Abstract

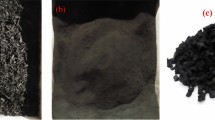

Rubberized concrete is highly effective in areas where more flexibility is required. Compared to standard concrete, rubberized concrete has greater flexibility, impact resistance, and lower unit weight. In this study, sulfuric acid is used in the surface treatment process of rubber particles to strengthen the bonding property of rubber particles and cement paste. Six waste tire rubber crumb contents (0, 10, 15, 20, 25, and 30%) and particle sizes of 0.6–2.36 mm were used as partial replacement of fine aggregate in concrete. Microstructural analyses (EDX, TGA, XRD) are conducted on rubber crumbs to examine rubber’s compatibility before using it in concrete. The fresh, hardened, microstructural properties (SEM and XRD) and stress vs. strain behavior of rubberized concrete are investigated. From the SEM image, it is analyzed that surface treatment improves the bonding properties of rubber particles and cement paste compared to untreated rubber particles. The mechanical properties of rubberized concrete reduce by increasing the rubber crumb in the mix. Still, the results are not much troubling up to 15% replacement level of rubber crumb, and the rubberized concrete has a highly deformable capacity than standard concrete.

Similar content being viewed by others

Availability of Data and Materials

The available data have been used and discussed in the manuscript.

References

By, O.; Khatib, Z.K.; Bayomy, F.M.: Rubberized portland cement concrete. J. Mater. Civ. Eng. 11, 206–213 (1999)

Gesoǧlu, M.; Guneyisi, E.: Strength development and chloride penetration in rubberized concretes with and without silica fume. Mater. Struct. 40, 953–964 (2007)

Toutanji, H.A.: The use of rubber tire particles in concrete to replace mineral aggregates. Cem. Concr. Compos. 18, 135–139 (1996). https://doi.org/10.1016/0958-9465(95)00010-0

Uygunoǧlu, T.; Topçu, I.B.: The role of scrap rubber particles on the drying shrinkage and mechanical properties of self-consolidating mortars. Constr. Build. Mater. 24, 1141–1150 (2010). https://doi.org/10.1016/j.conbuildmat.2009.12.027

Gupta, T.; Siddique, S.; Sharma, R.K.; Chaudhary, S.: Effect of aggressive environment on durability of concrete containing fibrous rubber shreds and silica fume. Struct. Concr. (2020). https://doi.org/10.1002/suco.202000043

Wang, R.; He, X.; Li, Y.: Evaluation of microcracks in the interfacial transition zone of recycled rubber concrete. Struct. Concr. 20, 1684–1694 (2019). https://doi.org/10.1002/suco.201900044

Aslani, F.; Gedeon, R.: Experimental investigation into the properties of self-compacting rubberised concrete incorporating polypropylene and steel fibers. Struct. Concr. 20, 267–281 (2019). https://doi.org/10.1002/suco.201800182

Verma, M.; Dev, N.: Sodium hydroxide effect on the mechanical properties of fly ash-slag based geopolymer concrete. Struct. Concr. (2020). https://doi.org/10.1002/suco.202000068

He, L.; Cai, H.; Huang, Y.; Ma, Y.; Van Den Bergh, W.; Gaspar, L.; Valentin, J.; Vasiliev, Y.E.; Kowalski, K.J.; Zhang, J.: Research on the properties of rubber concrete containing surface-modified rubber powders. J. Build. Eng. 35, 101991 (2021). https://doi.org/10.1016/j.jobe.2020.101991

Ismail, M.K.; Sherir, M.A.A.; Siad, H.; Hassan, A.A.A.; Lachemi, M.: Properties of self-consolidating engineered cementitious composite modified with rubber. J. Mater. Civ. Eng. (2018). https://doi.org/10.1061/(ASCE)MT.1943-5533.0002219

Kashani, A.; Ngo, T.D.; Hemachandra, P.; Hajimohammadi, A.: Effects of surface treatments of recycled tyre crumb on cement-rubber bonding in concrete composite foam. Constr. Build. Mater. 171, 467–473 (2018). https://doi.org/10.1016/j.conbuildmat.2018.03.163

