Abstract

Improvement of centrifugal pump performance (i.e., head and flow rate) is the main goal for designers since it plays a significant role in most industrial fields. Low flow rate and pump head cause low productivity in the industry. Centrifugal pumps involve several parameters that influence their performance. Thus, modifying some of these parameters within a reasonable range is significant in the centrifugal pump design. The blade numbers are an essential design parameter for pumps, which heavily affects the pump's characteristics. This article reviews the effects of the blade number variation on the centrifugal pumps' performance and synthesizes the current study status. Three research approaches are summarized: analytical studies, numerical simulation, and experimental measurement research to demonstrate blade numbers' influence and characteristics. This article highlighted unsolved issues and implications for future research based on prior research findings. It is clarified that the performance of the centrifugal pump was significantly affected by the number of blades. With increasing blade numbers head, and efficiency would increase until specific values. The blade numbers have optimum values for pumping liquids at the best performance. The data gathered in this review article are expected to contribute a guideline and reference for future research of centrifugal pump performance. It can help the designers estimate the optimum blade numbers to obtain better performance at the best design point of the centrifugal pump.

Similar content being viewed by others

Abbreviations

- b :

-

Blade thickness

- b 2 :

-

Blade width

- \(C_{{{\text{cond}}}}\) :

-

Condensation coefficient

- \(C_{{{\text{vap}}}}\) :

-

Vaporization coefficient

- \(C_{d}\) :

-

Cavitation when the head reduces to 3%.

- \(C_{i}\) :

-

Critical value of the cavitation incipience

- \(D_{1}\) :

-

Inlet diameter of the impeller

- D si :

-

Inlet diameter of splitter

- \(f_{{\text{b}}}\) :

-

Blade passing frequency

- h :

-

Head loss in pump

- I :

-

Liquid phase

- k :

-

Turbulence kinetic energy

- K :

-

Numerical constant

- \(L_{i}\) :

-

Impeller pitch

- \(\dot{m}_{{{\text{cond}}}}\) :

-

Condensation term

- \(\dot{m}_{{{\text{vap}}}}\) :

-

Vaporization term

- n :

-

Impeller rotating speed

- \(q_{s}\) :

-

Volume flow of entrained air

- Q :

-

Flow rate

- \(r_{{{\text{nuc}}}}\) :

-

Nucleation site volume fraction

- R :

-

Impeller radius

- \(R_{{\text{B}}}\) :

-

Average radius of the bubble

- \(R_{{\text{m}}}\) :

-

Maximum bubble radius

- S :

-

Surface tension coefficient

- t :

-

Blade metal thickness

- \(U_{1}\) :

-

Inlet circumferential velocity

- \(u_{2}\) :

-

Peripheral velocity

- v :

-

Vapor phase

- \(v_{m2}\) :

-

Average velocity at the impeller outlet

- \(W_{e}\) :

-

Weber number

- z :

-

Blade numbers

- α :

-

Volume fraction

- αs :

-

Deflection angle of splitter blades

- \(\beta_{1}\) :

-

Blade inlet angle

- \(\beta_{2}\) :

-

Blade outlet/exit angle

- \(\beta_{{\text{m}}}\) :

-

Mean blade angle

- Ɵ s :

-

Bias angle in a peripheral direction of splitter

- \(\rho_{1}\) :

-

Liquid density

- \(\uppsi\) :

-

Head coefficient

- \(\Delta\uppsi _{h}\) :

-

Increment of \(\uppsi _{h}\) due to air admission

- \(\sigma\) :

-

Cavitation parameter

- \(\eta_{{\text{h}}}\) :

-

Hydraulic efficiency

References

Sun, W.; Tan, L.: Cavitation-Vortex-Pressure fluctuation interaction in a centrifugal pump using bubble rotation modified cavitation model under partial load. J. Fluids Eng. (2020). https://doi.org/10.1115/1.4045615

