Abstract

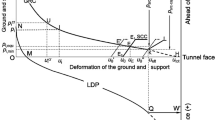

It is significant to study the tunnel mechanical behavior induced by excavation and support in order to ensure the safety and economy of the tunnel engineering. First of all, in order to take into account the effect of the intermediate principal stress on the tunnel mechanical behavior, the unified strength criterion is adopted to describe the plastic yield behavior of the surrounding rock. Secondly, the model proposed by Kastner does not consider the co-effect of the initial elastic displacement of the tunnel surrounding rock before the support structure is installed and the interaction between the surrounding rock and the support structure. Therefore, a new analytical model for the circular tunnel, which can overcome these two shortcomings, is proposed by accounting for the tunnel practical construction process on the basis of Kastner’s method. The effects of the calculation parameters such as the intermediate principal stress coefficient b, the initial elastic displacement u0 of the tunnel surrounding rock, the rock mechanical property and the stiffness ks of the support structure on the surrounding rock plastic zone, the radial displacement of the tunnel inner wall and the support stress are studied in detail. The results show that the proposed model for the circular tunnel, which considers the co-effect of the intermediate principal stress and interaction between the surrounding rock and support structure, can perfectly reflect the tunnel mechanical behavior. Finally, the proposed model is verified with the practical tunnel engineering.

Similar content being viewed by others

Abbreviations

- b :

-

The intermediate principal stress coefficient

- c, φ :

-

The rock cohesion and internal friction angle, MPa

- E, μ :

-

The rock elastic modulus (MPa) and Poisson’s ratio, respectively

- k s :

-

The support structure stiffness, MPa/m

- \(\sigma _{r}\),\(\sigma _{\theta }\) :

-

The radial and tangential normal stress components, respectively, MPa

- \(\sigma _{1}\), \(\sigma _{2}\), \(\sigma _{3}\) :

-

The major, intermediate and minor principal stress, respectively, MPa

- \(\sigma _{r} ^{{ep}}\), \(\sigma _{\theta } ^{{{\text{ep}}}}\) :

-

The stress components at the interface of the plastic zone and elastic zone, MPa

- \(\varepsilon _{r}^{p} ,\varepsilon _{\theta }^{p} ,\varepsilon _{z}^{p}\) :

-

The strain components at the plastic zone

- u 0, (u e)max :

-

The initial and maximum radial displacements at the tunnel inner wall before the support structure is installed, m

- \(u_{r}^{p}\) :

-

The radial displacement in the plastic zone, m

- u B :

-

The radial displacement at the outer boundary of the plastic zone, m

- △R:

-

The displacement at the inner wall of the tunnel, m

- r :

-

The polar radius, m

- r 0 :

-

The radius of the tunnel, m

- r p s :

-

The radius of the plastic zone, m

- p 0 :

-

The initial ground stress, MPa

- p f :

-

The radial stress at the interface of the plastic zone and elastic zone

- p s :

-

The support pressure, MPa

References

Haruyama, K.; Teramoto, S.; Taira, K.: Construction of large cross-section double-tier Metropolitan Inter-city Highway (Ken-O-Do) Ome Tunnel by NATM. Tunn. Undergr. Space Technol. 20, 111–119 (2005)

Karakus, M.; Fowell, R.J.: An insight into the New Austrian Tunnelling Method (NATM). In: Viith Regional Rock Mechanics Symposium, Sivas, Turkey (2004)

Zbigniew, N.; Piotr, M.; Tadeusz, M.: Application of the NATM method in the road tunneling works in difficult geological conditions—The Carpathian flysch. Tunn. Undergr. Space Technol. 74, 41–59 (2018)

Sugimoto, M.; Chen, J.; Sramoon, A.: Frame structure analysis model of tunnel lining using nonlinear ground reaction curve. Tunn. Undergr. Space Technol. 94, 103135 (2019)

Bobet, A.: Elastic solution for deep tunnels: application to excavation damage zone and rockbolt support. Rock Mech. Rock Eng. 42(2), 147–174 (2009)

