Abstract

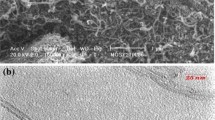

Magnetorheological (MR) properties of the carbon nanotube (CNT)–FeCo nanocomposite particle suspension were investigated to find a high-performance MR fluid with great stability. The composites were fabricated by chemical deposition of FeCo on the surface of amine functionalized CNTs. The strong magnetic polarization of the FeCo moiety led to strong MR performance of the nanocomposite particle suspension. The MR fluid exhibits high yield stress value, 4 times greater than that of the suspension including Fe3O4-deposited CNT at a magnetic field strength of 86 kA/m. A three-dimensional network-like structure formed by the non-magnetic CNTs in the MR suspension does not contribute to the additional yield stress. The low density and the surface roughness of the CNTs resulted in far better long-term stability for the CNT–FeCo nanocomposite suspension than for the MR suspension of hierarchically structured Fe3O4 suspension with a similar density. The effect of the three-dimensional network-like structures by the CNTs on the MR performance depends upon the interaction strength between the magnetic moiety on the CNTs.

Similar content being viewed by others

References

Ahamed R, Choi SB, Ferdaus M (2018) A state of art on magneto-rheological materials and their potential applications. J Intellig Mater Syst Struct 29:2051–2095

Ashtiani M, Hashemabadi S, Ghaffari A (2015) A review on the magnetorheological fluid preparation and stabilization. J Magn Magn Mater 374:716–730

Bagheri G, Bonadonna C (2016) On the drag of freely falling nonspherical particles. Powder Technol 301:526–544

Bell R, Zimmerman D, Wereley N (2013) In Magnetorheology: Advances and Applications, Wereley, N. RSC Smart Materials: Cambridge, UK, Chapter 2:31–55

Berasategi J, Salazar D, Gomez A, Gutirrez J, San Sebastian M, Bou-Ali M, Barandiaran JM (2020) Anisotropic behaviour analysis of silicone/carbonyl iron particles magnetorheological elastomers. Rheol Acta 59(7):469–476

Bitaraf M, Ozbulut OE, Hurlebaus S, Barroso L (2010) Application of semi-active control strategies for seismic protection of buildings with MR dampers. Eng Struct 32(10):3040–3047

Chen Z, Wang X, Ko J, Ni Y, Spencer Jr BF, Yang G (2003) In MR damping system on Dongting Lake cable-stayed bridge, Smart structures and materials 2003: smart systems and nondestructive evaluation for civil infrastructures. In: International Society for Optics and Photonics, pp 229–235

Chin BD, Park JH, Kwon MH, Park OO (2001) Rheological properties and dispersion stability of magnetorheological (MR) suspensions. Rheol Acta 40(3):211–219

Choi HJ, Zhang WL, Kim S, Seo Y (2014) Core-shell structured electro-and magneto-responsive materials: fabrication and characteristics. Materials 7(11):7460–7471

Choi J, Han S, Kim H, Sohn EH, Choi HJ, Seo Y (2019) Suspensions of hollow polydivinylbenzene nanoparticles decorated with Fe3O4 nanoparticles as magnetorheological fluids for microfluidics applications. ACS Appl Nano Mater 2(11):6939–6947

Choi J, Han S, Nam KT, Seo Y (2020) Hierarchically structured Fe3O4 nanoparticles for high-performance magnetorheological fluids with long-term stability. ACS Appl Nano Mater 3:10931–10940

Choi J, Nam KT, Kim S, Seo Y (2021) Synergistic effects of nonmagnetic carbon nanotubes on the performance and stability of magnetorheological fluids containing carbon nanotube-Co0.4Fe0.4Ni0.2 nanocomposite particles. Nano Lett 21(12):4973–4980

Chuah WH, Zhang WL, Choi HJ, Seo Y (2015) Magnetorheology of core–shell structured carbonyl iron/polystyrene foam microparticles suspension with enhanced stability. Macromolecules 48(19):7311–7319