Duplaa, S.; Coutier-Delgosha, O.; Dazin, A.; Roussette, O.; Bois, G.; Caignaert, G.: Experimental study of a cavitating centrifugal pump during fast startups. J. Fluids Eng. 132, 0213011–02130112 (2010). https://doi.org/10.1115/1.4000845

Zhang, Y.; Hu, S.; Zhang, Y.; Chen, L.: Optimization and analysis of centrifugal pump considering fluid-structure interaction. Sci. world J. (2014). https://doi.org/10.1155/2014/131802

Fu, Q.; Zhang, F.; Zhu, R.; He, B.: A systematic investigation on flow characteristics of impeller passage in a nuclear centrifugal pump under cavitation state. Ann. Nucl. Energy. 97, 190–197 (2016). https://doi.org/10.1016/j.anucene.2016.07.011

Sun, H.; Luo, Y.; Yuan, S.; Yin, J.: Hilbert spectrum analysis of unsteady characteristics in centrifugal pump operation under cavitation status. Ann. Nucl. Energy. 114, 607–615 (2018). https://doi.org/10.1016/j.anucene.2018.01.004

Wu, D.; Ren, Y.; Mou, J.; Gu, Y.; Jiang, L.: Unsteady flow and structural behaviors of centrifugal pump under cavitation conditions. Chinese J. Mech. Eng. English Ed. 32, 17 (2019). https://doi.org/10.1186/s10033-019-0328-8

Ding, H.H.; Visser, F.C.; Jiang, Y.; Furmanczyk, M.: Demonstration and validation of a 3D CFD simulation tool predicting pump performance and cavitation for industrial applications. J. Fluids Eng. (2011). https://doi.org/10.1115/1.4003196

Lin, Z.; Ruan, X.; Zou, J.; Fu, X.: Experimental study of cavitation phenomenon in a centrifugal blood pump induced by the failure of inlet cannula. Chinese J. Mech. Eng. 27, 165–170 (2014). https://doi.org/10.3901/CJME.2014.01.165

Wang, J.; Wang, Y.; Liu, H.; Huang, H.; Jiang, L.: An improved turbulence model for predicting unsteady cavitating flows in centrifugal pump. Int. J. Numer. Methods Heat Fluid Flow 25, 1198–1213 (2015). https://doi.org/10.1108/HFF-07-2014-0205

Jafarzadeh, B.; Hajari, A.; Alishahi, M.M.; Akbari, M.H.: The flow simulation of a low-specific-speed high-speed centrifugal pump. Appl. Math. Model. 35, 242–249 (2011). https://doi.org/10.1016/j.apm.2010.05.021

Tan, L.; Zhu, B.; Cao, S.; Bing, H.; Wang, Y.: Influence of blade wrap angle on centrifugal pump performance by numerical and experimental study. Chinese J. Mech. Eng. 27, 171–177 (2014). https://doi.org/10.3901/CJME.2014.01.171

Wang, T.; Kong, F.; Xia, B.; Bai, Y.; Wang, C.: The method for determining blade inlet angle of special impeller using in turbine mode of centrifugal pump as turbine. Renew. Energy. 109, 518–528 (2017). https://doi.org/10.1016/j.renene.2017.03.054

Ding, H.; Li, Z.; Gong, X.; Li, M.: The influence of blade outlet angle on the performance of centrifugal pump with high specific speed. Vacuum 159, 239–246 (2019). https://doi.org/10.1016/j.vacuum.2018.10.049

Wei, L.; Shi, W.; Jiang, X.; Chen, B.; Wu, Y.: Analysis on internal solid-liquid two-phase flow in the impellers of sewage pump. Procedia Eng. 31, 170–175 (2012). https://doi.org/10.1016/j.proeng.2012.01.1008

