Abstract

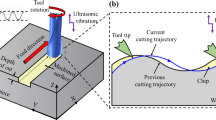

The purpose of this paper is to investigate the effects of assisted vibration on the drilling quality of aluminium alloy (Al 6061-T6) and structure steel (SS41). In the past, research methodology of vibration drilling on small-diameter holes has mainly involved vibrating from the spindle side. In this paper, a new approach to obtain the desired vibration is proposed from the workpiece side, by a self-made, vibrating worktable. Through extensive experiments with a twist drill size of 0.5 mm, we found that hole oversize, displacement of the hole centre, and surface roughness of the drilled wall could be improved with the increase of vibrating frequency and amplitude. Roundness of the drilled hole could also be improved when high amplitude and proper frequency are imposed.

Similar content being viewed by others

References

Moriwaki T, Shamoto E, et al. (1992) Ultraprecision ductile cutting of glass by applying ultrasonic vibration. Ann CIRP 41(1):141–144

Weber H, et al. (1984) Turning of machinable glass ceramics with an ultrasonically vibrated tool. Ann CIRP 33(1):85–87

Moriwaki T, Shamoto E (1991) Ultraprecision diamond turning of stainless steel by applying ultrasonic vibration. Ann CIRP 40(1):559–562

Wang LJ, Zhao J (1987) Influence on surface roughness in turning with ultrasonic vibration tool. Int J Mach Tools Manuf 27(2):181–190

Kumabe J, Sabuzawa T (1971) Study on the precision drilling of wood (1st report) – profile analysis of drilled hole. J Japan Soc Prec Eng 37(2):98–104 (in Japanese)

Kumabe J, Sabuzawa T (1972) Study on the precision drilling of wood (2nd report) – drilling force and its accuracy. J Japan Soc Prec Eng 38(5):456–461 (in Japanese)

Koyama T, Adachi K, et al. (1977) study on vibratory drilling (2nd report) – comparison of conventional drilling with vibratory drilling. J Japan Soc Prec Eng 43(1):55–60 (in Japanese)

Adachi K, Arai N, et al. (1987) A study on burr in low frequency vibratory drilling – drilling of aluminum. Bull JSPE 21(4):258–264

Takeyama H, Kato S (1991) Burrless Drilling by means of ultrasonic vibration. Ann CIRP 40(1):83–86

Zhang DY, et al. (1994) Study on the drill skidding motion in ultrasonic vibration microdrilling. Int J Mach Tools Manuf 34(6):847–857

Onikura H, Ohnishl O, et al. (1996) Effects of ultrasonic vibration on machining accuracy in microdrilling. Int J JSPE 30(3):210–216

Onikura H, Ohnishi O (1998) Drilling mechanisms in ultrasonic-vibration assisted microdrilling. J JSPE 64(11):1633–1637 (in Japanese)

Jin M, Murakawa M (2001) Development of a practical ultrasonic vibration cutting tool system. J Mater Process Technol 113:342–347

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chern, GL., Lee, HJ. Using workpiece vibration cutting for micro-drilling. Int J Adv Manuf Technol 27, 688–692 (2006). https://doi.org/10.1007/s00170-004-2255-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-004-2255-8