Cvek M, Mrlik M, Ilcikova M, Plachy T, Sedlacik M, Mosnacek J, Pavlinek V (2015) A facile controllable coating of carbonyl iron particles with poly(glycidyl methacrylate): a tool for adjusting MR response and stability properties. J Mater Chem C 3(18):4646–4656

Cvek M, Mrlík M, M. Ilčíkova, J. Mosnáček, L. Münster, and V. Pavlínek, (2017) Synthesis of silicone elastomers containing silyl-based polymer- grafted carbonyl iron particles: an efficient way to improve magnetorheological, damping, and sensing performances. Macromolecules 50(5):2189–2200

de Vicente J, Segovia-Gutierrez JP, Andabio-Reyes E, Vereda F, Hidalgo-Alvarez R (2009) Dynamic rheology of sphere- and rod-based magnetorheological fluids. J Chem Phys 131(194902):1–10

de Vicente J, Klingenberg DJ, Hidalgo-Alvarez R (2011) Magnetorheological fluids: a review. Soft Matter 7(8):3701–3710

Fang FF, Choi HJ, Seo Y (2010) Sequential coating of magnetic carbonyliron particles with polystyrene and multiwalled carbon nanotubes and its effect on their magnetorheology. ACS Appl Mater Interfaces 2(1):54–60

Fang FF, Liu YD, Choi HJ, Seo Y (2011) Core–shell structured carbonyl iron microspheres prepared via dual-step functionality coatings and their magnetorheological response. ACS Appl Mater Interf 3(9):3487–3495

Farjoud A, Vahdati N, Fah YF (2008) Mathematical model of drum-type MR brakes using Herschel-Bulkley shear model. J Intell Mater Syst Struct 19(5):565–572

Gabitto J, C., Tsouris, (2008) Drag coefficient and settling velocity for particles of cylindrical shape. Powder Technol 183:314–322

Ghaffari A, Hashemabadi SH, Ashtiani M (2015) A review on the simulation and modeling of magnetorheological fluids. J Intell Mater Syst Struct 26(8):881–904

Gómez-Ramírez A, López-López MT, González-Caballero F, Durán JDG (2011) Stability of magnetorheological fluids in ionic liquids. Smart Mater Struct 20:045001–045010

Haider A, Levenspiel O (1988) Drag coefficient and terminal velocity of spherical and nonspherical particles. Powder Tech 58:63–70

Hajalilou A, Amri Mazlan S, Lavvafi H, Shameli K (2016) Magnetorheological fluid applications. In: Field responsive fluids as smart materials. Engineering materials. Springer, Singapore. https://doi.org/10.1007/978-981-10-2495-5_5

Han S, Choi J, Seo YP, Park IJ, Choi HJ, Seo Y (2018) High-performance magnetorheological suspensions of pickering-emulsion-polymerized polystyrene/ Fe3O4 particles with enhanced stability. Langmuir 34(8):2807–2814

Han S, Choi J, Kim H, Kim S, Seo Y (2019) Static yield stress of a magnetorheological fluid containing pickering emulsion polymerized Fe3O4/polystyrene composite particles. AIP Conf Proc 2139:140001. https://doi.org/10.1063/1.5121687

Han S, Choi J, Han HN, Kim S, Seo Y (2021) Effect of particle shape anisotropy on the performance and stability of magnetorheological fluids. ACS Appl Electron Mater 3:2526–2533

Jing Y, He S, Wang J (2012) Composition- and phase-controlled high-magnetic-moment Fe1-xCox nanoparticles for biomedical applications. IEEE Trans Magnet 49(1):197–200

Karipoth P, Thirumurugan A, Joseyphus RJ (2013) Synthesis and magnetic properties of flower-like FeCo particles through a one pot polyol process. J Colloid Interf Sci 404:49–55

Kim YJ, Liu YD, Seo Y, Choi HJ (2013) Pickering-emulsion-polymerized polystyrene/ Fe2O3 composite particles and their magnetoresponsive characteristics. Langmuir 29(16):4959–4965

