Abstract

Elucidating reaction mechanisms is important for advancing many areas of science such as catalyst development. It is often difficult to probe fast reactions at ambient conditions with high temporal resolution. In addition, systems involving reagents that cross-react require analytical methods that can minimize interaction time and specify their order of introduction into the reacting system. Here, we explore the utility of transmission mode desorption electrospray ionization (TM-DESI) for reaction monitoring by directing a microdroplet spray towards a series of meshes with micrometer-sized openings coated with reagents, an approach we call multistage reactive TM-DESI (TMn-DESI, where n refers to the number of meshes; n = 2 in this report). Various stages of the reaction are initiated at each mesh surface, generating intermediates and products in microdroplet reaction vessels traveling towards the mass spectrometer. Using this method, we investigated the reactivity of iron porphyrin catalytic hydroxylation of propranolol and other substrates. Our experimental results indicate that TMn-DESI provides the ability to spatially separate reagents and control their order of introduction into the reacting system, thereby minimizing unwanted reactions that lead to catalyst deactivation and degradation products. In addition, comparison with DESI-MS analyses (the Zare and Latour laboratories published results suggesting accessible reaction times <1 ms) of the reduction of dichlorophenolindophenol by L-ascorbic acid suggest that TM1-DESI can access reaction times less than 1 ms. Multiple meshes allow sequential stages of desorption/ionization per MS scan, increasing the number of analytes and reactions that can be characterized in a single experiment.

ᅟ

Similar content being viewed by others

Introduction

Characterizing reaction mechanisms is important for developing new catalysts, drugs, and materials that address scientific and socioeconomic problems [1]. However, it is often difficult to obtain detailed molecular mechanistic information under normal operating conditions because intermediates have short lifetimes (typically less than ~1 s), exist in a complex and dynamic matrix involving multiple reaction pathways, and have low concentrations [2–5]. These difficulties are significantly more pronounced for homogenous multi-catalytic systems [6], which show great promise for rapidly achieving one-pot complex transformations that improve efficiency, selectivity, and enantiomeric purity. Advancing these areas of research demand analytical technologies that can capture fleeting intermediates in real-time at ambient conditions, as well as provide the ability to separate reagents and specify their order of introduction to minimize unwanted side reactions between incompatible reagents during analysis and to facilitate step-wise elucidation of reaction mechanisms.

Electrospray ionization mass spectrometry (ESI-MS) methods are one of the primary approaches for obtaining real-time information about solution-phase molecular species formed in the course of a reaction with high sensitivity, speed, and selectivity [7]. The recent introduction of ambient mass spectrometric techniques [8–15] such as desorption electrospray ionization (DESI) [16] developed by Cooks and co-workers has revolutionized analytical chemistry in the past decade, allowing chemical analyses with minimal sample preparation. A recent advance developed by Zare and co-workers involves using DESI to capture short-lived solution-phase reaction intermediates (< 1 ms) [17–23] at ambient conditions, while minimizing sample preparation times, carry over effects, and experimental complexity compared with ESI configurations. This elegant discovery has opened the possibility for the development of new types of ambient ionization sources and applications for characterizing fast solution-phase processes [4, 24–32].

Transmission-mode DESI (TM-DESI) [33–38], developed by Brodbelt and co-workers, is an ambient MS method that involves directing an electrostatically charged solvent spray at a mesh having micrometre-sized open areas on which analytes of interest are deposited. TM-DESI requires small sample volumes and minimal source optimization prior to analysis, making it easily amenable to high-throughput analyses [33, 36, 39, 40]. TM-DESI has been previously used for direct analysis of samples containing analytes such as peptides and small organic molecules [33]. In addition, the mesh can be functionalized for selective extraction of analytes from complex matrices followed by TM-DESI-MS [35, 40]. Despite its simplicity, the utility of TM-DESI for probing chemical reactivity has not yet been explored.

