Abstract

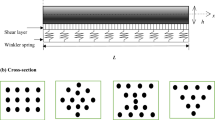

An experimental study to investigate the load at failure, failure mechanism, and crack propagation of a notched foamed concrete beam externally reinforced with a 200 mm length kenaf fiber reinforced polymer (KFRP) and tested under a four-point bending test (4PBT) is presented. In this study, the notch depth was varied. KFRP plates were fabricated by placing weaved yarns and smeared with Sika S31. From the experimental work, the shear failure and FRP rupture were seen. Various normalized notch depths significantly influenced allowable ultimate displacement, crack initiation, and failure modes. Following the preceding experimental series, a 2-D numerical modeling framework was developed to simulate the failure of the KFRP-strengthened foamed concrete beam. Independent tests had been carried out to determine material properties of the foamed concrete beam (i.e., un-notched beam strength, \({\sigma }_{o}\) and fracture energy, \({G}_{c}\)), later they were incorporated within a traction–separation relationship as a constitutive model of finite element modeling. The fracture energy values were calculated using Hillerborg’s model, which agrees well with the previous literature. Extended finite element model techniques were adopted for the strength prediction works. A good agreement was found between the predicted and experimental results with discrepancies of less than 15%.

Similar content being viewed by others

References

American Concrete Institute.: Building code requirements for structural Concrete. America. ACI 318 (2014)

Gencel, O.; Nodehi, M.; Yavuz Bayraktar, O.; Kaplan, G.; Benli, A.; Gholampour, A.; Ozbakkaloglu, T.: Basalt fiber-reinforced foam concrete containing silica fume: an experimental study. Constr. Build. Mater. 326(10), 126861 (2022). https://doi.org/10.1016/j.conbuildmat.2022.12686

Gökçe, H.S.; Hatungimana, D.; Ramyar, K.: Effect of fly ash and silica fume on hardened properties of foam concrete. Constr. Build. Mater. 194(8), 1–11 (2019). https://doi.org/10.1016/j.conbuildmat.2018.11.036

Lee, Y.L.; Tan, C.S.; Lim, S.K.; Mohammad, S.; Lim, J.H.: Strength performance on different mix of cement-sand ratio and sand condition for lightweight foamed concrete. E3S Web of Conf 65, 02006 (2018). https://doi.org/10.1051/e3sconf/20186502006

Ahmad, M.R.; Chen, B.; Shah, S.F.A.: Investigate the influence of expanded clay aggregate and silica fume on the properties of lightweight concrete. Constr. Build. Mater. 220, 253–266 (2019). https://doi.org/10.1016/j.conbuildmat.2019.05.171

Bagheri, A.; Samea, S.A.: Role of non-reactive powder in strength enhancement of foamed concrete. Constr. Build. Mater. 203(1), 134–145 (2019). https://doi.org/10.1016/j.conbuildmat.2019.01.052

Liu, M.Y.J.; Alengaram, U.J.; Jumaat, M.Z.; Mo, K.H.: Evaluation of thermal conductivity, mechanical and transport properties of lightweight aggregate foamed geopolymer concrete. Energy Build. 72(12), 238–245 (2014). https://doi.org/10.1016/j.enbuild.2013.12.029

Oren, O.H.; Gholampour, A.; Gencel, O.; Ozbakkaloglu, T.: Physical and mechanical properties of foam concretes containing granulated blast furnace slag as fine aggregate. Constr. Build. Mater. 238(12), 117774 (2020). https://doi.org/10.1016/j.conbuildmat.2019.117774

Nambiar, E.K.K.; Ramamurthy, K.: Influence of filler type on the properties of foam concrete. Cement Concr. Compos. 28(5), 475–480 (2006)

She, W.; Du, Y.; Zhao, G.; Feng, P.; Zhang, Y.; Cao, X.: Influence of coarse fly ash on the performance of foam concrete and its application in high-speed railway roadbeds. Constr. Build. Mater. 170(3), 153–166 (2018). https://doi.org/10.1016/j.conbuildmat.2018.02.207

American Concrete Institute.: Guide for the design and construction of externally bonded frp systems for strengthening concrete structures. America. ACI 440.2R-02 (2002).

Comite Euro-International du Beton.: Externally bonded FRP reinforcement for RC structures. Lausanne, CEB-FIP (2001).

Japan Society of Civil Engineers (JSCE).: Recommendations for upgrading of concrete structures with use of continuous fiber sheets, 88 (2001).

