Abstract

Capillary electrophoresis coupled with electrospray ionization typically employs two power supplies, one at each end of the capillary. One power supply is located at the proximal (injection) end of the capillary. The power supply located at the distal (detector) end of the capillary drives the electrospray. Electrophoresis is driven by the difference in potential between these power supplies. Separations that employ large capillary inner diameter, high conductivity background electrolyte, and high separation potentials generate higher current than that produced by the electrospray. Excess current flows through the electrospray power supply. Most power supplies are not designed to sink current, and the excess current will cause the electrospray voltage to deviate from its set point. We report a simple circuit to handle this excess current, allowing separations under a wide range of electrophoretic conditions.

ᅟ

Similar content being viewed by others

Introduction

Capillary-zone electrophoresis-electrospray ionization-mass spectrometry (CZE-ESI-MS) is attracting renewed interest [1–3]. This interest is stimulated by the development of high-sensitivity interfaces for coupling CZE to MS [4, 5]. The interfaces include a sheathless interface employing a porous capillary tip as the nanospray emitter developed by Moini [6], a flow-through microvial interface developed by Chen’s group [7], a sheathless CZE-MS interface using a large inner diameter separation capillary and a detachable smaller inner diameter porous ESI emitter developed by Tang’s group [8], and an electro-kinetically pumped sheath-flow nanospray interface developed by the Dovichi group [5, 9–11].

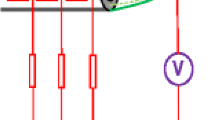

CZE-ESI systems consist of a separation capillary and two power supplies, Fig. 1a. The injection end of the capillary is placed in a reservoir containing the background electrolyte. The distal end of the capillary is threaded within the electrospray interface. A high-voltage power supply is connected to the injection end of the capillary. A second power supply controls the voltage at the distal end of the capillary. Connection between the second power supply and the distal end of the capillary is made through a sheath fluid, through a thin segment of etched capillary, or through direct electrical connection. The mass spectrometer inlet is typically held at ground potential.

The electrical circuit can be drawn as three resistors, one corresponding to the separation capillary, a second corresponding to the transfer capillary between the second power supply and the electrospray interface, and a third corresponding to the electrospray, Fig. 1b. The resistance associated with the transfer capillary (Rtransfer) tends to be quite low, and the potential applied to the electrospray interface is ideally very close to the potential supplied by HV2.

Conventional high voltage power supplies used for electrospray are sources of current but are unable to act as a current sink [5]. As explained by Hau et al. [12], tens of microamperes of current can pass through the separation capillary, while the electrospray current leaving the sprayer is typically hundreds of nanoamperes [13]. The power supply responsible for the spray voltage (HV2) operates as a current source and the control circuit of that power supply holds the electrospray emitter at the desired voltage. However, when the capillary electrophoresis system is operated under relatively high current conditions, a situation can arise wherein the current flowing through the capillary is greater than the current generated by HV2. In this case, the electrospray voltage is not controlled by HV2 and instead floats to a higher value.

When the electrospray voltage is not accurately controlled, the sensitivity, reproducibility, and detection limit of the instrument suffer due to the sensitivity of nanospray to the spray voltage. To avoid the current-sinking challenge, our group has performed separations in low current conditions (i.e., <10 μA). When we use a large inner diameter capillary (e.g., 50 μm) in order to improve the loading capacity, we use a low separation voltage (typically 400 V/cm or lower), which limits the analysis throughput. When we try to improve the analysis throughput by increasing the separation voltage (e.g., 1000 V/cm), we have to use a very small inner diameter separation capillary (e.g., 10 μm), which significantly limits the loading capacity, leading to low signal intensity and identification capacity. If the current-sinking challenge is mitigated, we are given greater freedom in experimental conditions. Shorter capillaries with larger inner diameters may be employed while using higher conductivity separation electrolytes, which enable faster separations and larger loading amounts.

The current-sinking challenge was identified two decades ago [14]. Two practical solutions for this problem have been identified. The first is to float the CE circuitry on the electrospray voltage, which would result in the effective capillary voltage no longer depending on the electrospray voltage. However, this first approach would increase the cost of the setup because of the need for additional safety precautions, such as isolated electronics on the CE instrument. The second approach requires that the electrospray power supply act not only as a current source but also have the capability to sink current, or at least be protected when there is a current reversal. This second approach is not without its own challenges. We are not aware of a commercially available, off-the-shelf high voltage power supply that is both a current source and is capable of sinking the current generated by capillary electrophoresis. Therefore, some design and fabrication is required to safely assemble an electrospray power supply capable of tackling this challenge. Here, we report an electrospray power supply coupled with a diode-based protection circuit that enables it to handle situations where there is significant current reversal. We demonstrate the system’s capabilities for CZE-ESI-MS and compare it to a Spellman CZE-1000R, which is commonly used by researchers in the field.

