:364–371. https://doi.org/10.1016/j.jenvman.2018.10.091

Siddiqui MTH, Nizamuddin S, Mubarak NM, Shirin K, Aijaz M, Hussain M, Baloch HA (2019) Characterization and process optimization of biochar produced using novel biomass, waste pomegranate peel: a response surface methodology approach. Waste Biomass Valor. 10:521–532. https://doi.org/10.1007/s12649-017-0091-y

Trendewicz A, Evans R, Dutta A, Sykes R, Carpenter D, Braun R (2015) Evaluating the effect of potassium on cellulose pyrolysis reaction kinetics. Biomass and Bioenergy. 74:15–25. https://doi.org/10.1016/j.biombioe.2015.01.001

Zaini IN, García López C, Pretz T, Yang W, Jönsson PG (2019) Characterization of pyrolysis products of high-ash excavated-waste and its char gasification reactivity and kinetics under a steam atmosphere. Waste Management. 97:149–163. https://doi.org/10.1016/j.wasman.2019.08.001

Hwang IH, Nakajima D, Matsuto T, Sugimoto T (2008) Improving the quality of waste-derived char by removing ash. Waste Management. 28:424–434. https://doi.org/10.1016/j.wasman.2006.11.015

Ghouma I, Jeguirim M, Guizani C, Ouederni A, Limousy L (2017) Pyrolysis of olive pomace: degradation kinetics, gaseous analysis and char characterization. Waste Biomass Valor. 8:1689–1697. https://doi.org/10.1007/s12649-017-9919-8

Xue Y, Zhou S, Brown R, Kelkar A, Bai X (2015) Fast pyrolysis of biomass and waste plastic in a fluidized bed reactor. Fuel. 156:40–46. https://doi.org/10.1016/j.fuel.2015.04.033

Kim KH, Bai X, Rover M, Brown RC (2014) The effect of low-concentration oxygen in sweep gas during pyrolysis of red oak using a fluidized bed reactor. Fuel. 124:49–56. https://doi.org/10.1016/j.fuel.2014.01.086

Khiari B, Ibn Ferjani A, Azzaz AA, Jellali S, Limousy L, Jeguirim M (2020) Thermal conversion of flax shives through slow pyrolysis process: in-depth biochar characterization and future potential use. Biomass Conv. Bioref. https://doi.org/10.1007/s13399-020-00641-0

Acknowledgments

The authors thank the technicians at the TIMR laboratory EA-4297 and at the Service of Physico-chemical Analysis of UTC for their contribution and technical help.

Funding

Financial support for this project provided by the TIMR laboratory is gratefully acknowledged.

Author information

Authors and Affiliations

Contributions

All authors contributed to this study. Experimental work was done by Jean-Noël Semaan, under the supervision of Elias Daouk, in collaboration with Maïté Huron who provided the samples. Jean-Noel Semaan wrote the preliminary form of this paper and all authors commented on previous versions. The final form of the manuscript was read and approved by all authors.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Code availability

Not applicable.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Statement of novelty

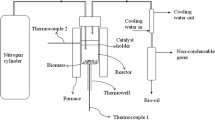

Thermochemical conversion processes have been the subject of increasing attention in clean energy sectors. Pyrolysis and gasification are considered as the most promising technologies. They enable conversion of biomass and wastes into combustible gases, synthetic fuels, and chemicals. In some cases, the solid co-product residue of these processes, which is also known as char, is without added value. The main focus of this study is to characterize pyro-gasification chars produced using a pilot scale reactor: Spirajoule® technology. It is an exclusive design for ETIA-Ecotechnologies. This reactor is a screw conveyor belt that is electrically heated to treat the material being processed. Char samples of several feedstock origins were tested in this project: Physicochemical, structural, and many more char properties were well defined and interpreted.

Rights and permissions

About this article

Cite this article

Semaan, JN., Huron, M. & Daouk, E. Pilot scale pyro-gasification of biomass and waste: char characterization. Biomass Conv. Bioref. 12, 5751–5765 (2022). https://doi.org/10.1007/s13399-020-01181-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-020-01181-3