Abstract

As a key portion of renewable energy resources (RESs), wind energy penetration is rapidly deployed. The effects of grid faults on grid-connected wind turbines (WTs) are causing problems for wind energy producers. To meet the necessary requirements, additional resources and technical interventions are needed. One of these requirements is low voltage ride-through (LVRT) of doubly fed induction generator (DFIG)-based WTs. This means that DFIG-WTs must stay connected to the grid during transient grid faults and supply active and reactive power after the fault is cleared. Many techniques for improving the LVRT capability of DFIG-WTs have been developed and this paper examines them. The paper also evaluates how well they align with grid codes, and offers case studies and simulations of the selected key techniques. Lastly, this paper provides guidelines and suggested designs for the LVRT techniques for DFIG-WTs to ensure they meet local grid codes.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In the last few years, the utilization of renewable energy sources (RESs) has grown rapidly in order to meet increasing energy requirements [1]. This is due to a number of advantages, such as affordable cost, high efficiency, minimal environmental impact, and inexhaustible energy sources. Among them, wind energy plays a vital role and has grown at the quickest pace [2, 3]. Where in 2019, 60 GW of installed wind energy capacity was added and 92 GW of installed capacity was added in 2020, despite the coronavirus. By 2025, the global wind energy council (GWEC) predicts even a higher yearly growth of about 94 GW [4, 5]. Wind turbines (WTs) are becoming more common in electrical power networks as wind energy develops. The four fundamental kinds of WTs are: fixed-speed WTs restricted variable-speed-controlled WTs, DFIG-WTs, and complete variable-speed-controlled WTs. In practical applications, DFIG-WTs are the most popular among the four kinds of wind turbines [6, 7].

1.1 Literature Review

The emergence of efficient wind turbine generators (WTGs) such as the permanent magnet synchronous generator (PMSG) and DFIG has led to a tremendous rise in power generation. Out of all the WTGs, DFIG has several advantages, such as variable speed and constant frequency operation, active/reactive powers control, and reduced power converter ratings [8, 9]. DFIG is the most widely used WTG and undoubtedly a market bestselling due to its exceptional performance. Although benefits of DFIG-WTs, they are extremely susceptible to grid voltage deviations for various grid failures [10,11,12,13]. When a DFIG encounters a rapid reduction in the grid voltage, the DFIG stator currents dramatically increase beyond the rated levels [14]. This is due to the magnetic connection between the stator and the rotor circuits. These currents have the potential to harm the power converter's power electronic equipment.

Furthermore, the electromagnetic torque of the DFIG begins to fluctuate with significant amplitudes; even a minor variation in the grid has an impact on the DFIG's performance. This aspect of DFIG has given rise to the LVRT capability feature. The capacity of a wind turbine generator to stay connected to the grid, and in certain circumstances support it, when the grid is experiencing a fault is known as LVRT capability [15]. To put it in another way, it is WTs' capability to ride through grid fault problems.

During grid voltage failure situations, the focus had previously been on the protection of DFIG-WTs by tripping the turbine. However, the power system is not permitted to disconnect the majority of WTs from the grid. The cause has a significant impact on the power system's ability to operate in a steady and secure manner [16]. As a result, in order to ensure the stable operation of the power system, in certain countries (such as Germany), network operators have revised the grid code by incorporating new standards [17, 18].Turbines should remain linked to the grid during grid failures, according to the new requirements. In order to maintain electrical systems running safely and reliably. Furthermore, WTs must produce reactive current during voltage drops in order to maintain grid voltage. This voltage control must be turned on within 20 ms after detecting voltage sag. The voltage dip determines the quantity of reactive current required. WTs must continue to provide active power that is at least 20% higher than the rated power per second after the fault has been addressed [19].

In order to comply with such grid requirements, it is major for the generators to have an improved LVRT capability. As a result, several researchers provided several LVRT-optimized approaches in Refs. [20,21,22,23,24,25]. To safeguard generators, the solutions employ extra circuitry. A crowbar circuit, direct current (DC) chopper, superconducting fault current limiter (SFCL), series dynamic brake resistor (SDBR), and other circuits may be fitted. Overcurrent suppression, machine torque oscillations, and DC link overvoltage are all included in these approaches. The most common method is to use a crowbar. During a fault, this method draws all of the needed reactive power from the grid, which is extremely undesirable. Furthermore, the controls are separated from the rotor, rendering the system inoperable. Because of the crowbar circuit's flaws, researchers have been looking for other protective mechanisms to improve LVRT capabilities. Various topologies have been proposed over the years.

In Refs. [26,27,28], LVRT techniques based on power injecting devices are introduced. In such techniques, devices like static synchronous compensators (STATCOM), dynamic voltage restorers (DVR), static synchronous series compensators (SSSC), and thyristor-controlled series compensator (TCSC), are utilised to regulate/optimise grid voltages. These devices can be tuned to push/set active and reactive powers in four quadrants, which will consequently improve its LVRT capabilities of wind generators. Using these devices adds to the system extra equipment/size, which has a negative impact on the compactness feature of the system. Control topologies-based solutions have been shown to be more successful in overcoming these difficulties.

In Refs. [29,30,31,32], it has been stated that, a combined method of virtual resistance and demagnetizing control was used. In these topologies, various system controllers are developed to reject perturbations in different parameters like rotor current, electromagnetic torque, and DC-link voltage under fault circumstances in these ways. Because of their potential to efficiently address nonlinear problems, artificial intelligence (AI) approaches have also been investigated. The researchers also gave several categories of LVRT approaches in Refs. [21, 33,34,35]. However, it is critical to examine thoroughly various LVRT strategies in order to select the optimum option for meeting network needs.

1.2 Contributions of Paper

As explored in the preceding subsection, several published papers reviewed the various types of LVRT techniques with an in-depth description. Techniques are categorized into numerous classes, which are backed by simulation findings. Other articles follow the evolution of LVRT technology. In this paper, the authors intended to concisely review and analyse the recently emerged LVRT techniques for DFIG-WTs. Furthermore, a thorough examination of LVRT techniques is provided with emphasis on their benefits and drawbacks. The primary contributions to the paper can be summarized as follows:

-

Present an overview of LVRT techniques for DFIG-WTs that have recently appeared with critical analysis.

-

A thorough examination of the numerous characteristics of the techniques used.

-

Discuss the effects of LVRT techniques in line with grid codes.