Experimental

Materials and Reagents

Acetic acid and hydrofluoric acid (HF) were purchased from Fisher Scientific (Pittsburgh, PA, USA). Angiotensin II (human, Asp-Arg-Val-Tyr-Ile-His-Pro-Phe), and formic acid (FA) were purchased from Sigma-Aldrich (St. Louis, MO, USA). Methanol and water were purchased from Honeywell Burdick and Jackson (Wicklow, Ireland). Fused silica capillary was purchased from Polymicro Technologies (Phoenix, AZ, USA). Electrospray emitters were borosilicate glass capillary (1.0 mm o.d., 0.75 mm i.d., and 10 cm in length, item #: B100-75-10) from Sutter Instrument (Novato, CA, USA) and were pulled with a Sutter Instrument P-1000 flaming/brown micropipette puller.

Methods

General Instrumentation Configuration

An LTQ-XL mass spectrometer (Thermo Fisher Scientific) was used for all experiments. Only MS1 spectra were acquired. The scan range of the ion trap mass analyzer was m/z 350–1800. The separation power supply was a Spellman CZE-1000R (Hauppauge, NY, USA).

Our group has traditionally used an additional Spellman CZE-1000R as the electrospray power supply. The Spellman power supply used as the electrospray power supply will be referred to as the Spellman power supply. An alternative electrospray power supply was fabricated in-house using a HVM Technologies CHV0017 high voltage amplifier (New Braunfels, TX, USA). The HVM amplifier used as an electrospray power supply will be referred to as the HVM amplifier.

A protection circuit was designed and fabricated for the HVM amplifier that prevented current from passing into the HVM amplifier when excess current was generated during electrophoresis. A schematic of the HVM Technologies amplifier protection circuit is available in the Supplemental Information (Figure S1). The protection circuit consisted of a series of rectifier diodes such that when the electrophoresis was operated under high current conditions, the excess current that flowed toward the HVM amplifier was instead diverted to ground. In particular, a series of three diodes (labeled D2, D3, and D4 in Supplementary Figure S1) comprise the equivalent of an electrical check valve. That is, they can permit a maximum positive current of 750 milliamps to be sourced from the HVM amplifier, while simultaneously blocking up to 30 kV from flowing back into the HVM. Thus, the arrangement allows both the separation and electrospray power supplies to source current to the CE-ESI circuit, while isolating the two supplies from each other. A fourth diode (labeled D5) protects the HVM amplifier from reverse current by shunting it directly to ground in the event that there is an excess of reverse current. We note that some reverse current can leak through the diodes (up to 5 μA through the D2-D3-D4 circuit). The HVM is also reported to have some current sinking ability from the manufacturer, and this current sinking likely played the role of a secondary protection against this leakage current. Overall, this combination of HVM and protection circuit created a power supply that could mitigate potential current reversals, and limit spray voltage instabilities.

Initial Power Supply Evaluations

A 60-cm bare fused silica capillary (50 μm i.d., 150 μm o.d.) was used to initially test the performance of the HVM amplifier and the Spellman power supply. The distal end of the separation capillary was not etched by HF in this initial experiment. The electrospray emitter had an opening of 10 μm. The sheath electrolyte used was 0.1% (v/v) FA in water containing 10% (v/v) methanol. Three background electrolytes were used. The first separation electrolyte was 0.1% (v/v) FA, the second separation electrolyte was 5% (v/v) acetic acid, and the third separation electrolyte was 0.5% (v/v) FA.

The power supplies were controlled by LabVIEW software. The injection end of the separation capillary and an electrode were fixed in an injection block [15]. The electrode provided high voltage for CE separation. Nitrogen gas was used to provide pressure for capillary flushing and sample injection; no pressure was used during separation.

A constant spray voltage (1.4 kV) was used for these experiments. The separation voltage applied at the injection block was increased from 1 to 30 kV in 2 kV increments. This procedure was performed for the background electrolytes listed above. Spray voltage was measured in the vial that supplied the sheath electrolyte using a Fluke 80K-40 HV Probe (Everett, WA, USA). Prior to applying the separation voltage, the spray voltage was set and measured with the high voltage probe.

