Abstract

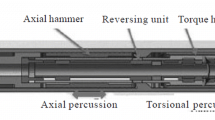

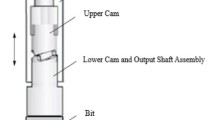

In this paper, the numerical simulation is used to study the rising mechanism of rotary-percussive drilling, which is under the combination of rotary cutting and axial impact. The main objective of the present work is to compare and investigate the breaking process of rock element and the motion state of drilling bit under the conventional drilling and rotary punching drilling. Additionally, the single-factor analysis is used to analyze the effects of impulse load, impulse frequency, rotary speed and formation hardness on rock breaking efficiency and acceleration effect of rotary percussion drilling. Through the investigation, it is found that there are more areas of tension stress breakage in rock elements under rotary-percussive drilling. Rotary percussion drilling can effectively alleviate the stick–slip vibration of drilling bit. At the same time, the relationship between the average penetration rate of the bit and the impulse load, impulse frequency, rotary speed and formation hardness is shown. The results of the study will be beneficial to provide some theoretical reference for the development of tools and the selection of working parameters of rotary-percussive drilling technology, as well as for the drilling methods of deep wells and hard rocks.

Similar content being viewed by others

References

Pang, X.Q.; Jia, C.Z.; Wang, W.Y.: Petroleum geology features and research developments of hydrocarbon accumulation in deep petroliferous basins. Pet. Sci. 12, 1–53 (2015)

Franca, L.F.P.: A bit–rock interaction model for rotary–percussive drilling. Int. J. Rock Mech. Min. Sci. 48, 827–835 (2011)

Melamed, Y.; Kiselev, A.; Gelfgat, M.; Dreesen, D.; Blacic, J.: Hydraulic hammer drilling technology: developments and capabilities. In: Energy Week 97 Conference and Exhibition (1996)

Zhang, H.; Guan, Z.; Liu, Y.; Liang, D.; Xu, Y.: A novel tool to improve the rate of penetration by transferring drilling string vibration energy to hydraulic energy. J. Pet. Sci. Eng. 146, 318–325 (2016)

Kivade, S.B.; Murthy, C.S.N.; Vardhan, H.: Experimental investigations on penetration rate of percussive drill. Procedia Earth Planet. Sci. 11, 89–99 (2015)

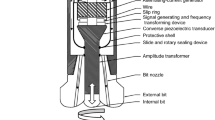

Zhang, X.; Zhang, S.; Luo, Y.; Wu, D.: Experimental study and analysis on a fluidic hammer—an innovative rotary-percussion drilling tool. J. Pet. Sci.Eng. 173, 362–370 (2019)

Zhi-Xue, C.; Wen-Hua, Y.U.; Jing-Zu, Z.; et al.: Application of hydraulic power percussive-rotary drilling technology in Qingxi Area. Oil Dril. Prod. Technol. 28, 19–21 (2006)

Lei, W.; Wengang, W.; Tongwei, D.; Lihua, X.; Xueyi, W.: Application of rotary percussion drilling technology in reverse thrust nappe structure formation. Oil Drill. Prod. Technol. 27, 8–10 (2005)

Wang, L.; Guo, Z.; Tan, X.; et al.: Application of percussive-rotary drilling technology in oil wells. Drill. Prod. Technol. 28, 8–10 (2005)

Zhang, W.; Zhijun, S.: The technique of auger-percussive-rotary drilling research. In: 2013 Fifth International Conference on Measuring Technology and Mechatronics Automation, IEEE, pp. 1241–1244 (2013)

Xiaoqing, Q.; Wei, L.; Li, L.; et al.: Application of rotary percussion drilling technology in hard formation of western Sichuan. Fault-Block Oil Gas Field. 20, 505–507 (2013)

Yang, C.; Lv, C.; Li, F.: New drilling technology was applied in SS2 well in Daqing peripheral oilfield. West China Explor. Eng. (in china) 29, 29–31 (2017)

Zou, Z.; Li, W.; Jiao, Z.: The application of hydraulic percussion tools in acceleration in Mahu region of Xinjiang. West China Explor. Eng. (in China) 29, 30–32 (2017)