Wang, G.; Liu, C.Z.; Jiang, Y.J.; Wu, X.Z.; Wang, S.G.: Rheological model of DMFC rockbolt and rockmass in a circular tunnel. Rock Mech. Rock Eng. 48(6), 2319–2357 (2015)

Zou, J.F.; Xia, Z.Q.; Dan, H.C.: Theoretical solutions for displacement and stress of a circular opening reinforced by grouted rock bolt. Geomech. Eng. 11(3), 439–455 (2016)

Kastner, H.: Static des Tunnel-und Stollenbaues. Springer, Berlin (1971)

Gonzalez-Nicieza, C.; Alvarez-Vigil, A.E.; Menendez-Diaz, A.; Gonzalez-Palacio, C.: Influence of the depth and shape of a tunnel in the application of the convergence-confinement method. Tunn. Undergr. Space Technol. 23(1), 25–37 (2008)

Cheng, Y.M.: Modified Kastner formula for cylindrical cavity contraction in Mohr-Coulomb medium for circular tunnel in isotropic medium. J. Mech. 28(1), 163–169 (2012)

Carranza-Torres, C.; Fairhurst, C.: Application of the convergence-confinement method of tunnel design to rock masses that satisfy the Hoek-Brown failure criterion. Tunn. Undergr. Space Technol. 15(2), 187–213 (2000)

Sharan, S.K.: Elastic–brittle–plastic analysis of circular openings in Hoek-Brown media. Int. J. Rock Mech. Min. Sci. 40, 817–824 (2003)

Park, K.H.; Kim, Y.J.: Analytical solution for a circular opening in an elastic–brittle–plastic rock. Int. J. Rock Mech. Min. Sci. 43(4), 616–622 (2006)

Park, K.H.; Tontavanich, B.; Lee, J.G.: A simple procedure for ground response curve of circular tunnel in elastic–strain softening rock masses. Tunn. Undergr. Space Technol. 23(2), 151–159 (2008)

Wang, Y.: Ground response of circular tunnels in poorly consolidated rock. J Geotech Eng-ASCE 122(9), 703–708 (1996)

Wang, H.N.; Zeng, G.S.; Utili, S.; Jiang, M.J.; Wu, L.: Analytical solutions of stresses and displacements for deeply buried twin tunnels in viscoelastic rock. Int. J. Rock Mech. Min. Sci. 93, 13–29 (2017)

Wu, X.Z.; Jiang, Y.J.; Guan, Z.C.: A modified strain-softening model with multi-post-peak behaviors and its application in circular tunnel. Eng. Geol. 240(5), 21–33 (2018)

Bian, K.; Liu, J.: Analytical study of hydraulic tunnel in brittle rock masses with strain-softening characteristic. Disaster Adv. 6(4), 200–213 (2013)

Bahrami, B.; Mohsenpour, S.; Miri, M.A.; Mirhaseli, R.: Quantitative comparison of fifteen rock failure criteria constrained by polyaxial test data. J. Petrol. Sci. Eng. 159, 564–580 (2017)

Wang, S.L.; Wu, Z.J.; Guo, M.W.; Ge, X.R.: Theoretical solutions of a circular tunnel with the influence of axial in situ stress in elastic-brittle-plastic rock. Tunn. Undergr. Space Technol. 30, 155–168 (2012)

Xiao, Y.; Zhao, M.H.; Zhang, R.; Zhao, H.; Wu, G.Q.: Stability of dual square tunnels in rock masses subjected to surcharge loading. Tunn. Undergr. Space Technol. 92, 103037 (2019)

Oettl, G.; Stark, R.F.; Hofstetter, G.: A comparison of elastic–plastic soil models for 2D FE analyses of tunneling. Comput. Geotech. 23(1–2), 19–38 (1998)

Jiang, L.Z.; Chen, J.; Li, J.: Seismic response of underground utility tunnels: shaking table testing and FEM analysis. Earthq. Eng. Eng. Vib. 9(4), 555–567 (2010)

Yu, D.M.; Fan, Y.F.; Duan, J.X.; Luo, X.W.: Elastoplastic unified solutions to deep-buried circular tunnels considering intermediate principal stress. J. Shanghai Jiao Tong Univ. 47(9), 1447–1453 (2013)

