Abstract

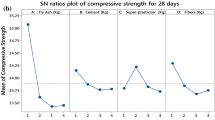

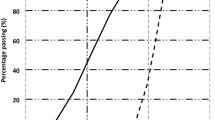

This research aims to develop a sustainable approach for selecting fiber-reinforced synthetic aggregate concrete (FRSAC) through experiments employing the Taguchi method and multi-criteria decision-making (MCDM) techniques. This study examined the fresh and mechanical behavior, as well as considering the environmental, and economic characteristics of FRSAC theoretically to determine the most environmentally friendly concrete, which may be suitable for various types of applications in concrete. The Taguchi optimization technique considered four functional parameters: binder content, water-to-cement ratio, fiber dosage, and synthetic aggregate replacement in three levels. Synthetic aggregates were manufactured from industrial byproducts in various geometries that may have enhanced aggregate mechanical properties compared to natural aggregates. Using multi-criteria decision-making technique, namely Technique of Ordering Preferences by Similarity to Ideal Solution (TOPSIS), a robust framework was developed and analyzed for FRSAC based on four performance factors including fresh (workability), mechanical (compressive and split tensile strength), and durability (water absorption) properties. Mechanical behavior of FRSAC has been assigned higher weightage in the first case, and the combination of fresh and durability behavior of the FRSAC in second case. In this study, a TOPSIS analysis was conducted in two instances using varying weights to optimize the proportions of fiber-reinforced synthetic aggregates in concrete. The optimal mix (OM1) has resulted in a maximum compressive strength of 55.12 MPa and split tensile strength of 5.50 MPa. Similarly, the optimal mix (OM2) resulted in higher workability of 90 mm and lower water absorption of 3.92%. The anticipated results of the optimal blends were experimentally confirmed. The obtained experimental results have been supported by microstructure analysis of the control and optimal mixes (scanning electron microscopy and X-ray diffraction).

Similar content being viewed by others

Abbreviations

- OPC:

-

Ordinary Portland cement

- GGBFS:

-

Ground granulated blast furnace slag

- MK:

-

Metakaolin

- LP:

-

Lime powder

- SCM:

-

Supplementary cementitious materials

- SP:

-

Superplasticizer

- PPF:

-

Polypropylene fibers

- W/C:

-

Water-to-cement ratio

- SSD:

-

Saturated surface dry

- CM:

-

Control mixture

- OM:

-

Optimized mixture

- MCDM:

-

Multi-criteria decision-making

- TOPSIS:

-

Technique of Ordering Preferences by Similarity to Ideal Solution

- OA:

-

Orthogonal array

- ANOVA:

-

Analysis of variance

- S/N ratio:

-

Signal-to-noise ratio

- NAC:

-

Natural aggregate concrete

- SAC:

-

Synthetic aggregate concrete

- FRSAC:

-

Fiber-reinforced synthetic aggregate concrete

- NA:

-

Natural aggregates

- SA:

-

Synthetic aggregates

- C–S–H:

-

Calcium silicate hydrate

- C–A–H:

-

Calcium aluminate hydrate

- CH:

-

Calcium hydroxide

- SEM:

-

Scanning electron microscope

- EDX:

-

Energy-dispersive X-ray spectroscopy

- XRD:

-

X-ray diffraction

- RMR:

-

Raw material ratio

References

Dong, B.; Chen, C.; Wei, G.; Fang, G.; Wu, K.; Wang, Y.: Fly ash-based artificial aggregates synthesized through alkali-activated cold-bonded pelletization technology. Constr. Build. Mater. 344, 128268 (2022). https://doi.org/10.1016/j.conbuildmat.2022.128268

Alqarni, A.S.; Albidah, A.; Abbas, H.; Almusallam, T.; Al-Salloum, Y.: Concrete performance produced using recycled construction and by-product industrial waste coarse aggregates. Materials (Basel). (2022). https://doi.org/10.3390/ma15248985

Risdanareni, P.; Schollbach, K.; Wang, J.; De Belie, N.: The effect of NaOH concentration on the mechanical and physical properties of alkali activated fly ash-based artificial lightweight aggregate. Constr. Build. Mater. 259, 119832 (2020). https://doi.org/10.1016/j.conbuildmat.2020.119832

Xu, L.Y.; Qian, L.P.; Huang, B.T.; Dai, J.G.: Development of artificial one-part geopolymer lightweight aggregates by crushing technique. J. Clean. Prod. 315, 128200 (2021). https://doi.org/10.1016/j.jclepro.2021.128200