-

Using MATLAB/SIMULINK to discuss the influence of the most promising LVRT techniques on DFIG performance.

1.3 Paper Layout

The following is a breakdown of the paper structure: Modelling of a grid-connected DFIG-WT is shown in Sect. 2. Section 3 discusses the primary contributions of LVRT approaches, including classifications, merits, and demerits, as well as assessments based on grid codes. In Sect. 4, we explore how to increase LVRT capabilities during grid failures by employing better protective strategies using MATLAB/Simulink. The simulation results for LVRT techniques are provided in Sect. 5. The guidelines and recommended technical designs for the LVRT techniques for DFIG-WTs to cope with local grid codes are highlighted in Sect. 6.

2 Grid-Connected DFIG-WTs Modelling

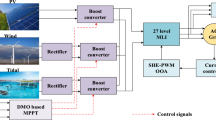

In DFIG-WTs, the DFIG stator winding and the grid are directly linked [36]. The turbine is controlled by back-to-back power converters, which comprise the rotor side converter (RSC), grid side converter (GSC), and a DC-link capacitor, as shown in Fig. 1.

The modelling equations are as follows [37]:

The current, voltage, flux, resistance, and inductance are represented as, \(\overrightarrow{\mathrm{i}}\), \(\overrightarrow{\mathrm{V}}\), \(\overrightarrow{\uppsi }\), R, L, respectively. The stator and rotor are denoted by the letters s and r, respectively. From Eqs. (3) and (4), the stator and rotor currents are indicated as follows:

3 LVRT Techniques

Systematic taxonomy of LVRT optimization techniques is presented as seen in Fig. 2 which includes (1) Exterior LVRT techniques. There are three parts of the exterior techniques that are protection-based techniques, FACTS-based techniques, and hybrid techniques. (2) Interior LVRT techniques include control strategies-based techniques. The goal of this classification is to offer a more detailed classification, evaluate the various techniques based on their effectiveness and provide a tabular breakdown of the various methods. The next subsections will go over the various techniques.

3.1 Exterior LVRT Techniques

Crowbar, series resistor (SR), chopper circuit, and other approaches are examples of these techniques. They' re divided into rotor and stator side protection circuits based on how they're connected. Initially, the rotor side was home to nearly all of the protective circuits. This configuration, however, resulted in the machine's uncontrolled operation and absorbed a lot of reactive power during breakdowns. To solve these concerns, efforts were made on the stator side to link protective circuits, with promising results [29, 38,39,40,41,42,43,44,45]. All the designs described in this category attempt to meet the requirements of grid codes. Furthermore, consideration is made to have provisions in place to limit excessive reactive power absorption. An overview of various methods is given below.

3.1.1 Protection Based Techniques

These techniques include the following:

3.1.1.1 The Crowbar Protection Technique

Figure 3 depicts the conventional diagram for crowbar protection [46, 47]. The crowbar purpose is to keep the rotor current low during a fault so that, the power converter can be protected [48, 49]. In addition, as described in [50, 51], there are several techniques based on crowbar protection. Reference [52] proposes two novel single-phase crowbar protection topologies. During asymmetric faults, the proposed single-phase dc crowbar shows great performance, which can replace the classic three-phase dc crowbar. The prominent advantage of the single-phase.

-

This method has the following advantage: It lowers overcurrent's in the rotor and stator.

-

The following are some of the disadvantages of this solution:

-

DFIG-WTs cannot be controlled during grid disturbances.

-

The generator absorbs reactive power, causing grid voltage to deteriorate further, and the possibility of disconnecting the turbine from the grid. As a result, the likelihood of other turbines going offline increases, causing grid instability [52, 53].

The crowbar protection technique [47]

Despite the crowbar disadvantages, many studies have been done to improve the crowbar's operation. In order to improve the performance of DFIG-WTs by ensuring active/reactive power control [54]. For example, to enable the RSC, an active crowbar proposed for disconnection at the correct time. The grid code requirements for reactive power injection could be met by disconnecting the crowbar after a few milliseconds [55,56,57].

3.1.1.2 The SR Protection Technique

The SR is made up of a series of resistors linked in series with the stator or rotor winding [28], as illustrated in Fig. 4. The SR's priority is to keep the rotor current under control. It also protects the DC-link from over-voltage and torque oscillations by dissipating active power. In various experiments, SR proposed that, the DFIG be allowed to ride through extreme voltage dips, both symmetrical and asymmetrical, such as:

-

Ref. [28] recommended a rotor current controller and dynamic resistors in series with the stator for unbalanced voltage dips.

-

Ref. [58] proposed the use of SR in addition to correct rotor current reference values.

-

On the stator side, a series passive-resistive network also explored in [59]. This approach had been proved to have higher and more effective performance.

3.1.1.3 DC Link Chopper Protection Technique

The chopper circuit is illustrated in Fig. 4. A DC-chopper is a circuit that consists of a switch and a resistor connected in parallel to the DC-link. When a grid malfunction is detected, the switch is closed and the resistor is connected in series with the DC-link capacitor, preventing overcharging at low grid voltage. The resistor will absorb the extra active power as shown in Ref. [53]. In Refs. [60, 61] control-delay approach for DC-chopper is explored. In this approach, a present rotor current threshold releases the chopper's application, and feedback control restores shorter rectification duration. However, the results of this sophisticated technique were unsatisfactory. It is also demonstrated that, the DC link chopper performs worse in terms of LVRT than a normal crowbar.

Moreover, there are many protection-based techniques introduced in the literature. So, a critical examination and comparison for these techniques have been presented in Tables 1 and 2.

3.1.2 FACTS Based Techniques

FACTS devices have the ability to regulate the parameters of transmission systems, allowing them to operate more efficiently. The static synchronous compensator (STATCOM) and the SSSC are two FACTS controllers that are rapidly gaining popularity in power systems. They employed to improve LVRT capability by compensating deep and shallow symmetric and asymmetric effort sags [26,27,28].

3.1.2.1 The Static Synchronous Compensator Technique

As illustrated in Figure 5, the STATCOM is a shunt-connected device that employs power electronics to manage voltage at its terminals by controlling the amount of reactive power introduced into or absorbed from the power system. As a result, in both steady state and transient-state conditions, high-performance voltage control is possible [66].

-

Despite the fact that the STATCOM or STATCOM/ESS is a common solution for improving LVRT capabilities, installing and maintaining this FACTS device in a wind farm will raise the total cost of the system.

