Abstract

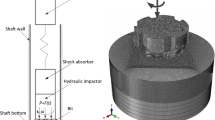

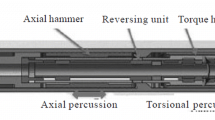

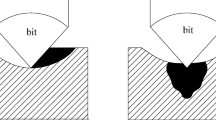

To overcome some shortcomings in conventional rotary percussion drilling, such as low impact frequency and enabling not to make the most of impact energy, this paper proposed a new rotary percussion drilling method. Based on this method, the corresponding drilling device was designed. At first, the inner structure and working principle of this device were illustrated in detail. This device has two bits, namely, internal bit and external bit. The internal bit can generate high-frequency impact on rocks and concentrate impact energy near central areas of the bottom hole. The coupled action of these two bits can produce an alternating shear stress zone, which can exacerbate fatigue damage to rocks. And then the mechanics models for analyzing alternating shear stress and impact energy were built. Finally, the effects of some key parameters on alternating shear stress and impact energy were analyzed. The key findings of this study are as follows. As blades number or dip angle of the internal bit decreases, the amplitude of the alternating shear stress increases, which is beneficial for rock fatigue damage. Moreover, as the loading and unloading speed of impact force increases, the impact energy increases, which will promote damage and fragmentation of rocks. Compared with other wave shapes, the square wave has the highest loading and unloading speed, which means its rock-breaking efficiency is the highest. The new rotary percussion drilling method proposed in this study provides a new idea to make full use of impact energy and improve rock-breaking efficiency.

Similar content being viewed by others

References

Zhang, H.; Guan, Z.; Liu, Y.; Liang, D.; Xu, Y.: A novel tool to improve the rate of penetration by transferring drilling string vibration energy to hydraulic energy. J. Petrol. Sci. Eng. 146, 318–325 (2016)

Wiercigroch, M.; Vaziri, V.; Kapitaniak, M.: RED: Revolutionary drilling technology for hard rock formations. In: SPE/IADC Drilling Conference and Exhibition (2017)

Zhang, C.; Yang, Y.; Lin, M.; Chen, L.: Research on rock-breaking mechanism of cross-cutting PDC bit. J. Petrol. Sci. Eng. 161, 657–666 (2017)

Lundberg, B.; Okrouhlik, M.: Efficiency of a percussive rock drilling process with consideration of wave energy radiation into the rock. Int. J. Impact Eng. 32, 1573–1583 (2006)

Lundberg, B.; Okrouhlik, M.: Influence of 3D effects on the efficiency of percussive rock drilling. Int. J. Impact Eng. 25, 345–360 (2001)

Yokota, T.; Onishi, K.; Karasawa, H.; Ohno, T.; Ota, A.; Kaneko, T.; Yokota, T.; Onishi, K.; Karasawa, H.; Ohno, T.: Seismic while drilling: basic experiments using a percussion drill as an energy source. Explor. Geophys. 35, 255–259 (2004)

Zhu, H.; Liu, Q.; Deng, J.; Wang, G.; Liao, J.: Rock-breaking mechanism of rotary-percussive drilling. J. Basic Sci. Eng. 20, 622–631 (2012)

Bui, H. D.; Gray, M. A.; Oliver, M. S.: Steerable percussion air drilling system. In: Natural Gas Research, Development and Demonstration Contractors Review Meeting, Baton Rouge, LA (United States), 4–6 Apr. 1995 (1995)

Liu, G.; Yumei, L. I.; Jun, L. I.; Zha, C.; Zhang, T.; Huo, M.: New technology with composite percussion drilling and rock breaking. Petrol. Drill. Tech. (2016)

Song, H.; Shi, H.; Li, G.; Ji, Z.; Li, S.; Liu, C.; Li, X.: Three-dimensional numerical simulation of energy transfer efficiency and rock damage in percussive drilling with multiple-button bit. J. Energy Resour. Technol. 143, 024501 (2021)

Cao, Q.; Shi, H.; Xu, W.; Xiong, C.; Yang, Z.; Ji, R.: Theoretical and experimental studies of impact energy and rock-drilling efficiency in vibro-impact drilling. J. Energy Res. Technol. 144, 023201 (2021)

Shi, H.; Ji, Z.; Jiang, J.; Li, B.: Numerical study on fragmentation characteristics of granite under a single polycrystalline diamond compact cutter in rotary-percussive drilling. J. Energy Resour. Technol. 144, 1–19 (2022)