De Domenico, D.; Urso, S.; Borsellino, C.; Spinella, N.; Recupero, A.: Bond behavior and ultimate capacity of notched concrete beams with externally-bonded FRP and PBO-FRCM systems under different environmental conditions. Constr. Build. Mater. 265(10), 121208 (2020). https://doi.org/10.1016/j.conbuildmat.2020.121208

Ding, J.; Wang, F.; Huang, X.; Chen, S.: The effect of CFRP length on the failure mode of strengthened concrete beams. J. Polym. 6(7), 1705–1726 (2014). https://doi.org/10.3390/polym6061705

Huang, X.; Wang, J.; Zhang, F.; Niu, S.S.; Ding, J.: An experimental investigation on the failure behavior of a notched concrete beam strengthened with carbon fiber-reinforced polymer. Int. J. Polym. Sci. 2015(8), 17 (2015). https://doi.org/10.1155/2015/729320

Al-Rousan, R.Z.; Alhassan, M.A.; AlShuqari, E.A.: Behavior of plain concrete beams with DSSF strengthened in flexure with anchored CFRP sheets—Effects of DSSF content on the bonding length of CFRP sheets. Case Stud Constr. Mater. 14(6), 195 (2018). https://doi.org/10.1016/j.cscm.2018.e00195

Misnon, M.I.; Islam, M.M.; Epaarachchi, J.A.; Lau, K.T.: Potentiality of utilising natural textile materials for engineering composites applications. Mater. Design 59, 359–368 (2014). https://doi.org/10.1016/j.matdes.2014.03.022

Mahjoub, R.; Yatim, J.M.; Mohd Sam, A.R.; Hashemi, S.H.: Tensile properties of kenaf fiber due to various conditions of chemical fiber surface modifications. Constr. Build. Mater. 55(2), 103–113 (2014). https://doi.org/10.1016/j.conbuildmat.2014.01.036

Anuar, H.; Zuraida, A.: Improvement in mechanical properties of reinforced thermoplastic elastomer composite with Kenaf Bast fibre. Compos. B Eng. 42(3), 462–465 (2011). https://doi.org/10.1016/j.compositesb.2010.12.013

Abdul, N.H.K.; Bhutta, M.A.R.; Jamaludin, M.Y.; Warid, M.H.; Ismail, M.; Rahman, M.S.; Azman, M.: Kenaf fiber reinforced polymer composites for strengthening RC beams. J. Adv. Concr. Technol. 12(6), 167–177 (2014). https://doi.org/10.3151/jact.12.167

Guo, A.; Sun, Z.; Satyavolu, J.: Experimental and finite element analysis on flexural behavior of mortar beams with chemically modified Kenaf fibers. Constr. Build. Mater. 292, 123449 (2021). https://doi.org/10.1016/j.conbuildmat.2021.123449

Park, K.; Choi, H.; Paulino, G.H.: Assessment of cohesive traction-separation relationships in ABAQUS: a comparative study. Mech. Res. Commun. 78, 71–78 (2016). https://doi.org/10.1016/j.mechrescom.2016.09.004

Elices, M.; Guinea, G.V.; Gómez, J.; Planas, J.: The cohesive zone model: Advantages, limitations and challenges. Eng. Fract. Mech. 69(2), 137–163 (2001). https://doi.org/10.1016/S0013-7944(01)00083-2

Freed, Y.; Banks-Sills, L.: A new cohesive zone model for mixed mode interface fracture in bimaterials. Eng. Fract. Mech. 75(15), 4583–4593 (2008). https://doi.org/10.1016/j.engfracmech.2008.04.013

Patrick McGarry, J.; Máirtín, É.Ó.; Parry, G.; Beltz, G.E.: Potential-based and non-potential-based cohesive zone formulations under mixed-mode separation and over-closure. Part I: theoretical analysis. J. Mech. Phys. Solids 63, 336–362 (2014). https://doi.org/10.1016/j.jmps.2013.08.020

Spring, D.W.; Giraldo-Londoño, O.; Paulino, G.H.: A study on the thermodynamic consistency of the Park–Paulino–Roesler (PPR) cohesive fracture model. Mech. Res. Commun. 78(4), 100–109 (2016). https://doi.org/10.1016/j.mechrescom.2016.05.006

Yu, Z.; Zhang, J.; Shen, J.; Chen, H.: Simulation of crack propagation behavior of nuclear graphite by using XFEM, VCCT and CZM methods. Nuclear Mater. Energy 29(2), 101063 (2021). https://doi.org/10.1016/j.nme.2021.101063

Omar, Z.; Sugiman, S.; Yusoff, M.M.; Ahmad, H.: Predicting the flexural behaviour of CFRP-strengthened concrete beam using combined XFEM and cohesive zone model. J. Appl. Sci. Eng. 25(6), 925–938 (2021). https://doi.org/10.6180/jase.202212_25(6).0003

