Abstract

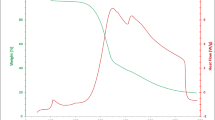

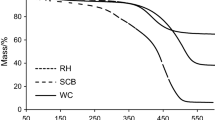

Agricultural biomasses are the underutilized sources that have extraordinary potential to synthesize green and cost-effective chemicals. This research focuses on the utilization of novel agricultural residue, i.e., waste neem cake, to produce highly efficient, cost-effective, and environment-friendly fuel, i.e., neem char (NC), through thermogravimetric pyrolysis. To study the effects of process variable on char yield and higher heating value (HHV), statistical modeling was applied by central composite design of response surface methodology. Furthermore, chemical and structural characterization of neem cake and char were carried out by using Fourier transform infrared spectroscopy, scanning electron microscopy (SEM), and thermogravimetric analysis (TGA). The reaction temperature was the most prominent variable found from the ANOVA (analysis of variances) to affect char yield and its HHV. The optimal result was achieved with 21.46% char yield and HHV value of 6371 kcal/kg at 600 °C, 60 min, and 3 mm. The heating value of char was highly improved indicating the potential application of char as a high-energy renewable fuel. Further, the carbon content and fixed carbon values increased, whereas hydrogen, oxygen, volatile matters, and moisture content decreased in char after the pyrolysis process.

Similar content being viewed by others

References

Chandra R, Takeuchi H, Hasegawa T (2012) Methane production from lignocellulosic agricultural crop wastes: a review in context to second generation of biofuel production. Renew Sust Energ Rev 16(3):1462–1476

Azargohar R, Nanda S, Kozinski JA, Dalai AK, Sutarto R (2014) Effects of temperature on the physicochemical characteristics of fast pyrolysis bio-chars derived from Canadian waste biomass. Fuel 125:90–100

Demirbas A (2004) Effects of temperature and particle size on bio-char yield from pyrolysis of agricultural residues. J Anal Appl Pyrolysis 72(2):243–248

Abnisa F, Daud WMAW, Husin WNW, Sahu JN (2011) Utilization possibilities of palm shell as a source of biomass energy in Malaysia by producing bio-oil in pyrolysis process. Biomass Bioenergy 35(5):1863–1872

Siddiqui MTH, Nizamuddin S, Mubarak NM, Shirin K, Aijaz M, Hussain M, Baloch HA (2017) Characterization and process optimization of biochar produced using novel biomass, waste pomegranate peel: a response surface methodology approach. Waste Biomass Valorization 1–12. https://doi.org/10.1007/s12649-017-0091-y

Eid, A., N. Jaradat, and N. Elmarzugi. (2017) A review of chemical constituents and traditional usage of neem plant (Azadirachta indica)

Immaraju JA (1998) The commercial use of azadirachtin and its integration into viable pest control programmes. Pestic Sci 54(3):285–289

Alagu, R. and E.G. Sundaram, Preparation and characterization of pyrolytic oil through pyrolysis of neem seed and study of performance, combustion and emission characteristics in CI engine. J Energy Inst, 2016

Singh V et al (2014) Pyrolysis of sal seed to liquid product. Bioresour Technol 151:432–435

Volli V, Singh R (2012) Production of bio-oil from de-oiled cakes by thermal pyrolysis. Fuel 96:579–585

Steiner C, Glaser B, Geraldes Teixeira W, Lehmann J, Blum WEH, Zech W (2008) Nitrogen retention and plant uptake on a highly weathered central Amazonian Ferralsol amended with compost and charcoal. J Plant Nutr Soil Sci 171(6):893–899

Beesley L, Moreno-Jiménez E, Gomez-Eyles JL (2010) Effects of biochar and greenwaste compost amendments on mobility, bioavailability and toxicity of inorganic and organic contaminants in a multi-element polluted soil. Environ Pollut 158(6):2282–2287

Sahu SG, Sarkar P, Chakraborty N, Adak AK (2010) Thermogravimetric assessment of combustion characteristics of blends of a coal with different biomass chars. Fuel Process Technol 91(3):369–378

Agrafioti E, Bouras G, Kalderis D, Diamadopoulos E (2013) Biochar production by sewage sludge pyrolysis. J Anal Appl Pyrolysis 101:72–78

