Abstract

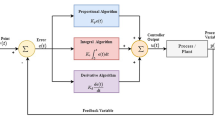

The coupled systems with numerous interdependent variables pose considerable control and stability issues in commercial chemical processes. These systems exhibit complex interactions, time delays, parameter uncertainties and disturbances, which can lead to poor performance and reduced productivity. Conventional single-loop controllers struggle to effectively manage the interactions between variables, leading to poor disturbance rejection and tracking accuracy. A more robust and efficient control strategy is essential to tackle these limitations. Hence, a robust decentralized PID controller design is proposed to address the shortcomings of coupled industrial chemical processes. The aim is to enhance control system performance by achieving better disturbance rejection and tracking accuracy, thereby improving process efficiency and product quality. The complementary sensitivity function is exploited to attain this, and a novel graphical tuning method is proposed for obtaining optimal PID controller parameters. The use of the \(H_\infty \) robust criterion ensures robust stability and minimizes the influence of external disturbances. The proposed approach offers an efficient means to design robust decentralized controllers for complex chemical processes. The simulation results demonstrate the effectiveness of the method compared to existing controllers. Numerically, the proposed controller is able to attain almost a 20\(\%\) reduction in integral absolute error and a 30\(\%\) decrease in the settling time for all cases compared to existing controllers. The graphical tuning method enables efficient parameter optimization, resulting in faster response times and reduced settling time. This work represents a significant step toward achieving enhanced control system performance and stability in coupled industrial chemical processes.

Similar content being viewed by others

Abbreviations

- MIMO:

-

Multi-input multi-output

- SISO:

-

Single-input single-output

- TITO:

-

Two-input two-output

- PID:

-

Proportional integral derivative

- PI:

-

Proportional integral

- FOPDT:

-

First-order plus dead time

- RHP:

-

Right half-plane

- \(h_{jj}\) :

-

Decoupled elements

- D(s):

-

Decoupling matrix

- C(s):

-

Controller

- \(\mathcal {K}_{\mathcal {P}}\) :

-

Proportional gain

- \(\mathcal {K}_{\mathcal {I}}\) :

-

Integral gain

- G :

-

Plant

- \(\mathcal {K}_{jj}\) :

-

Process gain

- \(\mathcal {T}_{jj}\) :

-

Effective dead time

- \(\Theta _{jj}\) :

-

Time constant

- \(\omega _{cjj}\) :

-

Phase crossover frequency

- \(\mathcal {W}_{\mathcal {T}}\) :

-

Multiplicative weight

- \(\mathcal {G}_{\delta }\) :

-

Perturbed plant

- \(\mathcal {T}(j\omega )\) :

-

Complimentary sensitivity function

- BLT:

-

Biggest logus tuning

- GB:

-

Gershgorin-based

- EOP:

-

Equivalent open loop

- ISP:

-

Industrial scale polymerization

- IAE:

-

Integral absolute error

- ITAE:

-

Integral time absolute error

- ISE:

-

Integral square error

- WB:

-

Wood and berry distillation

References

Mahapatro, S.R.; Subudhi, B.; Ghosh, S.: Design and experimental realization of a robust decentralized pi controller for a coupled tank system. ISA Trans. 89, 158–168 (2019). https://doi.org/10.1016/j.isatra.2018.12.003

Gao, S.; Hou, Y.; Dong, H.; Yue, Y.; Li, S.: Global nested pid control of strict-feedback nonlinear systems with prescribed output and virtual tracking performance. IEEE Trans. Circuits Syst. II Express Briefs 67(2), 325–329 (2019). https://doi.org/10.1109/TCSII.2019.2907141

Naik, R.H.; Kumar, D.V.A.; Rao, P.V.G.: Improved centralised control system for rejection of loop interaction in coupled tank system. Indian Chem. Eng. 62(2), 118–137 (2020). https://doi.org/10.1080/00194506.2019.1647800