Agrawal, U.S.; Wanjari, S.P.; Naresh, D.N.: Impact of replacement of natural river sand with geopolymer fly ash sand on hardened properties of concrete. Constr. Build. Mater. 209, 499–507 (2019). https://doi.org/10.1016/j.conbuildmat.2019.03.134

Qian, L.P.; Xu, L.Y.; Alrefaei, Y.; Wang, T.; Ishida, T.; Dai, J.G.: Artificial alkali-activated aggregates developed from wastes and by-products: a state-of-the-art review. Resour. Conserv. Recycl. 177, 105971 (2022). https://doi.org/10.1016/j.resconrec.2021.105971

Jian, S.M.; Wu, B.; Hu, N.: Environmental impacts of three waste concrete recycling strategies for prefabricated components through comparative life cycle assessment. J. Clean. Prod. (2021). https://doi.org/10.1016/j.jclepro.2021.129463

Singh Chouhan, H.; Kalla, P.; Nagar, R.; Kumar Gautam, P.: Influence of dimensional stone waste on mechanical and durability properties of mortar: a review. Constr. Build. Mater. 227, 116662 (2019). https://doi.org/10.1016/j.conbuildmat.2019.08.043

Souza, M.M.; Anjos, M.A.S.; Sá, M.V.V.A.; Souza, N.S.L.: Developing and classifying lightweight aggregates from sewage sludge and rice husk ash. Case Stud. Constr. Mater. 12, e00340 (2020). https://doi.org/10.1016/j.cscm.2020.e00340

Ul Rehman, M.; Rashid, K.; Ul Haq, E.; Hussain, M.; Shehzad, N.: Physico-mechanical performance and durability of artificial lightweight aggregates synthesized by cementing and geopolymerization. Constr. Build. Mater. 232, 117290 (2020). https://doi.org/10.1016/j.conbuildmat.2019.117290

Vignesh, R.: New insights into the production of sustainable synthetic aggregates and their microstructural evaluation. 73, (2023)

Assi, L.N.; Deaver, E.; Elbatanouny, M.K.; Ziehl, P.: Investigation of early compressive strength of fly ash-based geopolymer concrete. Constr. Build. Mater. 112, 807–815 (2016). https://doi.org/10.1016/j.conbuildmat.2016.03.008

Campos, H.F.; Klein, N.S.; Marques Filho, J.: Proposed mix design method for sustainable high-strength concrete using particle packing optimization. J. Clean. Prod. 265, 121907 (2020). https://doi.org/10.1016/j.jclepro.2020.121907

Upshaw, M.; Cai, C.S.: Feasibility study of MK-based geopolymer binder for RAC applications: effects of silica fume and added CaO on compressive strength of mortar samples. Case Stud. Constr. Mater. 14, e00500 (2021). https://doi.org/10.1016/j.cscm.2021.e00500

Uğurlu, A.İ; Karakoç, M.B.; Özcan, A.: Effect of binder content and recycled concrete aggregate on freeze-thaw and sulfate resistance of GGBFS based geopolymer concretes. Constr. Build. Mater. (2021). https://doi.org/10.1016/j.conbuildmat.2021.124246

Ganesh, A.C.; Muthukannan, M.: Development of high performance sustainable optimized fiber reinforced geopolymer concrete and prediction of compressive strength. J. Clean. Prod. 282, 124543 (2021). https://doi.org/10.1016/j.jclepro.2020.124543

Authority, C.E.: Report on fly ash generation at coal/lignite based thermal power stations and its utilization in the country for the year 2014–15. Cent. Electr. Auth. New Delhi. 1–50 (2016)

Sakulich, A.R.: Reinforced geopolymer composites for enhanced material greenness and durability. Sustain. Cities Soc. 1, 195–210 (2011). https://doi.org/10.1016/j.scs.2011.07.009

Berndt, M.L.: Properties of sustainable concrete containing fly ash, slag and recycled concrete aggregate. Constr. Build. Mater. 23, 2606–2613 (2009). https://doi.org/10.1016/j.conbuildmat.2009.02.011

Kamath, M.; Prashant, S.; Kumar, M.: Micro-characterisation of alkali activated paste with fly ash-GGBS-metakaolin binder system with ambient setting characteristics. Constr. Build. Mater. 277, 122323 (2021). https://doi.org/10.1016/j.conbuildmat.2021.122323

Huseien, G.F.; Mirza, J.; Ismail, M.; Ghoshal, S.K.; Ariffin, M.A.M.: Effect of metakaolin replaced granulated blast furnace slag on fresh and early strength properties of geopolymer mortar. Ain Shams Eng. J. 9, 1557–1566 (2018). https://doi.org/10.1016/j.asej.2016.11.011