Twenty μm i.d. Capillary Experimental Conditions

A second series of experiments used a 31 cm long, 20-μm i.d., 150 μm o.d. separation capillary. Approximately 5 mm of the distal end of the separation capillary was etched using HF to an o.d. of ~45 μm, as reported earlier [10]. The etched capillary allowed placing the distal end of the capillary a few micrometers from the emitter opening, which increased sensitivity. The electrospray emitter used in this experiment had an opening of 20 μm. The sheath electrolyte used in the electrospray emitter was 0.1% (v/v) FA in water containing 10% (v/v) methanol. The background electrolyte was 5% (v/v) acetic acid. The separation voltage was 27 kV and the spray voltage was 1.6 kV for all experiments with the 20 μm i.d. capillary.

Injection Conditions

The length of the injection plug was estimated using:

where L is the injection length in mm, P is the pressure in mbar (1 mbar ≈ 0.015 psi), S is the injection time in seconds, C is the capillary length in cm, and D is the capillary inner diameter in μm. The injection conditions used were 2.0 s at 10 psi, which gave an injection length of 5.4 mm. The sample was angiotensin II diluted in 0.1% (v/v) FA to concentrations of 2, 5, 10, and 20 μM. Data were collected in triplicate.

Fifty μm i.d. Capillary Experimental Conditions

A final set of experiments used a 31-cm long, 50-μm i.d., 150 μm o.d. separation capillary. Approximately 10 mm of the distal end of the capillary was etched using HF to an o.d. of ~65 μm. The electrospray emitter, sheath electrolyte, and separation electrolyte were identical to those used in the 20 μm i.d. capillary experiment.

For this set of experiments, we increased the spray voltage to 1.7 kV. Three experimental conditions were employed, Table 1. The first condition used the HVM amplifier with a separation voltage of 19 kV. The second condition used the Spellman power supply with a separation voltage of 11 kV. These first two conditions demonstrate the capabilities of each of the electrospray power supplies at the maximum voltage applied by the separation power supply that would not alter the spray voltage. The third condition used the Spellman power supply with a separation voltage of 19 kV and provides a comparison of the ability of the two electrospray power supplies to mitigate current reversal.

Injection Conditions

Injection conditions were calculated using Equation 1 to maintain a constant injection length of 5.4 mm. The injection conditions used were 0.8 s at 4 psi. The samples used for the 50 μm i.d. capillary experiment were identical to those used for the 20 μm i.d. capillary experiment. The sample used was angiotensin II diluted in 0.1% (v/v) FA to concentrations of 2, 5, 10, and 20 μM. Data were collected in triplicate.

Results and Discussion

Initial Power Supply Evaluations

A 60-cm long, 50-μm i.d. separation capillary was used for the initial experiments. The performance of the HVM amplifier and Spellman CZE-1000 power supplies were compared for three background electrolytes 0.1% (v/v) FA, 5% (v/v) acetic acid, and 0.5% (v/v) FA. The sheath electrolyte was 0.1% (v/v) FA in water containing 10% (v/v) methanol. A spray voltage of 1.4 kV was applied to the sheath electrolyte reservoir and monitored using a high voltage probe. This spray voltage, while lower than used below to generate electropherograms, is much more convenient to monitor.

Figure 2 presents the observed voltage in the sheath electrolyte reservoir as the separation voltage was increased. A positive deviation from 1.4 kV indicated that the electrospray power supply (HV2) failed to maintain the spray voltage due to the current passing through the separation capillary.

Spray voltage measured versus separation voltage applied for 0.1% FA (a), 5% acetic acid (b), and 0.5% FA (c). The solid (blue) trace corresponds to the Spellman power supply, and the dashed (red) trace corresponds to the HVM amplifier. Approximate conductivities of electrolytes: 0.1% formic acid ~0.3 mS/cm; 5% acetic acid ~1.2 mS/cm; and 0.5% formic acid ~5.6 mS/cm [16]

The HVM amplifier (red, dashed line) maintains the spray voltage at 1.4 kV while the separation voltage is ramped to 30 kV with both 0.1% FA and 5% acetic acid background electrolytes. Only when the highest conductivity electrolyte is used, 0.5% FA, does the HVM amplifier fail to maintain the 1.4 kV spray voltage at the highest separation voltages. In contrast, the Spellman power supply (solid, blue line) is unable to maintain the set electrospray voltage at the highest separation voltage for all three background electrolytes, and the separation voltage that produces a deviation from the set voltage tracks the electrolyte conductivity.

