Abstract

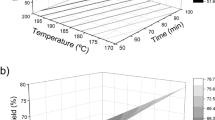

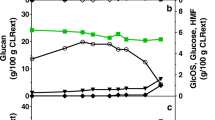

The generation of compounds derived from lignocellulosic biomass fractionation has a boost in recent years. An interesting plant could be tagasaste (Chamaecytisus proliferus) due to its high biomass production and its leguminous nature. A sequence of acid hydrolysis, as pretreatment, and pyrolysis of the solid residue, as treatment, has been used in its valorization. An experimental design (H2SO4 acid concentration 0.5–2%, temperature 130–170 °C, and time 30–60 min) has been used to study the hydrolysis process. In the proposed acid hydrolysis process, under 170 °C as operational temperature, 0.5% of H2SO4 and 30 min for the operation time, 91.75% of the initial xylose have been extracted. The thermal behavior of both tagasaste trunks-large branches and some solid residues after hydrolysis (furthest and center points in the experimental design) process and raw material have been studied by thermogravimetric analysis under nitrogen atmosphere at different heating rates (5, 10, 15, and 20 °C min−1). The thermal degradation of the studied materials is influenced by its initial composition. Then, the higher reactivity of hemicelluloses can accelerate the pyrolysis degradation reaction. However, higher cellulose content implies lower activation energy in pyrolysis process.

Similar content being viewed by others

References

Sánchez C, Serrano L, Andres MA, Labidi J (2013) Furfural production from corn cobs autohydrolysis liquors by microwave technology. Ind Crop Prod 42:513–519. doi:10.1016/j.indcrop.2012.06.042

Kamm B, Gruber PR, Kamm M (2006) Biorefineries—industrial processes and products: status quo and future directions. Wiley-VCH, Weinheim

Saeed A, Jahan MS, Li H, Liu Z, Ni Y, Heiningen AV (2012) Mass balances of components dissolved in the pre-hydrolysis liquor of kraft-based dissolving pulp production process from Canadian hardwoods. Biomass Bioenergy 39:14–19. doi:10.1016/j.biombioe.2010.08.039

Easterly JL, Burnham M (1996) Overview of biomass and waste fuel resources for power production. Biomass Bioenergy 10:79–92. doi:10.1016/0961-9534(95)00063-1

Kamm B, Kamm M (2006) Biorefineries—multi product processes. Advances in Biochemical Engineering/Biotechnology White Biotechnology pp:175–204. doi:10.1007/10_2006_040

Feria M, García J, Díaz MJ, Fernández M, López F (2012) Biorefinery process for production of paper and oligomers from Leucaena leucocephala K360 with or without prior autohydrolysis. Bioresour Technol 126:64–70. doi:10.1016/j.biortech.2012.09.051

López F, Pérez A, Zamudio MA, Alva HED, García JC (2012) Paulownia as raw material for solid biofuel and cellulose pulp. Biomass Bioenergy 45:77–86. doi:10.1016/j.biombioe.2012.05.010

Lange JP (2007) Lignocellulose conversion: an introduction to chemistry, process and economics. Biofuels Bioprod Biorefin 1:39–48. doi:10.1002/bbb.7

Kazi FK, Fortman JA, Anex RP, Hsu DD, Aden A, Dutta A, Kothandaraman G (2010) Techno-economic comparison of process technologies for biochemical ethanol production from corn stover. Fuel 89(S1):S20–S28. doi:10.1016/j.fuel.2010.01.001

Piccolo C, Bezzo F (2009) A techno-economic comparison between two technologies for bioethanol production from lignocellulose. Biomass and Bioenergy 33:478–491. doi:10.1016/j.biombioe.2008.08.008

Prasara JA, Cucek L, Varbanov PS, Klemes JJ (2012) Environmental and economic performances of different technologies for power generation from rice husks. Chem Eng Trans 29:751–756. doi:10.3303/CET1229125

Cherubini F (2010) The biorefinery concept: using biomass instead of oil for producing energy and chemicals. Energy Convers Manag 51:1412–1421. doi:10.1016/j.enconman.2010.01.015

Wang K, Yang H, Yao X, Xu F, Sun RC (2012) Structural transformation of hemicelluloses and lignin from triploid poplar during acid-pretreatment based biorefinery process. Bioresour Technol 116:99–106. doi:10.1016/j.biortech.2012.04.028

