Abstract

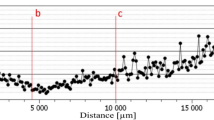

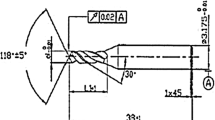

Miniature/micro-drilling of holes is increasingly utilized in manufacturing. While non-conventional machining methods (laser and spark erosion) were applied successfully for micro-drilling, mechanical drilling still of interest to industry due to its unmatched geometrical accuracy. However, tool wear and burr formation would hinder the economics of mechanical drilling supremacy. Hence, the need for understanding of tool wear, burr formation and cutting forces progression with process variables is a step towards comprehensive modelling of micro-drilling mechanics and subsequent enhanced process economics. The current research details experimental trials involving mechanical drilling of steel 1008/CR4 using twin-fluted twist drills of diameters 0.5, 1 and 1.5 mm. Full factorial design of experiments was utilized, and analysis of variance was accomplished to study the effects of feed rate and tool diameter (each of them at 3 levels) on tool flank wear and drilled hole quality. Entry and exit burr heights were increased by 80–150% when tool diameter and feed rate were two times higher. Progression of tool flank wear and usage of bigger tool diameter conversely reduced hole surface roughness. In addition, tool flank wear was increased when reducing of feed rate and using larger tool diameter. Catastrophic failure of 0.5-mm-diameter tool was noticed (after drilling of 46 holes at high feed rate level and after drilling of 97 holes at low feed levels) due to chip packing/jamming in the insufficient flute area.

Similar content being viewed by others

References

Masuzawa, T.: State of the art of micromachining. CIRP Ann. 49, 473–488 (2000). https://doi.org/10.1016/S0007-8506(07)63451-9

Abdelhafeez, A.M.; Soo, S.L.; Aspinwall, D.K.; Dowson, A.; Arnold, D.: The influence of burr formation and feed rate on the fatigue life of drilled titanium and aluminium alloys used in aircraft manufacture. CIRP Ann. 67, 103–108 (2018). https://doi.org/10.1016/j.cirp.2018.03.013

Alting, L.; Kimura, F.; Hansen, H.N.; Bissacco, G.: Micro engineering. CIRP Ann. 52, 635–657 (2003). https://doi.org/10.1016/S0007-8506(07)60208-X

Schaller, T.; Bohn, L.; Mayer, J.; Schubert, K.: Microstructure grooves with a width of less than 50 μm cut with ground hard metal micro end mills. Precis. Eng. 23, 229–235 (1999). https://doi.org/10.1016/S0141-6359(99)00011-2

Dornfeld, D.; Min, S.; Takeuchi, Y.: Recent advances in mechanical micromachining. CIRP Ann. 55, 745–768 (2006). https://doi.org/10.1016/j.cirp.2006.10.006

Chae, J.; Park, S.S.; Freiheit, T.: Investigation of micro-cutting operations. Int. J. Mach. Tools Manuf 46, 313–332 (2006). https://doi.org/10.1016/j.ijmachtools.2005.05.015

Hyacinth Suganthi, X.; Natarajan, U.; Ramasubbu, N.: A review of accuracy enhancement in microdrilling operations. Int. J. Adv. Manuf. Technol. 81, 199–217 (2015). https://doi.org/10.1007/s00170-015-6900-1

Biermann, D.; Kirschner, M.: Experimental investigations on single-lip deep hole drilling of superalloy Inconel 718 with small diameters. J. Manuf. Process. 20, 332–339 (2015). https://doi.org/10.1016/j.jmapro.2015.06.001

Iwata, K.; Moriwaki, T.; Hoshi, T.: Basic study of high speed micro deep drilling. CIRP Ann. 30, 27–30 (1981). https://doi.org/10.1016/S0007-8506(07)60889-0

Sugawara, A.; Inagaki, K.: Effect of workpiece structure on burr formation in micro-drilling. Precis. Eng. 4, 9–14 (1982). https://doi.org/10.1016/0141-6359(82)90107-6

Stein, J.M.; Dornfeld, D.A.: Burr formation in drilling miniature holes. CIRP Ann. 46, 63–66 (1997). https://doi.org/10.1016/S0007-8506(07)60776-8

Lee, K.; Dornfeld, D.A.: Micro-burr formation and minimization through process control. Precis. Eng. 29, 246–252 (2005). https://doi.org/10.1016/j.precisioneng.2004.09.002

Kim, D.W.; Lee, Y.S.; Chu, C.N.; Oh, Y.T.: Prevention of exit burr in microdrilling of metal foils by using a cyanoacrylate adhesive. Int. J. Adv. Manuf. Technol. 27, 1071–1076 (2005). https://doi.org/10.1007/s00170-004-2304-3

Chern, G.-L.; Lee, H.-J.: Using workpiece vibration cutting for micro-drilling. Int. J. Adv. Manuf. Technol. 27, 688–692 (2005). https://doi.org/10.1007/s00170-004-2255-8

Wu, X.; Li, L.; He, N.; Zhao, M.; Zhan, Z.: Investigation on the influence of material microstructure on cutting force and bur formation in the micro cutting of copper. Int. J. Adv. Manuf. Technol. 79, 321–327 (2015). https://doi.org/10.1007/s00170-015-6828-5

Aziz, M.; Ohnishi, O.; Onikura, H.: Innovative micro hole machining with minimum burr formation by the use of newly developed micro compound tool. J. Manuf. Process. 14, 224–232 (2012). https://doi.org/10.1016/j.jmapro.2011.12.006

