Abstract

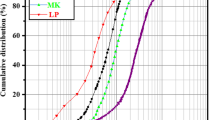

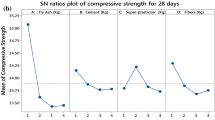

An increasing trend involves the creation of modified concrete by substituting traditional concrete components with waste materials. These waste materials encompass fly ash cenosphere as a replacement for M sand as fine aggregate. However, the utilization of fly ash in concrete is constrained by the need to strike a balance between cost and performance. This study delves into the cost benefits of employing fly ash cenosphere concrete, comparing the results to those of conventional concrete. The investigation focuses on assessing the compressive strength incorporating FAC, and this is achieved through the formulation of concrete mixes using Response Surface Methodology (RSM). A Central Composite Design (CCD) based on RSM is employed to analyze how the substitution of FAC (ranging from 0 to 100%) and M sand (ranging from 0 to 100%) influences both the cost of concrete production and its compressive strength. The study develops mathematical models of first and second orders through RSM based on the data generated in the experimental design. The accuracy of these mathematical models established by CCD is verified using Analysis of Variance (ANOVA). Subsequently, desirability analysis is employed to optimize the contents of FAC and M sand, aiming to attain maximum compressive strength while minimizing costs. The evaluation of RSM demonstrates that the empirical findings align well with linear and quadratic models for cost and compressive strength responses, respectively, with coefficients of determination exceeding 0.90 for all responses. The verification of the model findings demonstrates substantial agreement with the verified values. In conclusion, this study confirms that a reasonable balance between cost and performance can be achieved by incorporating FAC.

Similar content being viewed by others

Data availability

No datasets were generated or analysed during the current study.

References

Mannan MA, Ganapathy C (2002) Engineering properties of concrete with oil palm shell as coarse aggregate

Mahmoud HA, Tawfik TA, Abd El-razik MM, Faried AS (2023) Mechanical and acoustic absorption properties of lightweight fly ash/slag-based geopolymer concrete with various aggregates. Ceram Int 49:21142–21154. https://doi.org/10.1016/j.ceramint.2023.03.244

dos Anjos MAG, Sales ATC, Andrade N (2017) Blasted copper slag as fine aggregate in Portland cement concrete. J Environ Manage 196:607–613. https://doi.org/10.1016/j.jenvman.2017.03.032

Sinkhonde D (2022) Generating response surface models for optimisation of CO2 emission and properties of concrete modified with waste materials. Clean Mater 6:100146. https://doi.org/10.1016/j.clema.2022.100146

Sinkhonde D, Onchiri RO, Oyawa WO, Mwero JN (2021) Response surface methodology-based optimisation of cost and compressive strength of rubberised concrete incorporating burnt clay brick powder. Heliyon 7:e08565. https://doi.org/10.1016/j.heliyon.2021.e08565

Shaikuthali SA, Mannan MA, Dawood ET et al (2019) Workability and compressive strength properties of normal weight concrete using high dosage of fly ash as cement replacement. J Building Pathol Rehabilitation 4:26. https://doi.org/10.1007/s41024-019-0065-5

Bharathi KPP, Adari SK, Pallepamula U (2022) Mechanical properties of self-compacting concrete using steel slag and glass powder. J Building Pathol Rehabilitation 7:46. https://doi.org/10.1007/s41024-022-00184-z

Kirthika SK, Singh SK, Chourasia A (2020) Alternative fine aggregates in production of sustainable concrete- A review. J Clean Prod 268

Ranjbar N, Kuenzel C (2017) Cenospheres: a review. Fuel 207:1–12. https://doi.org/10.1016/j.fuel.2017.06.059

Kushnoore S, Kamitkar N, Atgur V et al (2020) A review on utilization of Light Weight fly Ash Cenosphere as Filler in both polymer and alloy-based composites. J Mech Eng Res 3:17–23. https://doi.org/10.30564/jmer.v3i2.1737

Anto Susanto, Abdullah M, Elma, Meilana Dharma Putra (2022) Characteristics of heterogeneous catalysts fly Ash Fraction of Light Shell and Fiber of Palm Oil Mill Solid Waste Grown on peatlands. J Adv Res Appl Sci Eng Technol 28:85–104. https://doi.org/10.37934/araset.28.3.85104

Danish A, Mosaberpanah MA (2020) Formation mechanism and applications of cenospheres: a review. J Mater Sci 55:4539–4557. https://doi.org/10.1007/s10853-019-04341-7

Kowsalya M, Sindhu Nachiar S, Anandh S (2022) A review on fly ash cenosphere as a solid waste in concrete application. Mater Today Proc. https://doi.org/10.1016/j.matpr.2022.08.363

Turkane SD, Chouksey SK (2022) Mechanical performance and stability analysis of moorum embankment partially replaced with fly ash. J Building Pathol Rehabilitation 7:94. https://doi.org/10.1007/s41024-022-00240-8

Alani AH, Johari MAM, Bunnori NM, Majid TA (2024) Application of response surface methodology for optimizing the compressive strength of green ultra high strength concrete using silica fume. J Building Pathol Rehabilitation 9:5. https://doi.org/10.1007/s41024-023-00361-8

Waqar A, Bheel N, Shafiq N et al (2023) Effect of volcanic pumice powder ash on the properties of cement concrete using response surface methodology. J Building Pathol Rehabilitation 8:17. https://doi.org/10.1007/s41024-023-00265-7

Shafiq N, Kumar R, Zahid M, Tufail RF (2019) Effects of modified metakaolin using nano-silica on the mechanical properties and durability of concrete. Materials 12:1–22. https://doi.org/10.3390/ma12142291

Poorarbabi A, Ghasemi M, Azhdary Moghaddam M (2020) Concrete compressive strength prediction using neural networks based on non-destructive tests and a self-calibrated response surface methodology. J Nondestr Eval 39. https://doi.org/10.1007/s10921-020-00718-w

Sinkhonde D, Onchiri RO, Oyawa WO, Mwero JN (2021) Response surface methodology-based optimisation of cost and compressive strength of rubberised concrete incorporating burnt clay brick powder. Heliyon 7. https://doi.org/10.1016/j.heliyon.2021.e08565

Zhang L, Zhai J (2021) Application of response surface methodology to optimize alkali-activated slag mortar with limestone powder and glass powder. Struct Concrete 22:E430–E441. https://doi.org/10.1002/suco.202000018

Kursuncu B, Gencel O, Bayraktar OY et al (2022) Optimization of foam concrete characteristics using response surface methodology and artificial neural networks. Constr Build Mater 337. https://doi.org/10.1016/j.conbuildmat.2022.127575

Bureau of Indian Standard (2013) Ordinary Portland Cement, 53 Grade — Specification, IS 12269:2013. New Delhi

Bureau of Indian Standard (2016) Coarse and Fine Aggregate for Concrete - Specification, IS 383:2016. New Delhi

Bureau of Indian Standard (2019) Concrete Mix Proportioning, IS 10262: 2019. New Delhi

Bureau of Indian Standards (2018) Method of Tests for Strength of Concrete,IS 516:2018. New Delhi

Funding

This research received no external funding.

Author information

Authors and Affiliations

Contributions

Conceptualization and methodology, writing—original draft preparation, Kowsalya M.; validation, editing and supervision, Sindhu Nachiar S.; data curation and supervision, Anandh S.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

M, K., S, S. & S, A. Desirability analysis of sustainable concrete containing fly ash cenosphere as fine aggregate replacement using RSM approach. J Build Rehabil 9, 83 (2024). https://doi.org/10.1007/s41024-024-00441-3

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41024-024-00441-3