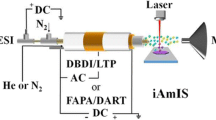

Herein, we describe a TM-DESI-based ionization source that employs two meshes in series (M1 and M2) (Figure 1), referred to hereafter as multistage reactive transmission-mode DESI (TMn-DESI, where n represents the number of desorption stages; conventional TM-DESI configuration has n = 1) for characterization of reaction mechanisms. Using TM2-DESI-MS, we studied iron (Fe) porphyrin-catalyzed hydroxylations such as Fe tetra(pentafluorophenyl)-porphyrin (Fe-TPFPP, 1) hydroxylation of substrate propranolol 2 (proposed mechanism shown in Scheme 1 [41]), previously analyzed by ESI Fourier transform ion cyclotron resonance MS [42, 43]. Experimental results show that TM2-DESI provides the ability to spatially separate reagents and to specify their order of introduction into microdroplet reaction vessels, reducing off-path processes such as oxidant-mediated hydroxylation of 2 (Scheme 1). In addition, comparison of TM1-DESI-MS and DESI-MS analyses of the chemical reduction of dichlorophenolindophenol (DCIP) by L-ascorbic acid (L-AA; Figure 3; reaction previously analyzed by liquid DESI-MS [44]) showed that TM1-DESI can access reaction times less than 1 ms. These capabilities, coupled with the high-throughput features of TM-DESI, demonstrate a unique ambient ionization approach for chemical analyses at ambient conditions. Multiple meshes increase the number of analytes and reaction steps that can be characterized per MS scan by a factor of n, which has great potential for reducing analysis time and increasing high-throughput analyses at ambient conditions.

(a) Two-dimensional representation of TM2-DESI-MS. (b) Three-dimensional rendition showing the meshes in front of the MS inlet (for clarity, the micromanipulators that attach the sprayer holder to the stage and the alignment bar are not shown; their locations are indicated with dashed lines). Inset shows a close-up 3D view of the rotatable posts, mesh holder, and alignment bar. These images are not drawn to scale

(a) Catalytic cycle for Fe-TPFPP oxidation of propranolol. Species 1a and 1c (red) could not be unambiguously identified because they are isobaric with degradation products having oxygen insertion into the porphyrin ring. (b) Degradation pathway of Fe-TPP from reference [55]

Experimental

Materials

All chemicals were purchased from Sigma-Aldrich (St. Louis, MO, USA) and used without further purification, except for the Fe porphyrin catalysts (Fe tetra(pentafluorophenyl)-porphyrin, Fe-TPFPP, 1; Fe tetraphenylporphyrin, Fe-TPP; Fe tetramesitylporphyrin, Fe-TMP; Fe tetra(2,6-dichlorophenyl)porphyrin TDCPP, Fe-TDCPP; Fe tetra(2,6-difluorophenyl)porphyrin, Fe-TDFPP), and propranolol 2, which were purchased from Frontier Scientific, Inc. (Logan, UT, USA). The polyether ether ketone (PEEK) meshes (71 μm strand diameter, 56% open area) were purchased from Small Parts, Inc. (Miramar, FL, USA). PEEK was chosen as the mesh material because of its high chemical resistance to dichloromethane (CH2Cl2) compared with other polymers such as polypropylene.

Design of the Multistage Reactive Transmission Mode Desorption Electrospray Ionization Source