Siddiqui M et al (2018) Synthesis of magnetic carbon nanocomposites by hydrothermal carbonization and pyrolysis. Environ Chem Lett:1–24

Jung K-W, Jeong TU, Kang HJ, Chang JS, Ahn KH (2016) Preparation of modified-biochar from Laminaria japonica: simultaneous optimization of aluminum electrode-based electro-modification and pyrolysis processes and its application for phosphate removal. Bioresour Technol 214:548–557

Aslan N (2008) Application of response surface methodology and central composite rotatable design for modeling and optimization of a multi-gravity separator for chromite concentration. Powder Technol 185(1):80–86

Said KAM, Amin MAM (2016) Overview on the response surface methodology (RSM) in extraction processes. J Appl Sci Process Engineering 2(1):8–17

Bezerra MA, Santelli RE, Oliveira EP, Villar LS, Escaleira LA (2008) Response surface methodology (RSM) as a tool for optimization in analytical chemistry. Talanta 76(5):965–977

Borges FC, du Z, Xie Q, Trierweiler JO, Cheng Y, Wan Y, Liu Y, Zhu R, Lin X, Chen P, Ruan R (2014) Fast microwave assisted pyrolysis of biomass using microwave absorbent. Bioresour Technol 156:267–274

Ghani ZA, Ishak MAM, Ismail K (2011) Direct liquefaction of Mukah Balingian low-rank Malaysian coal: optimization using response surface methodology. Asia Pac J Chem Eng 6(4):581–588

Mubarak N et al (2014) Synthesis of palm oil empty fruit bunch magnetic pyrolytic char impregnating with FeCl3 by microwave heating technique. Biomass Bioenergy 61:265–275

Shen J, Zhu S, Liu X, Zhang H, Tan J (2010) The prediction of elemental composition of biomass based on proximate analysis. Energy Convers Manag 51(5):983–987

Nhuchhen DR (2016) Prediction of carbon, hydrogen, and oxygen compositions of raw and torrefied biomass using proximate analysis. Fuel 180:348–356

Nizamuddin S et al (2016) A critical analysis on palm kernel shell from oil palm industry as a feedstock for solid char production. Rev Chem Eng 32(5):489–505

Moralı U, Şensöz S (2015) Pyrolysis of hornbeam shell (Carpinus betulus L.) in a fixed bed reactor: characterization of bio-oil and bio-char. Fuel 150:672–678

Uzun BB, Apaydin-Varol E, Ateş F, Özbay N, Pütün AE (2010) Synthetic fuel production from tea waste: characterisation of bio-oil and bio-char. Fuel 89(1):176–184

Onay O (2007) Influence of pyrolysis temperature and heating rate on the production of bio-oil and char from safflower seed by pyrolysis, using a well-swept fixed-bed reactor. Fuel Process Technol 88(5):523–531

Intani K, Latif S, Kabir AKMR, Müller J (2016) Effect of self-purging pyrolysis on yield of biochar from maize cobs, husks and leaves. Bioresource Technol 218:541–551

Tripathi M, Sahu J, Ganesan P (2016) Effect of process parameters on production of biochar from biomass waste through pyrolysis: a review. Renew Sust Energ Rev 55:467–481

Ola F, Jekayinfa S (2015) Pyrolysis of sandbox (Hura crepitans) shell: effect of pyrolysis parameters on biochar yield. Res Agric Eng 61(4):170–176

Calvo L et al (2004) Heating process characteristics and kinetics of rice straw in different atmospheres. Fuel Process Technol 85(4):279–291

Windeatt JH, Ross AB, Williams PT, Forster PM, Nahil MA, Singh S (2014) Characteristics of biochars from crop residues: potential for carbon sequestration and soil amendment. J Environ Manag 146:189–197

Fu P, Hu S, Xiang J, Sun L, Su S, Wang J (2012) Evaluation of the porous structure development of chars from pyrolysis of rice straw: effects of pyrolysis temperature and heating rate. J Anal Appl Pyrolysis 98:177–183

Anderson N, Jones J, Page-Dumroese D, McCollum D, Baker S, Loeffler D, Chung W (2013) A comparison of producer gas, biochar, and activated carbon from two distributed scale thermochemical conversion systems used to process forest biomass. Energies 6(1):164–183