3.1.2.2 The Dynamic Voltage Restorer (DVR)

As illustrated in Fig. 6, DVR is made up of a voltage source converter (VSC), inductors capacitors (LC) filters, and coupling transformers that are coupled in series with the grid to correct for voltage dips in the gridline during disturbances. Indeed, the DVR topologies have allowed DFIG to effectively ride through significant voltage dips. It is suggested that, it was connected to the generator in series to boost the stator voltage. As a result, the rotor current can be kept below the maximum allowable value. The DVR voltage can be controlled to the point where it absorbs all or almost all of the active power provided by the generator in order to optimize the generator injected reactive power [67]. In the case of asymmetric fault, Reference [27] proposes the coordinated control of the feedforward and feedback voltage of the DVR. The feedforward control adjusts the output power of the DVR according to the voltage drop depth. The feedback control is mainly to reduce the fluctuation of the PCC voltage of the wind farm. However, it has numerous drawbacks [67]:

-

The DVR's rating should match the WT's rated output;

-

DVRs are quite expensive due to many ancillary components;

-

Increased of system size.

3.1.2.3 Energy Storage System (ESS)

As shown in Fig. 7, this method employs a bidirectional dc/dc converter in conjunction with a dc bus. In this configuration, the dc bus voltage is controlled by either GSC or storage converter. Some energy is conserved in this situation, while the remaining is exported to the grid via the GSC. In order for fault currents to pass through the DFIG rotor circuit, the RSC must be sized appropriately [68].

Although an ESS can smooth the output power while stabilising the DC link voltage. Overcurrent and electromagnetic torque oscillations are notoriously difficult to avoid. However, the system's cost and complexity will increase, as more energy storage devices are required [69,70,71].

3.1.3 Hybrid Techniques

Methods that rely entirely on a single methodology were suggested in the previous sections' references. Every technique has its own set of challenges. As a result, the proposed methods based on these methodologies are not without flaws. However, it had been seen that, a feature that cannot be offered by one approach is contributed by a different method. As a result, by combining two methods, the disadvantages of one can be eliminated. As a result, hybrid techniques are now on the table. The following are the categories of hybrid techniques, which are made up of a blend of traditional methods:

3.1.3.1 The Crowbar Integrated with the Series R–L Technique

In Refs. [52, 72,73,74], crowbar in conjunction with a DC-link chopper and/or a series dynamic resistor, respectively. The authors presented a mechanism for redirecting transient rotor current while regaining generator power control in 45 ms, allowing DFIG-WT to fulfil grid-code requirements.

3.1.3.2 The Crowbar Integrated with the SDR

This is supported by Ref. [50]. The RSC is connected to the rotor winding by the Series Dynamic Resistor (SDR), which keeps generator power control until there are significant grid disruptions, in which case the crowbar is activated. Using a crowbar, on the other hand, results in the same conflicts, potentially destroying the converter and the DC-link capacitor.

3.1.3.3 The Crowbar, S R and the DC-Link Chopper

The DFIG-WTs' reflexes during both symmetrical and asymmetrical effort sags are considerably improved by this technology [51].

All of these technologies aim to reduce crowbar uptime and increase LVRT capacity. In addition to the aforementioned, Table 3 lists the benefits and drawbacks of other hybrid techniques.

3.2 Interior LVRT Techniques

3.2.1 Control Strategies Based Techniques

The power generated from the DFIG-WTs is regulated by the vector control (VC). On the other hand, the VCs are not able to obtain LVRT capabilities since they are primarily designed for DFIG-WT steady-state operation.As a result, the updated VC must be used to meet grid code requirements. Many changes were recommended by the researchers. Consider the following:

-

In Ref. [78] control technique, is suggested, which combined transient compensators into a standard RSC current regulator to increase the DFIG's LVRT capabilities. The control approach matched the RSC ac-side output voltage with the transient-induced voltage when a fault occurs, minimizing crowbar interruptions to a minimum.

-

According to Ref. [79], during grid faults, which might produce stator and rotor overcurrent, the stator currents as the reference rotor current must be reduced. The gains of the RSC's PI current controllers were ideally set to reduce rotor over-currents.

-

Also in [60, 80] the controllers for both the RSC and the GSC are built using a linear quadratic output feedback decentralized control approach to limit the oscillations and peak value of the rotor current and the DC-link voltage.

-

In addition, to improve the DFIG's LVRT capacity, an adaptive internal model controller with a variable gain adjustment method is presented in Ref. [81].

-

Refs. [82,83,84] increased the WT's LVRT capabilities during voltage dips without affecting system stability; advanced control-based techniques have been presented and adopted. The majority of them explain several methods for achieving the aim. The DFIG system's transient responsiveness was also improved using a robust control technique and a hysteresis-based current regulator.

-

Refs. [85, 86] improved the DFIG-LVRT WT's capabilities, model predictive control is employed to improve system stability and flux tracking control utilizing an upgraded vector control technique. Internal model control was also proposed to improve the DFIG-LVRT WT's capabilities. The fundamental concept is to algebraically transform the nonlinear system dynamics into an equivalent (completely or partially) linear one using an appropriate coordinate transformation and a nonlinear control input before employing linear control techniques.

-

However, a few of these strategies were just too complicated to be employed in practical applications, and they rely largely on the correct modelling and control parameters or the estimation of certain parameters, which may also jeopardize their resiliency [73].

-

In addition to the foregoing, Table 4 summarizes the benefits and drawbacks of other control strategies based techniques, as well as inferences made from references.

-

In Refs. [87, 88] some strategies designed to operate under asymmetric fault conditions have been proposed.These strategies allow to damp the torque oscillation or to balance the DFIG’s currents by controlling the positive- and negative-sequence rotor-current components. Since these strategies need positive- and negative-sequence detectors and a greater number of controllers with respect to the standard strategies, their implementation results are complex and the dynamic behaviour and stability can be degraded.

-

Some proposals allow controlling the DC-Link voltage and the active and reactive power injected into the grid when it has asymmetric voltages [89, 90]. Usually, they are focused on maintaining constant the active and reactive power injected by the DFIG-based system to the PCC, and not injecting sinusoidal currents with only positive-sequence components. Also, their implementation results are complex due to the requirement of positive- and negative-sequence detectors and additional PI regulators for each sequence component.