The microdroplet sprayer of the TMn-DESI source has similar specifications to the home-built DESI source described by Cooks and co-workers [45]. Briefly, the sprayer consists of a Swagelok (Swagelok Company, Fremont, CA, USA) 1/16′′ stainless steel (SS) tee through which a fused silica (FS1) capillary (75 μm internal diameter (i.d.); 190 μm outer diameter (o.d.); Polymicro Technologies, Phoenix, AZ, USA) delivers liquid from a Harvard Apparatus Standard Pump 22 (Holliston, MA, USA) syringe pump. FS1 passes through a 1/16′′ fluorinated ethylene propylene tubing (i.d.: 200 μm; length: 5 cm ; IDEX Health and Science, Oak Harbor, WA, USA) that holds FS1 in place with a stainless steel (SS) nut and ferrule. The other end of FS1 passes through a second FS capillary (FS2; length = ~1.5–2 cm; i.d. = 250 μm; o.d. 360 μm), which is held in place with a graphite ferrule and SS nut. FS1 and FS2 protrude from the end of the SS nut by ~0.7 and 0.5 cm, respectively. The FS1-to-MS inlet distance ranges from 5 mm to 13 mm (Figure 1a). Sheath gas (nitrogen; N2) enters the sprayer at the 90o opening of the tee (line pressure = ~150–200 PSI) and exits FS2, generating the microdroplet reagent spray. Measurements of [2 + H]+ (m/z 260.164) intensity as a function of N2 line pressure show that a threshold value of ~150 PSI is necessary for efficient desorption/ionization from M2 in TM2-DESI (Supplementary Figure S1a). The sprayer is connected to a 1/16′′ Swagelok bulkhead union that is mounted in an aluminium bar (sprayer holder; Figure 1b). The sprayer holder is connected to x, y, and z micromanipulators (location shown by dotted lines in Figure 1b) mounted on a modified PicoView 550 (New Objective, Inc., Woburn, MA, USA) stage. The stage mounts on the frame of an LTQ-Orbitrap XL mass spectrometer [46–51] via a pair of latches (Figure 1b).

Each mesh is held in place by a pair of rotatable posts (6.5 cm in height) that are secured to separate mesh holders via set screws (Figure 1b). The rotatable posts provide control of mesh position and tension, which are critical parameters for obtaining reproducible measurements; a loose mesh has erratic motion in the microdroplet plume, which causes large variations in signal intensity at a given concentration of analyte. The rotatable posts are composed of two segments that can be clamped together by a pair of screws (Figure 1b inset) to securely hold the meshes in place. The mesh holders are controlled by a set of x, y, and z micromanipulators mounted on a lab jack adjacent to the stage (Figure 1b). The micromanipulators are used to position the sprayer and meshes such that the sprayer is normal to the meshes and 0o relative to the MS inlet. To aid in positioning, the lower mesh holder rests against an aluminium alignment bar (Figure 1b inset) that is affixed to the TMn-DESI stage with a pair of clamps (location shown by dotted lines in Figure 1b). The alignment bar ensures that the mesh-to-inlet angle and distance remains constant when analyzing multiple samples located at different positions on the same mesh (different samples are accessed by motion in the y-z plane). The inter-mesh distance and M2-to-inlet distances are shown in Figure 1a.

Mass Spectrometry

In a typical TM2-DESI experiment, the meshes are first washed with a 1:1:1 mixture of water (H2O), methanol (CH3OH), and acetone (C3H6O) for 10 s and then air-dried. Each mesh is then secured to a holder via the rotatable posts. Using a micropipette, microliter volumes of catalyst and substrate are deposited on M1 and M2, respectively, and allowed to air-dry. The mesh holders are then attached to the micromanipulators while being careful to avoid contact between the meshes or with other surfaces. The mesh holders are adjusted to set the inter-mesh distance in the range of 2 mm–4 mm. Shorter M1–M2 distances have higher desorption/ionization efficiency for 2 deposited on M2, with 2 mm typically used for experiments (Supplementary Figure S1b). This is supported by COMSOL Multiphysics (ver. 4.4.0.248; COMSOL, Inc., Burlington, MA, USA) laminar flow simulations showing that N2 velocity decreases by ~20% after passing through M2 (Supplementary Figure S1b inset).