Klocke, F.; Gerschwiler, K.; Abouridouane, M.: Size effects of micro drilling in steel. Prod. Eng. 3, 69–72 (2009). https://doi.org/10.1007/s11740-008-0144-y

Abouridouane, M.; Klocke, F.; Lung, D.; Adams, O.: Size effects in micro drilling ferritic-pearlitic carbon steels. Procedia CIRP. 3, 91–96 (2012). https://doi.org/10.1016/j.procir.2012.07.017

Okasha, M.M.; Mativenga, P.T.; Li, L.: Sequential laser mechanical microdrilling of inconel 718 alloy. J. Manuf. Sci. Eng. 133, 011008 (2011). https://doi.org/10.1115/1.4003334

Okasha, M.M.; Driver, N.; Mativenga, P.T.; Li, L.: Mechanical microdrilling of negative-tapered laser-predrilled holes: a new approach for burr minimization. Int. J. Adv. Manuf. Technol. 61, 213–225 (2011). https://doi.org/10.1007/s00170-011-3714-7

Imran, M.; Mativenga, P.T.; Gholinia, A.; Withers, P.J.: Assessment of surface integrity of Ni superalloy after electrical-discharge, laser and mechanical micro-drilling processes. Int. J. Adv. Manuf. Technol. 79, 1303–1311 (2015). https://doi.org/10.1007/s00170-015-6909-5

Imran, M.; Mativenga, P.T.; Gholinia, A.; Withers, P.J.: Evaluation of surface integrity in micro drilling process for nickel-based superalloy. Int. J. Adv. Manuf. Technol. 55, 465–476 (2010). https://doi.org/10.1007/s00170-010-3062-z

Imran, M.; Mativenga, P.T.; Withers, P.J.: Assessment of machining performance using the wear map approach in micro-drilling. Int. J. Adv. Manuf. Technol. 59, 119–126 (2011). https://doi.org/10.1007/s00170-011-3497-x

Yoon, H.-S.; Wu, R.; Lee, T.-M.; Ahn, S.-H.: Geometric optimization of micro drills using Taguchi methods and response surface methodology. Int. J. Precis. Eng. Manuf. 12, 871–875 (2011). https://doi.org/10.1007/s12541-011-0116-6

Pramanik, A.; Basak, A.K.; Uddin, M.S.; Shankar, S.; Debnath, S.; Islam, M.N.: Burr formation during drilling of mild steel at different machining conditions. Mater. Manuf. Process. 34, 726–735 (2019). https://doi.org/10.1080/10426914.2019.1594276

Zhang, X.; Yu, T.; Wang, W.; Zhao, J.: Improved analytical prediction of burr formation in micro end milling. Int. J. Mech. Sci. 151, 461–470 (2019). https://doi.org/10.1016/j.ijmecsci.2018.12.005

Abdelhafeez, A.M.; Soo, S.L.; Aspinwall, D.K.; Dowson, A.; Arnold, D.: A coupled Eulerian lagrangian finite element model of drilling titanium and aluminium alloys. SAE Int. J. Aerosp. 9, 198–207 (2016). https://doi.org/10.4271/2016-01-2126

Sofronas, A.; Taraman, K.: Model development for exit burr thickness as a function of drill geometry and feed. SME Tech. Pap. MR76-253 (1976)

Kim, J.; Dornfeld, D.A.: Development of an analytical model for drilling burr formation in ductile materials. J. Eng. Mater. Technol. 124, 192–198 (2002). https://doi.org/10.1115/1.1429937

Bu, Y.; Liao, W.H.; Tian, W.; Shen, J.X.; Hu, J.: An analytical model for exit burrs in drilling of aluminum materials. Int. J. Adv. Manuf. Technol. 85, 2783–2796 (2016). https://doi.org/10.1007/s00170-015-8125-8

Abdelhafeez, A.M.; Soo, S.L.; Aspinwall, D.K.; Dowson, A.; Arnold, D.: Burr formation and hole quality when drilling titanium and aluminium alloys. Procedia CIRP. 37, 230–235 (2015). https://doi.org/10.1016/j.procir.2015.08.019

Soo, S.L.; Abdelhafeez, A.M.; Li, M.; Hood, R.; Lim, C.M.: The drilling of carbon fibre composite–aluminium stacks and its effect on hole quality and integrity. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 233, 1323–1331 (2019). https://doi.org/10.1177/0954405417728312

Abdelhafeez Hassan, A.; Leung Soo, S.; Aspinwall, D.K.; Arnold, D.; Dowson, A.: An analytical model to predict interlayer burr size following drilling of CFRP-metallic stack assemblies. CIRP Ann. 69 (2020) (in press)

Shaw, M.C.: Metal Cutting Principles. Oxford University Press, Oxford (2005)

Astakhov, V.P.: Effects of the cutting feed, depth of cut, and workpiece (bore) diameter on the tool wear rate. Int. J. Adv. Manuf. Technol. 34, 631–640 (2006). https://doi.org/10.1007/s00170-006-0635-y

Hassan, A.M.; Hayajneh, M.T.: Statistical analysis of the effects of machining parameters and workpiece hardness on the surface finish of machined medium carbon steel. J. Mater. Eng. Perform. 10, 282–289 (2001). https://doi.org/10.1361/105994901770344999

Grzesik, W.: Advanced machining processes of metallic materials: theory, modelling, and applications. Elsevier, Amsterdam (2016)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Abdelhafeez Hassan, A., Li, M.J. & Mahmoud, S. On Miniature Hole Quality and Tool Wear When Mechanical Drilling of Mild Steel. Arab J Sci Eng 45, 8917–8929 (2020). https://doi.org/10.1007/s13369-020-04549-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-020-04549-9