Kim H, Kim S, Seo Y (2019) High-performance magnetorheological suspensions of Fe3O4-deposited carbon nanotubes with enhanced stability. MRS Adv 4(3–4):217–224

Liu J, Wu K, Wang J (2016) Magnetic properties of cubic FeCo nanoparticles with anisotropic long chain structure. AIP Adv 6:056126

Olabi AG, Grunwald A (2007) Design and application of magneto-rheological fluid “MRF.” Mater Des 28(10):2658–2664

Oliveira F, de Morais PG, Suleman A (2015) Semi-active control of base-isolated structures. Procedia Eng 114:401–409

Parmar KPSY, Meheust BS, Fossum JO (2008) Electrorheological suspensions of laponite in oil: rheometry studies. Langmuir 24:1814–1822

Pramudya I, Sutrisno J, Fuchs A, Kavlicoglu B, Sahin H, Gordaninejad F (2013) Compressible magnetorheological fluids based on composite polyurethane microspheres. Macromol Mater Eng 298(8):888–895

Pu HT, Jiang FJ, Yang ZL (2006) Preparation and properties of soft magnetic particles based on Fe3O4 and hollow polystyrene microsphere composite. Mater Chem Phys 100(1):10–14

Pu HT, Jiang FJ (2015) Towards high sedimentation stability: magnetorheological fluids based on CNT/Fe3O4 nanocomposites. Nanotech 16(9):1486

Rajesh, P., S. Sellaiyan, A. Uedono, T. Arun and R. Justin Joseyphus, (2018) Positron annihilation studies on chemically synthesized FeCo alloy. Sci Rep 8:9764

Rankin PJ, Horvath T, Klingenberg DJ (1999) Magnetorheology in viscoplastic media. Rheol Acta 38(5):471–477

Reddy GS, Sahu SR, Prakash R, Jagannatham M (2019) Synthesis of cobalt-rich alloys with high saturation magnetization: a novel synthetic approach by hydrazine reduction method. Results Phys 12:652–661

Seo Y (2011) A new yield stress scaling function for electrorheological fluids. J Non-Newtonian Fluid Mech 166(3):241–243

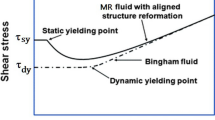

Seo YP, Choi HJ, Seo Y (2011) Analysis of the flow behavior of electrorheological fluids with the aligned structure reformation. Polymer 52(25):5695–5698

Seo YP, Seo Y (2012) Modeling and analysis of electrorheological suspensions in shear flow. Langmuir 28(6):3077–3084

Seo YP, Choi HJ, Seo Y (2012) A simplified model for analyzing the flow behavior of electrorheological fluids containing silica nanoparticle-decorated polyaniline nanofibers. Soft Matter 8(17):4659–4663

Seo YP, Kwak S, Choi HJ, Seo Y (2016) Static yield stress of a magnetorheological fluid containing Pickering emulsion polymerized Fe2O3/ polystyrene composite particles. J Colloid Interf Sci 463:272–278

Seo YP, Han S, Choi J, Takahara A, Choi HJ, Seo Y (2018) Searching for a stable high-performance magnetorheological suspension. Adv Mater 30:1704769

Seo Y, Choi HJ (2020) Core-shell structured Fe3O4 nanocomposite particles for high-performance/ stable magnetorheological fluids : preparation and characteristics. J Korean Ceram Soc 57:608–631

Seo YP, Han S, Kim J, Choi HJ, Seo Y (2020) Analysis of the flow behavior of electrorheological fluids containing polypyrrole nanoparticles or polypyrrole/silica nanocomposite particles. Rheol Acta 59(7):415–423

Seo YP, Seo Y (2022) Modeling of electrorheological fluids. In Encyclopedia of Smart Materials, Elsevier, pp 140–151. https://doi.org/10.1016/B978-0-12-803581-8.12057-0