Yin, S.; Zhao, D.; Zhai, G.: Investigation into the characteristics of rock damage caused by ultrasonic vibration. Int. J. Rock Mech. Min. Sci. 84, 159–164 (2016)

Oparin, V.N.; Timonin, V.V.; Karpov, V.N.: Quantitative estimate of rotary–percussion drilling efficiency in rocks. J. Min. Sci. 52, 1100–1111 (2016)

Chiang, L.E.; Elías, D.A.: A 3D FEM methodology for simulating the impact in rock-drilling hammers. Int. J. Rock Mech. Min. Sci. 45, 701–711 (2008)

Shadrina, A.; Kabanova, T.; Krets, V.; Saruev, L.: A study of specific fracture energy at percussion drilling. In: pp. 012036 (2014)

Nejati, H.R.; Ghazvinian, A.: Brittleness effect on rock fatigue damage evolution. Rock Mech. Rock Eng. 47, 1839–1848 (2014)

Xiao, J.Q.; Ding, D.X.; Jiang, F.L.; Xu, G.: Fatigue damage variable and evolution of rock subjected to cyclic loading. Int. J. Rock Mech. Min. Sci. 47, 461–468 (2010)

Dill, D.B.: The nature of fatigue. Geriatrics 10, 474 (1955)

Moinereau, D.; Yoon, K.K.; Choi, J.B.: Fatigue, fracture, and damage analysis. In: 2003: Presented at the 2003 ASME Pressure Vessels and Piping Conference, Cleveland, Ohio, July 20–24, 2003. American Society of Mechanical Engineers (2003)

Wei, L. I.; Zheng, H.; Kai, Y.; Zhang, H.; Wang, M.; Xu, M. A.; Zhao, M.: Drilling rate equation of cone bit basied on single tooth intrusive theory. J. Northeast Petrol. Univ. (2013)

Jianyong, P.: Interpretation of single cutter tests for rock mechanical properties. In: American Rock Mechanics Association (2012)

Erarslan, N.; Williams, D.J.: Mechanism of rock fatigue damage in terms of fracturing modes. Int. J. Fatigue 43, 76–89 (2012)

Erarslan, N.: Microstructural investigation of subcritical crack propagation and fracture process zone (FPZ) by the reduction of rock fracture toughness under cyclic loading. Eng. Geol. 208, 181–190 (2016)

Ren, S.; Bai, Y.M.; Zhang, J.P.; Jiang, D.Y.; Yang, C.H.: Experimental investigation of the fatigue properties of salt rock. Int. J. Rock Mech. Min. Sci. 64, 68–72 (2013)

Fei, X.D.; Dong, Z.Z.; Yu-Shou, L.I.; Wang, Y.Q.: Experimental study of mechanical properties of sandstone under a dynamic pore pressure. J. Min. Saf. Eng. 27, 425–428 (2010)

Wu, G.; Swift, G.: Laboratory investigation of the effects of temperature on the mechanical properties of sandstone. Geotech. Geol. Eng. 31, 809–816 (2013)

He, J.; Lin, C.; Li, X.; Zhang, Y.; Chen, Y.: Initiation, propagation, closure and morphology of hydraulic fractures in sandstone cores. Fuel 208, 65–70 (2017)

Letcher, T.; Shen, M.H.H.; Scott-Emuakpor, O.; George, T.; Cross, C.: Strain rate and loading waveform effects on an energy-based fatigue life prediction for AL6061-T6. J. Eng. Gas Turbines Power 136, 225–233 (2014)

Bagde, M.N.; Petroš, V.: Waveform effect on fatigue properties of intact sandstone in uniaxial cyclical loading. Rock Mech. Rock Eng. 38, 169–196 (2005)

Xiao, J.Q.; Feng, X.T.; Ding, D.X.; Jiang, F.L.: Investigation and modeling on fatigue damage evolution of rock as a function of logarithmic cycle. Int. J. Numer. Anal. Methods Geomech. 35, 1127–1140 (2011)

Acknowledgements

The authors give their thanks to the financial support of the Joint Funds of the National Natural Science Foundation of China (Grant No. U19B6003-05) and Research on Key Technologies of Geothermal Resources Development and Utilization of CNPC (Grant No. 2021DJ5502). The authors also thank Tianen Liu, Guangjie Yuan, and others for some help in writing and revising the paper.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Song, H., Shi, H. Theoretical Analysis and Optimal Design of a New Rotary Percussion Drilling Method. Arab J Sci Eng 48, 9195–9206 (2023). https://doi.org/10.1007/s13369-022-07252-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-022-07252-z