-

An integral control strategy for DFIG-based systems is presented in this [87]. The proposal allows minimizing the torque oscillations when the grid has asymmetric voltages by implementing an SFO-VC at the same time that it allows injecting sinusoidal currents to the grid by the control of the GSC. Therefore, mechanical efforts on the generator are minimized while the impact on the power quality of the grid is reduced by injecting sinusoidal currents into the PCC.

As stated previously, to emphasize different aspects of the LVRT techniques outlined above. To address this problem, researchers looked into the causes for DFIG's failure to stay connected to a malfunctioning grid, as well as potential solutions to assist it. Grid codes were created to serve as guidelines for the management of wind farms. According to these codes, Tables 5, 6 give a detailed evaluation of them in terms of the fundamental elements of LVRT improvement techniques [6, 87]. In these tables “√”denotes that, the utilized LVRT technology effectively controls the network fault impact, “x” denotes that, the utilized LVRT technology has no impact on the fault, and “*” denotes that, the utilized LVRT technology may exacerbate the network fault impact.

However, it has been seen from Tables 5 and 6 that, some interior LVRT techniques may satisfy the requirements of grid codes but some of these strategies are too complex to be implemented and used in industrial applications. In fact, the schemes sorted under exterior LVRT techniques attempt to satisfactorily meet the requirements of grid codes; some are also inexpensive and simple to install. As a result, the following section will demonstrate various exterior LVRT techniques for improving DFIG-WTS performance. The LVRT techniques ensures the safety of energy converters, rotor circuits, and DC-link capacitors while limiting rotor currents, DC-link voltages, and torque changes. The effectiveness of the LVRT techniques wares also assessed for asymmetrical and symmetrical fault situations. MATLAB/SIMULINK is used here to materlise and quatify the concepts of LVRT methods.

4 Improving LVRT Capability of DFIG-WTS

In this section, the exterior technologies that were utilized are discussed as follows:

4.1 SR Protection Technique

The SR protection method was employed in the rotor side of the DFIG. The SR made up of a series of resistors linked to the rotor winding as illustrated in Fig. 8. It uses power electronic switches to regulate the connect of resistance into the rotor circuit [91]. During faults, the resistor is to be inserted in series with the rotor winding circuit. When the SR inserted into the rotor circuit during a fault, the power from the induced voltages in the rotor that occur during the fault dissipated, limiting the rotor over current. The charging current of the DC-link capacitor reduced by limiting the rotor currents. This reduces the risk of DC-link overvoltage. The high voltage will be shared by the resistance due to SR. Converter control will not be lost due to the series topology. As a result, the SR not only prevents rotor overvoltage from causing the RSC to lose control, but it also prevents the RSC from losing control. During the fault, however, the RSC does not need to be stopped.

4.2 The Crowbar Integrated with the DC-Chopper

As illustrated in Fig. 9, the protective technique includes two circuits: a DC-chopper and a crowbar. A crowbar is a set of resistors linked to the rotor winding. During a fault, the crowbar action started by raising the rotor current value by blocking the converter. As a result, current flows into the DC-link via the freewheeling diodes, causing a fast voltage increase. For restricted overvoltage's, the DC-chopper is turned on during symmetrical and asymmetrical grid failures to safeguard the power electronic converter. The protective circuits have been improved to make use of resistors to reduce rotor current and DC-link overvoltage.

Additionally, Fig. 10 shows the detailed DFIG –WT simulation setup. The simulation was performed for a wind farm, which is linked to a 25 kV distribution system and outputs power to a 120 kV grid through 30 kms of 25 kV feeders. In MATLAB/SIMULINK, the wind farm is represented by a single DFIG machine model (6 * 1.5 MW) using the 1.5 MW DFIG's parameters shown in Table 7.

5 Simulation Results

In this section, we will give the above-mentioned simulation findings in the various scenarios of grid faults, including symmetric and asymmetric faults.

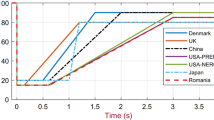

5.1 The Symmetrical Fault: A Case Study

5.1.1 SR Protection Technique

As shown in Fig. 11, a three-phase fault is simulated at the grid connection point, commencing at the time (t = 0.7 s) until clearing at the time (t = 0.9 s). This diagram depicts the system's response to a 0.95pu voltage drop lasting 0.2 s. The power from the induced voltages in the rotor that generated during the failure was dissipated in this simulation due to the inclusion of SR in the rotor winding. The increase in stator and rotor currents is minimized consequently. The stator currents are lowered from 2.66 to 2.02 pu for the most crucial phase. The rotor currents have been lowered from 2.5 to 1.21 pulsations per second. As a result, the DC-link voltage and electrical torque oscillations are decreased. In terms of raising the damping currents at the generator terminals, it can be shown that SR protection is more effective.

5.1.2 The Crowbar Integrated with the DC-Chopper

Figure 12 depicts the system's response to a 0.95pu voltage decrease lasting 0.2 s. The rotor currents that rise owing to the initial rotor current peak initiate the crowbar firing. The safeguard normally disables the converter's electronic switches. However, through the freewheeling diodes, current and energy continue to flow into the DC-link, resulting in a very rapid voltage rise. As a result, the DC-chopper is turned on to prevent overvoltage. The stator currents were reduced from 2.66 to 1.81 pu during the most dangerous phase by including parallel resistance in the rotor circuit and by connecting resistance in parallel with the DC-link. The rotor currents have been reduced from 2.5 to 1.42 pu. When using the technique, the enhanced state-transient response characteristic may be shown significantly.

5.2 The Asymmetrical Fault: A Case Study

5.2.1 SR Protection Technique

A double-phase (phase-b and phase-c) fault is simulated at t = 0.7 s, and Fig. 13 depicts the system reactions under asymmetrical fault circumstances. The SR is efficient in dissipating the induced voltage in the rotor when phase's b and c are short-circuited together. The stator currents dropped from 2.09 to 1.04 pu. In addition, at the most dangerous phase, the rotor currents are reduced from 1.91 to 1.104 pu. As a result, SR minimizes DC-link voltage and electrical torque variations greatly.

5.2.2 The Crowbar Integrated with the DC-Chopper

The system reactions during asymmetrical fault circumstances are depicted in Fig. 14. Short-circuiting occurs in phase's b and c. The stator currents are lowered from 2.09 to 1.38 pu at the most dangerous phase when the DC chopper and crowbar switches are triggered simultaneously. For the most serious phase, the rotor currents are reduced from 1.91 to 1.06 pu, resulting in a considerable reduction in DC-link voltage and electrical torque variations. As indicated in the figure, the crowbar and DC-chopper systems are fairly adequate.

