Abstract

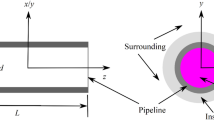

The heat transfer performance of the air–water double pipe heat exchanger (HE) was experimentally investigated. Segmental baffles with semi-circular perforations were introduced in the annular side of HE. Each baffle contains semi-circular fins. Air was used as a working fluid in the annular while, water for the inner tube. Seven different air Reynold’s numbers range from 2700 to 4000 were selected. While water side Reynold’s number fixed at 34,159. Three different semi-circular perforation diameters were studied (30, 25, and 20 mm) to investigate their effect on HE thermal performance. The Nu number, overall heat transfer coefficient, friction factor, and thermal performance factor (TPF) were calculated. Also, compassion for the baffled and un-baffled pipe was done. It was observed that the thermal performance of the baffled pipe HE was better than the un-baffled one. The average overall heat transfer coefficient increases by 29.7%, 62%, and 80.6% by using perforated baffles with 30, 25, and 20 mm perforation diameters. The TPF of the heat exchanger with all studied perforated baffles cases is above unity and the best thermal performance obtained by using baffles was with 20 mm perforation diameter.

Similar content being viewed by others

Abbreviations

- A :

-

Surface area, m2

- A c :

-

Cross-sectional area, m2

- Cp :

-

Specific heat, kJ/kg.K

- d :

-

Diameter, m

- D i :

-

Inside diameter of the annular pipe, m

- D o :

-

The outside diameter of the annular pipe, m

- D H :

-

Hydraulic diameter, m

- F :

-

Friction factor

- H :

-

Heat transfer coefficient, W/m2.K

- K :

-

Thermal conductivity, W/m.K

- L :

-

Length of the tube, m

- M :

-

Mass flow rate, kg/s

- Nu :

-

Nusselt number

- P :

-

Perimeter, m

- Pr :

-

Prandtl number

- Q :

-

Heat transfer rate, W

- Re :

-

Reynolds number

- T :

-

Temperature, K

- \(\Delta T_{m}\) :

-

Log mean temperature difference, K

- \(\Delta P\) :

-

Pressure drop, bar

- U :

-

Overall heat transfer coefficient, W/m2.K

- Un :

-

Uncertainty

- V :

-

Velocity, m/s

- µ:

-

Dynamic viscosity, kg/m.s

- \(\rho\) :

-

Density, kg/m3

- A:

-

Air

- an:

-

Annular

- I:

-

Inlet

- O:

-

Outlet

- W:

-

Water

References

Pacio, J.C.; Dorao, C.A.: A review on heat exchanger thermal hydraulic models for cryogenic applications. Cryogenics 51(7), 366–379 (2011). https://doi.org/10.1016/j.cryogenics.2011.04.005

Dhaiban, H.T.; Hussein, M.A.: The Optimal Design of Heat Sinks: A Review. J. Appl. Comput. Mech. 6(4), 14 (2020). https://doi.org/10.22055/JACM.2019.14852

M. Tejas Sonawane, M. Prafulla Patil, M. A. Chavhan, B. M. Dusane, “a Review on Heat Transfer Enhancement By Passive Methodss,” International Research Journal of Engineering and Technology, vol. 3, no. 9. pp. 1567–1574, 2016.

J. Mahesh, A. R., B. Diksha, B. Amol, and M. Mayura, “Review on Enhancement of Heat Transfer by Active Method,” International Journal of Current Engineering and Technology, vol. 6, no. Special Issue-6, pp. 221–225, 2016.

Gugulothu, R.; Reddy, K.V.K.; Somanchi, N.S.; Adithya, E.L.: A Review on Enhancement of Heat Transfer Techniques. Materials Today: Proceedings 4(2), 1051–1056 (2017). https://doi.org/10.1016/j.matpr.2017.01.119

Popov, I.A.; Gortyshov, Y.F.; Olimpiev, V.V.: Industrial applications of heat transfer enhancement: The modern state of the problem (a Review). Therm. Eng. 59(1), 1–12 (2012). https://doi.org/10.1134/S0040601512010119

T. Charate, N. Awate, J. Badgujar, and S. Jadhav, “Review of Literature on Heat Transfer Enhancement in Heat Exchangers.” International Journal of Scientific & Engineering Research, Volume 6, Issue 12, 2015.