Vignesh, R.; Rahim, A.A.: Mechanical and microstructural properties of quaternary binder system containing OPC-GGBS-Metakaolin-Lime. Mater. Today Proc. 64, 970–975 (2022). https://doi.org/10.1016/j.matpr.2022.05.074

Nepomuceno, M.C.S.; Pereira-De-Oliveira, L.A.; Lopes, S.M.R.; Franco, R.M.C.: Maximum coarse aggregate’s volume fraction in self-compacting concrete for different flow restrictions. Constr. Build. Mater. 113, 851–856 (2016). https://doi.org/10.1016/j.conbuildmat.2016.03.143

Poon, C.S.; Kou, S.C.; Lam, L.: Use of recycled aggregates in molded concrete bricks and blocks. Constr. Build. Mater. 16, 281–289 (2002). https://doi.org/10.1016/S0950-0618(02)00019-3

Talamona, D.; Hai Tan, K.: Properties of recycled aggregate concrete for sustainable urban built environment. J. Sustain. Cem. Mater. 1, 202–210 (2012). https://doi.org/10.1080/21650373.2012.754571

Satpathy, H.P.; Patel, S.K.; Nayak, A.N.: Development of sustainable lightweight concrete using fly ash cenosphere and sintered fly ash aggregate. Constr. Build. Mater. 202, 636–655 (2019). https://doi.org/10.1016/j.conbuildmat.2019.01.034

Ali, B.; Qureshi, L.A.: Influence of glass fibers on mechanical and durability performance of concrete with recycled aggregates. Constr. Build. Mater. 228, 116783 (2019). https://doi.org/10.1016/j.conbuildmat.2019.116783

Dong, J.F.; Wang, Q.Y.; Guan, Z.W.: Material properties of basalt fibre reinforced concrete made with recycled earthquake waste. Constr. Build. Mater. 130, 241–251 (2017). https://doi.org/10.1016/j.conbuildmat.2016.08.118

Das, C.S.; Dey, T.; Dandapat, R.; Mukharjee, B.B.; Kumar, J.: Performance evaluation of polypropylene fibre reinforced recycled aggregate concrete. Constr. Build. Mater. 189, 649–659 (2018). https://doi.org/10.1016/j.conbuildmat.2018.09.036

da Silva Alves, L.C.; dos Reis Ferreira, R.A.; Bellini Machado, L.; de Castro Motta, L.A.: Optimization of metakaolin-based geopolymer reinforced with sisal fibers using response surface methology. Ind. Crops Prod. (2019). https://doi.org/10.1016/j.indcrop.2019.111551

Sultana, N.; Hossain, S.M.Z.; Alam, M.S.; Hashish, M.M.A.; Islam, M.S.: An experimental investigation and modeling approach of response surface methodology coupled with crow search algorithm for optimizing the properties of jute fiber reinforced concrete. Constr. Build. Mater. 243, 118216 (2020). https://doi.org/10.1016/j.conbuildmat.2020.118216

Qureshi, L.A.; Ali, B.; Ali, A.: Combined effects of supplementary cementitious materials (silica fume, GGBS, fly ash and rice husk ash) and steel fiber on the hardened properties of recycled aggregate concrete. Constr. Build. Mater. 263, 120636 (2020). https://doi.org/10.1016/j.conbuildmat.2020.120636

Liu, Z.; Yuan, X.; Zhao, Y.; Chew, J.W.; Wang, H.: Concrete waste-derived aggregate for concrete manufacture. J. Clean. Prod. 338, 130637 (2022). https://doi.org/10.1016/j.jclepro.2022.130637

Hossain, F.M.Z.; Shahjalal, M.; Islam, K.; Tiznobaik, M.; Alam, M.S.: Mechanical properties of recycled aggregate concrete containing crumb rubber and polypropylene fiber. Constr. Build. Mater. 225, 983–996 (2019). https://doi.org/10.1016/j.conbuildmat.2019.07.245

Teimortashlu, E.; Dehestani, M.; Jalal, M.: Application of Taguchi method for compressive strength optimization of tertiary blended self-compacting mortar. Constr. Build. Mater. 190, 1182–1191 (2018). https://doi.org/10.1016/j.conbuildmat.2018.09.165

Panagiotopoulou, C.; Tsivilis, S.; Kakali, G.: Application of the Taguchi approach for the composition optimization of alkali activated fly ash binders. Constr. Build. Mater. 91, 17–22 (2015). https://doi.org/10.1016/j.conbuildmat.2015.05.005