The simulation results demonstrate that, the SR is helpful under symmetrical and asymmetrical grid failures because it reduces rotor over current, torque oscillations, and DC-link over-voltage compared to the other scheme. Thus, it supports the system's stability under grid failures. Also, the SR is reducing rotor currents more effectively than a crowbar or DC-chopper protection. During the fault, both techniques have reactive power and electrical torque changes. They are substantially bigger for crowbar protection. When compared to crowbar protection, the electrical torque ripple is smaller with SR protection.

6 Conclusion

This paper discussed the recently developed techniques for Low Voltage Ride Through (LVRT) of Doubly-Fed Induction Generator Wind Turbines (DFIG-WTs). Because of the expanding use of wind energy in the grid, improving the LVRT capability is crucial. Different LVRT techniques were described in detail, and the advantages and disadvantages of each were examined in order to meet grid code requirements. LVRT techniques can be divided into two categories: exterior (protection-based, FACTS-based, and hybrid) and interior (control strategies-based).

For simplicity, exterior LVRT techniques are extensively employed in previously installed WTs. However, cost considerations continue to be a key impediment to the adoption of these technologies. Hybrid approaches can help improve LVRT by overcoming the shortcomings of one method by inserting the benefits brought by the other. In fact, interior LVRT techniques adjustments can provide greater control effects during low grid voltage. As the LVRT capability of DFIG-WTs can be enforced without any external supplementary circuit, interior techniques have better economic benefits over exterior LVRT techniques. Thus, interior techniques are preferable in freshly erected WTs, considering the cost factor advantages. The simulation performances of the exterior LVRT techniques are analysed in this paper. The SR protection technique and the crowbar integrated with the DC-chopper are considered here. Both strategies enforce great LVRT performances in fault situations. However, the SR protection technique has been shown to be more effective than the crowbar integrated with the DC-chopper.

In brief, this paper has presented the formation of guidelines and recommended technical designs for LVRT technologies for DFIG-WTs to meet the requirements of local grid codes; key points follow. Recent grid regulations demand that wind turbines stay grid connected while providing reactive power assistance, necessitating the need for them to be outfitted with LVRT capability. While some LVRT techniques are only able to handle symmetric faults, asymmetric faults are more common and thus the techniques should be able to handle both types of flaws. Additionally, the methods used should be simple and cost-effective, and should be designed to work with weak power grids, as the infrastructure connecting wind farms is often not robust.

Abbreviations

- RESs:

-

Renewable energy sources

- WTs:

-

Wind turbines

- LVRT:

-

Low voltage ride-through

- DFIG:

-

Doubly fed induction generator

- DFIG-WTs:

-

DFIG-based wind turbines

- GWEC:

-

Global wind energy council

- WTGs:

-

Wind turbine generators

- PMSG:

-

Permanent magnet synchronous generator

- DC:

-

Direct current

- SFCL:

-

Superconducting fault current limiter

- SDBR:

-

Series dynamic brake resistor

- FACTS:

-

Flexible AC transmission system

- STATCOM:

-

Static synchronous compensator

- DVR:

-

Dynamic voltage restorer

- SSSC:

-

Static synchronous series compensator

- TCSC:

-

Thyristor controlled series compensator

- RSC:

-

Rotor side converter

- GSC:

-

Grid side converter

- SR:

-

Series resistor

- GCSC:

-

Gate-controlled series capacitor

- HTSFCL:

-

High-temperature superconducting fault current limiter

- ESS:

-

Energy storage system

- SC:

-

Superconducting coil

- VSC:

-

Voltage source converter

- LC:

-

Inductors capacitors

- VC:

-

Vector control

- BPA:

-

Blade pitch angle

- CC:

-

Current compensation

- SMC:

-

Sliding mode control

- DNC:

-

Decentralized nonlinear control

- ISS:

-

Input-to-state stability

- SDR:

-

Series dynamic resistor

- RNIO:

-

Real-time neural inverse optimal

- i :

-

Current

- V :

-

Voltage

- Ψ:

-

Flux

- R :

-

Resistance

- L :

-

Inductance

- s :

-

Stator

- r :

-

Rotor

References

Sattar, M.A.E.; Al Sumaiti, A.; Ali, H.; Diab, A.A.Z.: Marine predators algorithm for parameters estimation of photovoltaic modules considering various weather conditions. Neural Comput. Appl. 33, 11799–11819 (2021)

Abd El Sattar, M.; Hafez, W.A.; Elbaset, A.A.; Alaboudy, A.H.K.: Economic valuation of electrical wind energy in Egypt based on Levelized cost of energy. Int. J. Renew. Energy Res. 10(4), 1879–1891 (2020)

Diab, A.A.Z.; Ali, H.; Abdul-Ghaffar, H.I.; Abdelsalam, H.A.; Abdelsattar, M.: Accurate parameters extraction of PEMFC model based on metaheuristics algorithms. Energy Rep. 7, 6854–6867 (2021)

GWEC. Global Wind Report 2021; GWEC: Brussels, Belgium, 2021; p. 80. Available online: https://gwec.net/global-wind-report-2021/(accessed on 18 February 2022).

IEA. Renewables 2019: Analysis and forecast to 2024; International Energy Agency: Paris, France, 2019; ISBN 978-92-64-36998-6. Available online: https://iea.blob.core.windows.net/assets/a846e5cf-ca7d-4a1f-a81b-ba1499f2cc07/Renewables_2019.pdf (Accessed on 18 February 2022).

Saeed, M.A.; Khan, H.M.; Ashraf, A.; Qureshi, S.A.: Analysing electiveness of LVRT techniques for DFIG wind turbine system and implementation of hybrid combination with control schemes. Renew. Sustain. Energy Rev. 81, 2487–2501 (2018)

Hansen, A.D.; Iov, F.; Blaabjerg, F.; Hansen, L.: Review of contemporary wind turbine concepts and their market penetration. Wind Eng. 28, 247–263 (2004)

Rolan, A.; Pedra, J.; Corcoles, F.: Detailed study of DFIG-based wind turbines to overcome the most severe grid faults. Electr. Power Energy Syst. 62, 868–878 (2014)

Nian, H.; Song, Y.: Direct power control of doubly fed induction generator under distorted grid voltage. IEEE Trans. Power Electron 29(2), 894–905 (2014)

Dittrich, A.; Stoev, A.: “Comparison of fault ride-through strategies for wind turbines with DFIM generators”. In: 2005 European Conference on Power Electronics and Applications, pp. 1–8. (2005).

