Abstract

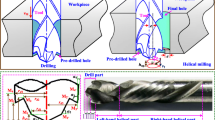

The objective of this paper was to determine mathematically a flute, to construct a CAD model and to determine the optimal geometric features of a 0.1mm diameter of a microdrill based on the stress analysis. The flute of a microdrill was determined mathematically by defining the undercutting relative positions of both the microdrill and grinding wheel and their profiles with respect to setting angle. The mathematically determined flute was used to construct a CAD model of a microdrill using Pro/Engineer software. The cross-sectional comparison between the model and fabricated microdrill was carried out by cutting at different lengths, and the results of the web thickness of the model and the fabricated microdrill were approximately the same. Similarly, the images of primary flank areas and secondary flank areas of fabricated microdrills were taken using optical microscope, and they were compared with the shapes of cutting edge, chisel edge, primary flank areas and secondary flank areas of the model. Based on this comparison, they were almost the same. Hence, the consideration of the mathematically determined flute for the construction of the CAD model of a microdrill was feasible. The optimal geometric features of a microdrill have been determined by setting design control parameters for geometric features and carrying out optimization of the stress/displacement analysis using Pro/Mechanica software so that the maximum Von Mises stress of the microdrill was minimized below the compressive strength of the material property.

Similar content being viewed by others

References

Coombs C.: Printed Circuits Handbook. McGraw-Hill, New York (2007)

Zheng L.J., Wang C.Y., Fu L.Y., Yang L.P., Qu Y.P., Song Y.X.: Wear mechanisms of micro-drills during dry high speed drilling of PCB. J. Mater. Process. Technol. 212(10), 1989–1997 (2012). doi:10.1016/j.jmatprotec.2012.05.004

Khorasani A.M., Asadnia M., Saadatkia P.: Modeling of TiC-N thin film coating process on drills using particle swarm optimization algorithm. Arab. J. Sci. Eng. 38(6), 1565–1571 (2013)

Uysal A.: A study on drilling of AISI 304L stainless steel with nanocomposite-coated drill tools. Arab. J. Sci. Eng. 39(11), 8279–8285 (2014)

Hsieh J.F.: Mathematical modeling of a complex helical drill point. J. Manuf. Sci. Eng. Trans. ASME 131(6), 0610061–06100611 (2009)

Hsieh J.-F., Lin P.D.: Drill point geometry of multi-flute drills. Int. J. Adv. Manuf. Technol. 26(5-6), 466–476 (2005). doi:10.1007/s00170-003-2027-x

Radhakrishnan T., Wu S.M., Lin C.: A mathematical model for split point drill flanks. J. Eng. Ind. 105(3), 137–142 (1983). doi:10.1115/1.3185879

Tsai W.D., Wu S.M.: A mathematical model for drill point design and grinding. J. Eng. Ind. 101(3), 333–340 (1979). doi:10.1115/1.3439515

Tandon P., Gupta P., Dhande S.G.: Modeling of twist drills in terms of 3D angles. Int. J. Adv. Manuf. Technol. 38(5-6), 543–550 (2008). doi:10.1007/s00170-007-1150-5

Paul A., Kapoor S.G., DeVor R.E.: Chisel edge and cutting lip shape optimization for improved twist drill point design. Int. J. Mach. Tools Manuf. 45(4–5), 421–431 (2005). doi:10.1016/j.ijmachtools.2004.09.010

Fujii S., DeVries M.F., Wu S.M.: An analysis of drill geometry for optimum drill design by computer. Part II—computer-aided design. J. Eng. Ind. 92(3), 657–666 (1970). doi:10.1115/1.3427828

Fujii S., DeVries M.F., Wu S.M.: An analysis of drill geometry for optimum drill design by computer. Part I—drill geometry analysis. J. Eng. Ind. 92(3), 647–656 (1970). doi:10.1115/1.3427827

Kang S.K., Ehmann K.F., Lin C.: A CAD approach to helical groove machining—I. Mathematical model and model solution. Int. J. Mach. Tools Manuf. 36(1), 141–153 (1996). doi:10.1016/0890-6955(95)92631-8

Kang S.K., Ehmann K.F., Lin C.: A CAD approach to helical groove machining. Part 2: numerical evaluation and sensitivity analysis. Int. J. Mach. Tools Manuf. 37(1), 101–117 (1997). doi:10.1016/0890-6955(95)00039-9

Sheth D.S., Malkin S.: CAD/CAM for geometry and process analysis of helical groove machining. CIRP Ann. Manuf. Technol. 39(1), 129–132 (1990). doi:10.1016/S0007-8506(07)61018-X

Kaldor S., Rafael A.M., Messinger D.: On the CAD of profiles for cutters and helical flutes-geometrical aspects. CIRP Ann. Manuf. Technol. 37(1), 53–56 (1988). doi:10.1016/S0007-8506(07)61584-4

Radhakrishnan T., Kawlra R.K., Wu S.M.: A mathematical model of the grinding wheel profile required for a specific twist drill flute. Int. J. Mach. Tool Des. Res. 22(4), 239–251 (1982)

Ehmann K.F., DeVries M.F.: Grinding wheel profile definition for the manufacture of drill flutes. CIRP Ann. Manuf. Technol. 39(1), 153–156 (1990). doi:10.1016/S0007-8506(07)61024-5

Chang W.-T., Chen T.-H., Tarng Y.-S.: Measuring characteristic parameters of form grinding wheels used for microdrill fluting by computer vision. Trans. Can. Soc. Mech. Eng. 35(3), 383–401 (2011)

Hinds B.K., Treanor G.M.: Analysis of stresses in micro-drills using the finite element method. Int. J. Mach. Tools Manuf. 40(10), 1443–1456 (2000). doi:10.1016/S0890-6955(00)00007-9

Chen W.-C.: Applying the finite element method to drill design based on drill deformations. Finite Elem. Anal. Des. 26(1), 57–81 (1997). doi:10.1016/S0168-874X(96)00071-6

Abele, E.; Fujara, M.; Schäfer, D.: Holistic approach for a simulation-based twist drill geometry optimization. In: ASME 2011 International Manufacturing Science and Engineering Conference, pp. 137–144 (2011). doi:10.1115/MSEC2011-50102

Selvam S.V.M., Sujatha C.: Twist drill deformation and optimum drill geometry. Comput. Struct. 57(5), 903–914 (1995). doi:10.1016/0045-7949(94)00615-A

Yan L., Jiang F.: A practical optimization design of helical geometry drill point and its grinding process. Int. J. Adv. Manuf. Technol. 64(9–12), 1387–1394 (2013). doi:10.1007/s00170-012-4109-0

Zhang W., Wang X., He F., Xiong D.: A practical method of modelling and simulation for drill fluting. Int. J. Mach. Tools Manuf. 46(6), 667–672 (2006). doi:10.1016/j.ijmachtools.2005.07.007

Shiou F.J., Hung K.H.: Determination of the optimal geometrical features of a microdrill. Appl. Mech. Mater. 284, 702–706 (2013)

Jain, K.C.; Chitale, A.K.: Textbook of Production Engineering. PHI Learning (2010)

Shaw M.C.: Metal Cutting Principles. Clarendon Press, Oxford (1984)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bogale, T.M., Shiou, FJ. & Tang, GR. Mathematical Determination of a Flute, Construction of a CAD Model, and Determination of the Optimal Geometric Features of a Microdrill. Arab J Sci Eng 40, 1497–1515 (2015). https://doi.org/10.1007/s13369-015-1632-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-015-1632-y