Melenk, J.M.; Babuška, I.: The partition of unity finite element method: basic theory and applications. Comput. Methods Appl. Mech. Eng. 139(4), 289–314 (1996). https://doi.org/10.1016/S0045-7825(96)01087-0

Karimi, M.; Rouzegar, J.: A CA-XFEM for mixed-mode variable-amplitude fatigue crack growth. Theor. Appl. Fract. Mech. 114(3), 102979 (2021). https://doi.org/10.1016/j.tafmec.2021.102979

Elruby, A.Y.; Nakhla, S.; Hussein, A.: Automating XFEM modeling process for optimal failure predictions. Math. Probl. Eng. 2018(8), 14 (2018)

Japanese Concrete Institute.: Method of test for fracture energy of concrete by use of Notched Beam, 2(2), 1–14 (2003).

ASTM-D6272.: Standard test method for flexural properties of unreinforced and reinforced plastics and electrical insulating materials by four-point bending 1, 1–9 (2008).

Kearsley, E.P.: The effect of high volumes of ungraded fly ash on the properties of foamed concrete. Univerisity of Leeds, UK (1991)

Hillerborg, A.: The theoretical basis of a method to determine the fracture energy G F of concrete. Mater. Struct. 18(4), 291–296 (1985). https://doi.org/10.1007/BF02472919

Bažant, Z.P.; Oh, B.H.: Crack band theory for fracture of concrete. Matér. et Constr. 16(3), 155–177 (1983). https://doi.org/10.1007/BF02486267

Comite Euro-International du Beton.: CEB-FIB model code 1990 (Thomas Telford Service). Lausanne, CEB-FIP (1993).

Rahman, N.A.; Jaini, Z.M.: An experimental study on the fracture energy of foamed concrete using V-Notched beams. InCIEC 2014(3), 1–13 (2015). https://doi.org/10.1007/978-981-287-290-6_9

Park, K.; Paulino, G.H.; Roesler, J.R.: Determination of the kink point in the bilinear softening model for concrete. Eng. Fract. Mech. 75(2), 3806–3818 (2008). https://doi.org/10.1016/j.engfracmech.2008.02.002

Lee, Y.S.; Ahmad, H.: XFEM modelling of single-Lap Kenaf fibre composite hybrid joints under quasi-static loading. Plast., Rubber Compos. 48(2), 48–56 (2019). https://doi.org/10.1080/14658011.2018.1541670

Tijssens, M.G.A.; Sluys, B.L.J.; Van der Giessen, E.: Numerical simulation of quasi-brittle fracture using damaging cohesive surfaces. Eur. J. Mech. A/Solids 19(5), 761–779 (2000). https://doi.org/10.1016/S0997-7538(00)00190-X

More, S.T.; Bindu, R.S.: Effect of mesh size on finite element analysis of plate structure. Int. J. Eng. Sci. Innov. Technol. 4(3), 181–185 (2015)

Koslan, M.F.S.; Zaidi, A.M.A.; Othman, M.Z.; Abdullah, S.; Thanakodi, S.: The effect of mesh sizing toward deformation result in computational dynamic simulation for blast loading application. Mod. Appl. Sci. 7(7), 23–28 (2013). https://doi.org/10.5539/mas.v7n7p2

Genikomsou, A.; Polak, M.A.: Finite element simulation of concrete slabs with various placement and amount of shear bolts. Proc. Eng. 193(4), 313–320 (2017). https://doi.org/10.1016/j.proeng.2017.06.219

Abad, B. F., Lantsoght, E. O. L., & Yang, Y.: Shear capacity of steel fibre reinforced concrete beams. In: Proceedings of the fib Symposium. Concrete - Innovations in Materials, Krakow (1710–1717). Krakow (2019).

Budi, A.S.; Safitri, E.; Sangadji, S.; Kristiawan, S.A.: Shear strength of HVFA-SCC beams without stirrups. Buildings 11(4), 177 (2021). https://doi.org/10.3390/buildings11040177

Acknowledgements

Communication of this research is made possible through monetary assistance by Universiti Tun Hussein Onn Malaysia and the UTHM Publisher’s Office via Publication Fund E15216. We also want to thank Research Management Center (RMC), University Tun Hussein Onn Malaysia (UTHM) for sponsoring this work under Postgraduate Research Grant (GPPS) (Research Grant No. H706).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Maulana, M.R., Sugiman, S., Ahmad, H. et al. Strength Prediction of Notched Foamed Concrete Beam Strengthened with KFRP Plates under Flexural Load. Arab J Sci Eng 48, 13059–13071 (2023). https://doi.org/10.1007/s13369-023-07688-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-023-07688-x