Abstract

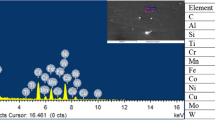

Wire electric discharge machining (WEDM) is a famous machining process for manufacturing intricate and 3D complex geometries on tough difficult-to-machine superalloys and composites. Stainless steel 304 (SS 304) alloy has excellent corrosion resistance and forming faces which is used in aerospace, chemical, petrochemical industries, etc. The present work focuses on WEDM of SS 304 using a brass wire electrode of ϕ 0.25 mm with rough cut trailed by trim cuts to improve the machinability. WEDM experiments were conducted as per Taguchi’s L9 experimental design with four-factor and three-level. The effect of pulse on time (Ton), pulse off time (Toff), current and wire offset during trim cuts on machinability characteristics, namely surface roughness, material removal rate (MRR), kerf width and microhardness, was analysed. Experimental results showed that trim cuts with varying wire offsets produced better surface finish, high MRR with hardness, and low kerf width compared with rough cut. Furthermore, surface characteristics of rough cut with trim cut surfaces were analysed using scanning electron microscope (SEM) images. Finally, grey relational analysis (GRA) was used to find the optimal input parameter combination and simultaneously optimize the selected machinability responses.

Similar content being viewed by others

References

Jayaganth, A.; Deepak Mani, A.; Jayakumar, K.: Experimental study on effect of machining parameters and environment on drilling characteristics of stainless steel 304. Appl. Mech. Mater. 852, 273–278 (2016)

Selvakumar, G.; Thiruppathi Kuttalingam, K.G.; Ram Prakash, S.: Investigation on machining and surface characteristics of AA5083 for cryogenic applications by adopting trim cut in WEDM. J. Braz. Soc. Mech. Sci. Eng. 40, 267 (2018)

Sarkar, S.; Ghosh, K.; Mitra, S.; Bhattacharyya, B.: An integrated approach to optimization of WEDM combining single-pass and multipass cutting operation. Mater. Manuf. Process. 25(8), 799–807 (2010)

Klink, A.; Guo, Y.B.; Klocke, F.: Surface integrity evolution of powder metallurgical tool steel by main cut and finishing trim cuts in wire-EDM. Procedia Eng 19, 178–183 (2011)

Jaafar, N.A.; Abdullah, A.B.; Samad, Z.: Optimization of WEDM cutting parameters on surface roughness of 2379 steel using Taguchi method. SAE Int. J. Mater. Manuf. 11(2), 97–103 (2018)

Sabudin, S.; Lie, I.C.; Mohamad, E.E.: Multi-cutting passes for a fine-cut wire electro discharge machining of stainless steel. Adv. Mater. Res. 418–420, 1288–1293 (2012)

Liu, J.F.; Li, L.; Guo, Y.B.: Surface integrity evolution from main cut to finish trim cut in W-EDM of shape memory alloy. Procedia CIRP 13, 137–142 (2014)

Jangra, K.K.: An experimental study for multi-pass cutting operation in wire electrical discharge machining of WC-5.3% Co composite. Int. J. Adv. Manuf. Technol. 76, 971–982 (2015)

Chalisgaonkar, R.; Kumar, J.: Multi-response optimization and modeling of trim cut WEDM operation of commercially pure titanium (CPTi) considering multiple user’s preferences. Eng. Sci. Technol. Int. J. 18, 125–134 (2015)

Arikatla, S.P.; Tamil Mannan, K.; Krishnaiah, A.: Surface integrity characteristics in wire electrical discharge machining of titanium alloy during main cut and trim cuts. Mater. Today Proc. 4, 1500–1509 (2017)

Selvakumar, G.; Bravilin Jiju, K.; Sarkar, S.; Mitra, S.: Enhancing die corner accuracy through trim cut in WEDM. Int. J. Adv. Manuf. Technol. 83, 791–803 (2016)

Goswami, A.; Kumar, J.: Trim cut machining and surface integrity analysis of Nimonic 80A alloy using wire cut EDM. Eng. Sci. Technol. Int. J. 20(1), 175–186 (2017)

Jadam, T.; Datta, S.; Masanta, M.: Study of surface integrity and machining performance during main/rough cut and trim/finish cut mode of WEDM on Ti–6Al–4V: effects of wire material. J. Braz. Soc. Mech. Sci. Eng. 41, 151 (2019)

Fuse, K.; Dalsaniya, A.; Modi, D.; Vora, J.; Pimenov, D.Y.; Giasin, K.; Wojciechowski, S.: Integration of fuzzy AHP and fuzzy TOPSIS methods for wire electric discharge machining of titanium (Ti6Al4V) alloy using RSM. Materials 14(23), 7408 (2021)

Harane, P.P.; Wojciechowski, S.; Unune, D.R.: Investigating the effect of different tool electrodes in electric discharge drilling of Waspaloy on process responses. J. Mater. Res. Technol. 20, 2542–2557 (2022)

Chohan, J.S.; Mittal, N.; Kumar, R.; Singh, S.; Sharma, S.; Dwivedi, S.P.; Wojciechowski, S.: Optimization of FFF process parameters by naked mole-rat algorithms with enhanced exploration and exploitation capabilities. Polymers 13(11), 1702 (2021)

Vakharia, V.; Vora, J.; Khanna, S.; Chaudhari, R.; Shah, M.; Pimenov, D.Y.; Wojciechowski, S.: Experimental investigations and prediction of WEDMed surface of Nitinol SMA using SinGAN and DenseNet deep learning model. J. Mater. Res. Technol. 18, 325–337 (2022)