Roy, P.; Roy, B.K.: Dual mode adaptive fractional order pi controller with feedforward controller based on variable parameter model for quadruple tank process. ISA Trans. 63, 365–376 (2016). https://doi.org/10.1016/j.isatra.2016.03.010

Bhookya, J.; Jatoth, R.K.: Fractional order pid controller design for multivariable systems using tlbo. Chem. Prod. Process. Model. 15(2), 20190061 (2019). https://doi.org/10.1515/cppm-2019-0061

Paliwal, N.; Srivastava, L.; Pandit, M.: Equilibrium optimizer tuned novel fopid-dn controller for automatic voltage regulator system. Int. Trans. Electr. Energy Syst. (2021). https://doi.org/10.1002/2050-7038.12930

Veerendar, T.; Kumar, D.; Sreeram, V.: Fractional-order pid and internal model control-based dual-loop load frequency control using teaching-learning optimization. Asian J. Control (2023). https://doi.org/10.1002/asjc.3022

Dey, S.; Banerjee, S.; Dey, J.: Practical application of fractional-order pid controller based on evolutionary optimization approach for a magnetic levitation system. IETE J. Res. (2022). https://doi.org/10.1080/03772063.2022.2052983

Liu, L.; Tian, S.; Xue, D.; Zhang, T.; Chen, Y.Q.; Zhang, S.: A review of industrial mimo decoupling control. Int. J. Control Autom. Syst. 17(5), 1246–1254 (2019). https://doi.org/10.1007/s12555-018-0367-4

Govind K.R.A.; Mahapatra, S.; Mahapatro, S.R.: A comparative analysis of various decoupling techniques using frequency domain specifications. In: 2023 3rd International Conference on Artificial Intelligence and Signal Processing (AISP), pp. 1–6. IEEE (2023)

Kozáková, A.; Veselỳ, V.; Kučera, V.: Robust decentralized controller design based on equivalent subsystems. Automatica 107, 29–35 (2019). https://doi.org/10.1016/j.automatica.2019.05.031

Mahapatro, S.R.; Subudhi, B.; Ghosh, S.: Design of a robust optimal decentralized pi controller based on nonlinear constraint optimization for level regulation: An experimental study. IEEE/CAA J. Automatica Sinica 7(1), 187–199 (2019). https://doi.org/10.1109/JAS.2019.1911516

Javadian, A.; Nariman-zadeh, N.; Jamali, A.: Evolutionary design of marginally robust multivariable pid controller. Eng. Appl. Artif. Intell. 121, 105938 (2023). https://doi.org/10.1016/j.engappai.2023.105938

Bejarano-Rincón, A.; Estrada, A.; Herrera-Hernández, E.C.; Alvarado-Orozco, J.M.: Control design for a class of multivariable nonlinear system with uncertain control direction: a laser cladding case study. Eur. J. Control 60, 114–124 (2021). https://doi.org/10.1016/j.ejcon.2021.04.007

Yousfi, M.; Njima, C.B.; Garna, T.: Decentralized robust control of nonlinear uncertain multivariable systems. Arab. J. Sci. Eng. 46, 9899–9924 (2021). https://doi.org/10.1007/s13369-021-05435-8

Khandelwal, S.; Detroja, K.P.: The optimal detuning approach based centralized control design for mimo processes. J. Process Control 96, 23–36 (2020). https://doi.org/10.1016/j.jprocont.2020.10.006

Özer, S.M.; İftar, A.: Eigenvalue optimisation-based centralised and decentralised stabilisation of time-delay systems. Int. J. Control 95(8), 2245–2266 (2022). https://doi.org/10.1080/00207179.2021.1906446

Borase, R.P.; Maghade, D.K.; Sondkar, S.Y.; Pawar, S.N.: A review of pid control, tuning methods and applications. Int. J. Dyn. Control 9, 818–827 (2021). https://doi.org/10.1007/s40435-020-00665-4

