Abstract

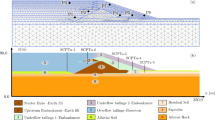

Temperature stress is one of the main reasons causing the cracking of high roller compacted concrete (RCC) arch dams during rapid construction. For the construction organization design and implementation of RCC dams, it is an important point to establish the scheme for temperature control and crack prevention, and evaluate its effect. The technology of concrete mixed with MgO is a new developing way for crack prevention of RCC dams. The expansion of MgO can compensate effectively for the tensile stress generated in the cooling period of RCC. To improve the effect of crack prevention for high RCC arch dams, the aforementioned technology needs to be combined with the conventional methods. FEM is used to implement the temperature stress calculation for high RCC arch dams mixed with MgO. The basic principle and process of simulation algorithm are introduced first. According to the actual characteristics of a high RCC arch dam, the following three schemes for temperature control and crack prevention are given. They are “no MgO and no joint”, “mixed with MgO and no joint”, “mixed with MgO and two induced joints”, respectively. The corresponding FEM models are established to calculate the equivalent temperature field and temperature stress of the RCC arch dam mixed with MgO or not. The calculated results under above three schemes are used to appraise the effect controlling the temperature stress by mixing MgO. The positive impact of the combined scheme is analyzed. Some valuable conclusions for the design and construction of actual dams are obtained.

Similar content being viewed by others

Abbreviations

- a :

-

Thermal diffusivity coefficient

- c :

-

Material specific heat

- \({ G(\tau, T)}\) :

-

Expansion deformation of MgO concrete at any temperature

- G(T):

-

Function of temperature

- k :

-

Convection coefficient

- m(T):

-

Function of temperature

- Q :

-

Rate of heat introduced per volume

- \({ Q (\tau )}\) :

-

Cement hydration heat

- \({Q(\tau )_{{\rm d}x} }\) :

-

Virtual heat

- s(T):

-

Function of temperature

- T :

-

Environment temperature

- T a :

-

Atmospheric temperature

- \({\alpha }\) :

-

Linear expansion coefficient of concrete

- \({\beta }\) :

-

Heat transfer coefficient

- \({{\Delta T}_{n} }\) :

-

Actual temperature difference

- \({{\Delta T}_ n^{{\rm e}} }\) :

-

Equivalent temperature difference

- \({{\Delta T}_ n^\upsilon }\) :

-

Virtual temperature difference

- \({{\Delta \tau}_{n} }\) :

-

Time interval

- \({{\Delta \varepsilon}_{n}^{\rm o}}\) :

-

Volume deformation caused by non-temperature difference

- \({{\Delta \varepsilon}_{n}^{\upsilon}}\) :

-

Volume deformation caused by temperature difference

- \({\lambda }\) :

-

Thermal conductivity coefficient

- \({{\theta (\tau )}}\) :

-

Adiabatic temperature rise

- \({{\theta (\tau )}_{{\rm d}x}}\) :

-

Virtual temperature difference caused by the expansion deformation of MgO

- \({\rho }\) :

-

Material density

- \({\tau }\) :

-

Age of concrete

- [B]:

-

Transition matrix of element strain

- [D]:

-

Elastic matrix

- [K ]e :

-

Element stiffness matrix

- \({\{{\delta}^\ast \}}\) :

-

Virtual displacement of element nodal

- \({\{{\Delta F}_{ n} \}}\) :

-

Nodal force increment

- \({\{ {\Delta P}_{ n}^{\rm c}\}^{\rm e}}\) :

-

Nodal load caused by creep increment

- \({\{ {\Delta P}_{ n}^{\rm T}\}^{\rm e}}\) :

-

Nodal load caused by the deformation of equivalent temperature difference

- \({\{ {\Delta \delta}_{ n}\}^{\rm e}}\) :

-

Displacement increment of element nodal

- \({\{ {{\Delta \varepsilon}_{ n}}\}}\) :

-

Total strain increment

- \({\{ {{\Delta \varepsilon}_{ n}^{\rm c}}\}}\) :

-

Creep increment

- \({\{ {{\Delta \varepsilon}_{ n}^{\rm e}}\}}\) :

-

Elastic strain increment

- \({\{ {{\Delta \varepsilon}_{ n}^{ \rm T}}\}}\) :

-

Strain increment caused by equivalent temperature difference

- \({\{ {{\Delta \sigma}_{ n}}\}}\) :

-

Stress increment

- \({\{ {{\varepsilon}^{ \ast}}\}}\) :

-

Virtual strain of element

References

Zhixiong Y., Jiaxiu Y.: First RCC arch dam of China-Puding dam. Hydroelectr. Power 9, 54–57 (2001)

Huaijian T., Wei H.: Overview of RCC dam construction technologies. J. Hydraul. Eng. S 1, 36–42 (2007)

Bofang Z.: On the feasibility of building high quality arch dams without cracking and the relevant techniques. J. Hydraul. Eng. 30(10), 1155–1162 (2006)

Noorzaei J., Bayagoob K.H., Thanoon W.A., Jaafar M.S.: Thermal and stress analysis of Kinta RCC dam. Eng. Struct. 28(13), 1795–1802 (2006)

Chengmu L.: The long-term research results of autogenous volume deformation of MgO oncrete. Water Power 58(6), 53–57 (1998)

Chengmu L.: The influences high content of fly ash on autogenous volume deformation of concrete with MgO. Sichuan Water Power 19(S1), 72–75 (2000)

Shouyi, L.; Jinke, R.; Tingting, Y.; Pengfei, C.: Analysis of the influence of concrete mixed with MgO on the mass concrete thermal stress. In: Proceedings of the 2010 Asia–Pacific Power and Energy Engineering Conference (APPEEC), Chengdu, China, 28–31 March 2010, pp. 978–981 (2010)

Peiwei G., Xiaolin L., Fei G., Xiaoyan L., Jie H., Hui L., Nannan S.: Production of MgO-type expansive agent in dam concrete by use of industrial by-products. Build. Environ. 43(4), 453–457 (2008)

Bofang Z., Guoxin Z., Weijun Y.: Two kinds of guiding thought and two results of practical engineering for application of MgO concrete to dams. Water Resour. Hydropower Eng. 23(6), 57–63 (2003)

Bofang Z.: Thermal Stresses and Temperature Control of Mass Concrete. China Electric Power Press, Beijing (1999)

Miglani A., Kaushal S.: Axi-symmetric deformation in generalized thermoelasticity with two temperatures. Arab. J. Sci. Eng. 36(8), 1581–1595 (2011)

Hanjiang X., Zumin L.: Concrete temperature stress analysis in consideration of its self-growing volume deformation. Yangtze River 29(2), 4–7 (1998)

Chengmu L.: Temperature effect for autogenous deformation of concrete mixed with MgO. Des. Hydroelectr. Power Stn. 15(2), 96–101 (1999)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Su, H., Li, J. & Wen, Z. Evaluation of Various Temperature Control Schemes for Crack Prevention in RCC Arch Dams During Construction. Arab J Sci Eng 39, 3559–3569 (2014). https://doi.org/10.1007/s13369-014-1010-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-014-1010-1