Abstract

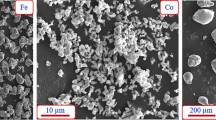

Equiatomic FeNiCo alloy was prepared by mechanical alloying using high energy planetary ball mill for 25 h. Structural properties of as-milled powders were characterized using X-ray diffraction technique (XRD), field emission scanning electron microscope and transmission electron microscope (TEM). The crystallite size and the % lattice strain obtained after 25 h of milling was found to be 19.26 nm and 0.43 % respectively. XRD analysis confirmed the dissolution of Co and Ni into Fe lattice and forming Fe (Co, Ni) supersaturated solid solution. XRD peak shift corresponding to (110) plane of major phase confirmed decrease in the lattice parameter from 0.288 to 0.286 nm after 25 h of milling. The initial powder morphology was irregular in shape which continued to reduce in size forming platelets after 25 h of milling. TEM study confirms the synthesis of nanocrystalline material. Magnetic properties of powder samples with milling time were evaluated using vibrating sample magnetometer (VSM). The maximum saturation magnetic flux density Bs obtained from VSM was 10.75 kilogauss which is comparatively higher than that of common soft ferrites and 80 % of Ni Permalloy.

Similar content being viewed by others

References

H. Shokrollahi, Mater. Des. 30, 3374–3387 (2009)

T. Sourmail, Prog. Mater Sci. 50, 816–880 (2005)

H. Ahmadian Baghbaderani, S. Sharafi, M. Delshad Chermahini, Powder Technol. 230, 241–246 (2012)

K. Gupta, K.K. Raina, S.K. Sinha, J. Alloys Compd. 429, 357–364 (2007)

A.S.M. Handbook, Metallography and Microstructures (ASM International, Geauga County, 1995), p. 538

D.W. Dietrich, Magnetically Soft Materials, properties and Selection: Non-ferrous Alloys and Special Purpose Materials (ASM Handbook, ASM International, Geauga County, 1990), p. 761

D. Jiles, Introduction to Magnetism and Magnetic Materials (Chapman and Hall, London, 1991), pp. 280–297

T. Pikula, D. Oleszak, J. Magn. Magn. Mater. 320, 413–420 (2008)

T.T. Zuo, R.B. Li, X.J. Ren, Y. Zhang, J. Magn. Magn. Mater. 371, 60–68 (2014)

Y. Zhang, T.T. Zuo, Y. Cheng, P.K. Liaw, Sci. Rep. 1455, 1–6 (2013)

R. Hamzaoui, O. Elkedim, N. Fenineche, E. Gaffet, J. Craven, Mater. Sci. Eng., A 360, 299–305 (2003)

F.E. Luborsky, J. Appl. Phys. 32, 171–178 (1961)

M. Tavakoli, H. Shokrollahi, L. Karimi, K. Janghorban, Powder Technol. 234, 13–18 (2013)

A.H. Bahrami, H. Ghayour, S. Sharafi, Powder Technol. 249, 7–14 (2013)

Y.L. Chen, Y.H. Hu, C.A. Hsieh, J.W. Yeh, S.K. Chen, J. Alloys Compd. 481, 768–775 (2009)

V. Kumar, R.S. Govind, R. Shekhar, R. Balasubramaniam, K. Balani, Mater. Sci. Eng., A 547, 38–50 (2012)

M. Khajepour, S. Sharafi, Powder Technol. 232, 124–133 (2012)

M. Yousefi, S. Sharafi, A. Mehrolhosseiny, Adv. Powder Technol. 25, 752–760 (2014)

Madina Abshinova, Procedia Eng. 76, 35–44 (2014)

G.K. Williamson, Acta Metall. 1, 22–31 (1953)

B.D. Cullity, Elements of X-Ray Diffraction, 2nd edn. (Addision-Wesley, Massachusetts, 1978), p. 356

Sh Nasibi, H. Shokrollahi, L. Karimi, K. Janghorban, Powder Technol. 228, 404–409 (2012)

C. Suryanarayana, Mechanical Alloying and Milling (Marcel Dekker, New York, 2004)

M. Yousefi, S. Sharafi, Mater. Des. 37, 325–333 (2012)

M. Khajepour, S. Sharafi, J. Alloys Compd. 509, 7729–7737 (2011)

S.H. Kim, Y.J. Lee, B.H. Lee, K.H. Lee, K. Narasimhan, Y.D. Kim, J. Alloys Compd. 424, 204–208 (2006)

W. Lu, Y. Xu, J. Shi, Y. Song, X. Li, J. Alloys Compd. 638, 233–238 (2015)

G.E. Fish, Proc. IEEE 78, 947–972 (1990)

G. Herzer, Acta Mater. 61, 718–734 (2013)

M.D. Chermahini, S. Sharafi, H. Shokrollahi, M. Zandrahimi, A. Shafyei, J. Alloys Compd. 484, 54–58 (2009)

A.H. Bahramai, S. Sharafi, H.A. Baghbaderani, Adv. Powder Technol. 24, 235–241 (2013)

E.M. McHenry, A.M. Willard, E.D. Laughlin, Prog. Mater Sci. 44, 291–433 (1999)

G. Herzer, IEEE Trans. Magn. 26, 1397 (1990)

K. Suzuki, J.M. Cadogan, Phys. Rev. B. 58, 2730–2739 (1998)

X. Amils, J. Nogues, S. Surinach, M.D. Baro, J. Magn. Magn. Mater. 203, 129–131 (1999)

D. Yuping, Z. Yahong, W. Tongmin, G. Shuchao, L. Xin, L. Xingjun, Mater. Sci. Eng., B 185, 86–93 (2014)

Acknowledgments

Authors are thankful to DST-SERB Project No. SERB/F/4552/2013-2014, New Delhi for financial assistance.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Prasad, N.K., Kumar, V. Microstructure and magnetic properties of equiatomic FeNiCo alloy synthesized by mechanical alloying. J Mater Sci: Mater Electron 26, 10109–10118 (2015). https://doi.org/10.1007/s10854-015-3695-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-015-3695-7