Fu, L.; Zhu, X.; Jiang, W.; Li, G.: Numerical investigation on influence of diffuser vane height of centrifugal pump. Int. Commun. Heat Mass Transf. 82, 114–124 (2017). https://doi.org/10.1016/j.icheatmasstransfer.2017.02.014

Hlbocan, P.; Varchola, M.: Prime Geometry Solution of a Centrifugal Impeller Within a 3D Setting. Procedia Eng. 39, 197–203 (2012). https://doi.org/10.1016/j.proeng.2012.07.025

Rakibuzzaman, R.; Suh, S.H.; Kim, K.W.; Kim, H.H.; Cho, M.T.; Yoon, I.S.: A study on multistage centrifugal pump performance characteristics for variable speed drive system. Procedia Eng. 105, 270–275 (2015)

Aldi, N.; Buratto, C.; Casari, N.; Dainese, D.; Mazzanti, V.; Mollica, F.; Munari, E.; Occari, M.; Pinelli, M.; Randi, S.; Ruggero Spina, P.; Suman, A.: Experimental and Numerical Analysis of a Non-Newtonian Fluids Processing Pump. In: Energy Procedia. pp. 762–769. Elsevier Ltd (2017)

Shao, C.; Li, C.; Zhou, J.: Experimental investigation of flow patterns and external performance of a centrifugal pump that transports gas-liquid two-phase mixtures. Int. J. Heat Fluid Flow. 71, 460–469 (2018). https://doi.org/10.1016/j.ijheatfluidflow.2018.05.011

Korkmaz, E.; Gölcü, M.; Kurbanoğlu, C.: Effects of blade discharge angle, blade number and splitter blade length on deep well pump performance. J. Appl. Fluid Mech. 10, 529–540 (2017)

Rababa, K.S.: The effect of blades number and shape on the operating characteristics of groundwater centrifugal pumps. Eur. J. Sci. Res. 52, 243–251 (2011)

SANDA, B., Daniela, C.V.: The influence of the inlet angle over the radial impeller geometry design approach with Ansys. J. Eng. Stud. Res. 18, 32 (2012). https://doi.org/10.29081/jesr.v18i4.146

Luo, X.; Zhang, Y.; Peng, J.; Xu, H.; Yu, W.: Impeller inlet geometry effect on performance improvement for centrifugal pumps. J. Mech. Sci. Technol. 22, 1971–1976 (2008). https://doi.org/10.1007/s12206-008-0741-x

Varley, F.A.: Effects of impeller design and surface roughness on the performance of centrifugal pumps. Proc. Inst. Mech. Eng. 175, 955–989 (1961). https://doi.org/10.1243/pime_proc_1961_175_062_02

Tan, M., Liu, H., Yuan, S., Wang, Y., Wang, K.: Effects of blade outlet width on flow field and characteristic of centrifugal pumps. In: Fluids Engineering Division Summer Meeting. pp. 51–60 (2009)

Zhou, L.; Shi, W.; Wu, S.: Performance optimization in a centrifugal pump impeller by orthogonal experiment and numerical simulation. Adv. Mech. Eng. 5, 385809 (2013). https://doi.org/10.1155/2013/385809

Jin, Y.X.; Song, W.W.; Jie, F.: A study on the effects of blade thickness on the performance of low specific speed centrifugal pump. Adv. Mater. Res. 1070–1072, 1957–1962 (2014). https://doi.org/10.4028/www.scientific.net/amr.1070-1072.1957

Yang, J.-H.; Zhang, J.-H.; Sun, Q.-C.; Wang, X.-H.: Influence of variation of blade thickness and profile on centrifugal pump performance [J]. J. Lanzhou Univ. Technol. 37, 50–55 (2011)

Weigang, W.C.S.W.L.; Qihua, L.T.Z.: Effect and experiment of different blade thickness on stainless steel stamping well pump performance. Trans. Chinese Soc. Agric. Mach. 7 (2012)