Twenty μm i.d. Capillary Experiment - Low Electrophoresis Current

Following the initial evaluation, we compared electropherograms generated using the HMV amplifier and Spellman power supply with a separation voltage of 27 kV and spray voltage of 1.6 kV with the 20 μm i.d. capillary. The purpose of this experiment was to determine if the HVM amplifier could produce comparable CE data to the Spellman power supply under conditions with relatively low electrophoretic separation current.

We generated electropherograms for angiotensin II at concentrations of 20, 10, 5, and 2 μM. Electropherograms of 2 μM angiotensin II are presented in Fig. 3 for the HVM amplifier (Fig. 3a) and the Spellman power supply (Fig. 3b). The data from each electropherogram were smoothed with a 5-point Gaussian convolution. The peak intensities and migration times are very similar between the two power supplies.

Unweighted least squares fits to the calibration curve data were linear for both the HVM amplifier (slope = 1.8 × 106, R = 0.9920) and the Spellman power supply (slope = 2.1 × 106, R = 0.9940). The y-intercepts for the HVM amplifier and the Spellman power supply were both equal to zero within experimental error. Thus, in general, the two power supplies both produced similar quantitative CE-ESI-MS performance.

Fifty μm i.d. Capillary Experiment - High Electrophoresis Current

As a more stringent evaluation of the electrospray power supplies, we repeated the experiment with a 50 μm i.d. capillary. The increased inner diameter of the separation capillary provides a ~6-fold increase in capillary cross-section, which results in a proportional increase in current flowing through the separation capillary.

In the initial test of the 50 μm i.d. capillary, the Spellman power supply was not able to mitigate spray voltage instability above a separation voltage of 11 kV, causing the spray voltage to deviate from its setting and degrading performance. The difference between the HVM amplifier and the Spellman power supply is illustrated most dramatically when comparing the electropherograms with the 2 μM angiotensin II at the three voltage conditions in this experiment (Fig. 4), which correspond to the three cases in Table 1.

The electropherogram generated by the HVM amplifier and a separation voltage of 19 kV (Fig. 4a) results in a migration time just over 2 min and a base peak intensity of roughly 800,000. The electropherogram generated by the Spellman power supply and a separation voltage of 11 kV (Fig. 4b) results in a significantly later migration time (~6 min) with similar base peak intensity. The electropherogram generated by the Spellman power supply and a separation voltage of 19 kV (Fig. 4c) results in a higher background and a lower base peak intensity of approximately 525,000. In Fig. 4c, the migration time of angiotensin II is identical to that of Fig. 4a where the HVM amplifier was used under the exact same conditions. However, the base peak intensity in Fig. 4a is approximately 50% greater and the background is roughly one-third of what is seen in Fig. 4c.

Again, unweighted least squares calibration curves were linear for the HVM amplifier (slope = 1.4 × 106, R = 0.9945), the Spellman power supply with a separation voltage of 11 kV (slope = 1.5 × 106, R = 0.9962), and the Spellman power supply with a separation voltage of 19 kV (slope = 6.1 × 105, R = 0.9967). The y-intercepts for all three plots were equal to zero within experimental error.

Conclusion

Spellman CZE-1000R power supplies are used widely for capillary electrophoresis separations and have been used extensively by our group as an electrospray power supply. However, as illustrated in this work, the Spellman power supplies are not well suited for fast separations that employ high electric fields with high ionic strength separation electrolytes. Our group identified this limitation in a publication that characterized our third-generation electrokinetically pumped sheath-flow nanospray interface [5]. The HVM amplifier protection circuit we have developed is clearly capable of mitigating spray voltage instability. The HVM amplifier is marketed as being able to sink current; however, we did not test this capability of the amplifier directly. Rather, we employed a circuit that protects the amplifier from current reversal. In the event that some current passes into the HVM amplifier, its manufactured ability to sink current could offer a secondary protection to the integrity of the spray voltage. We identified the limit of where the HVM amplifier protection circuit failed to maintain the applied spray voltage (Fig. 1c). Overall, the HVM amplifier and the associated protection circuit are well suited for fast separations that employ high electric fields and high ionic strength separation electrolytes.