Dong, C.; Chen, Y.P.; Wu, J.F.: Influence of baffle configurations on flow and heat transfer characteristics of trisection helical baffle heat exchangers. Energy Convers. Manage. 88, 251–258 (2014). https://doi.org/10.1016/j.enconman.2014.08.005

A. El Maakoul, A. Laknizi, S. Saadeddine, A. Ben Abdellah, M. Meziane, and M. El Metoui, “Numerical design and investigation of heat transfer enhancement and performance for an annulus with continuous helical baffles in a double-pipe heat exchanger,” Energy Convers. Manag., vol. 133, pp. 76–86, doi: 10.1016/j. enconman.2016.12.002.

Wang, Q.; Chen, G.; Chen, Q.; Zeng, M.: Review of Improvements on Shell-and-Tube Heat Exchangers With Helical Baffles. Heat Transf. Eng. J. 31(10), 836–853 (2010). https://doi.org/10.1080/01457630903547602

S. S. Kamthe and S. B. Barve," Effect of Different types of Baffles on Heat Transfer & Pressure Drop of Shell and Tube Heat Exchanger: A review", Int. J. of Current Eng. and Tech., Special Issue-7, 2017.

Bichkar, P.; Dandgaval, O.; Dalvi, P.; Godase, R.; Dey, T.: Study of Shell and Tube Heat Exchanger with the Effect of Types of Baffles. Procedia Manuf. 20, 195–200 (2018). https://doi.org/10.1016/j.promfg.2018.02.028

Gu, X.; Luo, Y.; Xiong, X.; Wang, K.; Wang, Y.: Numerical and experimental investigation of the heat exchanger with trapezoidal baffle. Int. J. Heat Mass Transf. 127, 598–606 (2018). https://doi.org/10.1016/j.ijheatmasstransfer.2018.07.045

R. Das, R.K. Singla, Inverse Heat Transfer Study of A Nonlinear Straight Porous Fin using Hybrid Optimization, Proceedings of the ASME 2014 Gas Turbine India Conference, New Delhi, India, 2014.

Das, R.: Forward and inverse solutions of a conductive, convective and radiative cylindrical porous fin. Energy Convers. Manage. 87, 96–106 (2014). https://doi.org/10.1016/j.enconman.2014.06.096

Das, R.; Prasad, D.K.: Prediction of porosity and thermal diffusivity in a porous fin using differential evolution algorithm. Swarm Evol. Comput. (2017). https://doi.org/10.1016/j.swevo.2015.03.001

Singh, K.; Das, R.: Approximate Analytical Method for Porous Stepped Fins with Temperature-Dependent Heat Transfer Parameters. J. Thermophys. Heat Transfer (2016). https://doi.org/10.2514/1.T4831

Das, R.: Prediction of Heat Generation in a Porous Fin from Surface Temperature. JOURNAL OF THERMOPHYSICS AND HEAT TRANSFER (2017). https://doi.org/10.2514/1.T5098

Xiao, X.; Zhang, L.; Li, X.; Jiang, B.; Yang, X.; Xia, Y.: Numerical investigation of helical baffles heat exchanger with different Prandtl number fluids. Int. J. Heat Mass Transf. 63, 434–444 (2013). https://doi.org/10.1016/j.ijheatmasstransfer.2013.04.001

Wang, S.; Xiao, J.; Wang, J.; Jian, G.; Wen, J.; Zhang, Z.: Configuration optimization of shell-and-tube heat exchangers with helical baffles using multi-objective genetic algorithm based on fluid-structure interaction. Int. Commun. Heat Mass Transf. 85, 62–69 (2017). https://doi.org/10.1016/j.icheatmasstransfer.2017.04.016

Wen, J.; Gu, X.; Wang, M.; Wang, S.; Tu, J.: Numerical investigation on the multi-objective optimization of a shell-and-tube heat exchanger with helical baffles. Int. Commun. Heat Mass Transf. 89, 91–97 (2017). https://doi.org/10.1016/j.icheatmasstransfer.2017.09.014

Dong, C.; Chen, Y.-P.; Wu, J.-F.: Flow and heat transfer performances of helical baffle heat exchangers with different baffle configurations. Appl. Therm. Eng. 80, 328–338 (2015). https://doi.org/10.1016/j.applthermaleng.2015.01.070

Dong, C., et al.: An analysis of performance on trisection helical baffles heat exchangers with diverse inclination angles and baffle structures. Chem. Eng. Res. Des. 121, 421–430 (2017). https://doi.org/10.1016/j.cherd.2017.03.027