Yu, M.H.: Unified strength criterion and its application. Springer, Berlin (2004)

Yu, M.H.; Zan, Y.W.; Zhao, J.; Yoshimine, M.: A unified strength criterion for rock material. Int. J. Rock Mech. Min. Sci. 39, 975–989 (2002)

Xu, S.Q.; Yu, M.H.: The effect of the intermediate principal stress on the ground response of circular openings in rock mass. Rock Mech. Rock Eng. 39(2), 169–181 (2006)

Fan, W.; Yu, M.H.; Deng, L.S.; Peng, X.L.; Chen, L.W.: New strength formulae for rock surrounding a circular opening. Can. Geotech. J. 50(7), 735–743 (2013)

Aftes: Groupe de travail numerio 7-Recommendation sur l’emploi de la methode convergence-confnement. Dans Tunnels et ouvrages souterrains. 59, 218–238 (1983)

Brown, E.T.; Bray, J.W.; Ladanyi, B.; Hoek, E.: Ground response curves for rock tunnels. J. Geotech. Eng. 109, 15–39 (1983)

Oreste, P.P.: A procedure for determining the reaction curve of the shotcrete lining considering transient conditions. Rock Mech. Rock Eng. 36(3), 209–236 (2003)

Oreste, P.P.: The convergence-confinement method: roles and limits in modern geomechanical tunnel design. Am. J. Appl. Sci. 6(4), 757–771 (2009)

Oreste, P.P.: Analysis of structural interaction in tunnels using the convergence-confinement approach. Tunn. Undergr. Space Technol. 18, 347–363 (2003)

Fang, Q.; Zhang, D.L.; Zhou, P.; Wong, L.N.Y.: Ground reaction curves for deep circular tunnels considering the effect of ground reinforcement. Int. J. Rock Mech. Min. Sci. 60, 401–412 (2013)

Jeffrey, O.; Nicholas, V.; Mark, D.: Improvement to the convergence-confinement method: inclusion of support installation proximity and stiffness. Rock Mech. Rock Eng. 51, 1495–1519 (2018)

Shin, Y.J.; Song, K.; Lee, I.M.; Cho, G.C.: Interaction between tunnel supports and ground convergence-consideration of seepage forces. Int. J. Rock Mech. Min. Sci. 48, 394–405 (2011)

Cai, Y.; Jiang, Y.J.; Ibrahim, D.; Tomomi, I.; Tetsuro, E.: An analytical model considering interaction behavior of grouted rock bolts for convergence-confinement method in tunneling design. Int. J. Rock Mech. Min. Sci. 76, 112–126 (2015)

Hou, G.Y.: Review of interaction mechanism between surrounding rock and support and analysis of conceptual model of rheological deformation mechanism. Chin. J. Rock Mech. Eng. 27(Supp2), 3618–3629 (2008)

Jaeger, J.C.; Cook, N.G.W.; Zimmerman, R.W.: Fundamentals of Rock Mechanics. Fourth Edition), Blackwell publishing (2007)

Zhu, Y.F.; Zhang, X.S.; Wang, H.P.: Analysis of complete process of interaction of surrounding rock and support under elastoplastic deformation condition. J. Xi’an Univ. Arch Tech. (Nat. Sci. Ed). 52(2), 200–206 (2020)

Huang, F.; Zhu, H.H.; Li, Q.S.: Field test and theoretical analysis of the loose zone of the surrounding rock of the tunnel. Rock Soil Mech. 37(S1), 145–150 (2016)

Acknowledgements

This study is supported by the National Key Research and Development Plan of China (Grant No: 2019YFC1509701).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that there are no conflicts of interest regarding the publication of this paper.

Rights and permissions

About this article

Cite this article

Lv, S., Liu, H. An Analytical Model to Predict the Tunnel Mechanical Behavior Induced by Excavation and Support. Arab J Sci Eng 47, 4079–4091 (2022). https://doi.org/10.1007/s13369-021-05868-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-021-05868-1