Abstract

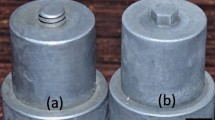

The solid-state friction stir welding is found to be popular for the joining of thermoplastic materials in different configurations. However, the process variables have to be precisely adjusted with proper selection of tool pin profile to achieve uniform longitudinal weld along the tool traversing direction. The axial thrust and tool stirring torque signals are often used for the process monitoring and associated weld quality prediction. The present work addresses the effect of swept ratio of tool pin contour on the degree of non-uniformity in lap weld profile and index of symmetries in weld bead shape with associated mechanical behavior in tensile–shear loading for polycarbonate sheets. The hexagonal tool pin was found to be the best in terms of stability in weld contour, flawless symmetric weld bead shape with the highest strength efficiency (75.4%) and improved joint ductility particularly at high tool revolving speed (2400 rpm). The input power signal along with thrust–torque signals have also been acquired during welding procedure that was found to be chief indicator of weld quality. The electrical power loss was significantly less at higher tool rotational speed by using this hexagonal tool pin. Thus, this time field power signal has been further analyzed in time–frequency wavelet domain to completely characterize the process variations with corresponding deviations in weld profile. The high-frequency power wavelets were found to be highly sensitive on the deviations in weld quality features though low-frequency power information mainly dictated the variations in weld bead profile.

Similar content being viewed by others

Abbreviations

- PC-PC:

-

Polycarbonate to polycarbonate lap

- CY, HX, SQ:

-

Cylindrical, hexagonal, and square pin profile

- S-ratio(r) :

-

Swept ratio

- N :

-

Tool rotational speed, rpm

- V :

-

Traverse speed, mm/min

- T :

-

Spindle torque, Nm

- F RMS :

-

Root mean square axial force, N

- T RMS :

-

Root mean square stirring torque, Nm

- P RMS :

-

Root mean square power, watt (W)

- σ ut :

-

Ultimate tensile strength, MPa

- ε f :

-

Elongation at fracture point, mm

- η joint :

-

Joint efficiency

- A ex :

-

Expelled area, mm2

- A SZ :

-

Stir zone area, mm2

- HAZ:

-

Heat-affected zone

- SZ:

-

Stir zone

- UZ:

-

Undercut zone

- P Mech :

-

Mechanical power, watt (W)

- F traverse :

-

Traverse force, N

- η Plunging :

-

Plunging efficiency, %

- η Welding :

-

Welding efficiency, %

- [AUZ]AS :

-

Undercut area in advancing side, mm2

- [AUZ]RS :

-

Undercut area in retracting side, mm2

- [ASZ]AS :

-

Stir zone area in advancing side, mm2

- [ASZ]RS :

-

Stir zone area in retracting side, mm2

- SIVSZ :

-

Symmetric index value for stir zone

- SIVUZ :

-

Symmetric index value undercut zone

- DWT:

-

Discrete wavelet transform

- CWT:

-

Continuous wavelet transform

- Db:

-

Daubechies

- w :

-

Wavelet function

- W :

-

Weld quality features

- S :

-

Sensor-based features

References

Eslami, S.; Miranda, J.F.; Mourão, L.; Tavares, P.J.; Moreira, P.M.G.P.: Polyethylene friction stir welding parameter optimization and temperature characterization. Int. J. Adv. Manuf. Technol. 99, 127–136 (2018). https://doi.org/10.1007/s00170-018-2504-x

Vinson, J.R.: T 1332. (1971)

Modarres, M.; Tahmasebipour, M.: Investigation of the effect of ultrasonic micro-welding process parameters on the microstructure components bonding. J. Braz. Soc. Mech. Sci. Eng. 44, 1–14 (2022). https://doi.org/10.1007/s40430-022-03614-8

Galińska, A.: Mechanical joining of fibre reinforced polymer composites to metals—a review. Part i: Bolted joining. Polymers 12, 1–48 (2020). https://doi.org/10.3390/polym12102252

Aghajani Derazkola, H.; Simchi, A.; Lambiase, F.: Friction stir welding of polycarbonate lap joints: relationship between processing parameters and mechanical properties. Polym. Testing 79, 105999 (2019). https://doi.org/10.1016/j.polymertesting.2019.105999

Sharma, A.K.R.; Roy Choudhury, M.; Debnath, K.: Experimental investigation of friction stir welding of PLA. Weld. World. 64, 1011–1021 (2020). https://doi.org/10.1007/s40194-020-00890-7

Shah, F.; Younas, M.; Khan, M.; Khan, A.; Khan, Z.; Khan, N.: Mechanical properties and weld characteristics of friction stir welding of thermoplastics using heat-assisted tool. Weld. World. 67, 309–323 (2023). https://doi.org/10.1007/s40194-022-01385-3