Gupta, T.; Chaudhary, S.; Sharma, R.K.: Mechanical and durability properties of waste rubber fiber concrete with and without silica fume. J. Clean. Prod. 112, 702–711 (2016). https://doi.org/10.1016/j.jclepro.2015.07.081

Gupta, T.; Chaudhary, S.; Sharma, R.K.: Assessment of mechanical and durability properties of concrete containing waste rubber tire as fine aggregate. Constr. Build. Mater. 73, 562–574 (2014). https://doi.org/10.1016/j.conbuildmat.2014.09.102

He, L.; Ma, Y.; Liu, Q.; Mu, Y.: Surface modification of crumb rubber and its influence on the mechanical properties of rubber-cement concrete. Constr. Build. Mater. 120, 403–407 (2016). https://doi.org/10.1016/j.conbuildmat.2016.05.025

Raffoul, S.; Garcia, R.; Pilakoutas, K.; Guadagnini, M.; Medina, N.F.: Optimisation of rubberised concrete with high rubber content: an experimental investigation. Constr. Build. Mater. 124, 391–404 (2016). https://doi.org/10.1016/j.conbuildmat.2016.07.054

Ganjian, E.; Khorami, M.; Maghsoudi, A.A.: Scrap-tyre-rubber replacement for aggregate and filler in concrete. Constr. Build. Mater. 23, 1828–1836 (2009). https://doi.org/10.1016/j.conbuildmat.2008.09.020

Tian, S.; Zhang, T.; Li, Y.: Research on modifier and modified process for rubber-particle used in rubberized concrete for road. Adv. Mater. Res. 243–249, 4125–4130 (2011). https://doi.org/10.4028/www.scientific.net/AMR.243-249.4125

Li, G.; Stubblefield, M.A.; Garrick, G.; Eggers, J.; Abadie, C.; Huang, B.: Development of waste tire modified concrete. Cem. Concr. Res. 34, 2283–2289 (2004). https://doi.org/10.1016/j.cemconres.2004.04.013

Richardson, A.E.; Coventry, K.A.; Ward, G.: Freeze/thaw protection of concrete with optimum rubber crumb content. J. Clean. Prod. 23, 96–103 (2012). https://doi.org/10.1016/j.jclepro.2011.10.013

Tarry, S.R.: Effect of partial replacement of coarse aggregates in concrete by untreated and treated tyre rubber aggregates. Int. J. Adv. Sci. Res. 3, 65–69 (2018)

IS: 4031 (Part 6): Methods of Physical Tests For Hydraulic Cement Part 6 Determination of Compressive Strength of Hydraulic Cement Other Than Masonry Cement (First Revision). Bur. Indian Stand. Delhi. 1–3 (2005)

IS 4031- Part IV: Methods of physical tests for hydraulic cement. Part IV- Determination of consistency of standard cement paste. Bur. Indian Stand. New Delhi. Reaffirmed in 2005 (1988)

IS 4031 ( Part 11 ) - 1988: METHODS OF PHYSICAL TESTS FOR HYDRAULIC CEMENT 4031 ( Part 11 ) - 1988. Bur. Indian Stand. New Delhi (2005)

IS 4031- Part V: Methods of physical tests for hydraulic cement. Part V- Determination of initial and final setting times. Bur. Indian Stand. New Delhi. Reaffirmed in 2005 (1988)

IS 4031 - 3 (1988) (Reaffirmed 2005): Methods of Physical Tests for Hydraulic Cement, Part 3: Determination of Soundness [CED 2: Civil Engineering]. Bur. Indian Stand. New Delhi. 1–10 (2005)

C1365-18: Standard Test Method for Determination of the Proportion of Phases in Portland Cement and Portland-Cement Clinker Using X-Ray Powder. ASTM Int. 1–11 (1998). https://doi.org/10.1520/C1365-18.2

Bureau of Indian Standards: IS 383: 1970 Specification for Coarse and Fine Aggregates From Natural Sources for Concrete. IS 383 1970(Reaffirmed 2002). 1–24 (1970)

