Abstract

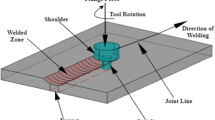

Wire arc additive manufacturing (WAAM) is a comparatively new wire-based technology used to produce complex products that cannot be made using traditional manufacturing methods. Selecting the best WAAM technique based on product specifications, manufacturability and functionality is a critical issue. In this paper, an attempt is made to evaluate different WAAM techniques using a hybrid multi-criteria decision-making technique. The objective of the proposed work is to demonstrate the weights and ranking of different WAAM techniques under the novel idea of integrated fuzzy CRITIC and fuzzy WASPAS. Gas metal arc welding (GMAW), double electrode GMAW (DE-GMAW), gas tungsten arc welding (GTAW), plasma arc welding-based WAAM (PAW-AM), and electron beam-based WAAM (EBM-AM) are considered as alternatives. Geometrical features, material supply, mechanical and thermal properties, operational characteristics, and economic challenges are considered as main criteria. Further, under each main criterion, sub-criteria are considered. The weights of the main criteria and sub-criteria are obtained by fuzzy CRITIC (criteria importance through inter-criteria correlation). With the help of these weights, the alternatives are ranked by fuzzy WASPAS (weighted aggregated sum-product assessment) for finding the most suitable technique. From the findings of this research, it is concluded that electron beam-based WAAM (EBM-AM) is preferable as per the chosen criteria type. Moreover, the consistency of the hybrid MCDM model has been verified using sensitivity analysis.

Similar content being viewed by others

Data Availability

The data and materials that support the findings of this study are available from the corresponding author [Dega Nagaraju].

References

Marenych, O.O.; Kostryzhev, A.G.; Pan, Z.; Li, H.; van Duin, S.: Application of wire arc additive manufacturing for repair of Monel alloy components. Australian J. Mech. Eng. 19(5), 609–617 (2021). https://doi.org/10.1080/14484846.2021.1981528

Vishnukumar, M.; Pramod, R.; Kannan, A.R.: Wire arc additive manufacturing for repairing aluminium structures in marine applications. Mater. Lett. 299, 130112 (2021)

Ralph, B.:U.S. Patent No. 1,533,300. Washington, DC: U.S. Patent and Trademark Office (1925).

Shockey, H.K.: Machine for reclaiming worn brake drums. ACM SIGGRAPH Comput. Graph 28, 131–134 (1930)

Derekar, K.S.: A review of wire arc additive manufacturing and advances in wire arc additive manufacturing of aluminium. Mater. Sci. Technol. 34(8), 895–916 (2018)

Geng, Y.; Panchenko, I.; Chen, X.; Ivanov, Y.; Konovalov, S.: Investigation of microstructure and fracture mechanism of Al-5.0 Mg alloys fabricated by wire arc additive manufacturing. J. Mater. Eng. Perform. 30(10), 7406–7416 (2021)

Stevic, Z.; Pamucar, D.; Puska, A.; Chatterjee, P.: Sustainable supplier selection in healthcare industries using a new MCDM method: measurement of alternatives and ranking according to COmpromise solution (MARCOS),". Comput. Indust. Eng. 140, 106231 (2020)

Mardani, A.; Jusoh, A.; Nor, K.; Khalifah, Z.; Zakwan, N.; Valipour, A.: Multiple criteria decision-making techniques and their applications - a review of the literature from 2000 to 2014. Economic Res. -Ekonomska Istrazivanja 28(1), 516–571 (2015)

Alias, M.A.; Hashim, S.Z.M.; Samsudin, S.: Multi criteria decision making and its applications: a literature review. Jurnal Teknologi Maklumat 20(2), 129–152 (2008)

Huang, C.C.; Chu, P.Y.; Chiang, Y.H.: A fuzzy AHP application in government sponsored R&D project selection. Omega 36(6), 1038–1052 (2008)

Gungor, Z.; Serhadlioǧlu, G.; Kesen, S.E.: A fuzzy AHP approach to personnel selection problem. Appl. Soft Comput. J. 9(2), 641–646 (2009)

Lu, M.T.; Hsu, C.C.; Liou, J.J.H.; Lo, H.W.: A hybrid MCDM and sustainability balanced scorecard model to establish sustainable performance evaluation for international airports. J. Air Transp. Manag. 71, 9–19 (2018)

Ghimire, L.P.; Kim, Y.: An analysis on barriers to renewable energy development in the context of Nepal using AHP. Renew. Energy 129, 446–456 (2018). https://doi.org/10.1016/j.renene.2018.06.011

Nassereddine, M.; Eskandari, H.: An integrated MCDM approach to evaluate public transportation systems in Tehran. Transp. Res. Part A Policy Pract. 106, 427–439 (2017)