Singh, S.; Singh, G.; Prakash, C.; Kumar, R.: On the mechanical characteristics of friction stir welded dissimilar polymers: statistical analysis of the processing parameters and morphological investigations of the weld joint. J. Braz. Soc. Mech. Sci. Eng. 42, 1–12 (2020). https://doi.org/10.1007/s40430-020-2227-4

Nath, R.K.; Maji, P.; Barma, J.D.: Development of a Self-Heated Friction Stir Welding tool for welding of polypropylene sheets. J. Braz. Soc. Mech. Sci. Eng. 41, 1–13 (2019). https://doi.org/10.1007/s40430-019-2059-2

Sahu, S.K.; Mishra, D.; Pal, K.: A comparative study between weldability of polycarbonate and nylon-6 using different pin geometries in friction stir welding. Proc. Inst. Mech. Eng. Part B J Eng. Manuf. (2021). https://doi.org/10.1177/09544054211040705

Arici, A.; Selale, S.: Effects of tool tilt angle on tensile strength and fracture locations of friction stir welding of polyethylene. Sci. Technol. Weld. Join. 12, 536–539 (2007). https://doi.org/10.1179/174329307X173706

Arif, M.; Kumar, D.; Siddiquee, A.N.: Morphological and mechanical characterization of friction stir welded zones in acrylonitrile butadiene styrene (ABS) polymer. J. Mater. Eng. Perform. (2023). https://doi.org/10.1007/s11665-023-08402-6

Nath, R.K.; Maji, P.; Barma, J.D.: Joining of advance engineering thermoplastic using novel self-heated FSW Tool. Jom. 73, 1774–1785 (2021). https://doi.org/10.1007/s11837-021-04686-y

Kumar, S.; Roy, B.S.: A comparative analysis on friction stir welding of similar and dissimilar polymers: acrylonitrile butadiene styrene and polycarbonate plates. Weld. World. 66, 1141–1153 (2022). https://doi.org/10.1007/s40194-022-01294-5

Mert, S.; Arici, A.: Design of optimal joining for friction stir spot welding of polypropylene sheets. Sci. Technol. Weld. Join. 16, 522–527 (2011). https://doi.org/10.1179/1362171811Y.0000000034

Junior, W.S.; Handge, U.A.; dos Santos, J.F.; Abetz, V.; Amancio-Filho, S.T.: Feasibility study of friction spot welding of dissimilar single-lap joint between poly(methyl methacrylate) and poly(methyl methacrylate)-SiO2 nanocomposite. Mater. Des. 64, 246–250 (2014). https://doi.org/10.1016/j.matdes.2014.07.050

Kumar, R.; Singh, R.; Ahuja, I.P.S.; Hashmi, M.S.J.: Friction-stir-spot welding of 3D printed ABS and PA6 composites: flexural, thermal and morphological investigations. Adv. Mater. Process. Technol. 8, 909–916 (2022). https://doi.org/10.1080/2374068X.2020.1835014

Pattanaik, A.K.; Nayak, L.P.; Bisoyi, R.K.; Pal, K.; Mishra, D.: Monitoring of friction stirred spot weld quality for dissimilar Al6061 to polycarbonate using tool assisted thrust-torque signatures. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. (2023). https://doi.org/10.1177/09544062231173280

Sun, Y.; Sun, Y.; Zhang, Y.; Sun, Y.; Zou, L.; Yang, X.: Study on the thermal-assisted underwater friction stir lap welding for thermoplastic PC. Mater. Lett. 333, 133571 (2023). https://doi.org/10.1016/j.matlet.2022.133571

Derazkola, H.A.; Kashiry Fard, R.; Khodabakhshi, F.: Effects of processing parameters on the characteristics of dissimilar friction-stir-welded joints between AA5058 aluminum alloy and PMMA polymer. Weld. World. 62, 117–130 (2018). https://doi.org/10.1007/s40194-017-0517-y

Goswami, N.; Pal, K.: Comparative assessment on weldability of Al 6061 to polycarbonate for dissimilar sheets placement in friction stir lap welding using sensor signals. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 236, 3474–3496 (2022). https://doi.org/10.1177/09544062211042663

Yusof, F.; Miyashita, Y.; Seo, N.; Mutoh, Y.; Moshwan, R.: Utilising friction spot joining for dissimilar joint between aluminium alloy (A5052) and polyethylene terephthalate. Sci. Technol. Weld. Join. 17, 544–549 (2012). https://doi.org/10.1179/136217112x13408696326530