Gao, W.; Wang, G.; Ning, J.: Development of low voltage ride-through control strategy for wind power generation using real time digital simulator. In: IEEE/PES Power Systems Conference and Exposition (PSCE), pp. 1–6. Seattle, WA (2009)

Ling, Y.; Cai, X.: Rotor current dynamics of doubly fed induction generators during grid voltage dip and rise. Int. J. Electr. Power Energy Syst. 44, 17–24 (2013)

Yang, J.; Dorrell, D. G.; Fletcher, J. E.: A new converter protection scheme for doubly-fed induction generators during disturbances. In: 34th IEEE Annual Conference on Industrial Electronics (IECON), pp. 2100–2105. (2008)

Morren, J.; De Haan S. W. H.: “Ride through of wind turbines with doubly-fed induction generator during a voltage dip”. In: IEEE Transactions on Energy Conversion, Vol. 20, pp. 435–441. (2005).

Rahim, A.H.M.A.; Nowicki, E.P.: Supercapacitor energy storage system for fault ride-through of a DFIG wind generation system. Energy Conv. Mangag. 59, 96–102 (2012)

Zhan, C.; Barker, C. D.: Fault ride-through capability investigation of a doubly-fed induction generator with an additional series connected voltage source converter. In: The 8th IEE International Conference on AC and DC Power Transmission (ACDC), pp. 79–84. (2006)

Hansen, A.D.; Michalke, G.; Sorense, P., et al.: Co-ordinated voltage control of DFIG wind turbines in uninterrupted operation during grid faults. Wind Energy 10, 51–68 (2007)

Erlich, I.; Winter, W.; Dittrich, A.: Advanced grid requirements for the integration of wind turbines into the German transmission system. In: IEEE Power Engineering Society General Meeting, pp. 1–7. (2006).

Kim, K.-H.; Jeung, Y.-C.; Lee, D.-C.; Kim, H.-G.: LVRT scheme of PMSG wind power systems based on feedback linearization. IEEE Trans. Power Electron. 27, 2376–2384 (2012)

Alsmadi, Y.M. et al.: Detailed investigation and performance improvement of the dynamic behaviour of grid-connected DFIG-based wind turbines under LVRT conditions. IEEE Trans. Apple 54(5), 4795–4812 (2018)

Tohidi, S.; Mohammadi-ivatloo, B.: A comprehensive review of low voltage ride through of doubly fed induction wind generators. Renew. Sustain. Energy Rev. 57, 412–419 (2016)

Niu, L.; Wang, X.; Wu, L.; Yan, F.; Xu, M.: Review of low voltage ride-through technology of doubly-fed induction generator. J. Eng. 3(16), 3106–3108 (2019)

Pannell, G.; Zahawi, B.; Atkinson, D.J.: Missailidis P “Evaluation of the performance of a dc-link brake chopper as a DFIG low-voltage fault-ride-through device.” IEEE Trans. Energy Conv. 28(3), 535–542 (2013)

Duong, M.; Leva, S.; Mussetta, M.; Le, K.H.: A Comparative study on controllers for improving transient stability of DFIG wind turbines during large disturbances. Energies 11, 480 (2018)

Din, Z.; Zhang, J.; Zhu, Y.; Xu, Z.: El-Naggar an “Impact of grid impedance on LVRT performance of DFIG system with rotor crowbar technology.” IEEE Access 7, 127999–128008 (2019)

Benali, A.; Khiat, M.; Allaoui, T.; Denaï, M.: Power Quality improvement and low voltage ride through capability in hybrid wind-PV farms grid-connected using dynamic voltage restorer. IEEE Access 6, 68634–68648 (2018)

Mokryani, G.; Siano, P.; Piccolo, A.; Chen, Z.: Improving fault ride-through capability of variable speed wind turbines in distribution networks. IEEE Syst. J. 7(4), 713–722 (2013)

Mohammadi, J.; Afsharnia, S.; Vaez-Zadeh, S.: efficient fault-ride-through control strategy of DFIG-based wind turbines during the grid faults. Energy Convers. Manag. 78, 88–95 (2014)

Alaraifi, S.; Moawwad, A.; Moursi, M.S.E.; Khadkikar, V.: Voltage booster schemes for fault ride through enhancement of variable speed wind turbines”. IEEE Trans. Sustain. Energy 4(4), 1071–1081 (2013)

Vrionis, T.D.; Koutiva, X.I.; Vovos, N.A.: A genetic algorithm-based low voltage ride-through control strategy for grid connected doubly fed induction wind generators. IEEE Trans. Power Syst. 29(3), 1325–1334 (2014)

Wessels, C.; Gebhardt, F.; Fuchs, F.W.: Fault ride-through of a DFIG wind turbine using a dynamic voltage restorer during symmetrical and asymmetrical grid faults. IEEE Trans. Power Electron. 26(3), 807–815 (2011)

Falehi, A.D.; Rafiee, M.: Enhancement of DFIG-wind turbine’s LVRT capability using novel DVR based odd-nary cascaded asymmetric multi-level inverter. Int. J. Eng. Sci. Tech 20, 805–824 (2017)

Maga, J.; Jadhav, H.T.: (2013) “Improving fault ride through capability of DFIG connected wind turbine system: a review”. In: International Conference on Power, Energy And Control, pp. 613–618.