IS 2386- Part III: Method of Test for aggregate for concrete. Part III- Specific gravity, density, voids, absorption and bulking. Bur. Indian Stand. New Delhi. (Reaffirmed 2002) (1963)

Bureau of Indian Standards (BIS): IS : 2366 (Part IV )-1963-Methods of test for Aggregates for Concrete, part 4 : Mechanical properties. Indian Stand. 1–37 (2002)

M.S. Shetty: Concrete Technology: Theory and Practice. S.Chand, New Delhi (2013)

RANKEM (A AVANTOR BRAND): Sulphuric Acid, https://in.vwr.com/store/product/27465747/sulphuric-acid-98-00-ar-rankem (1889)

Ma, Q.W.; Yue, J.C.: Effect on mechanical properties of rubberized concrete due to pretreatment of waste tire rubber with NaOH. Appl. Mech. Mater. 357–360, 897–904 (2013). https://doi.org/10.4028/www.scientific.net/AMM.357-360.897

D934-13: Identification of Crystalline Compounds in Water-Formed Deposits by X-Ray Diffraction. ASTM Int. 11, 1–10 (2014). https://doi.org/10.1520/D0934-13.2

ASTM-E2550: Standard Test Method for Thermal Stability by Thermogravimetry. ASTM Int. i, 1–6 (2017). https://doi.org/10.1520/E2550-17.Development

Zhu, H.; Rong, B.; Xie, R.; Yang, Z.: Experimental investigation on the floating of rubber particles of crumb rubber concrete. Constr. Build. Mater. 164, 644–654 (2018). https://doi.org/10.1016/j.conbuildmat.2018.01.001

IS: 1199 - 1959 Reaffirmed: Methods of sampling and analysis of concrete. Indian Stand (2004)

IS: 10086-1982 Reaffirmed: Specification for moulds for use in tests of cement and concrete. Indian Stand (2008)

IS 516:1959: Method of Tests for Strength of Concrete. IS 516 - 1959 ( Reaffirmed 2004 ). New Delhi, India (2004)

Najim, K.B.; Hall, M.R.: Mechanical and dynamic properties of self-compacting crumb rubber modified concrete. Constr. Build. Mater. 27, 521–530 (2012). https://doi.org/10.1016/j.conbuildmat.2011.07.013

Marie, I.: Thermal conductivity of hybrid recycled aggregate—Rubberized concrete. Constr. Build. Mater. 133, 516–524 (2017). https://doi.org/10.1016/j.conbuildmat.2016.12.113

Batayneh, M.K.; Marie, I.; Asi, I.: Promoting the use of crumb rubber concrete in developing countries. Waste Manag. 28, 2171–2176 (2008). https://doi.org/10.1016/j.wasman.2007.09.035

Taha, M.M.R.; Asce, M.; El-wahab, M.A.A.: Mechanical. Fracture, and Microstructural Investigations. 20, 640–649 (2009)

Bheel, N.; Memon, F.A.; Meghwar, S.L.: Study of fresh and hardened properties of concrete using cement with modified blend of millet husk ash as secondary cementitious material. SILICON (2020). https://doi.org/10.1007/s12633-020-00794-7

Xue, G.; Pei, Z.: Experimental study on axial compressive properties of rubber concrete at low temperature. J. Mater. Civ. Eng. 30, 1–8 (2018). https://doi.org/10.1061/(ASCE)MT.1943-5533.0002178

Liu, F.; Zheng, W.; Li, L.; Feng, W.; Ning, G.: Mechanical and fatigue performance of rubber concrete. Constr. Build. Mater. 47, 711–719 (2013). https://doi.org/10.1016/j.conbuildmat.2013.05.055

Gurunandan, M.; Phalgun, M.; Raghavendra, T.; Udayashankar, B.C.: Mechanical and damping properties of rubberized concrete containing polyester fibers. J. Mater. Civ. Eng. 31, 1–10 (2019). https://doi.org/10.1061/(ASCE)MT.1943-5533.0002614

Su, H.; Yang, J.; Ling, T.C.; Ghataora, G.S.; Dirar, S.: Properties of concrete prepared with waste tyre rubber particles of uniform and varying sizes. J. Clean. Prod. 91, 288–296 (2015). https://doi.org/10.1016/j.jclepro.2014.12.022