Ratanathavorn, W.; Melander, A.: Dissimilar joining between aluminium alloy (AA 6111) and thermoplastics using friction stir welding. Sci. Technol. Weld. Join. 20, 222–228 (2015). https://doi.org/10.1179/1362171814Y.0000000276

Shahmiri, H.; Movahedi, M.; Kokabi, A.H.: Friction stir lap joining of aluminium alloy to polypropylene sheets. Sci. Technol. Weld. Join. 22, 120–126 (2017). https://doi.org/10.1080/13621718.2016.1204171

Kumar, G.S.V.S.; Kumar, A.; Rajesh, S.; Chekuri, R.B.R.; Sundaramurthy, V.P.: Experimental and thermal investigation with optimization on friction stir welding of nylon 6A using Taguchi and microstructural analysis. Adv. Mech. Eng. 13, 1–14 (2021). https://doi.org/10.1177/16878140211050737

Bilici, M.K.; Yükler, A.I.; Kurtulmuş, M.: The optimization of welding parameters for friction stir spot welding of high density polyethylene sheets. Mater. Des. 32, 4074–4079 (2011). https://doi.org/10.1016/j.matdes.2011.03.014

Pirizadeh, M.; Azdast, T.; Rash Ahmadi, S.; Mamaghani Shishavan, S.; Bagheri, A.: Friction stir welding of thermoplastics using a newly designed tool. Mater. Des. 54, 342–347 (2014). https://doi.org/10.1016/j.matdes.2013.08.053

Rezaee Hajideh, M.; Farahani, M.; Alavi, S.A.D.; Molla Ramezani, N.: Investigation on the effects of tool geometry on the microstructure and the mechanical properties of dissimilar friction stir welded polyethylene and polypropylene sheets. J. Manuf. Process. 26, 269–279 (2017). https://doi.org/10.1016/j.jmapro.2017.02.018

Sadeghian, N.; Besharati Givi, M.K.: Experimental optimization of the mechanical properties of friction stir welded Acrylonitrile Butadiene Styrene sheets. Mater. Des. 67, 145–153 (2015). https://doi.org/10.1016/j.matdes.2014.11.032

Goswami, N.K.; Nayak, L.P.; Pal, K.: Investigation on tool positioning in friction stir lap welding of AA6061 to polycarbonate sheets using force-torque signals. J. Adhes. Sci. Technol. (2022). https://doi.org/10.1080/01694243.2022.2080963

Mishra, D.; Gupta, A.; Raj, P.; Kumar, A.; Anwer, S.; Pal, S.K.; Chakravarty, D.; Pal, S.; Chakravarty, T.; Pal, A.; Misra, P.; Misra, S.: Real time monitoring and control of friction stir welding process using multiple sensors. CIRP J. Manuf. Sci. Technol. 30, 1–11 (2020). https://doi.org/10.1016/j.cirpj.2020.03.004

Rabi, J.; Balusamy, T.; Raj Jawahar, R.: Analysis of vibration signal responses on pre induced tunnel defects in friction stir welding using wavelet transform and empirical mode decomposition. Defence Technol. 15, 885–896 (2019). https://doi.org/10.1016/j.dt.2019.05.014

Mishra, D.; Shree, S.; Gupta, A.; Priyadarshi, A.; Das, S.M.; Pal, S.K.; Chakravarty, D.; Pal, S.; Chattopadhyay, T.; Pal, A.: Weld defect localization in friction stir welding process. Weld. World. 65, 451–461 (2021). https://doi.org/10.1007/s40194-020-01028-5

Kumari, S.; Jain, R.; Kumar, U.; Yadav, I.; Ranjan, N.; Kumari, K.; Kesharwani, R.K.; Kumar, S.; Pal, S.; Pal, S.K.; Chakravarty, D.: Defect identification in friction stir welding using continuous wavelet transform. J. Intell. Manuf. 30, 483–494 (2019). https://doi.org/10.1007/s10845-016-1259-1

Das, B.; Pal, S.; Bag, S.: Weld defect identification in friction stir welding using power spectral density. IOP Conf. Ser. Mater. Sci. Eng. (2018). https://doi.org/10.1088/1757-899X/346/1/012049

Choi, W.J.; Morrow, J.D.; Pfefferkorn, F.E.; Zinn, M.R.: Welding parameter maps to help select power and energy consumption of friction stir welding. J. Manuf. Process. 33, 35–42 (2018). https://doi.org/10.1016/j.jmapro.2018.04.017

Cui, S.; Chen, Z.W.; Robson, J.D.: A model relating tool torque and its associated power and specific energy to rotation and forward speeds during friction stir welding/processing. Int. J. Mach. Tools Manuf 50, 1023–1030 (2010). https://doi.org/10.1016/j.ijmachtools.2010.09.005