Jutso, J.J.; Mwasilu, F.; Jung, J.W.: Doubly-fed induction generator based wind turbines: a comprehensive review of fault ride-through strategies. Renew. Sustain. Energy Rev. 57, 447–467 (2015)

Mahela, O.P.; Gupta, N.; Khosravy, M.; Patel, N.: Comprehensive overview of low voltage ride through methods of grid integrated wind generator. IEEE Access 7, 99299–99326 (2019)

Zin, A.A.B.M.; Ha, M.P.; Khairuddin, A.B.; Jahanshaloo, L.; Shariati, O.: An overview on doubly fed induction generators′ controls and contributions to wind based electricity generation. Renew. Sustain. Energy Rev. 27, 692–708 (2013)

Morren, J.; Sjoerd, W.: “Short-circuit current of wind turbines with doubly fed induction generator. IEEE Trans. Energy Convers. 22, 174–180 (2007)

Haidar, A.M.A.; Muttaqi, K.M.; Hagh, M.T.: A coordinated control approach for DC link and rotor crowbars to improve fault ride-through of DFIG-based wind turbine. IEEE Trans. Ind. Appl. 53(4), 4073–4086 (2017)

Wei, F.; Vilathgamuwa, D.M.; Shing, C.S.: Design of mode switching scheme for low-voltage ride-through of doubly fed induction generators”. IET Renew. Power Gen. 9(2), 109–119 (2015)

Elshiekh, M.E.; Mansour, D.E.A.; Azmy, A.M.: Improving fault ride-through capability of DFIG-based wind turbine using superconducting fault current limiter. IEEE Trans. Appl. Supercond. 23(3), 5601204 (2013)

Zheng, Z.; Huang, C.; Yang, R.; Xiao, X.; Li, C.: A low voltage ride through scheme for DFIG-based wind farm with SFCL and RSC Control. IEEE Trans. Appl. Supercond. 29(2), 1–5 (2019)

Guo, W.; Xiao, L.; Dai, S.; Li, Y.; Xu, X.; Zhou, W.; Li, L.: LVRT capability enhancement of DFIG with switch-type fault current limiter. IEEE Trans. Ind. Electron. 62(1), 332–342 (2015)

Okedu, K.E.; Muyeen, S.M.; Takahashi, R.; Tamura, J.: Wind farms fault ride through using DFIG with new protection scheme. IEEE Trans. Sustain. Energy 3(2), 242–254 (2012)

Rashid, G.; Ali, M.H.: Nonlinear control-based modified BFCL for LVRT capacity enhancement of DFIG-based wind farm. IEEE Trans. Energy Convers. 32(1), 284–295 (2017)

Hossain, M.E.: Low voltage ride through capability improvement methods ford FIG based wind farm. J. Electr. Syst. Inform. Tech. 5(3), 550–561 (2018)

Rahimi, M.; Parniani, M.: “Efficient control scheme of wind turbines with doubly fed induction generators for low-voltage ride-through capability enhancement. IET Renew. Power Gen. 4, 242–252 (2010)

Lima, F.K.A.; Luna, A.; Rodriguez, P.; Watanabe, E.H.; Bleiberg, F.: “Rotor voltage dynamics in the doubly fed induction generator during grid faults. IEEE Trans. Power Electron. 25, 118–130 (2010)

Morren, J.; de Haan, S.W.H.: Short-circuit of wind turbine with doubly fed induction generator. IEEE Trans. Energy Convers. 22, 174–180 (2007)

Kayikci, M.; Milanovic, J.V.: Assessing transient response of DFIG-based wind plants-the influence of model simplifications and parameters. IEEE Trans. Power Syst. 23, 545–554 (2008)

Vidal, J.; Abad, G.; Arza, J.; Aurtenechea, S.: Single-phase DC. Crowbar topologies for low voltage ride through fulfillment of high-power doubly fed induction generator-based wind turbines. Energy Convers. IEEE Trans. 28, 81–768 (2013)

Sattar, M.A.E.; Hafez, W.A.; Alaboudy, A.H.K.; Elbaset, A.A.: Fuzzy logic controlled shunt active power filter for power quality improvement of an egyptian electrical network connected wind energy system. Int. J. Innov. Eng. Manag. Res. 10(08), 134–145 (2020)

Jayanthi, P., Devaraj, D.: Enhancement of LVRT capability in grid connected wind energy systems using crowbar. In: 2019 IEEE International Conference on Clean Energy and Energy Efficient Electronics Circuit for Sustainable Development (INCCES). IEEE, (2019).

Tohidi, S.; Behnam, M.-I.: A comprehensive review of low voltage ride through of doubly fed induction wind generators. Renew. Sustain. Energy Rev. 57, 412–419 (2016)

Rahimi, M.; Parniani, M.: Coordinated control approaches for low-voltage ride through enhancement in wind turbines with doubly fed induction generators. IEEE Trans. Energy Convers. 25, 873–883 (2010)

Lopez, J.; Gubia, E.; Olea, E.; Ruiz, J.; Marroyo, L.: Ride through of wind turbines with doubly fed induction generator under symmetrical voltage dips. Ind. Electron. IEEE Trans. 56, 4246–4254 (2009)

Zhang, X.-G.; Xu, D.-G.: Research on control of DFIG with active crowbar under symmetry voltage fault condition. Electr. Mach. Control 1, 020 (2009)

Pannell, G.; Atkinson, D.J.; Zahawi, B.: “Minimum-threshold crowbar for a fault ride-through grid-code-compliant DFIG wind turbine. Energy Convers. IEEE Trans. 25, 9–750 (2010)

Rahimi, M.; Parniani, M.: “Low voltage ride-through capability improvement of DFIG-based wind turbines under unbalanced voltage dips. Int. J Electr. Power Energy Syst. 60, 82–95 (2014)

Yan, X.; Venkataramanan, G.; Wang, Y.; Dong, Q.; Zhang, B.: Grid-fault tolerant operation of a DFIG wind turbine generator using a passive resistance network. Power Electron. IEEE Trans. 26, 905–2896 (2011)

Nielsen, J.G.; Blaabjerg, F.: A detailed comparison of system topologies for dynamic voltage restorers. Ind. Appl. IEEE Trans 41, 80–1272 (2005)

Tohidi, S.; Behnam, M.-I.: A comprehensive review of low voltage ride through of doubly fed induction wind” generators. Renew. Sustain. Energy Rev. 57, 412–419 (2016)

Zou, Z.; Liao, J.; Lei, Y.; Mu, Z.; Xiao, X.: Post fault LVRT Performance enhancement of DFIG using a stage-controlled SSFCL-RSDR”. IEEE Trans. Appl. Supercond. 29(2), 1–6 (2019)

Mohammadpour, H.; Zadeh, S.G.; Tohidi, S.: Symmetrical and asymmetrical low-voltage ride through of doubly-fed induction generator wind turbines using gate controlled series capacitor. IET Renew. Power Gen. 9(7), 840–846 (2015)

Yang, L.; Xu, Z.; Ostergaard, J.; Dong, Z.Y.; Wong, K.P.: Advanced control strategy of DFIG wind turbines for power system fault ride through. IEEE Trans Power Syst. 27(2), 713–722 (2012)