After setting the meshes and sprayer in desired positions relative to the MS inlet, N2 gas and liquid flow are initiated to generate a microdroplet spray containing a reagent such as oxidant mCPBA (Figure 1). Detection of [2 + H]+ from M2 indicates a linear dynamic range of approximately one to two orders of magnitude and signal intensity scales linearly with liquid flow rate (Supplementary Figure S1c and d). We hypothesize that impact of the primary microdroplets on M1 initiate reactions in desorbed secondary microdroplets generating active catalytic species that interact with the substrate upon impacting M2. Catalytic conversion of the substrate occurs in desorbed tertiary microdroplets as they travel towards the mass spectrometer. Unless specified otherwise, the Orbitrap MS is typically operated using the following parameters for full-scan mass spectra: m/z range = 250–1500, resolution = 100,000 at m/z 400, mass accuracy = 2–5 ppm, microscan = 1, injection time = 500 ms; capillary voltage = 275°C, tube lens voltage = 110 V, and spray voltage = 0 kV. Settings that are different for tandem MS (MS/MS) include: microscans = 3, injection time = 50, 500, or 1000 ms.

Results and Discussion

TMn-DESI has the ability to monitor catalytic cycles (on- and off-path processes) and capture highly reactive intermediates. Iron porphyrins such as Fe-TPFPP chloride ([1 + Cl]) are a class of biomimetic catalysts capable of a wide variety of oxidation reactions including C–H hydroxylation [41, 52, 53]. The mechanism of Fe-mediated hydroxylation involves activation of 1 by an oxidant such as meta-chloroperbenzoic acid (mCPBA) to produce a Fe peroxo intermediate 1a, which undergoes homolytic and heterolytic cleavage to yield high-valent iron oxo catalytic intermediates 1b and 1c, respectively (Scheme 1a). The active catalytic species (1b and 1c) can then hydroxylate organic compounds such as propranolol [54] (2, Scheme 1a) on the aromatic ring (2b), regenerating 1 to complete the catalytic cycle [41].

When [1 + Cl] (5 μL of 5 × 10–5 M in CH2Cl2) is deposited on M1 and activated by mCPBA (5 × 10–5 M in 4:1 CH2Cl2:CH3OH) in the reagent spray (no ionization voltage applied; 200 PSI N2 pressure), desorbed secondary microdroplets containing active catalyst species react with [2 + HCl] (5 μL of 5 × 10–5 M in CH2Cl2) deposited on M2. Desorbed microdroplets from M2 were analyzed by Orbitrap MS to identify species 1 (m/z 1027.977), 2 (m/z 260.164), and 2b (m/z 276.159), indicating that the complete catalytic transformation of 2 can be observed on the TM2-DESI time scale (Figure 2a). Fe-TPFPP can hydroxylate other substrates such as dapoxetine by TM2-DESI-MS (Figure 2a inset), as well as activate catalysts such as Fe-TDFPP (Figure 2b) and Fe-TDCPP (Figure 2c), indicating that the technique is generalizable for studying chemical reactivity. Analysis of the activation of 1 by mCPBA using negative mode TM1-DESI (Figure 2d) identifies the formation of 1b at m/z 1078.939 [1b + Cl]– and m/z 1198.962 [1b + mCBA]–, corresponding to the homolytic catalytic pathway. To our knowledge, these results represent the first direct observation of the Fe-porphyrin homolytic catalytic pathway by MS (previous FT-ICR ESI-MS studies observed the radical cation iron oxo 1a) [42, 43].

Positive-mode TM2-DESI-MS of the hydroxylation of 2 by (a) 1, (b) Fe-TDFPP, and (c) Fe-TDCPP using oxidant mCPBA. Inset of (a) shows the hydroxylated products of 2 and dapoxetine. (d) Negative mode TM1-DESI-MS of the hydroxylation of 2 by Fe-TPFPP using oxidant mCPBA. (e) Positive-mode TM1-DESI-MS showing self-oxidation of Fe-TPP (Scheme 1b). (f) Reactivity of five Fe porphyrin catalysts towards aromatic and aliphatic oxidation of 2 by TM2-DESI-MS (green dotted line represents aliphatic oxidation by mCPBA). Structures: TPFPP (Scheme 1a), TDFPP (Figure 2b), TDCPP (Figure 2c), TMP (Figure 2f), and TPP (Scheme 1b)