Mu, J.G.; Zhu, B.; Zheng, S.H.; Gan, J.J.: Response of Blade Thickness to Hydraulic Performance of Stamping and Welding Multistage Centrifugal Pump. In: Applied Mechanics and Materials. pp. 351–356. Trans Tech Publ (2012)

Jin, J.; Fan, Y.; Han, W.; Hu, J.: Design and analysis on hydraulic model of the ultra -low specific-speed centrifugal pump. In: Procedia Engineering. pp. 110–114 (2012)

Bellary, S.A.I.; Samad, A.: Centrifugal impeller blade shape optimization through numerical modeling. Int. J. Fluid Mach. Syst. 9, 313–324 (2016). https://doi.org/10.5293/IJFMS.2016.9.4.313

Yang, S.-S.S.; Kong, F.-Y.Y.; Qu, X.-Y.Y.; Jiang, W.-M.M.: Influence of blade number on the performance and pressure pulsations in a pump used as a turbine. J. Fluids Eng. (2012). https://doi.org/10.1115/1.4007810

Ismail, M.A.I.; Othman, A.K.; Zen, H.; Misran, M.S.: CFD modelling of pump as turbine with various number of blade for microhydro system. J. Appl. Sci. Process Eng. (1970). https://doi.org/10.33736/jaspe.171.2016

Bellary, S.A.I.I.; Hussain, A.; Samad, A.; Kanai, R.A.; Husain, A.; Samad, A.; Kanai, R.A.: Performance optimization of centrifugal pump for crude oil delivery. J. Eng. Res. [TJER] 15, 88–101 (2018). https://doi.org/10.24200/tjer.vol15iss1pp88-101

Chakraborty, S.; Choudhuri, K.; Dutta, P.; Debbarma, B.: Performance prediction of Centrifugal Pumps with variations of blade number. J. Sci. Ind. Res. (India) 72, 373–378 (2013)

Elyamin, G.R.H.A.; Bassily, M.A.; Khalil, K.Y.; Gomaa, M.S.: Effect of impeller blades number on the performance of a centrifugal pump. Alexandria Eng. J. 58, 39–48 (2019)

Hawas, M.N.; Mohammed, A.A.; Al-Abbas, A.H.: Improving the efficiency and performance of centrifugal pump through model development and numerical analysis for the pump impeller. Int. J. Mech. Eng. Robot. Res. 9, 60–65 (2020). https://doi.org/10.18178/ijmerr.9.1.60-65

Al-Obaidi, A.R.: Monitoring the performance of centrifugal pump under single-phase and cavitation condition: a CFD analysis of the number of impeller blades. J. Appl. Fluid Mech. 12, 445–459 (2019). https://doi.org/10.29252/jafm.12.02.29303

Zhao, F.; Kong, F.; Zhou, Y.; Xia, B.; Bai, Y.: Optimization design of the impeller based on orthogonal test in an ultra-low specific speed magnetic drive pump. Energies 12, 4767 (2019). https://doi.org/10.3390/en12244767

Yu-qin, W.; Ze-wen, D.: Influence of blade number on flow-induced noise of centrifugal pump based on CFD/CA. Vacuum 172, 109058 (2020). https://doi.org/10.1016/j.vacuum.2019.109058

Kocaaslan, O.; Ozgoren, M.; Babayigit, O.; Aksoy, M.H.: Numerical investigation of the effect of number of blades on centrifugal pump performance. In: AIP Conference Proceedings. American Institute of Physics Inc. (2017)

Feng, J.J.; Benra, F.-K.K.; Dohmen, H.J.: Numerical investigation on pressure fluctuations for different configurations of vaned diffuser pumps. Int. J. Rotating Mach. (2007). https://doi.org/10.1155/2007/34752

Jian, W.; Yong, W.; Houlin, L.; Qiaorui, S.; Dular, M.: Rotating corrected-based cavitation model for a centrifugal pump. J. Fluids Eng. (2018). https://doi.org/10.1115/1.4040068

