Abstract

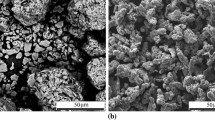

The tensile properties of a Cu/Ni fine clad prepared by surface activation bonding were investigated as a function of the heat-treatment temperature and the diffusion layer thickness. A negligibly thin diffusion layer, less than 5 nm in thickness, was formed in the as-bonded Cu/Ni fine clad, but the thickness increased significantly after subsequent heat treatments. As the temperature increased, the yield strength and tensile strength increased; this was attributable to the microstructural features of the raw materials. The yield strength values calculated using a rule-of-mixture model were lower than those determined experimentally. We attributed this difference in the values to the diffusion layer and friction at the interfaces between the various phases. The friction strength of the copper/nickel foils was higher than those of the copper foil/diffusion layer and the nickel foil/diffusion layer. The results of the study suggested that the tensile properties of the Cu/Ni fine clad were affected by the following: (1) the volume fraction of the raw materials and their individual strengths, (2) the volume fraction of the diffusion layer and its strength, and (3) the friction strength at the interfaces of the various phases.

Similar content being viewed by others

References

H. D. Manesh and A. K. Taheri, J. Alloy Compd. 361, 138 (2003).

A. K. Taheri and S. A. Majlessi, J. Mater. Eng. Perform. 2, 285 (1992).

H. Yan and J. G. Lenard, Mater. Sci. Eng. A. 358, 419 (2004).

D. Y. Moon, W. S. Kim, and J. W. Park, J. Nanosci. Nanotechnol. 12, 3661 (2012).

E. El Hamri, M. Meddah, L. Boulkadat, A. Elfansoui, K. Bouabid, M. Nya, X. Portier, and A. Ihlal, J. Nanosci. Nanotechnol. 12, 6800 (2012).

T. Tabata, S. Masaki, and K. Azekura, Mater. Sci. Technol. 5, 377 (1989).

N. D. Lucaschkin, A. P. Borissow, and A. I. Elrikh, J. Mater. Proc. Technol. 66, 264 (1997).

K. H. Kim, S. H. Hong, S. I. Cha, S. C. Lim, H. C. Kwon, and W. K. Yoon, Mater. Trans. 51, 787 (2012).

T. G. Woo, I. S. Park, K. H. Jung, W. Y. Jeon, Y. K. Hwang, and K. W. Seol, Electron. Mater. Lett. 8, 151 (2012).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jung, TK., Kim, KH., Joh, DW. et al. Tensile properties of copper-nickel fine clad prepared by surface activation bonding and subsequent heat treatment. Electron. Mater. Lett. 9, 767–770 (2013). https://doi.org/10.1007/s13391-013-6005-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13391-013-6005-7