Jha, K.; Kumar, R.; Verma, K.; Chaudhary, B.; Tyagi, Y.K.; Singh, S.: Application of modified TOPSIS technique in deciding optimal combination for bio-degradable composite. Vacuum 157, 259–267 (2018)

Zeynep Didem Unutmaz Durmuşoğlu: Assessment of techno-entrepreneurship projects by using analytical hierarchy process (AHP). Technol. Soc. 54, 41–46 (2018). https://doi.org/10.1016/j.techsoc.2018.02.001

Lolli, F., et al.: On the elicitation of criteria weights in PROMETHEE-based ranking methods for a mobile application. Expert Syst. Appl. 120, 217–227 (2019)

M. A. Ilgin; S. M. Gupta; O. Battaïa; M. A. Ilgin; S. M. Gupta; and O. Battaï:, "Use of MCDM techniques in environmentally conscious manufacturing and product recovery: State of the art to cite this version: HAL Id: emse-01145818,"( 2018).

Diakoulaki, D.; Mavrotas, G.; Papayannakis, L.: Determining objective weights in multiple criteria problems: the CRITIC method. Comput. Oper. Res. 22(7), 763–770 (1995)

Aznar Bellver, J.; Cervelló, R.R.; García, G.F.: Spanish savings banks and their future transformation into private capital banks. Determining their value by a multi-criteria valuation methodology. Eur. J. Econ. Finance Admin. Sci. 35, 155–164 (2011)

Tuş, A.; Aytaç Adalı, E.: Personnel assessment with CODAS and PSI methods. Alphanumeric J. 6(2), 243–256 (2018)

Mukhametzyanov, I.: Specific character of objective methods for determining weights of criteria in MCDM problems: entropy, CRITIC and SD. Decision Making: Appl. Manag. Eng. 4(2), 76–105 (2021)

Lu, C.; Li, L.; Wu, D.: Application of combination weighting method to weight calculation in performance evaluation of ICT. In: 15th International Conference on Advanced Learning Technologies, pp. 258–259 (2015)

Guo, C.; Wang, Y.; Jiang, W.: An empirical study of evaluation index system and measure method on city’s soft power: 17 cities in Shandong Province. Cross-Cultural Commun. 9(6), 27–31 (2013)

Aytaç Adalı, E.; Tuş Işık, A.: Critic and Maut methods for the contract manufacturer selection problem. Eur. J. Multidiscip. Stud. 5(1), 93–101 (2017)

Luo, S.M.: Evaluation of sustainability index for urban water management system in Macau [Outstanding Academic Papers by Students (OAPS)]. Retrieved from University of Macau, Outstanding Academic Papers by Students Repository (2014)

Tuş, A.; Aytac, E.: The new combination with CRITIC and WASPAS methods for the time and attendance software selection problem. Opsearch (2019). https://doi.org/10.1007/s12597-019-00371-6

Zavadskas, E.K.; Turskis, Z.; Antucheviciene, J.; Zakarevicius, A.: Optimization of weighted aggregated sum product assessment. Elektron. Elektrotech. 122(6), 3–6 (2012)

Zavadskas, E.K.; Baušys, R.; Lazauskas, M.: Sustainable assessment of alternative sites for the construction of a waste incineration plant by applying WASPAS method with single-valued neutrosophic set. Sustainability 7, 15923–15936 (2015)

Anupam, Kumar; Goley, Pankaj Kumar; Yadav, Anil: WASPAS Multi-Criteria Decision-Making Approach for Selecting Oxygen Delignification Additives in the Pulp and Paper Industry. In: Avikal, Shwetank; Singh, Amit Raj; Ram, Mangey (Eds.) Sustainability in Industry 4.0: Challenges and Remedies, pp. 95–117. CRC Press, Boca Raton (2021). https://doi.org/10.1201/9781003102304-5

Lashgari, S.; Antuchevičienė, J.; Delavari, A.; Kheirkhah, O.: Using QSPM and WASPAS methods for determining outsourcing strategies. J. Bus. Econ. Manag. 15(4), 729–743 (2014)

Chakraborty, S.; Bhattacharyya, O.; Zavadskas, E.K.; Antucheviciene, J.: Application of WASPAS method as an optimization tool in non-traditional machining processes. Inf. Technol. Control 44(1), 77–88 (2015)

Madić, M.; Gecevska, V.; Radovanović, M.; Petković, D.: Multi-criteria economic analysis of machining processes using the WASPAS method. J. Prod. Eng. 17(2), 79–82 (2014)