Further analysis of acquired Orbitrap mass spectra indicate that the m/z values corresponding to 1a (Figure 2d) and 1c (Figure 2a) are isobaric with ligand oxidation degradation products (Scheme 1b) [41]. Oxidative degradation of porphyrin ligands can produce species having opened rings and containing oxygen atoms in various functional forms, as exemplified by reacting Fe-TPP (nominal Δm/z = 360 compared with Fe-TPFPP) 3 (deposited on M1) with mCPBA (reagent spray) yielding structures 3a–3c (Scheme 1b). The structures of these TPP degradation products are in agreement with previous studies employing ultraviolet-visible spectroscopy and MS [55]. For Fe-TPFPP, the [TPFPP + O-H]– (m/z 989.044; Supplementary Figure S2) degradation product is observed when free TPFPP ligand ([TPFPP-H]– at m/z 973.051; 5 μL of 5 × 10-4 M in CH2Cl2) and [1 + Cl] (5 μL of 5 × 10-4 M in 4:1 CH2Cl2:CH3OH) are deposited at the same spot and then reacted with mCPBA in TM1-DESI (there is a 10-fold increase in the signal compared with the absence of [1 + Cl]; Supplementary Figure S2). These results clearly indicate that [1 + Cl] undergoes self-oxidation. In addition to being isobaric with ligand oxidation products, species 1a is estimated to have a lifetime on the order of tens of microseconds [56], [see Supporting Information (SI)], for the calculation), which is significantly shorter than the estimated reaction time of TMn-DESI (based on the N2 velocity and DCIP estimations discussed below). As a result, ion signals at m/z 1233.929 and 1353.951 are unlikely to contain the Fe-peroxo intermediate. However, observation of both 1b and 2b combined with the higher reported reactivity of 1c towards hydroxylation of 2 [41] suggest that the peak at m/z 1043.972 possibly also contains the high-valent radical cation Fe-oxo 1c.

TM2-DESI provides a simple approach for separating reagents and controlling their order of introduction into the microdroplet spray. These capabilities are useful for step-wise elucidation of reaction mechanisms and for minimizing off-path processes. For example, mCPBA can oxidize 2 without catalyst interaction to generate 2a (aliphatic chain oxidation; green dotted line in Figure 2f), which is isobaric with catalytic product 2b (aromatic oxidation) [41]. Species 2a and 2b were distinguished using MS/MS experiments (see SI; Supplementary Figure S3). When a premixed solution of [2 + HCl] (2.5 × 10–6 M) and mCPBA (2.5 × 10–5 M) in 4:1 CH2Cl2:CH3OH was sprayed towards the mass spectrometer at 30 μL/min (no ionization voltage applied), a peak at m/z 276.160 ([2a + H]+) is observed at ~4% intensity relative to m/z 260.165 ([2 + H]+), indicating aliphatic oxidation in the absence of the catalyst (Supplementary Figure S3). However, when [2 + HCl] (5 μL of 5 × 10–5 M in CH2Cl2) is deposited on a mesh and analyzed using a microdroplet spray containing mCPBA (5 × 10–5 M), the relative intensity of [2a + H]+ is ~0.06%, indicating a reduction in the off-path process by a factor of ~60. When a mesh bearing [1 + Cl] (5 μL of 5 × 10–5 M in CH2Cl2) was placed in front of the mesh bearing 2, the peak at m/z 276.160 had relative intensity of ~0.8% compared with [2 + H]+. So, when TM2-DESI was used to separate reagents and specify their order of introduction, the off-path process was reduced and the ion population at m/z 276.160 primarily represented on-path product 2b.