Khan, U.-A., et al.: Modeling and simulation using simulink and sim power system of optimized HTS FCL location in a smart grid having a wind turbine connected with the grid. Progress Supercond. Cryog 12, 17–20 (2010)

Gkavanoudis, S.I.; Demoulias, C.S.: “A combined fault ride-through and power smoothing control method for full-converter wind turbines employing super capacitor energy storage system. Electr. Power Syst. Res. 106, 62–72 (2014)

Muyeen, S.M.; Takahashi, R.; Murata, T.; Tamura, J.; Ali, M.H.; Matsumura, Y.; Kuwayama, A.; Matsumoto, T.: Low voltage ride through capability enhancement of wind turbine generator system during network disturbance. IET Renew. Power Gen. 3, 65–74 (2009)

Wenyong, G.; Liye, X.; Shaotao, D.: Enhancing low-voltage ride-through capability and smoothing output power of DFIG with a superconducting fault current limiter-magnetic energy storage system. Energy Conv. IEEE Trans. 27, 95–277 (2012)

Elshiekh, M.E.; Mansour, D.A.; Azmy, A.M.: Improving fault ride-through capability of DFIG-based wind turbine using superconducting fault current limiter. Appl. Super Cond. IEEE Trans. 23, 5601204–5601204 (2013)

Abbey, C.; Joos, G.: Super capacitor energy storage for wind energy applications. IEEE Trans. Ind. Appl. 43, 769–776 (2007)

Díaz-González, F.; Sumper, A.; Gomis-Bellmunt, O.; VillafáfilaRobles, R.: A review of energy storage technologies for wind power applications. Renew. Sustain. Energy Rev. 16, 2154–2171 (2012)

Geng, H.; Liu, C.; Yang, G.: LVRT capability of DFIG-based WECS under asymmetrical grid fault condition. IEEE Trans. Ind. Electron 60, 509–2495 (2013)

Liu, X.; Kong, X.: Nonlinear model predictive control for DFIG-based wind power generation. IEEE Trans. Autom. Sci. Eng. 99, 1–10 (2013)

Barambones, O.: Sliding mode control for wind turbine power maximization. Energy 5, 2310–2330 (2010)

Mohammadpour, H.; Zadeh, S.G.; Tohidi, S.: Symmetrical and asymmetrical low voltage ride through of doubly fed induction generator wind turbines using gate controlled series capacitor. IET Renew. Power Gen. 9(8), 840–846 (2015)

Karaipoom, T.; Ngamroo, I.: Optimal superconducting coil integrated into DFIG wind turbine for fault ride through capability enhancement and output power fluctuation suppression. IEEE Trans. Sustain. Energy 6(1), 28–42 (2015)

Rahimi, M.; Parniani, M.: Low voltage ride-through capability improvement of DFIG based wind turbines under unbalanced voltage dips. Electr. Power Energy Syst. 60, 82–95 (2014)

Liang, J.; Qiao, W.; Harley, R.G.: Feed-forward transient current control for low-voltage ride-through enhancement of DFIG wind turbines. IEEE Trans. Energy Convers. 25(3), 836–843 (2010)

Jing, S.; Yuejin, T.; Yajun, X.; Li, R.; Jingdong, L.: SMES based excitation system for doubly-fed induction generator in wind power application. Appl. Super Cond. IEEE Trans. 21, 8–1105 (2011)

Ibrahim, A.O.; Nguyen, T.H.; Lee, D.C.; Kim, S.C.: Faults ride-through technique of DFIG wind turbine systems using dynamic voltage restorers. IEEE Trans. Energy Convers. 26, 82–871 (2011)

Hossain, M.J.; Saha, T.K.; Mithulananthan, N.; Pota, H.R.: “Control strategies for augmenting LVRT capability of DFIGs in interconnected power systems. IEEE Trans. Ind. Electron. 60, 22–2510 (2013)

Xiao, S.; Yang, G.; Zhou, H.; Geng, H.: An LVRT control strategy based on flux linkage tracking for DFIG-based WECS. IEEE Trans Ind. Electron 60, 32–2820 (2013)

Soares, O.; Gonçalves, H.; Martins, A.; Carballo, A.: Nonlinear control of doubly-fed induction generator in wind power systems. Renew. Energy 35, 70–1662 (2010)

Rahimi, M.; Parniani, M.: Transient performance improvement of wind turbines with doubly fed induction generators using nonlinear control strategy. IEEE Trans. Energy Convers. 25, 5–524 (2010)

Long, T.; Shao, S.; Malliband, P.; Abdi, E.; MacMahon, R.A.: Crowbar less fault ride through of the brushless doubly fed induction generator in a wind turbine under symmetrical voltage dips. IEEE Trans. Ind. Electron. 60, 41–2833 (2013)

Mohsen, M.; Islam, S.M.; Masoum, M.A.S.: Enhanced hysteresis-based current regulators in vector control of DFIG wind turbines. IEEE Trans. Power Electron. 26, 34–223 (2011)

González, G.N.; De Angelo, C.H.; Aligia, D.A.: A control strategy for DFIG-based systems operating under unbalanced grid voltage conditions. Int. J. Electr. Power Energy Syst. 142, 108273 (2022)

Abokhalil, A.G.: Grid connection control of DFIG for variable speed wind turbines under turbulent conditions. Int. J. Renew. Energy Res. 9(3), 1260–1271 (2019)

Wongyai, T.; Kumsuwan, Y.: A slip angle computation algorithm for synchronization and current control of a grid-connected doubly-fed induction generator. In: 2020 2nd International Conference on Smart Power & Internet Energy Systems (SPIES). IEEE, (2020).

Yan, X.; Cheng, M.: A robust grid synchronization method for cascaded brushless doubly fed induction generator. In: 2019 22nd International Conference on Electrical Machines and Systems (ICEMS). IEEE, (2019).

Jerin, A.R.A.; Kaliannan, P.; Subramanian, U.; El Moursi, M.S.: A review on FRT solutions for improving transient stability in DFIG-WTs. IET Renew. Power Gener. 12, 1786–1799 (2018)

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Alaboudy, A.H.K., Mahmoud, H.A., Elbaset, A.A. et al. Technical Assessment of the Key LVRT Techniques for Grid-Connected DFIG Wind Turbines. Arab J Sci Eng 48, 15223–15239 (2023). https://doi.org/10.1007/s13369-023-07975-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-023-07975-7