Dave, S.V.; Bhogayata, A.; Arora, N.K.: Mix design optimization for fresh, strength and durability properties of ambient cured alkali activated composite by Taguchi method. Constr. Build. Mater. 284, 122822 (2021). https://doi.org/10.1016/j.conbuildmat.2021.122822

Ozbay, E.; Oztas, A.; Baykasoglu, A.; Ozbebek, H.: Investigating mix proportions of high strength self compacting concrete by using Taguchi method. Constr. Build. Mater. 23, 694–702 (2009). https://doi.org/10.1016/j.conbuildmat.2008.02.014

Güneyisi, E.; Gesoǧlu, M.; Algin, Z.; Mermerdaş, K.: Optimization of concrete mixture with hybrid blends of metakaolin and fly ash using response surface method. Compos. Part B Eng. 60, 707–715 (2014). https://doi.org/10.1016/j.compositesb.2014.01.017

Li, Q.; Cai, L.; Fu, Y.; Wang, H.; Zou, Y.: Fracture properties and response surface methodology model of alkali-slag concrete under freeze-thaw cycles. Constr. Build. Mater. 93, 620–626 (2015). https://doi.org/10.1016/j.conbuildmat.2015.06.037

Bektas, F.; Bektas, B.A.: Analyzing mix parameters in ASR concrete using response surface methodology. Constr. Build. Mater. 66, 299–305 (2014). https://doi.org/10.1016/j.conbuildmat.2014.05.055

Mohammed, B.S.; Fang, O.C.; Anwar Hossain, K.M.; Lachemi, M.: Mix proportioning of concrete containing paper mill residuals using response surface methodology. Constr. Build. Mater. 35, 63–68 (2012). https://doi.org/10.1016/j.conbuildmat.2012.02.050

Awolusi, T.F.; Oke, O.L.; Akinkurolere, O.O.; Sojobi, A.O.: Application of response surface methodology: predicting and optimizing the properties of concrete containing steel fibre extracted from waste tires with limestone powder as filler. Case Stud. Constr. Mater. (2019). https://doi.org/10.1016/j.cscm.2018.e00212

El-mir, A.: Development and optimization of geopolymers made with desert dune sand and blast furnace slag (2022)

El-mir, A.; Hwalla, J.; El-hassan, H.; Assaad, J.J.; El-dieb, A.: Valorization of waste perlite powder in geopolymer composites. Constr. Build. Mater. 368, 130491 (2023). https://doi.org/10.1016/j.conbuildmat.2023.130491

Chokkalingam, P.; El-hassan, H.; El-dieb, A.: Multi-response optimization of ceramic waste geopolymer concrete using BWM and TOPSIS- based taguchi methods. J. Mater. Res. Technol. 21, 4824–4845 (2022). https://doi.org/10.1016/j.jmrt.2022.11.089

Tansel, Y.; Emir, H.Ş: A TOPSIS-based Taguchi optimization to determine optimal mixture proportions of the high strength self-compacting concrete. Chemometr. Intell. Lab. Syst. 125, 18–32 (2013). https://doi.org/10.1016/j.chemolab.2013.03.012

Uygunog, T.: Multi-response optimization of polymer blended concrete: a TOPSIS based Taguchi application ß ims. Materials 117, 251–262 (2016). https://doi.org/10.1016/j.conbuildmat.2016.05.027

Slebi-acevedo, C.J.; Pascual-muñoz, P.; Lastra-gonz, P.; Castro-fresno, D.: Multi-response optimization of porous asphalt mixtures reinforced with aramid and polyolefin fibers employing the CRITIC-TOPSIS based on Taguchi methodology. Materials 12(22), 3789 (2019)

Anwar, F.H.; El-hassan, H.; Hamouda, M.; El-mir, A.; Mohammed, S.: Optimization of pervious geopolymer concrete using TOPSIS-based Taguchi method. Sustainability 14(14), 8767 (2022)

Barı, H.K.; Yarta, A.: A TOPSIS-based Taguchi design to investigate optimum mixture proportions of graphene oxide powder synthesized by hummers method. Arab. J. Sci. Eng. (2018). https://doi.org/10.1007/s13369-018-3184-4

Çakır, Ö.; Dilbas, H.: Durability properties of treated recycled aggregate concrete: effect of optimized ball mill method. Constr. Build. Mater. (2021). https://doi.org/10.1016/j.conbuildmat.2020.121776

