Abstract

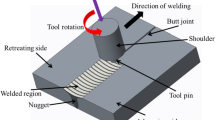

The ability to produce high quality joints, with improved mechanical and metallurgical properties, without any harmful emissions, has caused friction stir welding (FSW) to emerge as an efficient and eco-friendly solid-state welding method that has widespread use in many of the industries, especially railway, aerospace and automotive industries. However, the quality of weld produced by FSW process is significantly impacted by the welding parameters involved. To obtain the optimal values of FSW parameters, multi-criteria decision making (MCDM) methods have proven to be an effective way of dealing with multiple input parameters and conflicting responses. Relative importance assigned to various weld characteristics by the concerned stakeholders (welders, process engineers and end users) also greatly influences the final decision with respect to optimal combination of different input parameters for a given welding operation. In this paper, application of a newly developed MCDM tool, in the form of multi-attributive border approximation area comparison (MABAC) method in neutrosophic fuzzy environment considering truth-membership, indeterminacy-membership and falsity-membership functions in a single decision making framework for parametric optimization of two FSW processes is demonstrated. The optimal combination of input parameters for the first FSW process is obtained as tool rotational speed = 1200 rpm, welding speed = 275 mm/min, shoulder diameter = 18 mm and taper-cylindrical tool pin profile. On the other hand, in the second FSW process, an optimal parametric intermix of tool rotational speed = 1000 rpm, traverse speed = 140 mm/min, tool offset = 1 mm and tilt angle = 1.5° would provide the most desired values of the weld characteristics under consideration. This integrated approach would thus help in effectively optimizing FSW processes in single-valued neutrosophic fuzzy environment.

Similar content being viewed by others

References

Sun, Y., Gong, W., Feng, J., Lu, G., Zhu, R., Li, Y.: A review of the friction stir welding of dissimilar materials between aluminium alloys and copper. Metals 12, 675 (2022)

Christy, J.V., Mourad, A.H.I., Sherif, M.M., Shivamurthy, B.: Review of recent trends in friction stir welding process of aluminium alloys and aluminium metal matrix composites. Trans. Nonferrous Met. Soc. China 31, 3281–3309 (2021)

Rudrapati, R.: Effects of welding process conditions on friction stir welding of polymer composites: A review. Composites Part C 8, 100269 (2022)

Cam, G., Mistikoglu, S.: Recent developments in friction stir welding of Al-alloys. J. Mater. Eng. Perform. 23, 1936–1953 (2014)

Ma, Z.Y., Feng, A.H., Chen, D.L., Shen, J.: Recent advances in friction stir welding/processing of aluminium alloys: Microstructural evolution and mechanical properties. Crit. Rev. Solid State Mater. Sci. 43, 269–333 (2018)

Mohan, D.G., Wu, C.: A review on friction stir welding of steels. Chin. J. Mech. Eng. 34, 1–29 (2021)

Sharma, S., Handa, A., Singh, S.: Influencing geometrical parameters of tools in friction stirring technology: A short review. J. Mech. Eng. 71, 257–290 (2021)

Janeczek, A., Tomkow, J., Fydrych, D.: The Influence of tool shape and process parameters on mechanical properties of AW-3004 aluminium alloy friction stir welded joints. Materials 14, 3244 (2021)

Shehabeldeen, T.A., Abd Elaziz, M., Elsheikh, A.H., Zhou, J.: Modeling of friction stir welding process using adaptive neuro-fuzzy inference system integrated with Harris Hawks optimizer. J. Market. Res. 8, 5882–5892 (2019)

Nguyen, T.T., Nguyen, C.T., Van, A.L.: Sustainability-based optimization of dissimilar friction stir welding parameters in terms of energy saving, product quality, and cost-effectiveness. Neural Comput. Appl. (2022). https://doi.org/10.1007/s00521-022-07898-8

Van, A.L., Nguyen, T.T.: Optimization of friction stir welding operation using optimal Taguchi-based ANFIS and genetic algorithm. J. Mech. Eng. 68, 424–438 (2022)

Babajanzade Roshan, S., Behboodi Jooibari, M., Teimouri, R., Asgharzadeh-Ahmadi, G., Falahati-Naghibi, M., Sohrabpoor, H.: Optimization of friction stir welding process of AA7075 aluminium alloy to achieve desirable mechanical properties using ANFIS and simulated annealing algorithm. Int. J. Adv. Manuf. Technol. 69, 1803–1818 (2013)