Kumar P, Barrett DM, Delwiche MJ, Stroeve P (2009) Methods for pretreatment of lignocellulosic biomass for efficient hydrolysis and biofuel production. Ind Eng Chem Res 48:3713–3729. doi:10.1021/ie801542g

Wyman CE, Dale BE, Elander RT, Holtzapple M, Ladisch MR, Lee Y (2005) Coordinated development of leading biomass pretreatment technologies. Bioresour Technol 96:1959–1966. doi:10.1016/j.biortech.2005.01.010

Lavarack B, Griffin G, Rodman D (2002) The acid hydrolysis of sugarcane bagasse hemicellulose to produce xylose, arabinose, glucose and other products. Biomass Bioenergy 23:367–380. doi:10.1016/s0961-9534(02)00066-1

Dominguez JM, Cao N, Gong C, Tsao G (1997) Dilute acid hemicellulose hydrolysates from corn cobs for xylitol production by yeast. Bioresour Technol 61:85–90. doi:10.1016/s0960-8524(97)84703-7

Mussatto SI, Roberto IC (2005) Acid hydrolysis and fermentation of brewer’s spent grain to produce xylitol. J Sci Food Agric 85:2453–2460. doi:10.1002/jsfa.2276

García JC, Díaz MJ, Garcia M, Feria MJ, Gómez D, López F (2013) Search for optimum conditions of wheat straw hemicelluloses cold alkaline extraction process. Biochem Eng J 71:127–133. doi:10.1016/j.bej.2012.12.008

Vázquez M, Alonso J, Domínguez H, Parajó J (2000) Xylooligosaccharides: manufacture and applications. Trends Food Sci Technol 11:387–393. doi:10.1016/s0924-2244(01)00031-0

Rivas B, Domínguez JM, Domínguez H, Parajó J (2002) Bioconversion of posthydrolysed autohydrolysis liquors: an alternative for xylitol production from corn cobs. Enzym Microb Technol 31:431–438. doi:10.1016/s0141-0229(02)00098-4

Iranmahboob J, Nadim F, Monemi S (2002) Optimizing acid-hydrolysis: a critical step for production of ethanol from mixed wood chips. Biomass Bioenergy 22:401–404. doi:10.1016/s0961-9534(02)00016-8

Barrett G, Alexander P, Robinson J, Bragg N (2016) Achieving environmentally sustainable growing media for soilless plant cultivation systems—a review. Sci Hortic 212:220–234. doi:10.1016/j.scienta.2016.09.030

Papanastasis V, Yiakoulaki M, Decandia M, Dini-Papanastasi O (2008) Integrating woody species into livestock feeding in the Mediterranean areas of Europe. Anim Feed Sci Technol 140:1–17. doi:10.1016/j.anifeedsci.2007.03.012

Wu S, Shen D, Hu J, Zhang H, Xiao R (2016) Cellulose-lignin interactions during fast pyrolysis with different temperatures and mixing methods. Biomass and Bioenergy 90:209–217. doi:10.1016/j.biombioe.2016.04.012

Saidur R, Abdelaziz E, Demirbas A, Hossain M, Mekhilef S (2011) A review on biomass as a fuel for boilers. Renew Sust Energ Rev 15:2262–2289. doi:10.1016/j.rser.2011.02.015

Wise LE, Marphy M, D'Adieco A (1946) Chlorite holocellulose, its fractionation and bearing on summative wood analysis and on studies on the hemicelluloses. Paper Trade Journal 122:35–43. doi:10.1002/jsfa.2740430404

Alfaro A, López F, Pérez A, García JC, Rodríguez A (2010) Integral valorization of tagasaste (Chamaecytisus proliferus) under hydrothermal and pulp processing. Bioresour Technol 101:7635–7640. doi:10.1016/j.biortech.2010.04.059

López F, García MT, Feria MJ, García JC, Diego CD, Zamudio M, Díaz MJ (2014) Optimization of furfural production by acid hydrolysis of Eucalyptus globulus in two stages. Chem Eng J 240:195–201. doi:10.1016/j.cej.2013.11.073

Alfaro A, Rivera A, Pérez A, Yáñez R, García JC, López F (2009) Integral valorization of two legumes by autohydrolysis and organosolv delignification. Bioresour Technol 100:440–445. doi:10.1016/j.biortech.2008.05.003

Caparrós S, Ariza J, Garrote G, López F, Díaz MJ (2007) Optimization of Paulownia fortunei L. autohydrolysis–organosolv pulping as a source of xylooligomers and cellulose pulp. Ind Eng Chem Res 46:623–631. doi:10.1021/ie060561k