References

Heemsker, A.A.M., Deelder, A.M., Mayboroda, O.A.: CE-ESI-MS for bottom-up proteomics: advances in separation, interfacing, and applications. Mass Spectrom. Rev. 26, 223–257 (2014)

Sun, L., Zhu, G., Yan, X., Champion, M.M., Dovichi, N.J.: Capillary zone electrophoresis for analysis of complex proteomes using an electrokinetically pumped sheath flow nanospray interface. Proteomics 14, 622–628 (2014)

Sun, L., Zhu, G., Yan, X., Dovichi, N.J.: High sensitivity capillary zone electrophoresis-electrospray ionization-tandem mass spectrometry for the rapid analysis of complex proteomes. Curr. Opin. Chem. Biol. 17, 795–800 (2013)

Maxwell, E.J., Chen, D.D.Y.: Twenty years of interface development for capillary electrophoresis-electrospray ionization-mass spectrometry. Anal. Chim. Acta 627, 25–33 (2008)

Sun, L., Zhu, G., Zhang, Z., Mou, S., Dovichi, N.J.: Third-generation electrokinetically pumped sheath-flow nanospray interface with improved stability and sensitivity for automated capillary zone electrophoresis-mass spectrometry analysis of complex proteome digests. J. Proteome Res. 14, 2312–2321 (2015)

Moini, M.: Simplifying CE-MS operation. 2. interfacing low-flow separation techniques to mass spectrometry using a porous tip. Anal. Chem. 79, 4241–4246 (2007)

Maxwell, E.J., Zhong, X., Zhang, H., Van Zeijl, N., Chen, D.D.Y.: Decoupling CE and ESI for a more robust interface with MS. Electrophoresis 31, 1130–1137 (2010)

Wang, C., Lee, C.S., Smith, R.D., Tang, K.: Capillary isotachophoresis-nanoelectrospray ionization-selected reaction monitoring MS via a novel sheathless interface for high sensitivity sample quantification. Anal. Chem. 85, 7308–7315 (2013)

Wojcik, R., Dada, O.O., Sadilek, M., Dovichi, N.J.: Simplified capillary electrophoresis nanospray sheath-flow interface for high efficiency and sensitive peptide analysis. Rapid Commun. Mass Spectrom. 24, 2554–2560 (2010)

Sun, L., Zhu, G., Zhao, Y., Yan, X., Dovichi, N.J.: Ultrasensitive and fast bottom-up analysis of femtogram amounts of complex proteome digests. Angew. Chem. Int. Ed. 52, 13661–13664 (2013)

Sun, L., Hebert, A.S., Yan, X., Zhao, Y., Westphall, M.S., Rush, M.J., Zhu, G., Champion, M.M., Coon, J.J., Dovichi, N.J.: Over 10,000 peptide identifications from the HeLa proteome by using single-shot capillary zone electrophoresis combined with tandem mass spectrometry. Angew. Chem. Int. Ed. Engl. 53, 13931–13933 (2014)

Hau, J., Roberts, M.: Advantages of pressurization in capillary electrophoresis/electrospray ionization mass spectrometry. Anal. Chem. 71, 3977–3984 (1999)

Hau, J.: [Ionisation bei Atmosphärendruck: Entwicklung, Charakterisierung und Anwendung einer Elektrospray-Ionenquelle für ein doppelfokussierendes Sektorfeld-Massenspektrometer.] Deutscher Universitäts-Verlag: Wiesbaden (1994)

Cole, R.B.: Electrospray ionization mass spectrometry: fundamentals, instrumentation, and applications. Wiley: (1997)

Krylov, S.N., Starke, D.A., Arriaga, E.A., Zhang, Z., Chan, N.W., Palcic, M.M., Dovichi, N.J.: Instrumentation for chemical cytometry. Anal. Chem. 15, 872–877 (2000)

Zhao, Y., Sun, L., Champion, M.M., Knierman, M.D., Dovichi, N.J.: Capillary zone electrophoresis-electrospray ionization-tandem mass spectrometry for top-down characterization of the Mycobacterium marinum secretome. Anal. Chem. 86, 4873–4878 (2014)

Acknowledgments

The authors thank Dr. William Boggess of the Notre Dame Mass Spectrometry and Proteomics Facility for his help with this project. This project was supported by a grant from the National Institutes of Health (R01GM096767).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(DOCX 261 kb)

Rights and permissions

About this article

Cite this article

Flaherty, R.J., Sarver, S.A., Sun, L. et al. A High Voltage Power Supply That Mitigates Current Reversals in Capillary Zone Electrophoresis-Electrospray Mass Spectrometry. J. Am. Soc. Mass Spectrom. 28, 247–252 (2017). https://doi.org/10.1007/s13361-016-1529-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13361-016-1529-3