Zhong K, Wang Q (2010) Optimization of ultrasonic extraction of polysaccharides from dried longan pulp using response surface methodology. Carbohydr Polym 80(1):19–25

Boey P-L, Maniam GP, Hamid SA (2009) Biodiesel production via transesterification of palm olein using waste mud crab (Scylla serrata) shell as a heterogeneous catalyst. Bioresour Technol 100(24):6362–6368

Mayoral M et al (2001) Different approaches to proximate analysis by thermogravimetry analysis. Thermochim Acta 370(1):91–97

Gupta BS, Ako JE (2005) Application of guar gum as a flocculant aid in food processing and potable water treatment. Eur Food Res Technol 221(6):746–751

Pütün AE, Özbay N, Önal EP, Pütün E (2005) Fixed-bed pyrolysis of cotton stalk for liquid and solid products. Fuel Process Technol 86(11):1207–1219

Telmo C, Lousada J, Moreira N (2010) Proximate analysis, backwards stepwise regression between gross calorific value, ultimate and chemical analysis of wood. Bioresour Technol 101(11):3808–3815

Lee Y, Park J, Ryu C, Gang KS, Yang W, Park YK, Jung J, Hyun S (2013) Comparison of biochar properties from biomass residues produced by slow pyrolysis at 500 C. Bioresour Technol 148:196–201

Patel SU, Jeevan Kumar B, Badhe YP, Sharma BK, Saha S, Biswas S, Chaudhury A, Tambe SS, Kulkarni BD (2007) Estimation of gross calorific value of coals using artificial neural networks. Fuel 86(3):334–344

Singh S, Ram LC, Masto RE, Verma SK (2011) A comparative evaluation of minerals and trace elements in the ashes from lignite, coal refuse, and biomass fired power plants. Int J Coal Geol 87(2):112–120

Idris SS, Rahman NA, Ismail K, Alias AB, Rashid ZA, Aris MJ (2010) Investigation on thermochemical behaviour of low rank Malaysian coal, oil palm biomass and their blends during pyrolysis via thermogravimetric analysis (TGA). Bioresour Technol 101(12):4584–4592

Antal MJ, Grønli M (2003) The art, science, and technology of charcoal production. Ind Eng Chem Res 42(8):1619–1640

Koufopanos C, Lucchesi A, Maschio G (1989) Kinetic modelling of the pyrolysis of biomass and biomass components. Can J Chem Eng 67(1):75–84

Pavia, D., G. Lampman, and G. Kriz, Introduction to spectroscopy: a guide for students of organic chemistry—chap. 2 and appendix 1. Saunders Golden Sunburst Series, 1979. 367

Nizamuddin S et al (2018) Upgradation of chemical, fuel, thermal, and structural properties of rice husk through microwave-assisted hydrothermal carbonization. Environ Sci Pollut Res:1–11

Yuan J-H, Xu R-K, Zhang H (2011) The forms of alkalis in the biochar produced from crop residues at different temperatures. Bioresour Technol 102(3):3488–3497

Joseph BL et al (1987) Introduction to organic spectroscopy. Macmillan, New York

Olsson A-M, Salmén L (2004) The association of water to cellulose and hemicellulose in paper examined by FTIR spectroscopy. Carbohydr Res 339(4):813–818

Rashid K, Reddy KSK, al Shoaibi A, Srinivasakannan C (2014) Process optimisation of porous carbon preparation from date palm pits and adsorption kinetics of methylene blue. Can J Chem Eng 92(3):426–434

Ahmad MA, Puad NAA, Bello OS (2014) Kinetic, equilibrium and thermodynamic studies of synthetic dye removal using pomegranate peel activated carbon prepared by microwave-induced KOH activation. Water Res Industry 6:18–35

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Siddiqui, M.T.H., Nizamuddin, S., Baloch, H.A. et al. Thermogravimetric pyrolysis for neem char using novel agricultural waste: a study of process optimization and statistical modeling. Biomass Conv. Bioref. 8, 857–871 (2018). https://doi.org/10.1007/s13399-018-0336-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-018-0336-4