Abstract

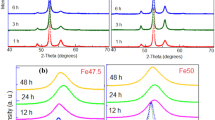

Magnetic structures have attracted a great interest due to their multiple applications, from physics to biomedicine. Iron, nickel and cobalt are among the most important ferromagnetic elements, therefore the synthesis of Fe-based alloys processed by ball milling from the Fe, Ni and Co powders is of particular interest. This subject mainly concerned the structural and magnetic properties evolution of Fe50Co25Ni25 nanocrystalline powder mixture prepared by mechanical alloying in a high-energy planetary ball mill under argon atmosphere. For extended milling time of 100 h, two nanocrystalline Fe (Co,Ni) (∼ 87 nm) and fcc-Co-rich (∼ 47 nm) phases were identified. This phase transformations, dependent on the alloying time, are related to the increase in dislocations and accumulation of stacking faults. Dislocation density of 1.25 × 1015 m−2 is estimated after 100 h of milling. The milled FeCoNi alloy displays a soft ferromagnetic behavior with single magnetic domain (Hc ∼ 12.5 Oe and Mr/Ms ∼ 0.007 for 100 h milling). Mössbauer analysis gives three main magnetic components: two different components attributed to metallic Fe species located in bcc and fcc Fe–Co–Ni domains and a magnetic component characterized by larger hyperfine fields and isomer shifts typical of Fe3+, Fe2+ species and Fe ions.

Similar content being viewed by others

References

Prasad, N.K.; Kumar, V.: Structure–magnetic properties correlation in mechanically alloyed nanocrystalline Fe–Co–Ni–(Mg–Si)x alloy powders. J. Mater. Sci. Mater. Elect. 26, 10109–10118 (2015). https://doi.org/10.1007/s10854-015-3695-7

Raanaei, H.; Eskandari, H.; Mohammad, H.V.: Structural and magnetic properties of nanocrystalline Fe–Co–Ni alloy processed by mechanical alloying. J. Magn. Magn. Mater. 98, 190–195 (2016). https://doi.org/10.1016/j.jmmm.2015.09.031

Siyuan, D.; Tao, N.; Jing, Y.; Hucheng, Y.; Shukui, Z.: Recent advances and applications of magnetic nanomaterials in environmental sample analysis. Trac. Trend. Anal. Chem. 126, 115864 (2020). https://doi.org/10.1016/j.trac.2020.115864

Liming, S.; Yi, Xu: Amorphous behavior of ZrxFeNiSi0.4B0.6 high entropy alloys synthesized by mechanical alloying. J. Non. Cryst. Solids. 530, 119854 (2020). https://doi.org/10.1016/j.jnoncrysol.2019.119854

Pikula, T.; Oleszak, D.; Pękała, M.; Jartych, E.: Structure and some magnetic properties of mechanically synthesized and thermally treated Co–Fe–Ni alloys. J. Magn. Magn. Mater. 320, 413–420 (2008). https://doi.org/10.1016/j.jmmm.2007.06.020

Hiroaki, K.; Hitoshi, M.: Mechanical alloying of Ga2O3 and Ga2O3-Al2O3. Mater. Chem. Phys. 250, 123080 (2020). https://doi.org/10.1016/j.matchemphys.2020.123080

Hapishah, A.N.; Hamidon, M.N.; Syazwan, M.M.; Shafiee, F.N.: Effect of grain size on microstructural and magnetic properties of holmium substituted yttrium iron garnets (Y1.5Ho1.5Fe5O12) mmm Results. Phys. 14, 102391 (2019). https://doi.org/10.1016/j.rinp.2019.102391

Guittoum, A.; Layadi, A.; Bourzami, A.; Tafat, H.; Souami, N.; Boutarfaia, S.; Lacour, D.: X- ray diffraction, microstructure, Mössbauer and magnetization studies of nanostructured Fe50Ni50 alloy prepared by mechanical alloying. J. Magn. Magn. Mater. 320, 1385–1392 (2008). https://doi.org/10.1016/j.jmmm.2007.11.021

Inoue, A.; Shen, B.L.; Koshiba, H.; Kato, H.; Yavari, A.R.: Ultra-high strength above 5000 MPa and soft magnetic properties of Co–Fe–Ta–B bulk glassy alloys. Acta Mater. 52, 1631–1637 (2004). https://doi.org/10.1016/j.actamat.2003.12.008