Flynn JH, Wall LA (1966) General treatment of the thermogravimetry of polymers. Journal of Research of the National Bureau of Standards Section A: Physics and Chemistry 70A:487–491. doi:10.6028/jres.070a.043

Ozawa T (1965) A new method of analyzing thermogravimetric data. Bull Chem Soc Jpn 38:1881–1886. doi:10.1246/bcsj.38.1881

Slopiecka K, Bartocci P, Fantozzi F (2012) Thermogravimetric analysis and kinetic study of poplar wood pyrolysis. Appl Energy 97:491–497. doi:10.1016/j.apenergy.2011.12.056

Poletto M, Zattera AJ, Santana RM (2012) Thermal decomposition of wood: kinetics and degradation mechanisms. Bioresour Technol 126:7–12. doi:10.1016/j.biortech.2012.08.133

Opfermann J, Kaisersbergerv E, Flammersheim H (2002) Model-free analysis of thermoanalytical data-advantages and limitations. Thermochim Acta 391:119–127. doi:10.1016/s0040-6031(02)00169-7

Weiqi W, Shubin W, Liguo L (2013) Combination of liquid hot water pretreatment and wet disk milling to improve the efficiency of the enzymatic hydrolysis of eucalyptus. Bioresour Technol 128:725–730. doi:10.1016/j.biortech.2012.08.130

Gütsch JS, Nousiainen T, Sixta H (2012) Comparative evaluation of autohydrolysis and acid-catalyzed hydrolysis of Eucalyptus globulus wood. Bioresour Technol 109:77–85. doi:10.1016/j.biortech.2012.01.018

Feria MJ, López F, García JC, Pérez A, Zamudio M, Alfaro A (2011) Valorization of Leucaena leucocephala for energy and chemicals from autohydrolysis. Biomass Bioenergy 35:2224–2233. doi:10.1016/j.biombioe.2011.02.038

Yang H, Yan R, Chen H, Lee DHDH, Zheng C Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 86:1781–1788. doi:10.1016/j.fuel.2006.12.013

Velden MVD, Baeyens J, Brems A, Janssens B, Dewil R (2010) Fundamentals, kinetics and endothermicity of the biomass pyrolysis reaction. Renew Energy 35:232–242. doi:10.1016/j.renene.2009.04.019

Bhagavatula A, Huffman G, Shah N, Honaker R (2014) Evaluation of thermal evolution profiles and estimation of kinetic parameters for pyrolysis of coal/corn Stover blends using thermogravimetric analysis. Journal of Fuels 2014:1–12. doi:10.1155/2014/914856

Gašparovič L, Koreňová Z, Jelemenský L (2010) Kinetic study of wood chips decomposition by TGA. Chem Pap 64. doi:10.2478/s11696-009-0109-4

Wagenaar B, Prins W, Swaaij WV (1993) Flash pyrolysis kinetics of pine wood. Fuel Processing Technology 36:291–298. doi:10.1016/0378-3820(93)90039-7

Lv G, Wu SB, Lou R (2010) Kinetic study of the thermal decomposition of hemicellulose isolated from corn stalk. Bioresources 5:1281–1291. doi:10.15376/biores.5.2.1281-1291

Carrier M, Loppinet-Serani A, Denux D, Lasnier JM, Ham-Pichavant F, Cansell F (2011) Thermogravimetric analysis as a new method to determine the lignocellulosic composition of biomass. Biomass and Bioenergy 35:298–307. doi:10.1016/j.biombioe.2010.08.067

Lin YC, Cho J, Tompsett GA, Westmoreland PR, Huber GW (2009) Kinetics and mechanism of cellulose pyrolysis. The Journal of Physical Chemistry C 113:20097–20107. doi:10.1021/jp906702p.

Acknowledgements

The authors gratefully acknowledge the funding of this work from the Andalusian Regional Ministry of Economy, Innovation, Science, and Employment (project number RNM 2323 and FPI grant) and Ministry of Economy and Competitiveness (National Programme for Research Amend at the Challenges of Society, CTQ2013-46804-C2-1-R).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Loaiza, J.M., López, F., García, M.T. et al. Integral valorization of tagasaste (Chamaecytisus proliferus) under thermochemical processes. Biomass Conv. Bioref. 8, 265–274 (2018). https://doi.org/10.1007/s13399-017-0258-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-017-0258-6