It is essential to determine the reactivity of ligands with different chemical motifs in the discovery and development of new catalysts. TMn-DESI allows rapid simultaneous characterization of reaction mechanisms and reaction progress. Depositing simultaneously five Fe catalysts with different porphyrin ligands on M1 and substrate 2 on M2, allowed rapid comparison of the relative yields of aliphatic and aromatic hydroxylation products in a single experiment (Figure 2f and Supplementary Figure S3; ratio of aliphatic to aromatic oxidation determined by MS/MS as described in the SI). The observed reactivity trend agrees with previously published reports showing that oxidizing power decreases with increasing electron density at the metal centre [41], suggesting that TM2-DESI-MS also provides information relevant to bulk solution-phase chemistry. Other spray-based ionization sources (e.g., continuous-flow ESI, stopped-flow ESI, and DESI) would require additional tubing, pumps, microdroplet emitters, or valves to achieve high-throughput analyses of complex reactions similar to TMn-DESI-MS.

In addition to 2, dapoxetine (Figure 2a inset) and 1-naphthyl-3-pyrrolidinyl (Supplementary Figure S4), which share an oxynaphthyl moiety, as well as four other substrates were successfully hydroxylated using Fe-TPFPP as the catalyst (structures of 1-naphthyl-3-pyrrolidinyl, rhodamine B, rhodamine 6G, fluorescein, and lauric acid shown in Supplementary Figure S4). A spray voltage of –5 kV was applied (Bertan 205b high voltage power supply, Spellman, Hauppauge, New York, USA) for TM2-DESI-MS oxidation of fluoroscein and lauric acid to improve sensitivity (the effect of spray voltage on signal intensities is discussed later in this article). Product-to-substrate ratios (P:S) calculated from the single-stage MS experiments indicate that the substrates containing aromatic rings are more easily oxidized by Fe-TPFPP compared with alkyl compounds. The location of the hydroxyl group was determined using MS/MS (Supplementary Figures S5–S9).

TM2DESI characterization of the Fe-TPFPP reactions described above were performed without applying voltage to the spray solutions in order to closely mimic bulk-phase reaction conditions, except for fluorescein and lauric acid, which required –5 kV for adequate sensitivity. Application of 5 kV (positive and negative modes) in TM1-DESI-MS characterization of Fe-TPFPP activation by mCPBA (deposited 5 μL of 10–4 M Fe-TPFPP in CH2Cl2; DESI microdroplet spray contains 10–5 M mCPBA in 4:1 CH2Cl2:CH3OH) increased absolute signal intensities without significantly altering relative intensities (Supplementary Figure S10; viz., applying a voltage increased sensitivity). In addition, ion signals suggesting formation of reactive oxygen species [57] or other unwanted by-products were not observed (Supplementary Figure S10). Experiments carried out at different capillary inlet temperatures, 225°C (Supplementary Figure S11a), 275°C (Figure 2d), and 325°C (Supplementary Figure S11b) in negative mode (0 kV) show that the relative intensities change, indicating effects on desolvation/ionization processes and/or reaction kinetics. Ion signals for [1 + 2Cl]– (m/z 1097.916), [1b + mCBA]– (m/z 1198.963), and [1 + Cl + mCBA]– (m/z 1217.938) increased relative to [1 + 2mCBA]– (m/z 1337.959). Increasing the capillary inlet temperature did not yield any new ion signals indicative of unwanted side reactions. All these observations suggest that applying standard ionization voltages and temperatures in TMn-DESI does not significantly influence the observed reaction pathways in acquired mass spectra for this catalytic system, thereby demonstrating the ability of TM-DESI to provide information relevant to bulk-phase chemistry.