Rashid, K.; Rehman, M.U.; de Brito, J.; Ghafoor, H.: Multi-criteria optimization of recycled aggregate concrete mixes. J. Clean. Prod. (2020). https://doi.org/10.1016/j.jclepro.2020.124316

United, T.H.E.; Of, S.: By Authority Of. ASTM C150 Stand. Specif. fot Portl. Cem. 552, 203 (1997)

ASTM C989: Standard Specification for Ground Granulated Blast-Furnace Slag for Use in Concrete and Mortars. ASTM International i, 2–6 (2005)

ASTM C 618: Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete, ASTM International, West Conshohocken, PA, 2012, www.astm.org. ASTM Int. 1–5 (2014). Doi: https://doi.org/10.1520/C0618

Documents, R., Variations, P., Analyses, R., Analyses, O., Preparation, S., Procedures, G., Methods, R.T., Residue, I., Dioxide, S., Group, A.H., Oxide, F., Pentoxide, P., Dioxide, T., Oxide, Z., Oxide, A., Oxide, C., Oxide, M.: Standard Test Methods for Chemical Analysis of Hydraulic Cement 1 Reproduction authorized per License Agreement with Kathe Hooper. 1–32 (2006)

C128 − 15.pdf

American Society for Testing and Materials: ASTM C 33–99a : Standard Specification for Concrete Aggregates. Annu. B. ASTM Standard i, 1–11 (2010)

Astm:C29/C29M-09: Standard Test Method for Bulk Density (“Unit Weight ”) and Voids in Aggregate. ASTM International, 1–5 (2009). https://doi.org/10.1520/C0029

American Society for Testing and Materials: ASTM C127–15: Standard Test Method for Density, Relative Density ( Specific Gravity ), and Absorption of Coarse Aggregate. ASTM Stand. B. 1–6 (2013)

ASTM C-136: Astm C136. Annu. B. ASTM Stand. i, 1–5 (2014). https://doi.org/10.1520/C0136

BS-812-Part-110-1990-Determine-Aggregate-Crushing-Value.pdf

BS812–112: Impact value Testing aggregates. Br. Stand. Institution. (1990)

ASTM International: C131/C131M-14 Standard Test Method for Resistance to Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in the Los Angeles Machine. Annu. B. Am. Soc. Test. Mater. ASTM Stand. Conshohocken, USA, 04, 5–8 (2014). https://doi.org/10.1520/C0131

ASTM International: Test method for soundness of aggregates by use of sodium sulfate or magnesium sulfate. Annu. B. Am. Soc. Test. Mater. ASTM Stand. Conshohocken, USA, 04, 1–5 (1999). https://doi.org/10.1520/C0088

ASTM C 457/C 457M-12: Standard Test Method for Microscopical Determination of Parameters of the Air-Void System in Hardened Concrete 1. ASTM International 05, 1–15 (2013)

ASTM C305: Standard Practice for Mechanical Mixing of Hydraulic Cement Pastes and Mortars of Plastic Consistency. ASTM International 1–3 (2011)

ASTM: Astm C330. Standard Specification for Lightweight Aggregates for Structural Concrete 04, 3–6 (2000). Doi: https://doi.org/10.1520/C0330

Zhao, H.; Sun, W.; Wu, X.; Gao, B.: The properties of the self-compacting concrete with fly ash and ground granulated blast furnace slag mineral admixtures. J. Clean. Prod. 95, 66–74 (2015). https://doi.org/10.1016/j.jclepro.2015.02.050

Bouali, A.; Grairia, S.; Nettour, D.; Chérait, Y.; Arabi, N.; Montagne, A.; Iost, A.; Chicot, D.: Instrumented indentation based methods to assess fracture toughness (KIC) of self-compacting concrete: influence of water to binder (w/b) ratio and type of concrete. Eng. Fract. Mech. (2022). https://doi.org/10.1016/j.engfracmech.2022.108796

Fallah, S.; Nematzadeh, M.: Mechanical properties and durability of high-strength concrete containing macro-polymeric and polypropylene fibers with nano-silica and silica fume. Constr. Build. Mater. 132, 170–187 (2017). https://doi.org/10.1016/j.conbuildmat.2016.11.100

Mo, L.; Yang, S.; Huang, B.; Xu, L.; Feng, S.; Deng, M.: Preparation, microstructure and property of carbonated artificial steel slag aggregate used in concrete. Cem. Concr. Compos. (2020). https://doi.org/10.1016/j.cemconcomp.2020.103715

ASTM: C 143/C 143M – 03 Standard Test Method for Slump of Hydraulic-Cement Concrete. Annu. B. ASTM Stand. 1–4 (2003)