Venkateshwar Reddy, P.; Suresh Kumar, G.; Satish Kumar, V.: Multi-response optimization in machining inconel-625 by abrasive water jet machining process using WASPAS and MOORA. Arab J Sci Eng 45, 9843–9857 (2020)

Chakraborty, S.; Zavadskas, E.K.: Applications of WASPAS method in manufacturing decision making. Informatica 25(1), 1–20 (2014)

Turskis, Z.; Zavadskas, E.K.; Antucheviciene, J.; Kosareva, N.: A hybrid model based on fuzzy AHP and fuzzy WASPAS for construction site selection. Int. J. Comput. Commun. Control 10(6), 873–888 (2015)

Rostamzadeh, R.; Keshavarz-Ghorabaee, M.; Govindan, K.; Esmaeili, A.; Nobar, H.: Evaluation of sustainable supply chain risk management using an integrated fuzzy TOPSIS- CRITIC approach. J. Clean. Prod. 175, 651–669 (2017). https://doi.org/10.1016/j.jclepro.2017.12.071

Turskis, Z.; Goranin, N.; Nurusheva, A.; Boranbayev, S.: A Fuzzy WASPAS-based approach to determine critical information infrastructures of EU sustainable development. Sustainability 11, 424 (2019). https://doi.org/10.3390/su11020424

Peng, Yi.; Kou, G.; Li, J.: A fuzzy PROMETHEE approach for mining customer reviews in Chinese. Arab. J. Sci. Eng. 39(6), 5245–5252 (2014)

Yi, L.; Guo, Y.; Liu, N., et al.: Health status sensing of catenary based on combination weighting and normal cloud model. Arab J Sci Eng (2021). https://doi.org/10.1007/s13369-021-05837-8

Aktas, A.; Kabak, M.: A hybrid hesitant fuzzy decision-making approach for evaluating solar power plant location sites. Arab. J. Sci. Eng. 44(8), 7235–7247 (2019)

Köhler, M.; Sun, Li.; Hensel, J.; Pallaspuro, S.; Kömi, J.; Dilger, K.; Zhang, Z.: Comparative study of deposition patterns for DED-Arc additive manufacturing of Al-4046. Mater. Des. 210, 110122 (2021)

Wu, B.; Pan, Z.; Ding, D.; Cuiuri, D.; Li, H.; Jing, Xu.; Norrish, J.: A review of the wire arc additive manufacturing of metals: properties, defects and quality improvement. J. Manuf. Process. 35, 127–139 (2018)

Geng, H.; Li, J.; Xiong, J.; Lin, X.; Huang, D.; Zhang, F.: Formation and improvement of surface waviness for additive manufacturing 5A06 aluminium alloy component with GTAW system. Rapid Prototyping Journal 24(2), 342–350 (2018)

Li, K. H.; J. S. Chen; and YuMing Zhang.: "Double-electrode GMAW process and control." WELDING JOURNAL-NEW YORK- 86, no. 8 (2007): 231.

Gurnett, Donald A.; Amitava Bhattacharjee.: Introduction to plasma physics: with space and laboratory applications. Cambridge university press,(2005).

Wu, C.S.; Wang, L.; Ren, W.J.; Zhang, X.Y.: Plasma arc welding: Process, sensing, control and modeling. J. Manuf. Process. 16(1), 74–85 (2014)

Phinazee, S.: Efficiencies: Saving Time and Money with Electron Beam Free Form Fabrication, Fabricator, p 15–20 (2007)

S. Stecker; S and K.W.: Lachenberg, et al. Electron Beam Welding 35–46 (2006).

Hanss, M.: Applied fuzzy arithmetic. Springer-Verlag, Berlin Heidelberg (2005)

Chakraverty, S.; Sahoo, D.M.; Mahato, NRani: Fuzzy Numbers. In: Concepts of Soft Computing: Fuzzy and ANN with Programming, pp. 53–69. Springer Singapore, Singapore (2019). https://doi.org/10.1007/978-981-13-7430-2_3

Zhao, J.; Bose, B.K.: November. Evaluation of membership functions for fuzzy logic controlled induction motor drive. In: IEEE 2002 28th Annual Conference of the Industrial Electronics Society. IECON 02 (Vol. 1, pp. 229–234). IEEE (2002).

