Abstract

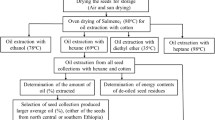

This research is on the introduction and the effect of the pre-treatment method on oil recovery from African oil bean seeds for biodiesel production. Samples were dried in the solar dryer, open sun, and the oven at 50 °C, 60 °C, and 70 °C. The solvent extraction process with hexane was used to extract oil from the product, and their saponification value, peroxide value, acid value, iodine value, specific gravity, and the color of the bio-oil were analyzed. The oil was further used in acid-catalyzed esterification and alkaline transesterification for biodiesel production, and the effects of temperature, catalyst concentration, feedstock to methanol molar ratio, and reaction time on biodiesel conversion were investigated. Solar drying of the seed yielded the highest volume of oil compared with other drying methods. Peroxide values of the oil meet the standard values from CODEX but showed an increase in rancidity in the solar-dried and open sundried products. Bio-oil produced has good lubricating properties as its iodine properties showed that it is not a drying oil. The cetane number and heating value of the biodiesel produced are within the range when compared with the ASTM standard of diesel properties. By using a feedstock to methanol molar ratio of 1:6 and a sulfuric acid concentration of 0.8%, a biodiesel conversion of 81% was obtained after 6 h of reaction at 60 °C. The biodiesel produced by this process met the American Society for Testing and Materials (ASTM) standard.

Similar content being viewed by others

References

Abayeh OJ, Aina EA, Okounghae CO (1998) Oil content and oil quality characteristics of some Nigerian oils seeds. Sci Forum: J Pure Appl Sci 1:17–23

Achinewhu SC, Anthony UO, Offiong UE (1998) Nutritional quality F plants foods. Nigeria, Post Harvest Research Unit, University of Benin, pp 134–159

AOAC International (2007) Official methods of analysis of AOAC inter-national, 18th Ed. methods 925.10, 985.29, 991.42, 991.43, 993.19, 994.13, 996.01, 2001.03, 2002.01, 2002.02, 2009.01, and 2011.25. AOAC International, Gaithersburg

Ayetor GK, Sunnu A, Parbey J (2015) Effect of biodiesel production parameters on viscosity and yield of methyl esters: Jatropha curcas, Elaeis Guineensis and Cocos nucifera. Alexandria Eng J 2015:1285–1290. https://doi.org/10.1016/j.aej.2015.09.011

Ayodele A, Ayoola K, Hymore F, Omonhinmi CA (2017) Optimization of biodiesel production from selected waste oils using response surface methodology. Biotechnology 16(1):1–9

Becker K, Makkar HPS (2008) Jatropha curcas: a biodiesel source for tomorrow’s oil and biodiesel. Lipid Technol 20:104–107

Bello EI (2016) Effects of transesterification on the colour of biodiesel. Sci Agric 13:10–13

Canakci M (2007) The potential of restaurant waste lipids as biodiesel feedstocks. Bioresour Technol 98:183

Canakci M, Van Gerpen J (1999) Biodiesel production via acid catalysis. Trans ASAE 42:1203

Chimsook T, Assawarachan (2017) Effect of drying methods on yield and quality of the avocado oil. Key Eng Mater 735:127–131. https://doi.org/10.4028/www.scientific.net/KEM.735.127

CODEX (n.d.) Alimentarius Commission. Codex Stan 19–1981: edible fats and oils not covered by individual

CODEX STAN 210–1999: European Union comments on: CL 2017/60-FO: Amendment to the standard for named vegetable oils

Demirbas A (1998) Fuel properties and calculation of higher heating values of vegetable oils. Fuel. 77(9–10):1117–1120

Demirbas A (2008) Relationships derived from physical properties of vegetable oil and biodiesel fuels. Fuel 87(8–9):1743–1748

Egan H, Kirk RS, Sawyer R (1981) Pearson’s chemical analysis of foods, 8th edn. Churchill Livingstone, London, New York

Eliasz J, Osipowicz T, AbramekK F, Mozga L (2019) Model issues regarding modification of fuel injector components to improve the injection parameters of a modern compression ignition engine powered by biofuel. Appl Sci 9:5479. https://doi.org/10.3390/app9245479