ASTM C873/C873M-10: Standard Test Method for Compressive Strength of Concrete Cylinders Cast in Place in Cylindrical Molds, ASTM International, West Conshohocken, PA, 2010, www.astm.org. 65, 1–4 (2010)

American Society for Testing and Materials: Astm C39/C39M. Standard Test Method Compressive Strength Cylind. Concr. Specimens. 04, 1–5 (2001)

ASTM International: Astm C496/C496M. ASTM Standard B. 545–545–3 (2008)

Test, C.C., Drilled, T., Ag-, C., Test, C.C., Concrete, H., Mass, D.: Astm C1585–5. Stand. Test Method Meas. Rate Absorpt. Water by Hydraul. Cem. Concr. 41, 1–6 (2018). Doi: https://doi.org/10.1520/C1585-13.2

Avşar, Y.E.; Cihan, M.T.: Multi-response optimization of mechanical properties of alkali-activated mortars. Arab. J. Sci. Eng. (2023). https://doi.org/10.1007/s13369-023-07957-9

Zhang, Y.; Sun, X.; Zhu, X.; Xiao, J.: Multi-criteria optimization of concrete mixes incorporating cenosphere waste and multi-minerals. J. Clean. Prod. (2022). https://doi.org/10.1016/j.jclepro.2022.133102

Alqahtani, F.K.; Ghataora, G.; Dirar, S.; Khan, M.I.; Zafar, I.: Experimental study to investigate the engineering and durability performance of concrete using synthetic aggregates. Constr. Build. Mater. 173, 350–358 (2018). https://doi.org/10.1016/j.conbuildmat.2018.04.018

Verian, K.P.; Ashraf, W.; Cao, Y.: Properties of recycled concrete aggregate and their influence in new concrete production. Resour. Conserv. Recycl. 133, 30–49 (2018). https://doi.org/10.1016/j.resconrec.2018.02.005

Mefteh, H.; Kebaïli, O.; Oucief, H.; Berredjem, L.; Arabi, N.: Influence of moisture conditioning of recycled aggregates on the properties of fresh and hardened concrete. J. Clean. Prod. 54, 282–288 (2013). https://doi.org/10.1016/j.jclepro.2013.05.009

Alhozaimy, A.M.: Effect of absorption of limestone aggregates on strength and slump loss of concrete. Cem. Concr. Compos. 31, 470–473 (2009). https://doi.org/10.1016/j.cemconcomp.2009.04.010

Nath, P.; Sarker, P.K.: Effect of GGBFS on setting, workability and early strength properties of fly ash geopolymer concrete cured in ambient condition. Constr. Build. Mater. 66, 163–171 (2014). https://doi.org/10.1016/j.conbuildmat.2014.05.080

Smirnova, O.: Concrete mixtures with high-workability for ballastless slab tracks. J. King Saud Univ. Eng. Sci. 29, 381–387 (2017). https://doi.org/10.1016/j.jksues.2017.06.004

Ahmmad, R.; Jumaat, M.Z.; Alengaram, U.J.; Bahri, S.; Rehman, M.A.; Hashim, H.: Bin: performance evaluation of palm oil clinker as coarse aggregate in high strength lightweight concrete. J. Clean. Prod. 112, 566–574 (2016). https://doi.org/10.1016/j.jclepro.2015.08.043

Zhang, B.; Poon, C.S.: Use of furnace bottom ash for producing lightweight aggregate concrete with thermal insulation properties. J. Clean. Prod. 99, 94–100 (2015). https://doi.org/10.1016/j.jclepro.2015.03.007

Akçaözoǧlu, S.; Akçaözoǧlu, K.; Atiş, C.D.: Thermal conductivity, compressive strength and ultrasonic wave velocity of cementitious composite containing waste PET lightweight aggregate (WPLA). Compos. Part B Eng. 45, 721–726 (2013). https://doi.org/10.1016/j.compositesb.2012.09.012

Xie, J.; Huang, L.; Guo, Y.; Li, Z.; Fang, C.; Li, L.; Wang, J.: Experimental study on the compressive and flexural behaviour of recycled aggregate concrete modified with silica fume and fibres. Constr. Build. Mater. 178, 612–623 (2018). https://doi.org/10.1016/j.conbuildmat.2018.05.136

Dilbas, H.; Şimşek, M.; Çakir, Ö.: An investigation on mechanical and physical properties of recycled aggregate concrete (RAC) with and without silica fume. Constr. Build. Mater. 61, 50–59 (2014). https://doi.org/10.1016/j.conbuildmat.2014.02.057