Upadhyay R, Laherisheth Z, Shah K (2013) Rheological properties of soft magnetic flake shaped iron particle based magnetorheological fluid in dynamic mode. Smart Mater Struct 23(1):015002

Vadillo V, A. Go´mez, J. Berasategi, J. Gutie´rrez, M. Insausti, I. G. de Muro, J. S. Garitaonandia, A. Arbe, A. Iturrospe, M. M. Bou-Alib and J. Manuel Barandiara, (2021) High magnetization FeCo nanoparticles for magnetorheological fluids with enhanced response. Soft Matter 17:840–852

Zhang T, Z., G. Ma, Z. Li, B. Wang, Y. Zhao, and Y. Luo, (2016) Electrostatic interactions for directed assembly of high performance nanostructured energetic materials of Al/Fe2O3/multi-walled carbon nanotube(MWCNT). J Solid State Chem 237:394–403

Acknowledgements

The authors would like to thank the support from the Institute of Engineering Research at Seoul National University and Research Institute of Advanced Materials (RIAM) and the support from the Technology Innovation Program(#20015971, Development of piezoelectric fluoropolymers and their applied technology) funded by the Ministry of Trade, Industry & Energy (MOCIE, Korea).

Funding

None.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix: Particle sedimentation and suspension stability [28]

Appendix: Particle sedimentation and suspension stability [28]

The sedimentation profile recorded for each sample using Turbiscan is presented in Fig. 8 as a function of time. The light transmission amounts for all three suspensions rapidly increase within 2–3 h. The measured transmission increases gradually over time and eventually stabilizes. After 24 h, the Turbiscan recorded a light transmissions of 72%, 45%, 13%, and 4% for the pure Fe3O4, HS-Fe3O4, CNT–FeCo, and CNT–Fe3O4 suspensions, respectively. Although the density of CNT–FeCo is greater than that of pure Fe3O4, the CNT–FeCo suspension is much more stable than the pure Fe3O4 suspension. Almost 87% of the CNT–FeCo particles did not settle to the bottom. This excellent stability is attributed to the CNT network-like structure and the surface roughness change [12, 32]. The terminal velocity of a particle in a fluid can be defined as follows,

where \({\mathrm{Re}}\) is the Reynolds number based on the equivalent spherical diameter of a particle, \({C}_{D}\) is the drag coefficient, ρf is the density of the liquid medium, ρs is the density of the solid particle, g is gravitational acceleration, and µ is the viscosity of the liquid medium [3, 26, 32]. Terminal velocity ratio between the Fe3O4 and CNT–FeCo suspension is approximated as

if we neglect the density difference between the HS-Fe3O4 (3.32 g/cm3) and the CNT–FeCo particle (3.47 g/cm3) for the simplification. At low Reynolds number, the drag coefficient for a sphere is CD = 24/Re; for a non-spherical particle, CD = 24* (1 + 0.18* ReCNT–FeCo0.65) /ReCNT–FeCo [3, 21, 24, 28]. Thus, the terminal velocity at a low Reynolds number is

where DCNT–FeCo is the equivalent sphere diameter. Therefore,

Since the hydrodynamic radius of CNT–FeCo is roughly approximated as ~ 90 nm, and DHS-Fe3O4 ≈ 357 nm [5, 28, 54] the terminal velocity ratio is approximately 0.254. Thus, the terminal velocity of the CNT–FeCo particle is 11.4% of that of a HS-Fe3O4 particle, which is close to the experimental measurement (13%), though crude approximations for the density and the equivalent hydrodynamic radius were adopted.

Rights and permissions

About this article

Cite this article

Cho, S., Kim, H., Kim, S. et al. Effects of non-magnetic carbon nanotubes on the performance and stability of magnetorheological fluids containing FeCo-deposited carbon nanotubes. Korea-Aust. Rheol. J. 34, 137–146 (2022). https://doi.org/10.1007/s13367-022-00023-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13367-022-00023-0