Enujiugha VN (2003) Nutrient changes during the fermentation of African oil bean (Pentaclethra macrophylla Benth) seeds. Pak J Nutr 2:320–323

Esonye C, Onukwuli OD, Ofoefule AU (2019) Characterization and oxidation modeling of oils from Prunus amygdalus, Dyacrodes edulis and Chrysophyllum albidium. Ind Crop Prod 128:298–307

Gabriel CM, Toni JL, Rafael D, MarinthoBastos Q, Ariovaldo B (2014) Production of biodiesel with seed soybean and supercritical ethanol. Federal University of Rio Grande (FURG), Campus Santo Antônio da Patrulha (SAP), Rio Grande do Sul

Georgogianni KG, Kontominas MG, Pomonis PJ, Avlonitis D, Gergis V (2008) Conventional and in situ transesterification of sunflower seed oil for the production of biodiesel. Fuel Process Technol 89:503–509

ISO 3657 (2020) Animal and vegetable fats and oils — Determination of saponification value. ISO/TC 34/SC 11

IUPAC (1979) Standard methods for the analysis of the oils, fats and derivatives, 6th edn. Pergamon Press, Oxford

Kalayasiri P, Jayashoke N, Krisnangkura K (1996) Survey of seed oils for use as diesel fuels. J Am Oil Chem Soc 73:471–474

Karaj S, Müller J (2014) Effect of container depth and sedimentation time on quality of Jatropha curcas L. oil. Fuel 118:206–213

Kartika A, Yulani S, Ariono D, Sugiarto D (2011) In situ transesterification of Jatropha seeds: effect of moisture content and particle size on yield and quality of biodiesel. 31:342–9 [AGRITECH]

Kartika A, Yani M, Ariono D, Evon PH, Rigal L (2013) Biodiesel production from Jatropha seeds: solvent extraction and in situ transesterification in a single step. Fuel 106:111–117

Keay WR (1989) Flora of west tropical Africa, Nigerian Trees. Ed 2. Millbank, London

Kumar SPJ, Rajendra SP, Rintu B, Dinesh KA, Kalyani SK, Ramesh KV (2017) Green solvents and technologies for oil extraction from oilseeds. Chem Central J 11:9

Kumar S, Kumar R, Pandey A. 2019. Current developments in biotechnology and bioengineering waste treatment processes for energy generation. Elsevier B.V

Morrison WH, Robertson JA (1978) Effect of drying on sunflower seed oil quality and germination. J Am Oil Chem Soc 55:271–274

Mushtaq A, Shazia S, Lee KT, Ahmed ZA, Haleema S, Muhammed Z, Taibi BH, Muhammed AA, Rasool BT (2014) Distaff thistle oil: a possible new non-edible feedstock for biogas energy. Int J Green Energy 10:1–27

Ndukwu MC (2013) Moisture dependent physical properties of african oil bean seed. Agric Forestry 59:193–202 Podgorica 193

Ndukwu MC, Bennamoun L (2018) Potential of integrating Na2SO4 · 10H2O pellets in solar drying system. Dry Technol 36:1017–1030. https://doi.org/10.1080/07373937.2017.1366506

Ndukwu MC, Simonyan KJ, Ndirika VIO (2012) Investigation of the structural changes of cocoa bean (with and without seed coat) during convective drying. Int J Agric Biol Eng 5:75–82

Ndukwu MC, Dirioha C, Abam FI, Ihediwa VE (2017) Heat and mass transfer parameters in the drying of cocoyam slice. Case Stud Thermal Eng 9:62–71. https://doi.org/10.1016/j.csite.2016.12.003

Ndukwu MC, Bennamoun L, Anozie O (2018a) Evolution of thermo-physical properties of Akuama (picralima nitida) seed and antioxidants retention capacity during hot air drying. Heat Mass Transf 54:3533–3546. https://doi.org/10.1007/s00231-018-2379-2