Duan, P.; Shui, Z.; Chen, W.; Shen, C.: Effects of metakaolin, silica fume and slag on pore structure, interfacial transition zone and compressive strength of concrete. Constr. Build. Mater. 44, 1–6 (2013). https://doi.org/10.1016/j.conbuildmat.2013.02.075

Elsharief, A.; Cohen, M.D.; Olek, J.: Influence of aggregate size, water cement ratio and age on the microstructure of the interfacial transition zone. Cem. Concr. Res. 33, 1837–1849 (2003). https://doi.org/10.1016/S0008-8846(03)00205-9

Lv, J.; Zhou, T.; Du, Q.; Wu, H.: Effects of rubber particles on mechanical properties of lightweight aggregate concrete. Constr. Build. Mater. 91, 145–149 (2015). https://doi.org/10.1016/j.conbuildmat.2015.05.038

Sengul, O.; Azizi, S.; Karaosmanoglu, F.; Tasdemir, M.A.: Effect of expanded perlite on the mechanical properties and thermal conductivity of lightweight concrete. Energy Build. 43, 671–676 (2011). https://doi.org/10.1016/j.enbuild.2010.11.008

Zhang, X.G., Kuang, X.M., Yang, J.H., Wang, S.R.: 2017-1-10.Pdf. 17, 85–94 (2017)

Wu, F.; Liu, C.; Sun, W.; Zhang, L.; Ma, Y.: Mechanical and creep properties of concrete containing apricot shell lightweight aggregate. KSCE J. Civ. Eng. 23, 2948–2957 (2019). https://doi.org/10.1007/s12205-019-0738-2

Yang, S.; Yue, X.; Liu, X.; Tong, Y.: Properties of self-compacting lightweight concrete containing recycled plastic particles. Constr. Build. Mater. 84, 444–453 (2015). https://doi.org/10.1016/j.conbuildmat.2015.03.038

Zhang, L.; Mo, K.H.; Yap, S.P.; Gencel, O.; Ling, T.C.: Mechanical strength, water resistance and drying shrinkage of lightweight hemihydrate phosphogypsum-cement composite with ground granulated blast furnace slag and recycled waste glass. Constr. Build. Mater. 345, 128232 (2022). https://doi.org/10.1016/j.conbuildmat.2022.128232

Hsie, M.; Tu, C.; Song, P.S.: Mechanical properties of polypropylene hybrid fiber-reinforced concrete. Mater. Sci. Eng. A 494, 153–157 (2008). https://doi.org/10.1016/j.msea.2008.05.037

Aslam, M.; Shafigh, P.; Alizadeh Nomeli, M.; Zamin Jumaat, M.: Manufacturing of high-strength lightweight aggregate concrete using blended coarse lightweight aggregates. J. Build. Eng. 13, 53–62 (2017). https://doi.org/10.1016/j.jobe.2017.07.002

He, W.; Kong, X.; Fu, Y.; Zhou, C.; Zheng, Z.: Experimental investigation on the mechanical properties and microstructure of hybrid fiber reinforced recycled aggregate concrete. Constr. Build. Mater. 261, 120488 (2020). https://doi.org/10.1016/j.conbuildmat.2020.120488

Bekkeri, G.B.; Shetty, K.K.; Nayak, G.: Synthesis of artificial aggregates and their impact on performance of concrete: a review. J. Mater. Cycles Waste Manag. 25, 1988–2011 (2023). https://doi.org/10.1007/s10163-023-01713-9

Piyaphanuwat, R.; Asavapisit, S.: Utilization ceramic wastes from porcelain ceramic industry in lightweight aggregate concrete. Int. J. Environ. Sci. Dev. 8, 342–346 (2017). https://doi.org/10.18178/ijesd.2017.8.5.975

Wongkvanklom, A.; Posi, P.; Khotsopha, B.; Ketmala, C.; Pluemsud, N.; Lertnimoolchai, S.; Chindaprasirt, P.: Structural lightweight concrete containing recycled lightweight concrete aggregate. KSCE J. Civ. Eng. 22, 3077–3084 (2018). https://doi.org/10.1007/s12205-017-0612-z

Myers, J.L.; Well, A.D.; Lorch, R.F.: Research Design and Statistical Analysis, 3rd edn. Routledge, London (2010)

ASTM C1723 − 10: Standard guide for examination of hardened concrete using scanning electron microscopy. Annu. B. ASTM Stand. (2006). Doi: https://doi.org/10.1520/C1723-10.Copyright

