Abstract

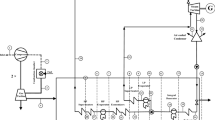

In today’s scenario, ensuring sustainability of energy system particularly in the field of power generation is a major concern, and in this regard, exergy analysis is widely accepted tool. For this purpose, first, a comprehensive performance is carried out between two gas turbine plants, i.e., GT2 (case I) and GT1 (case II) using various exergy performance parameters. Further, a comprehensive performance evaluation is carried out between three cases; GT2 (case I), GT1 (case II) and CCPP (case III) using different sustainability indicators such as exergy efficiency, waste exergy ratio, exergy destruction factor and recoverable exergy ratio. Results demonstrate that exergetic sustainability index of combined cycle power plant (CCPP) is 0.45 when compared with GT2 (0.29) and GT1 (0.28). The increased sustainability index is because of the incorporation of a bottoming cycle, which ultimately decreases waste exergy ratio and leads to an increase in exergy efficiency and sustainability index of CCPP.

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from [Haldia Petrochemical Limited]. Restrictions apply to the availability of these data, however, it was used under for the current study and so are not publicly available.

Abbreviations

- \(c_{p}\) :

-

Specific heat (\({\text{kJ/kgK}}\))

- \(\dot{E}x\) :

-

Exergy rate (MW)

- \({\text{ex}}\) :

-

Specific exergy (kJ/kg)

- \(\dot{Q}\) :

-

Heat

- \(h\) :

-

Specific enthalpy (kJ/kg)

- \(s\) :

-

Specific entropy (kJ/kgK)

- \(I\dot{P}\) :

-

Exergetic improvement potential rate

- \({\text{LHV}}\) :

-

Lower heating value

- cbfs:

-

Carbon black fluid stock

- HRSG:

-

Heat recovery steam generator

- AB:

-

Auxiliary boiler

- BPST:

-

Back pressure steam turbine

- CST:

-

Condensing steam turbine

- rfg:

-

Residual fuel gas

- \(\dot{m}\) :

-

Mass flow rate (kg/sec)

- \(P\) :

-

Pressure (\({\text{kPa}}\))

- \(R\) :

-

Specific gas constant (kJ/kgK)

- \(X\) :

-

Relative exergy destruction

- \(T\) :

-

Temperature (\({\text{K}}\))

- \(\dot{W}\) :

-

Work rate (MW)

- \(x\) :

-

Chemical component

- \(\theta_{{{\text{esi}}}}\) :

-

Exergetic sustainability analysis

- \(\eta\) :

-

Efficiency

- \(a\) :

-

Air

- \({\text{ph}}\) :

-

Physical

- \({\text{ch}}\) :

-

Chemical

- \({\text{dest}}\) :

-

Destroyed

- \(f\) :

-

Fuel

- \(i\) :

-

Successive number of elements

- \({\text{in}}\) :

-

Inlet

- \({\text{out}}\) :

-

Outlet

- \({\text{re}}\) :

-

Recoverable

- \({\text{exd}}\) :

-

Exergy destruction factor

- \({\text{eef}}\) :

-

Environmental effect factor

- \({\text{esi}}\) :

-

Exergetic sustainability index

- \(t\) :

-

Total

- \({\text{we}}\) :

-

Waste

- \(u\) :

-

Useful

References

V. Gowrishankar, C. Angelides, H. Druckenmiller, Combined Heat and Power Systems: Improving the Energy Efficiency of Our Manufacturing Plants, Buildings, and Other Facilities, New York, 2013. https://www.nrdc.org/sites/default/files/combined-heat-power-IP.pdf.

Ahmadi, G.; Toghraie, D.; Akbari, O.: Energy, exergy and environmental (3E) analysis of the existing CHP system in a petrochemical plant. Renew. Sustain. Energy Rev. 99, 234–242 (2019). https://doi.org/10.1016/j.rser.2018.10.009

Lucia, U.; Grisolia, G.: Exergy inefficiency: an indicator for sustainable development analysis. Energy Rep. 5, 62–69 (2019). https://doi.org/10.1016/j.egyr.2018.12.001

Sikdar, S.K.; Sengupta, D.; Mukherjee, R.: Measuring progress towards sustainable forest. Springer (2017)

Kaygusuz, K.; Bilgen, S.: ˙ Ilgen energy sources, part a: recovery, utilization, and environmental effects thermodynamic aspects of renewable and sustainable development thermodynamic aspects of renewable and sustainable development. Energy Sourc., Part A. 31, 287–298 (2009). https://doi.org/10.1080/15567030701715401

Ersayin, E.; Ozgener, L.: Performance analysis of combined cycle power plants: a case study. Renew. Sustain. Energy Rev. 43, 832–842 (2015). https://doi.org/10.1016/j.rser.2014.11.082

Balli, O.; Ekici, S.; Karakoc, T.H.: TF33 Turbofan engine in every respect: Performance, environmental, and sustainability assessment. Environ. Prog Sustain Energy 40, 87 (2021). https://doi.org/10.1002/ep.13578

Rosen, M.A.; Dincer, I.: On exergy and environmental impact. Int. J. Energy Res. 21, 643–654 (1997). https://doi.org/10.1002/(SICI)1099-114X(19970610)21:7%3c643::AID-ER284%3e3.0.CO;2-I

Nielson, S.N.: Sustainable developemenet indicators an exergy-based approach, first edit. Taylor & Francis Group (2016)