Vijayan, D., Seshagiri Rao, V.: Parametric optimization of friction stir welding process of age hardenable aluminium alloys—ANFIS modelling. J. Cent. South Univ. 23, 1847–1857 (2016)

Deepandurai, K., Parameshwaran, R.: Multiresponse optimization of FSW parameters for cast AA7075/SiCp composite. Mater. Manuf. Processes 31, 1333–1341 (2016)

Parida, B., Pal, S.: Fuzzy assisted grey Taguchi approach for optimisation of multiple weld quality properties in friction stir welding process. Sci. Technol. Weld. Joining 20, 35–41 (2015)

Sahu, P., Kumari, K., Pal, S., Pal, S.K.: Hybrid fuzzy-grey-Taguchi based multi weld quality optimization of Al/Cu dissimilar friction stir welded joints. Adv. Manuf. 4, 237–247 (2016)

Chauhan, A., Kumar, S.: An overview of optimization techniques used for friction stir welding process parameters. Res. J. Eng.Technol. 9, 21–26 (2018)

Singh MK, Porwal RK, Mishra S (2020) Optimization-related studies on the operational parameters of friction stir welding: An overview. In: Singh I, Bajpai P, Panwar K (eds) Trends in Manufacturing Processes. Lecture Notes on Multidisciplinary Industrial Engineering. Springer, Singapore https://doi.org/10.1007/978-981-32-9099-0_1

Zadeh, L.A.: Fuzzy sets. Inf. Control 8, 338–353 (1965)

Atanassov, K.T.: Intutionistic fuzzy sets. Fuzzy Sets Syst. 20, 87–96 (1986)

Smarandache F (1999) A unifying field in logics: Neutrosophic logic. In: Philosophy, American Research Press 1–141

Biswas, P., Pramanik, S., Giri, B.C.: Entropy based grey relational analysis for multi-attribute decision making under single valued neutrosophic assessments. Neutrosophic Sets Syst. 2, 102–110 (2014)

Wang, H., Smarandache, F., Zhang, Y., Sunderraman, R.: Single valued neutrosophic sets. Multispace Multistruct. 4, 410–413 (2010)

Pamučar, D., Ćirović, G.: The selection of transport and handling resources in logistics centers using multi-attributive border approximation area comparison (MABAC). Expert Syst. Appl. 42, 3016–3028 (2015)

Peng, X., Dai, J.: Approaches to single-valued neutrosophic MADM based on MABAC, TOPSIS and new similarity measure with score function. Neural Comput. Appl. 29, 939–954 (2018)

Jain, N., Kumar, R.: Multi-response optimization of process parameters in friction stir welded aluminium 6061–T6 alloy using Taguchi grey relational analysis. World J. Eng. 19, 707–716 (2022)

Biswas, P., Pramanik, S., Giri, B.C.: TOPSIS method for multi-attribute decision-making under single-valued neutrosophic environment. Neural Comput. Appl. 27, 727–737 (2016)

Tamjidy, M., Baharudin, B.H.T., Paslar, S., Matori, K.A., Sulaiman, S., Fadaeifard, F.: Multi-objective optimization of friction stir welding process parameters of AA6061-T6 and AA7075-T6 using a biogeography-based optimization algorithm. Materials 10, 533 (2017)

Saeedy, S., Givi, M.B.: Investigation of the effects of critical process parameters of friction stir welding of polyethylene. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 225, 1305–1310 (2011)

Aydin, M.: Effects of welding parameters and pre-heating on the friction stir welding of UHMW-polyethylene. Polym. Plast. Technol. Eng. 39, 595–601 (2010)

Fuse, K., Badheka, V.: Effect of shoulder diameter on bobbin tool friction stir welding of AA 6061–T6 alloy. Mater. Today Proc. 42, 810–815 (2021)

Kadaganchi, R., Gankidi, M.R., Gokhale, H.: Optimization of process parameters of aluminium alloy AA 2014–T6 friction stir welds by response surface methodology. Def. Technol. 11, 209–219 (2015)

Rajamanickam, N., Balusamy, V.: Effects of process parameters on mechanical properties of friction stir welds using design of experiments. Indian J. Eng. Mater. Sci. 15, 293–299 (2008)

Funding

No external funding is required for this research study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chatterjee, S., Chakraborty, S. Optimization of friction stir welding processes using multi-attributive border approximation area comparison (MABAC) method in neutrosophic fuzzy environment. Int J Interact Des Manuf 17, 1979–1994 (2023). https://doi.org/10.1007/s12008-023-01308-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12008-023-01308-6