Karthik, A.; Sudalaimani, K.; Vijayakumar, C.T.; Saravanakumar, S.S.: Effect of bio-additives on physico-chemical properties of fly ash-ground granulated blast furnace slag based self cured geopolymer mortars. J. Hazard. Mater. 361, 56–63 (2019). https://doi.org/10.1016/j.jhazmat.2018.08.078

Chen, K.; Wu, D.; Yi, M.; Cai, Q.; Zhang, Z.: Mechanical and durability properties of metakaolin blended with slag geopolymer mortars used for pavement repair. Constr. Build. Mater. 281, 122566 (2021). https://doi.org/10.1016/j.conbuildmat.2021.122566

Saxena, S.; Tembhurkar, A.R.: Developing biotechnological technique for reuse of wastewater and steel slag in bio-concrete. J. Clean. Prod. 229, 193–202 (2019). https://doi.org/10.1016/j.jclepro.2019.04.363

Huang, C.H.; Wu, C.H.; Lin, S.K.; Yen, T.: Effect of slag particle size on fracture toughness of concrete. Appl. Sci. (2019). https://doi.org/10.3390/app9040805

Binici, H.; Aksogan, O.; Cagatay, I.H.; Tokyay, M.; Emsen, E.: The effect of particle size distribution on the properties of blended cements incorporating GGBFS and natural pozzolan (NP). Powder Technol. 177, 140–147 (2007). https://doi.org/10.1016/j.powtec.2007.03.033

Miller, S.A.; Horvath, A.; Monteiro, P.J.M.: Impacts of booming concrete production on water resources worldwide. Nat. Sustain. 1, 69–76 (2018). https://doi.org/10.1038/s41893-017-0009-5

Deebika, P.; Saravanakumar, M.P.: Utilization of RO rejects and waste aluminum scraps for hydrogen generation. Int. J. Hydrogen Energy (2023). https://doi.org/10.1016/j.ijhydene.2023.06.015

Varshney, H.; Khan, R.A.; Khan, I.K.: Sustainable use of different wastewater in concrete construction: a review. J. Build. Eng. (2021). https://doi.org/10.1016/j.jobe.2021.102411

Saxena, P.; Pagone, E.; Salonitis, K.; Jolly, M.R.: Sustainability metrics for rapid manufacturing of the sand casting moulds: a multi-criteria decision-making algorithm-based approach. J. Clean. Prod. (2021). https://doi.org/10.1016/j.jclepro.2021.127506

Meddah, M.S.; Ismail, M.A.; El-Gamal, S.; Fitriani, H.: Performances evaluation of binary concrete designed with silica fume and metakaolin. Constr. Build. Mater. 166, 400–412 (2018). https://doi.org/10.1016/j.conbuildmat.2018.01.138

Samad, S.; Shah, A.: Role of binary cement including supplementary cementitious material (SCM), in production of environmentally sustainable concrete: a critical review. Int. J. Sustain. Built Environ. 6, 663–674 (2017). https://doi.org/10.1016/j.ijsbe.2017.07.003

Mukherjee, A.; Sumit, D.; Dhiman, V.K.; Srivastava, P.; Kumar, A.: Intellectual tool to compute embodied energy and carbon dioxide emission for building construction materials. J. Phys. Conf. Ser. (2021). https://doi.org/10.1088/1742-6596/1950/1/012025

Yu, J.; Chen, Y.; Leung, C.K.Y.: Mechanical performance of Strain-Hardening Cementitious Composites (SHCC) with hybrid polyvinyl alcohol and steel fibers. Compos. Struct. 226, 111198 (2019). https://doi.org/10.1016/j.compstruct.2019.111198

Medjigbodo, G.; Rozière, E.; Charrier, K.; Izoret, L.; Loukili, A.: Hydration, shrinkage, and durability of ternary binders containing Portland cement, limestone filler and metakaolin. Constr. Build. Mater. 183, 114–126 (2018). https://doi.org/10.1016/j.conbuildmat.2018.06.138

Acknowledgements

The authors would like to thank the Department of Structural and Geotechnical Engineering, School of Civil Engineering, Vellore Institute of Technology, Vellore, for their continuous support in conducting experiments and providing laboratory facilities and material characterization instrumental facilities used in this investigation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Vignesh, R., Rahim, A.A. Multi-response Optimization of Fiber-Reinforced-Shaped Synthetic Aggregate Concrete. Arab J Sci Eng 49, 5027–5054 (2024). https://doi.org/10.1007/s13369-023-08305-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-023-08305-7