Wang, Y.-M.; Yang, J.-B.; Dong-Ling, Xu.; Chin, K.-S.: On the centroids of fuzzy numbers. Fuzzy Sets Syst. 157(7), 919–926 (2006)

Xiong, J.; Li, Y.; Li, R.; Yin, Z.: Influences of process parameters on surface roughness of multi-layer single-pass thin-walled parts in GMAW-based additive manufacturing. J. Mater. Process. Technol. 252, 128–136 (2018)

Yang, D.; Wang, G.; Zhang, G.: A comparative study of GMAW- and DE-GMAW-based additive manufacturing techniques: thermal behavior of the deposition process for thin-walled parts. Int J Adv Manuf Technol 91, 2175–2184 (2017)

Yang, D.; He, C.; Zhang, G.: Forming characteristics of thin-wall steel parts by double electrode GMAW based additive manufacturing. J. Mater. Process. Technol. 227, 153–160 (2016)

Gokhale, N.P.; Kala, P.; Sharma, V.: Thin-walled metal deposition with GTAW welding-based additive manufacturing process. J Braz. Soc. Mech. Sci. Eng. 41, 569 (2019)

Hsiao, Y.F.; Tarng, Y.S.; Huang, W.J.: Optimization of plasma arc welding parameters by using the taguchi method with the grey relational analysis. Mater. Manuf. Processes 23(1), 51–58 (2007)

Silvestru, V.-A.; Ariza, I.; Vienne, J.; Michel, L.; Sanchez, A.M.A.; Angst, U.; Rust, R.; Gramazio, F.; Kohler, M.; Taras, A.: Performance under tensile loading of point-by-point wire and arc additively manufactured steel bars for structural components. Mater. Des. 205, 109740 (2021)

Jin, W.; Zhang, C.; Jin, S.; Tian, Y.; Wellmann, D.; Liu, W.: Wire arc additive manufacturing of stainless steels: a review. Appl. Sci. 10(5), 1563 (2020)

Vimal, K.E.K.; Naveen Srinivas, M.; Rajak, Sonu: Wire arc additive manufacturing of aluminium alloys: a review. Mater. Today: Procee. 41, 1139–1145 (2021). https://doi.org/10.1016/j.matpr.2020.09.153

Moore, P.; Addison, A.; Nowak-Coventry, M.: Mechanical properties of wire plus arc additive manufactured steel and stainless-steel structures. Welding in the World 63(6), 1521–1530 (2019)

Fachkunde Metall, 58th edition, publisher Europa-Lehrmittel (2017).

Wu, C.S.; Hu, Z.; Zhang, Y.: Suppression of weld-bead defects and increase in the critical welding speed during high-speed arc welding. Procee Inst Mech Eng Part B-J Eng Manufact - PROC INST MECH ENG B-J ENG MA. 223, 751–757 (2009). https://doi.org/10.1243/09544054JEM1369SC

Raju, Nandhini; Balaganesan, G.; Gurunathan, Saravana Kumar: Energy Consumption of Welding-Based Additively Manufactured Materials. https://doi.org/10.1007/978-981-32-9433-2_11 (2019).

Torkayesh, Ali Ebadi; Pamucar, Dragan; Ecer, Fatih; Chatterjee, Prasenjit: An integrated BWM-LBWA-CoCoSo framework for evaluation of healthcare sectors in Eastern Europe. Socio-Economic Plann. Sci. 78, 101052 (2021). https://doi.org/10.1016/j.seps.2021.101052

Acknowledgements

The authors are thankful to the management of VIT (Vellore Institute of Technology), Vellore, for providing consistent support and encouragement for carrying out this research.

Funding

The authors did not receive any financial support for carrying out this research work.

Author information

Authors and Affiliations

Contributions

PT designed the figures for all WAAM processes demonstrated in the paper. PT and RV worked on the collection of data values for each WAAM alternative's performance parameters and decision matrix creation. RV and SE researched the MCDM methods, performance parameters of the WAAM alternatives and performed the sensitivity analysis. PT, RV, and SE worked on literature research about the WAAM process, and the methodological framework and provided numerical illustration. SN and DN finalized the main criteria and sub-criteria, provided expert advice for decision-making, and contributed to experimental results calculations. PT, SN, and DN contributed to constructing the hybrid model and justified the rankings. All authors played a part in the preparations of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no potential conflicts of interest.

Consent for Publication

The author transfers non-exclusive publication rights to Arabian Journal for Science and Engineering, and he warrants that his/her contribution is original. The author signs for and accepts responsibility for releasing this material on behalf of any and all co-authors. This transfer of publication rights covers the non-exclusive right to reproduce and distribute the article, including reprints, translations, photographic reproductions, microform, electronic form (offline, online) or any other reproductions of similar nature.

Ethics Approval

Not applicable.

Human and Animals

Not applicable.

Informed Consent

Not applicable.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Trivedi, P., Vansjalia, R., Erra, S. et al. A Fuzzy CRITIC and Fuzzy WASPAS-Based Integrated Approach for Wire Arc Additive Manufacturing (WAAM) Technique Selection. Arab J Sci Eng 48, 3269–3288 (2023). https://doi.org/10.1007/s13369-022-07127-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-022-07127-3