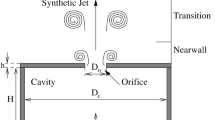

Murakami, M.; Minemura, K.: Effects of entrained air on the performance of centrifugal pumps: 2nd report, effects of number of blades. Bull. JSME. 17, 1286–1295 (1974)

Minemura, K.; Murakami, M.: A theoretical study on air bubble motion in a centrifugal pump impeller. ASME J. Fluids Eng. 102, 446–453 (1980)

Murakami, M.; Minemura, K.: Flow of air bubbles in centrifugal impellers and its effect on the pump performance. In: Proc. 6th Australasian Hydraulics and Fluid Mechanics Conf. pp. 382–385 (1977)

Markatos, N.C.; Singhal, A.K.: Numerical analysis of one-dimensional, two-phase flow in a vertical cylindrical passage. Adv. Eng. Softw. 4, 99–106 (1982). https://doi.org/10.1016/0141-1195(82)90032-8

Evans, G.M.; Jameson, G.J.; Atkinson, B.W.: Prediction of the bubble size generated by a plunging liquid jet bubble column. Chem. Eng. Sci. 47, 3265–3272 (1992). https://doi.org/10.1016/0009-2509(92)85034-9

Gölcü, M.; Usta, N.; Pancar, Y.: Effects of splitter blades on deep well pump performance. J. Energy Resour. Technol. Trans. ASME. 129, 169–176 (2007). https://doi.org/10.1115/1.2748810

Li, W.-G.W.G.: Influence of the number of impeller blades on the performance of centrifugal oil pumps. World Pumps. (2002). https://doi.org/10.1016/s0262-1762(02)80126-2

Subroto, Effendy, M.: Optimization of centrifugal pump performance with various blade number. In: AIP Conference Proceedings. p. 20016. AIP Publishing LLC (2019)

Zhang, Y.L.; Li, W.G.: An analytical method for determining the optimum number of blades of the compound impeller in a low specific speed centrifugal pump. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 234, 576–587 (2020). https://doi.org/10.1177/0954408920934665

Murakami, M.; Minemura, K.; Takimoto, M.: Effects of entrained air on the performance of centrifugal pumps under cavitating conditions. Bull. JSME. 23, 1435–1442 (1980)

Barrio, R.; Blanco, E.; Parrondo, J.; González, J.; Fernández, J.: The effect of impeller cutback on the fluid-dynamic pulsations and load at the blade-passing frequency in a centrifugal pump. J. Fluids Eng. Trans. ASME. 130, 1111021–11110211 (2008). https://doi.org/10.1115/1.2969273

Boyce, M.P.: Gas Turbine Engineering Handbook. Elsevier, Amsterdam (2011)

Eaton, A.; Ahmed, W.H.; Hassan, M.: Monitoring the best operating point of centrifugal pumps using blade passing vibration signals. Int. Conf. Fluid. Flow. Heat. Mass. Transf. (2019). https://doi.org/10.11159/ffhmt19.137

Gao, Z.; Zhu, W.; Lu, L.; Deng, J.; Zhang, J.; Wuang, F.: Numerical and experimental study of unsteady flow in a large centrifugal pump with stay vanes. J. Fluids Eng. Trans. ASME. (2014). https://doi.org/10.1115/1.4026477

Acknowledgements

Acknowledgment to "Ministry of Higher Education Malaysia for Fundamental Research Grant Scheme with Project Code FRGS/1/2020/TK0/USM/03/6. The authors would also like to thank Universiti Sains Malaysia and Al-Muthanna University for providing technical support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sakran, H.K., Abdul Aziz, M.S., Abdullah, M.Z. et al. Effects of Blade Number on the Centrifugal Pump Performance: A Review. Arab J Sci Eng 47, 7945–7961 (2022). https://doi.org/10.1007/s13369-021-06545-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-021-06545-z