Lin, L.; Chen, Y.; Wu, J.; Guo, Y.; Dong, C.: Performance of flow and heat transfer in vertical helical baffle condensers. Int. Commun. Heat Mass Transf. 72, 64–70 (2016). https://doi.org/10.1016/j.icheatmasstransfer.2016.01.014

Wen, J.; Yang, H.; Wang, S.; Xue, Y.; Tong, X.: Experimental investigation on performance comparison for shell-and-tube heat exchangers with different baffles. Int. J. Heat Mass Transf. 84, 990–997 (2015). https://doi.org/10.1016/j.ijheatmasstransfer.2014.12.071

Yang, S.; Chen, Y.; Wu, J.; Gu, H.: Influence of baffle configurations on flow and heat transfer characteristics of unilateral type helical baffle heat exchangers. Appl. Therm. Eng. 133, 739–748 (2018). https://doi.org/10.1016/j.applthermaleng.2018.01.091

Xiao, J.; Wang, S.; Ye, S.; Wang, J.; Wen, J.; Tu, J.: Experimental investigation on pre-heating technology of coal water slurry with different concentration in shell-and-tube heat exchangers with ladder-type fold baffles. Int. J. Heat Mass Transf. 132, 1116–1125 (2019). https://doi.org/10.1016/j.ijheatmasstransfer.2018.12.082

Yang, S.; Chen, Y.; Wu, J.; Gu, H.: Investigation on shell side performance in half-cylindrical desuperheating zone of ladder type helical baffle heat exchangers. Appl. Therm. Eng. 175, 115334 (2020). https://doi.org/10.1016/j.applthermaleng.2020.115334

He, L.; Li, P.: Numerical investigation on double tube-pass shell-and-tube heat exchangers with different baffle configurations. Appl. Therm. Eng. 143, 561–569 (2018). https://doi.org/10.1016/j.applthermaleng.2018.07.098

Cao, X.; Chen, D.; Du, T.; Liu, Z.; Ji, S.: Numerical investigation and experimental validation of thermo-hydraulic and thermodynamic performances of helical baffle heat exchangers with different baffle configurations. Int. J. Heat Mass Transf. 160, 120181 (2020). https://doi.org/10.1016/j.ijheatmasstransfer.2020.120181

El Maakoul, A., et al.: Numerical comparison of shell-side performance for shell and tube heat exchangers with trefoil-hole, helical and segmental baffles. Appl. Therm. Eng. 109, 175–185 (2016). https://doi.org/10.1016/j.applthermaleng.2016.08.067

F. Incropera, P.D. Dewitt, Introduction to heat transfer, fifth ed., John Wiley & Sons Inc, 2006.

Dawid Taler , and Jan Taler, “Simple heat transfer correlations for turbulent tube flow”, E3S Web of Conferences 13, 0200 2017, doi: https://doi.org/10.1051/e3sconf/20171302008.

B. S. Petukhov, Irvine in T. F. and Hartnett J. P., Eds., Advances in Heat Transfer. Vol. 6. Academic Press. New York, 1970.

Kline, S.J.; McClintock, F.A.: Describing uncertainties in single-sample experiments. Mech Eng 75(1), 3–8 (1953)

M. Sheikholeslami, D.D. Ganji , M. Gorji-Bandpy," Experimental and numerical analysis for effects of using conical ring on turbulent flow and heat transfer in a double pipe air to water heat exchanger", Appl. Therm. Eng., vol. 100 pp. 805–819, 2016, doi:https://doi.org/10.1016/j.applthermaleng.2016.02.075

Sheikholeslami, M.; Ganji, D.D.: Heat transfer improvement in a double pipe heat exchanger by means of perforated turbulators. Energy Convers. Manage. 127, 112–123 (2016)

Sheikholeslami, M.; Ganji, D.D.: Heat transfer enhancement in an air to water heat exchanger with discontinuous helical turbulators; experimental and numerical studies. Energy 116, 341–352 (2016)

Sheikholeslami, M.; Ganji, D.D.: Turbulent heat transfer enhancement in an air-to-water heat exchanger. J Process Mechanical Engineering 231(6), 1235–1248 (2017)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hussein, M.A., Hameed, V.M. Experimental Investigation on the Effect of Semi-circular Perforated Baffles with Semi-circular Fins on Air–Water Double Pipe Heat Exchanger. Arab J Sci Eng 47, 6115–6124 (2022). https://doi.org/10.1007/s13369-021-05869-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-021-05869-0