Rodríguez-Molina, A.; Mezura-Montes, E.; Villarreal-Cervantes, M.G.; Aldape-Pérez, M.: Multi-objective meta-heuristic optimization in intelligent control: a survey on the controller tuning problem. Appl. Soft Comput. 93, 106342 (2020). https://doi.org/10.1016/j.asoc.2020.106342

Govind, K.R.A.; Mahapatra, S.: Frequency domain specifications based robust decentralized pi/pid control algorithm for benchmark variable-area coupled tank systems. Sensors 22(23), 9165 (2022)

Govind, K.R.A.; Mahapatra, S.; Mahapatro, S.R.: Design of an optimal control strategy for coupled tank systems using nonlinear constraint optimization with Kharitonov–Hurwitz stability analysis. IEEE Access 11, 72618–72629 (2023)

Euzebio, T.A.M.; Yamashita, A.S.; Pinto, T.V.B.; Barros, P.R.: Siso approaches for linear programming based methods for tuning decentralized pid controllers. J. Process Control 94, 75–96 (2020). https://doi.org/10.1016/j.jprocont.2020.08.004

Le, B.N.; Nie, Z.-Y.; Wang, Q.-G.: Parametric approach to computing stabilizing proportional-integral-derivative regions. Trans. Inst. Meas. Control. 41(1), 165–181 (2019). https://doi.org/10.1177/0142331218757863

Wang, H.; Liu, W.; Qiu, J.; Liu, P.X.: Adaptive fuzzy decentralized control for a class of strong interconnected nonlinear systems with unmodeled dynamics. IEEE Trans. Fuzzy Syst. 26(2), 836–846 (2017). https://doi.org/10.1109/TFUZZ.2017.2694799

Mercader, P.; Åström, K.J.; Baños, A.; Hägglund, T.: Robust pid design based on qft and convex–concave optimization. IEEE Trans. Control Syst. Technol. 25(2), 441–452 (2016). https://doi.org/10.1109/TCST.2016.2562581

Mahapatro, S.R.; Subudhi, B.: A robust stability region-based decentralized pi controller for a multivariable liquid level system. IEEE Syst. J. 16(1), 124–131 (2021). https://doi.org/10.1109/JSYST.2021.3079293

Feng, Z.-Y.; Guo, H.; She, J.; Li, X.: Weighted sensitivity design of multivariable pid controllers via a new iterative lmi approach. J. Process Control 110, 24–34 (2022). https://doi.org/10.1016/j.jprocont.2021.11.016

Chu, M.: Imc-pid tuning method based on maximum sensitivity for uncertain multivariable systems. Int. J. Robust Nonlinear Control (2023). https://doi.org/10.1002/rnc.6757

Kalim, Md.; Imran; Ali, A.: Maximum sensitivity constrained graphical controller tuning for a dc-dc boost converter loaded with a cpl. IEEE Trans. Ind. Electron. 99, 1–9 (2023)

Alyoussef, F.; Kaya, I.: Simple pi-pd tuning rules based on the centroid of the stability region for controlling unstable and integrating processes. ISA Trans. 134, 238–255 (2023). https://doi.org/10.1016/j.isatra.2022.08.007

Li, X.; Gao, L.: A simple frequency-domain tuning method of fractional-order pid controllers for fractional-order delay systems. Int. J. Control Autom. Syst. 20(7), 2159–2168 (2022). https://doi.org/10.1007/s12555-021-0206-x

Govind K.R., Achu; Mahapatra, Subhasish: Design of decentralized pi/pid control algorithm for a benchmark continuously stirred tank reactor system using frequency domain specifications. Int. J. Modelling, Identif. Control 43(4), (2023)

Hägglund, T.; Shinde, S.; Theorin, A.; Thomsen, U.: An industrial control loop decoupler for process control applications. Control. Eng. Pract. 123, 105138 (2022). https://doi.org/10.1016/j.conengprac.2022.105138