Chiang, L.E.; Elías, D.A.: A 3D FEM methodology for simulating the impact in rock-drilling hammers. Int. J. Rock Mech. Min. Sci. 45, 701–711 (2008)

Hailiang, X.U.; Wang, L.I.; Zhao, H.; Shaojun, X.U.: Cuttings carrying characteristics of back-reaming pneumatic impactor exhaust during drilling operation. Pet. Explor. Dev. Online 43, 131–137 (2016)

Guo, C.; Yi, J.: Modeling and experiments of rotary percussive drilling for robotic civil infrastructure rehabilitation. IFAC Pap 50, 9784–9789 (2017)

Kahraman, S.: Rotary and percussive drilling prediction using regression analysis. Int. J. Rock Mech. Min. Sci. 36, 981–989 (1999)

Alimov, O.D.; Shaposhnikov, I.D.; Dvornikov, L.T.: Efficiency of the pulse shape in rotary-percussive borehole drilling. Sov. Min. 7, 529–537 (1971)

Chen, J.; Yue, Z.Q.: Ground characterization using breaking-action-based zoning analysis of rotary-percussive instrumented drilling. Int. J. Rock Mech. Min. Sci. 75, 33–43 (2015)

Xiao, Y.; Hurich, C.; Butt, S.D.: Characterization of rotary-percussion drilling as a seismic-while-drilling source. J. Appl. Geophys. 151, S1969160348 (2018)

Siqi, L.I.; Wei, L.I.; Yan, T.; Gao, H.; Fuqing, B.I.; Hongbin, M.A.: A study on the rock breaking mechanism of drill bits under combined loads and field applications. J. Vib. Shock. 36, 51–55 (2017)

Liu, W.; Zhu, X.; Li, B.: The rock breaking mechanism analysis of rotary percussive cutting by single PDC cutter. Arab. J. Geosci. 11, 192 (2018)

Tulu, I.B.: Modeling PDC cutter rock interaction. Dissertations and Theses—Gradworks (2009)

Zhu, X.H.; Tang, L.P.; Hua, T.: Rock breaking mechanism of a high frequency torsional impact drilling. J. Vib. Shock 31, 75–78 (2012)

Zhong, Z.H.: Finite Element Procedures for Contact-Impact Problems. Oxford University Press, Oxford (1993)

Chu, X.H.; Yuan-Jie, X.U.: Studies on transformation from M–C criterion to Drucker–Prager criterions based on distortion energy density. Rock Soil Mech. 30, 2985–2990 (2009)

Aubertin, M.; Simon, R.: A damage initiation criterion for low porosity rocks. Int. J. Rock Mech. Min. Sci. 34, 11–17 (1997)

Sun, H.; Li, Z.; Ping, F.: Comparison of numerical modeling with predictions from laboratory tests and field observations of deformation in a potash mine in Sergipe, Brazil: Da Costa, A M; Fairhurst, C. In: Research and Engineering Applications in Rock Masses (Paper to the 26th US S.: Van Nostrand Reinhold) (1980)

Lin, T.; Lian, Z.; Meng, Y.; Yang, B.; Xianzhu, W.U.; Zhou, X.: Finite elements method study on dynamic rock breaking in air drilling. Chin. J. Rock Mech. Eng. 27, 3592–3597 (2008)

Tian, J.; Hu, S.; Li, Y.; Yang, Z.; Yang, L.; Cai, X.; et al.: Vibration characteristics analysis and experimental study of new drilling oscillator. Adv. Mech. Eng. 8, 1687814016652090 (2016)

Acknowledgements

This research work was supported by Key Laboratory of Oil and Gas Equipment Foundation of Ministry of Education of China (OGE201701-02), Major National Science and Technology Project of China (No. 2016ZX05038) and the State Foundation for Studying Abroad (No. 201608515039).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Wu, K., Ye, Z. The Numerical Research on Rock Breaking and Rising Mechanism of Rotary-Percussive Drilling. Arab J Sci Eng 44, 10561–10580 (2019). https://doi.org/10.1007/s13369-019-04170-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-019-04170-5