Singh, S.K.; Mali, H.S.; Unune, D.R.; Wojciechowski, S.; Wilczyński, D.: Application of generalized regression neural network and gaussian process regression for modelling hybrid micro-electric discharge machining: a comparative study. Processes 10(4), 755 (2022)

Alduroobi, A.A.A.; Ubaid, A.M.; Tawfiq, M.A.; Elias, R.R.: Wire EDM process optimization for machining AISI 1045 steel by use of Taguchi method, artificial neural network and analysis of variances. Int. J. Syst. Assur. Eng. Manag. 11, 1314–1338 (2020)

Jangra, K.K.; Kumar, V.; Kumar, V.: An experimental and comparative study on rough and trim cutting operation in WEDM of hard to machine materials. Procedia Mater. Sci. 5, 1603–1612 (2014)

Mandal, A.; Dixit, A.R.; Das, A.K.; Mandal, N.: Modeling and optimization of machining nimonic C-263 superalloy using multicut strategy in WEDM. Mater. Manuf. Process. 31(7), 860–868 (2016)

Gautier, G.; Priarone, P.C.; Rizzuti, S.; Settineri, L.; Tebaldo, V.: A contribution on the modelling of wire electrical discharge machining of a γ-TiAl alloy. Procedia CIRP 31, 203–208 (2015)

Sahu, A.K.; Pattanayak, S.; Panda, S.: WEDM microdrilling of 316 L stainless steel orthopedic implant. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 234(17), 3416–3435 (2020)

Azam, M.; Jahanzaib, M.; Abbasi, J.A.; Wasim, A.: Modeling of cutting speed (CS) for HSLA steel in wire electrical discharge machining (WEDM) using moly wire. J. Chin. Inst. Eng. Trans. Chin. Inst. Eng. A 39(7), 802–808 (2016)

Ghodsiyeh, D.: Review on current research trends in wire electrical discharge machining (WEDM). Indian J. Sci. Technol. 6(2), 1–15 (2013)

Huang, Y.; Ming, W.; Guo, J.; Zhang, Z.; Liu, G.; Li, M.; Zhang, G.: Optimization of cutting conditions of YG15 on rough and finish cutting in WEDM based on statistical analyses. Int. J. Adv. Manuf. Technol. 69, 993–1008 (2013)

Nakwong, P.A.M.: Experimental investigation for main cut and trim cuts of wire electrical discharge machining on tungsten carbide. Int. J. Mech. Eng. Technol. 9(10), 1518–1528 (2018)

Chalisgaonkar, R.; Kumar, J.: Investigation of wire consumption and wear mechanism in trim cut WEDM operation of commercially pure titanium. Mater. Sci. Forum 808, 43–50 (2015)

Manikandan, K.; Ranjith Kumar, P.; Raj Kumar, D.; Palanikumar, K.: Machinability evaluation and comparison of Incoloy 825, Inconel 603 XL, Monel K400 and Inconel 600 super alloys in wire electrical discharge machining. J. Mater. Res. Technol. 9(6), 12260–12272 (2020)

Mouralova, K.; Prokes, T.; Benes, L.: Surface and subsurface layers defects analysis after WEDM affecting the subsequent lifetime of produced components. Arab. J. Sci. Eng. 44, 7723–7735 (2019)

Ikram, A.; Mufti, N.A.; Saleem, M.Q.; Khan, A.R.: Parametric optimization for surface roughness, kerf and MRR in wire electrical discharge machining (WEDM) using Taguchi design of experiment. J. Mech. Sci. Technol. 27, 2133–2141 (2013)

Khan, N.Z.; Wahid, M.A.; Singh, S.; Siddiquee, A.N.; Khan, Z.A.: A study on micro hardness in wire electrical discharge machining based on Taguchi method. Int. J. Mech. Prod. Eng. 1(1), 10–15 (2013)

Sharma, N.; Khanna, R.; Gupta, R.D.: WEDM process variables investigation for HSLA by response surface methodology and genetic algorithm. Eng. Sci. Technol. Int. J. 18(2), 171–177 (2015)

Ishfaq, K.; Ahmad, N.; Jawad, M.; Ali, M.A.; Al-Ahmari, A.M.: Evaluating material’s interaction in wire electrical discharge machining of stainless steel (304) for simultaneous optimization of conflicting responses. Materials 12(12), 1–15 (2019)

Cakıroglu, R.; Günay, M.: Comprehensive analysis of material removal rate, tool wear and surface roughness in electrical discharge turning of L2 tool steel. J. Mater. Res. Technol. 9(4), 7305–7317 (2020)

Gunay, M.; Meral, T.: Modelling and multiresponse optimization for minimizing burr height, thrust force and surface roughness in drilling of ferritic stainless steel. Sadhana 45, 1–10 (2020)

Çakıroğlu, R.: Machinability analysis of Inconel 718 superalloy with AlTiN-coated carbide tool under different cutting environments. Arab. J. Sci. Eng. (2021). https://doi.org/10.1007/s13369-021-05626-3

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Suresh, T., Jayakumar, K., Selvakumar, G. et al. Experimental Investigation on Improvement of Machinability of SS 304 Through Multipass Cutting in WEDM. Arab J Sci Eng 48, 11577–11590 (2023). https://doi.org/10.1007/s13369-022-07508-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-022-07508-8