Ndukwu MC, Bennamoun L, Abam FI (2018b) Experience of solar drying in Africa: presentation of designs, operations, and models. Food Eng Rev 10:211–244. https://doi.org/10.1007/s12393-018-9181-2

Ndukwu MC, Ekop IE, Etim PJ, Ohakwe CN, Ezejiofor NR, Onwude DI, Abam FI, Igboayaka EC, Ohia A (2019) Response surface optimization of Bambara nut kernel yield as affected by speed of rotation, and impeller configurations. Sci African 6(2019):e00174

Ndukwu MC, Onyenwigwe D, Abam FI, Eke AB, Dirioha C (2020) Development of a low-cost wind-powered active solar dryer integrated with glycerol as thermal storage. Renew Energy 154:553–568. https://doi.org/10.1016/j.renene.2020.03.016

Ogrodowska D, Tańska M, Brandt W (2017) The influence of drying process conditions on the physical properties, bioactive compounds and stability of encapsulated pumpkin seed oil. Food Bioprocess Technol 10:1265–1280. https://doi.org/10.1007/s11947-017-1898-z

Okwundu OS, El-Shazly AH, Elkady M (2019) Comparative effect of reaction time on biodiesel production from low free fatty acid beef tallow: a definition of product yield. Appl Sci 1:140. https://doi.org/10.1007/s42452-018-0145-1

Qian J, Shi H, Yun Z (2010) Preparation of biodiesel from Jatropha curcas L. oil produced by two-phase solvent extraction. Bioresour Technol 101:7025–7031

Qu Q, Yang X, Fu M, Chen Q, Zhang X, He Z, Qiao X (2016) Effects of three conventional drying methods on the lipid oxidation, fatty acids composition, and antioxidant activities of walnut (Juglans regia L.). Dry Technol 34:822–829. https://doi.org/10.1080/07373937.2015.1081931

RafsanNahian MD. Islam N, Shaheen M K. (2016) Production of biodiesel from palm oil and performance test with diesel in CI Engine. International Conference on Mechanical, Industrial and Energy Engineering 2016 26–27 December, 2016

Saxena P, Jawale S, Joshipura MH (2013) A review on prediction of properties of biodiesel and blends of biodiesel. Procedia Eng 51:395–402

Sharma YC, Singh B, Upadhyay SN (2008) Advancements in development and characterization of biodiesel: a review. Fuel 87:2355–2373

Silva GN, Gross JAS, Carvalh MS, Kuki KN, Goular S, Pimentel LD (2020) Air drying of macauba fruits: maintaining oil quality for biodiesel production. Acta Scientiarum Agron 42(e43451):2020. https://doi.org/10.4025/actasciagron.v42i1.43451

Simo-Tagne M, Ndukwu MC, Zoulalian A, Bennamoun L, Kifani-Sahban F, Rogaume Y (2019) Numerical analysis and validation of a natural convection mix-mode solar dryer for drying red chili under variable conditions. Renew Energy 151:659–673. https://doi.org/10.1016/j.renene.2019.11.055

Thames SF, Yu H (1999) Cationic UV-cured coatings of epoxide-containing vegetable oils. Surf Coat Technol 115:208–214

Wanyo P, Meeso N, Kaewseejan N, Siriamornpun S (2015) Effects of drying methods and enzyme aided on the fatty acid profiles and lipid oxidation of rice by-products. Dry Technol 34(8):953–961. https://doi.org/10.1080/07373937.2015.1087407

Wei-Jia T, Chun-Ming H, Nair G, Wen-Teng W (2008) An enzymatic/acid-catalyzed hybrid process for biodiesel production from soybean oil. J Chin Inst Chem Eng 39:203–210

Zhang Z, Liu Y, Che L (2018) Effects of different drying methods on the extraction rate and qualities of oils from demucilaged flaxseed. Drying Tec

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ndukwu, M.C., Onyeoziri, C.I. African oil bean seed as feedstock for bio-oil and biodiesel production and on the effects of thermal pre-treatments on the quality of the bio-oil. Biomass Conv. Bioref. 12, 2799–2810 (2022). https://doi.org/10.1007/s13399-020-00754-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-020-00754-6