Chu, H.; Yue, D.; Dou, C.; Chu, L.: Adaptive pi control for consensus of multiagent systems with relative state saturation constraints. IEEE Trans. Cybern. 51(4), 2296–2302 (2019). https://doi.org/10.1109/TCYB.2019.2954955

Wang, Q.-G.; Ye, Z.; Cai, W.-J.; Hang, C.-C.: PID Control for Multivariable Processes. Springer, New York (2008). https://doi.org/10.1007/978-3-540-78482-1

Srikanth, M.V.; Yadaiah, N.: Analytical tuning rules for reduced-order active disturbance rejection control with fopdt models through multi-objective optimization and multi-criteria decision-making. ISA Trans. 114, 370–398 (2021). https://doi.org/10.1016/j.isatra.2020.12.035

Govind K.R., Achu; Mahapatra, Subhasish: Design of pi/pid control algorithm for a benchmark heat exchanger system using frequency domain specifications. In: 2022 IEEE International Power and Renewable Energy Conference (IPRECON), pp. 1–5. IEEE (2022)

Govind, K.R.A.; Mahapatra, S.; Mahapatro, S.R.: Nonlinear constraint optimization based robust decentralized pid controller for a benchmark cstr system using Kharitonov-Hurwitz stability analysis. Arab. J. Sci. Eng. (2023). https://doi.org/10.1007/s13369-023-08076-1

Euzébio, T.A.M.; Da Silva, M.T.; Yamashita, A.S.: Decentralized pid controller tuning based on nonlinear optimization to minimize the disturbance effects in coupled loops. IEEE Access 9, 156857–156867 (2021). https://doi.org/10.1109/ACCESS.2021.3127795

Naik, R.H.; Kumar, D.V.A.; Sujatha, P.: Independent controller design for mimo processes based on extended simplified decoupler and equivalent transfer function. Ain Shams Eng. J. 11(2), 343–350 (2020). https://doi.org/10.1016/j.asej.2017.10.011

Garrido, J.; Ruz, M.L.; Morilla, F.; Vázquez, F.: Iterative method for tuning multiloop pid controllers based on single loop robustness specifications in the frequency domain. Processes 9(1), 140 (2021)

Chuong, V.L.; Vu, T.N.L.; Truong, N.T.N.; Jung, J.H.: An analytical design of simplified decoupling smith predictors for multivariable processes. Appl. Sci. 9(12), 2487 (2019). https://doi.org/10.3390/app9122487

Garrido, J.; Vázquez, F.; Morilla, F.; Normey-Rico, J.E.: Smith predictor with inverted decoupling for square multivariable time delay systems. Int. J. Syst. Sci. 47(2), 374–388 (2016). https://doi.org/10.1080/00207721.2015.1067338

Gomathy, V.; Singh, T.; Nasir, A.W.; Devi, E.; Shiny, M.: Non integer order pid controller tuning using grey wolf optimization methodfor sea water reverse osmosis desalination process. Int. J. Control Autom. 13, 282–291 (2020)

Mahadeva, R.; Kumar, M.; Patole, S.P.; Manik, G.: Pid control design using agpso technique and its application in tito reverse osmosis desalination plant. IEEE Access 10, 125881–125892 (2022). https://doi.org/10.1109/ACCESS.2022.3224127

Author information

Authors and Affiliations

Contributions

The authors contributed equally to this work.

Corresponding author

Ethics declarations

conflict of interest

There is no conflict of interest in this work.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Govind, K.R.A., Mahapatra, S. & Mahapatro, S.R. An \(H_\infty \) Robust Decentralized PID Controller Design for Multi-Variable Chemical Processes Using Loop Shaping Technique. Arab J Sci Eng 49, 6587–6611 (2024). https://doi.org/10.1007/s13369-023-08348-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-023-08348-w