Chokprasombat, K.; Pinitsoontorn, S.; Maensiri, S.: Effect of Ni content on nanocrystalline Fe–Co–Ni ternary alloys synthesized by chemical reduction method. J. Magn. Magn. Mater. 405, 174–180 (2016). https://doi.org/10.1016/j.jmmm.2015.12.064

Koohkan, R.; Sharafi, S.; Shokrollahi, H.; Janghorban, K.: Preparation of nanocrystalline Fe–Ni powders by mechanical alloying used in soft magnetic composites. J. Magn. Magn. Mater. 320, 1089–1094 (2008). https://doi.org/10.1016/j.jmmm.2007.10.033

Jiles, D.: Introduction to Magnetism and Magnetic Materials, pp. 280–297. Chapman & Hall, London (1991)

Moumeni, H.; Alleg, S.; Greneche, J.M.: Structural properties of Fe50Co50 nanostructured Powder prepared by mechanical alloying. J. Alloy. Compd. 386, 12–19 (2005). https://doi.org/10.1016/j.jallcom.2004.05.017

Msellak, K.; Chopart, J.P.; Jbara, O.; Aaboubi, O.; Amblard, J.: Magnetic field effects on Ni–Fe alloys codeposition. J. Magn. Magn. Mater. 281, 295–304 (2004). https://doi.org/10.1016/j.jmmm.2004.04.118

El-Gendy, A.A.; Ibrahim, E.M.M.; Khavrus, V.O.; Krupskaya, Y.; Hampel, S.; Leonhardt, A.; Büchner, B.; Klingeler, R.: The synthesis of carbon coated Fe, Co and Ni nanoparticles and an examination of their magnetic properties. Carbon 47, 2821–2828 (2009). https://doi.org/10.1016/j.carbon.2009.06.025

Bai, A.; Hu, C.C.; Wen, T.C.: Composition control of ternary FeCoNi deposits using cyclic voltammetry. Electrochim. Acta 48, 2425–2434 (2003). https://doi.org/10.1016/S0013-4686(03)00266-4

Hisada, D.; Fujiwara, Y.; Sato, H.; Jimbo, M.; Kobayashi, T.; Hata, K.: Structure and magnetic properties of FeCo nanoparticles encapsulated in carbon nanotubes grown by microwave plasma enhanced chemical vapordeposition. J. Magn. Magn. Mater. 323, 3184–3188 (2011). https://doi.org/10.1016/j.jmmm.2011.06.029

Mizutani, S.; Yokoshima, T.; Nam, H.S.; Nakanishi, T.; Osaka, T.; Yamazaki, Y.: High-frequency permeability and thermal stability of electrodeposited high-Bs CoNiFe thin films. IEEE. T. Magn. 36, 2539–2541 (2000). https://doi.org/10.1109/20.908499

Loginov, P.; Sidorenko, D.; Bychkova, M.; Petrzhik, M.; Levashov, M.: Mechanical alloying as an effective way to achieve superior properties of Fe–Co–Ni binder alloy. Metals 7, 570 (2017). https://doi.org/10.3390/met7120570

Rathi, A.; Meka, V.M.; Jayaraman, T.V.: Synthesis of nanocrystalline equiatomic nickel-cobalt-iron alloy powders by mechanical alloying and their structural and magnetic characterization. J. Magn. Magn. Mater. 469, 467–482 (2019). https://doi.org/10.1016/j.jmmm.2018.09.002

Muratov, D.G.; Kozhitov, L.V.; Karpenkov, D.Y.; Yakushko, E.V.; Korovin, E.Yu.; Vasil’ev, A.V.; Popkova, A.V.; Kazaryan, T.M.; Shadrinov, A.V. : Synthesis and magnetic properties of Fe–Co–Ni/C nanocomposites. Russ. Phys. J. 60, 1924–1930 (2018). https://doi.org/10.1007/s11182-018-1304-y

Lutterotti, L.: MAUD CPD Newsletter (IUCr). 24 (2000)

Varret, F.; Teillet, J.: Unpublished Mosfit Program, Université du Maine France (1976)

Cardellini, F.; Mazzone, G.: Thermal and structural study of the h.c.p.-to-f.c.c. transformation in cobalt. Philos. Mag. 67A(6), 1289–1300 (1993). https://doi.org/10.1080/01418619308225355