Buffa, G.; Ingarao, G.; Campanella, D.; Di Lorenzo, R.; Micari, F.; Fratini, L.: An insight into the electrical energy demand of friction stir welding processes: the role of process parameters, material and machine tool architecture. Int. J. Adv. Manuf. Technol. 100, 3013–3024 (2019). https://doi.org/10.1007/s00170-018-2896-7

Kumar, U.; Yadav, I.; Kumari, S.; Kumari, K.; Ranjan, N.; Kesharwani, R.K.; Jain, R.; Kumar, S.; Pal, S.; Chakravarty, D.; Pal, S.K.: Defect identification in friction stir welding using discrete wavelet analysis. Adv. Eng. Softw. 85, 43–50 (2015). https://doi.org/10.1016/j.advengsoft.2015.02.001

Bhat, N.N.; Kumari, K.; Dutta, S.; Pal, S.K.; Pal, S.: Friction stir weld classification by applying wavelet analysis and support vector machine on weld surface images. J. Manuf. Process. 20, 274–281 (2015). https://doi.org/10.1016/j.jmapro.2015.07.002

Chen, C.; Kovacevic, R.; Jandgric, D.: Wavelet transform analysis of acoustic emission in monitoring friction stir welding of 6061 aluminum. Int. J. Mach. Tools Manuf 43, 1383–1390 (2003). https://doi.org/10.1016/S0890-6955(03)00130-5

Das, B.; Pal, S.; Bag, S.: A combined wavelet packet and Hilbert-Huang transform for defect detection and modelling of weld strength in friction stir welding process. J. Manuf. Process. 22, 260–268 (2016). https://doi.org/10.1016/j.jmapro.2016.04.002

Roy, R.B.; Ghosh, A.; Bhattacharyya, S.; Mahto, R.P.; Kumari, K.; Pal, S.K.; Pal, S.: Weld defect identification in friction stir welding through optimized wavelet transformation of signals and validation through X-ray micro-CT scan. Int. J. Adv. Manuf. Technol. 99, 623–633 (2018). https://doi.org/10.1007/s00170-018-2519-3

Barik, T.; Pal, K.: Prediction of drilled hole quality in bidirectional woven carbon fiber reinforced plastic using wavelet packets of force–torque signals. J. Reinf. Plast. Compos. 40, 800–826 (2021). https://doi.org/10.1177/07316844211011757

Barik, T.; Pal, K.: Prediction of TiAlN- and TiN-coated carbide tool wear in drilling of bidirectional CFRP laminates using wavelet packets of thrust–torque signatures. J. Braz. Soc. Mech. Sci. Eng. 44, 1–30 (2022). https://doi.org/10.1007/s40430-022-03673-x

Yildiz, M.; Ozturk, F.; Sheikh-ahmad, J.: A Comprehensive review on friction stir welding of high-density polyethylene. Arab. J. Sci. Eng. 48, 11167–11210 (2023). https://doi.org/10.1007/s13369-023-08048-5

Pattanaik, A.K.; Pradhan, S.; Panda, S.N.; Bagal, D.K.; Pal, K.; Patnaik, D.: Effect of process parameters on friction stir spot welding using grey based Taguchi methodology. Mater. Today Proc. 5, 12098–12102 (2018). https://doi.org/10.1016/j.matpr.2018.02.186

Chatterjee, S.; Chatterjee, R.; Pal, S.; Pal, K.; Pal, S.K.: Adaptive chirplet transform for sensitive and accurate monitoring of pulsed gas metal arc welding process. Int. J. Adv. Manuf. Technol. 60, 111–125 (2012). https://doi.org/10.1007/s00170-011-3597-7

Sahu, S.K.; Pal, K.; Das, S.: Parametric study on joint quality in friction stir welding of polycarbonate. Mater. Today Proc. 39, 1275–1280 (2020). https://doi.org/10.1016/j.matpr.2020.04.218

Acknowledgements

The authors extend their sincere thanks and heartfelt appreciation to the "Friction Stir Welding Laboratory" at the Department of Mechanical Engineering, IIT Kharagpur, and the Department of Production Engineering at Veer Surendra Sai University of Technology, Burla, for their invaluable contributions in conducting the welding experiment, as well as for their assistance in post-weld sample preparations and testing.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

This article has no conflict of interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Goswami, N.K., Pal, K., Bisoyi, R.K. et al. Monitoring of Weld Bead Profile in Friction Stir Lap Welding for Polycarbonate Sheets Using Wavelet Packets of Power Signal. Arab J Sci Eng (2024). https://doi.org/10.1007/s13369-024-09057-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13369-024-09057-8