Gupta, T.; Tiwari, A.; Siddique, S.; Sharma, R.K.; Chaudhary, S.: Response assessment under dynamic loading and microstructural investigations of rubberized concrete. J. Mater. Civ. Eng. 29, 1–15 (2017). https://doi.org/10.1061/(ASCE)MT.1943-5533.0001905

IS 13311 part 2 - 1992 Reaffirmed: IS 13311-2 (1992): Method of non-destructive testing of concrete-methods of test, Part 2: Rebound hammer. Indian Stand. (2004)

IS 13311 Part 1 - 1992 Reaffirmed: Method of Non-destructive testing of concrete, Part 1: Ultrasonic pulse velocity. Indian Stand. 1–7 (2004)

Wu, Y.F.; Kazmi, S.M.S.; Munir, M.J.; Zhou, Y.; Xing, F.: Effect of compression casting method on the compressive strength, elastic modulus and microstructure of rubber concrete. J. Clean. Prod. 264, 121746 (2020). https://doi.org/10.1016/j.jclepro.2020.121746

Khaloo, A.R.; Dehestani, M.; Rahmatabadi, P.: Mechanical properties of concrete containing a high volume of tire-rubber particles. Waste Manag. 28, 2472–2482 (2008). https://doi.org/10.1016/j.wasman.2008.01.015

Goulias, D.G.; Ali, A.H.: Evaluation of rubber-filled concrete and correlation between destructive and nondestructive testing results. Cem. Concr. Aggregates. 20, 140–144 (1998). https://doi.org/10.1520/cca10447j

Xue, J.; Shinozuka, M.: Rubberized concrete: A green structural material with enhanced energy-dissipation capability. Constr. Build. Mater. 42, 196–204 (2013). https://doi.org/10.1016/j.conbuildmat.2013.01.005

Najim, K.B.; Hall, M.R.: Crumb rubber aggregate coatings/pre-treatments and their effects on interfacial bonding, air entrapment and fracture toughness in self-compacting rubberised concrete (SCRC). Mater. Struct. Constr. 46, 2029–2043 (2013). https://doi.org/10.1617/s11527-013-0034-4

IS 456 - 2000: Indian Standard Plain and Reinforced Concrete - Code of Practice, IS-456:2000. Bur. Indian Stand. New Delhi. New Delhi,India (2000)

A.M. Neville: concrete technology, (2013)

Mansur, M.A.; Wee, T.H.; Cheran, L.S.: Crushed bricks as coarse aggregate for concrete. ACI Mater. J. 96, 478–484 (1999). https://doi.org/10.14359/649

Akhtaruzzaman, A.A. and hasnat A.: Properties of concrete using crushed brick as aggregate, Concrete International (1983)

Rashid, M.A., Salam, M.A., Kumar Shill, S., Hasan, M.K.: Effect of replacing natural coarse aggregate by brick aggregate on the properties of concrete. Dhaka Univ. Eng. Technol. Gazipur. 1, (2012)

Miličević, I.; Štirmer, N.; Bjegović, D.: Relation between the compressive strength and modulus of elasticity of concrete with crushed brick and roof tile aggregates. Struct. Concr. 18, 366–375 (2017). https://doi.org/10.1002/suco.201500207

Acknowledgements

This work is supported by the Civil Engineering Department, Delhi Technological University. Mr. Sandeep Mishra, Department of Applied Physics, helped in the XRD analysis related to the central instrumentation facility of the Delhi Technological University.

Funding

The Delhi Technological University in Delhi, India, funded this research.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Consent to Participate

As a corresponding author or on behalf of all authors of the research paper, I consent to participate.

Consent to Publication

All authors of the research paper agree with the publication.

Conflict of interest

This article does not include any conflicts of interest.

Rights and permissions

About this article

Cite this article

Kumar, R., Dev, N. Mechanical and Microstructural Properties of Rubberized Concrete After Surface Modification of Waste Tire Rubber Crumb. Arab J Sci Eng 47, 4571–4587 (2022). https://doi.org/10.1007/s13369-021-06154-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-021-06154-w