Sort, J.; Nogués, J.; Suriñach, S.; Muñoz, J.S.; Baró, M.D.: Correlation between stacking fault formation, allotropic phase transformations and magnetic properties of ball-milled cobalt. Mater. Sci. Eng., A A375–377, 869–873 (2004). https://doi.org/10.1016/j.msea.2003.10.186

Shokrallahi, H.: The magnetic and structural properties of the most important alloys of iron produced by mechanical alloying. Mater. Des. 30, 3374–3387 (2009). https://doi.org/10.1016/j.matdes.2009.03.035

Alleg, S.; Kartoutb, S.; Ibrir, M.; Azzaza, S.; Fenineche, N.E.; Sunol, J.J.: Magnetic, structural and thermal properties of the Finemet-type powders prepared by mechanical alloying. J. Phys. Chem. Sol. 74, 550–557 (2013). https://doi.org/10.1016/j.jpcs.2012.12.002

Lachheb, R.; Bachaga, T.; Khitouni, M.; Makhlouf, T.: Phase transformations and microstructural properties of nanocrystalline Fe75Si10B10Nb5 alloy synthesized by mechanical alloying. Adv. Powder Technol. 26(6), 1563–1569 (2015). https://doi.org/10.1016/j.apt.2015.08.010

Mhadhbi, M.; Khitouni, M.; Azabou, M.; Kolsi, A.: Characterization of Al and Fe nanosized powders synthesized by high-energy mechanical milling. Mater. Charact. 59, 944–950 (2008). https://doi.org/10.1016/j.matchar.2007.08.001

Suryanarayana, C.: Mechanical alloying and milling. Prog. Mater Sci. 46, 1–184 (2001). https://doi.org/10.1016/S0079-6425(99)00010-9

Fecht, H.J.: Nanostructure formation by mechanical attrition. Nanostruct. Mater. 6, 33–42 (1995). https://doi.org/10.1016/0965-9773(95)00027-5

Herzer, G.; in: K.H.J. Buschow (Ed.), Handbook of Magnetic Materials, Elsevier Science B.V., 10 (1997)

DelshadChermahini, M.; Sharafi, S.; Shokrollahi, H.; Zandrahimi, M.; Shafyei, A.: The evolution of heating rate on the microstructural and magnetic properties of milled nanostructured Fe1-xCox (x = 0.2, 0.3, 0.4, 0.5 and 0.7) powder. J. Alloys. Compds. 484, 54–58 (2009). https://doi.org/10.1016/j.jallcom.2009.05.055

Souilaha, S.; Alleg, S.; Djebbaria, C.; Bensalema, R.; Sunol, J.J.: Magnetic and microstructural properties of the mechanically alloyed Fe57Co21Nb7B15 powder mixture. Mater. Chem. Phys. 132, 766–772 (2012). https://doi.org/10.1016/j.matchemphys.2011.12.010

Zeng, Q.; Baker, I.; Mc Creary, V.; Yan, Z.C.: Soft ferromagnetism in nanostructured mechanical alloying FeCo based powders. J. Magn. Magn. Mater. 318, 28 (2007). https://doi.org/10.1016/j.jmmm.2007.04.037

Luborsky, F.E.: Development of elongated particle magnets. J. Appl. Phys. 32, 171 (1961). https://doi.org/10.1063/1.2000392

Kneller, E.; Fine particle theory. In: A.E. Berkowitz, E. Kneller (Eds.), Magnetism and Metallurgy, Academic Press, New York. 1. 365–471(1969)

Abdellaoui, M.; Djega-Mariadassou, C.; Gaffet, E.: Structural study of Fe–Si nanostructured materials. J. Alloys. Compds. 259, 241 (1997). https://doi.org/10.1016/S0925-8388(97)00102-3

Bensebaa, N.; Loudjani, N.; Alleg, S.; Dekhil, L.; Suñol, J.J.; Sae, M.Al.; Bououdina, M.: XRD analysis and magnetic properties of nanocrystalline Ni20Co80 alloys. J. Magn. Magn. Mater. 349, 51–56 (2014). https://doi.org/10.1016/j.jmmm.2013.08.045

Author information

Authors and Affiliations

Corresponding author

Electronic Supplementary Material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Daly, R., Khitouni, N., Escoda, M.L. et al. Microstructure, Magnetic and Mössbauer Studies of Mechanically Alloyed FeCoNi Nanocrystalline Powders. Arab J Sci Eng 46, 5633–5643 (2021). https://doi.org/10.1007/s13369-020-05166-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-020-05166-2