Turan, O.; Aydın, H.; Karakoc, T.H.; Midilli, A.: Some exergetic measures of a JT8D turbofan engine. J. Autom. Control Eng. 2, 110–114 (2014). https://doi.org/10.12720/joace.2.2.110-114

Aydin, H.; Turan, O.; Karakoc, T.H.; Midilli, A.: Exergetic sustainability indicators as a tool in commercial aircraft: a case study for a turbofan engine. Int. J. Green Energy. 12, 28–40 (2015). https://doi.org/10.1080/15435075.2014.889004

Aydin, H.: Exergetic sustainability analysis of LM6000 gas turbine power plant with steam cycle. Energy 57, 766–774 (2013). https://doi.org/10.1016/j.energy.2013.05.018

Balli, O.; Ekici, S.; Karakoc, H.T.: Achieving a more efficient and greener combined heat and power system driven by a micro gas turbine engine: Issues, opportunities, and benefits in the presence of thermodynamic perspective. Int. J. Energy Res. 45, 8620–8638 (2021). https://doi.org/10.1002/er.6398

Zisopoulos, F.K.; Rossier-Miranda, F.J.; van der Goot, A.J.; Boom, R.M.: The use of exergetic indicators in the food industry – a review. Crit. Rev. Food Sci. Nutr. 57, 197–211 (2017). https://doi.org/10.1080/10408398.2014.975335

Midilli, A.; Dincer, I.: Development of some exergetic parameters for PEM fuel cells for measuring environmental impact and sustainability. Int. J. Hydrogen Energy. 34, 3858–3872 (2009). https://doi.org/10.1016/j.ijhydene.2009.02.066

Tuly, S.S.; Islam, M.S.; Hassan, R.; Das, B.K.; Sarker, M.R.I.: Investigation of a modified double slope solar still integrated with nanoparticle-mixed phase change materials: energy, exergy, exergo-economic, environmental, and sustainability analyses. Case Stud. Therm. Eng. 37, 102256 (2022). https://doi.org/10.1016/j.csite.2022.102256

Shahbeig, H.; Shafizadeh, A.; Rosen, M.A.; Sels, B.F.: Exergy sustainability analysis of biomass gasification: a critical review. Biofuel Res. J. 9, 1592–1607 (2022). https://doi.org/10.18331/BRJ2022.9.1.5

Yıldız, G.; Ergün, A.; Gürel, A.E.; Ceylan, İ; Ağbulut, Ü.; Eser, S.; Afzal, A.; Saleel, C.A.: Exergy, sustainability and performance analysis of ground source direct evaporative cooling system. Case Stud. Therm. Eng. 31, 84 (2022). https://doi.org/10.1016/j.csite.2022.101810

HPL, Haldia Petrochemicals Limited, (2022). https://www.haldiapetrochemicals.com/ (Accessed February 28, 2022).

S. and Lundy, 116 MW Haldia Combined Cycle Co-Generation Power Plant, West Bengal, India, (2000). https://www.lntsnl.com/our-services/detail-engineering/projects/116-mw-haldia-combined-cycle-co-generation-power-plant-west-bengal-india/ (Accessed December 28, 2020).

Sankalp Arpit, S.K.D.; Saren, S.; Kumar Das, P.: Exergy-based comparison of two gas turbine plants with naphtha and naphtha-rfg mixture as fuels. Springer (2019)

Yunus, M.A.B.; Cengel, A.: Thermodynamics an engineering approach. Mc-Graw Hill (2011)

Kaushik, S.C.; Singh, O.K.: Estimation of chemical exergy of solid, liquid and gaseous fuels used in thermal power plants. J. Therm. Anal. Calorim. 115, 903–908 (2014). https://doi.org/10.1007/s10973-013-3323-9

Abusoglu, A.; Kanoglu, M.: First and second law analysis of diesel engine powered cogeneration systems. Energy Convers. Manag. 49, 2026–2031 (2008). https://doi.org/10.1016/j.enconman.2008.02.012

Process Waste Heat Recovery Boiler-KCIL, (n.d.).

Egzergia, J.S.: Poradnik obliczania I stosowania. WIT Press (2005)

Bin, Z.: Solid oxide fuel cell (SOFC) technical challenges and solutions from nano-aspects. Int. J. Energy Res. 31, 135–147 (2009).

Rösch, C.; Bräutigam, K.R.; Kopfmüller, J.; Stelzer, V.; Lichtner, P.: Indicator system for the sustainability assessment of the German energy system and its transition. Energy. Sustain. Soc. 7, 1–13 (2017). https://doi.org/10.1186/s13705-016-0103-y

Acknowledgements

In the present work, a detailed exergetic sustainability analysis of naphtha-based CCPP has been carried out. For this, a comprehensive performance evaluation is carried out between three cases; GT2 (case I), GT1 (case II) and CCPP (case III) using different sustainability indicators such as exergy efficiency, waste exergy ratio, exergy destruction factor and recoverable exergy ratio. For carrying out this work, the author acknowledges Haldia Petrochemicals Limited for providing actual data from the control unit of a power plant.

Funding

Not applicable.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Appendix

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Arpit, S., Das, P.K. & Dash, S.K. Exergetic Sustainability Analysis of a Naphtha-Based Combined Cycle Power Plant (CCPP). Arab J Sci Eng 48, 11741–11753 (2023). https://doi.org/10.1007/s13369-022-07548-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-022-07548-0