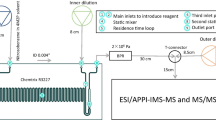

TMn-DESI has the ability to probe reactions on time scales less than 1 ms. When L-AA [58] (2 × 10–3 M in 1:1 CH3OH:H2O) was sprayed (5 μL/min; 200 psi nebulizing gas; 0.6 cm and 1.0 cm emitter-to-inlet distances; +3 kV) towards a mesh bearing DCIP (4a; 5 μL of 5 × 10–3 M in CH3OH) in TM1-DESI-MS, [4b + H]+ was observed at m/z 270.008 (Figure 3a) with intensity of ~4% relative to [4a + H]+ at m/z 267.993. Assuming that the concentration of DCIP in the secondary microdroplets is low compared with L-AA, the observed reaction time in microdroplets (t) for TM1-DESI (t TM ) and DESI (t DESI ) can be approximated using pseudo-first-order kinetics [58] (see SI)

where k f is the rate constant, [AA]0 the initial L-AA concentration, I 4a the intensity of [4a + H]+, and I 4b the intensity of [4b + H]+. For DESI (Figure 3b) , L-AA (2 × 10–3 M in 1:1 CH3OH: H2O) was sprayed (5 μL/min; 200 PSI nebulizing gas; 0.6 cm and 1.0 cm emitter-to-inlet distances; +3 kV applied) towards a paper surface containing DCIP (deposited 5 μL of 5 × 10–3 M in CH3OH). The ratio [t DESI /t TM ] ≅ 2–3 (Supplementary Table S1), which suggests that t TM and t DESI have the same order of magnitude of less than 1 ms (t DESI was experimentally estimated by Latour and coworkers [59, 60]). These results agree with previous studies proposing that TM-DESI and DESI have relatively similar desorption/ionization mechanisms [34], calculations showing that [t ESI /t TM ] > 40 at various emitter-inlet distances and concentrations (Supplementary Table S1), and calculations showing that microdroplets of TM2-DESI travel at twice the velocity of droplets generated with DESI; see Electronic Supplementary Information for the calculations) [45].

In this report, we describe an ambient ionization source that involves directing a microdroplet spray through a series of micrometer-sized meshes bearing reagents, referred to as multistage reactive transmission mode desorption electrospray ionization. This technique provides a simple approach for separating reagents and specifying their order of introduction into the microdroplet stream, which facilitates the step-wise analysis of complex catalytic reactions. In addition, the short travel time of the microdroplet spray from the emitter to the mass spectrometer inlet provides access to short reaction time scales less than 1 ms.

References

Vikse, K.L., Ahmadi, Z., McIndoe, J.S.: The application of electrospray ionization mass spectrometry to homogeneous catalysis. Coord. Chem. Rev. 279, 96–114 (2014)

Lento, C., Audette, G.F., Wilson, D.J.: Time-resolved electrospray mass spectrometry—a brief history. Can. J. Chem. 93(1), 7–12 (2015)

Chen, P.: Electrospray ionization tandem mass spectrometry in high-throughput screening of homogeneous catalysts. Angew. Chem. Int. Ed. 42(25), 2832–2847 (2003)

Espy, R.D., Badu-Tawiah, A., Cooks, R.G.: Analysis and modification of surfaces using molecular ions in the ambient environment. Curr. Opin. Chem. Biol. 15(5), 741–747 (2011)

Vikse, K.L., Ahmadi, Z., Manning, C.C., Harrington, D.A., McIndoe, J.S.: Powerful insight into catalytic mechanisms through simultaneous monitoring of reactants, products, and intermediates. Angew. Chem. Int. Ed. 50(36), 8304–8306 (2011)

Du, Z., Shao, Z.: Combining transition metal catalysis and organocatalysis—an update. Chem Soc Rev 42(3), 1337–1378 (2013)

Eberlin, M.N.: Electrospray ionization mass spectrometry: a major tool to investigate reaction mechanisms in both solution and the gas phase. Eur. J. Mass. Spectrom. 13(1), 19–28 (2007)

Awad, H., Khamis, M.M., El-Aneed, A.: Mass spectrometry, review of the basics: ionization. Appl. Spectrosc. Rev. 50(2), 158–175 (2015)

Cooks, R.G., Ouyang, Z., Takats, Z., Wiseman, J.M.: Ambient mass spectrometry. Science 311(5767), 1566–1570 (2006)

Harris, G.A., Galhena, A.S., Fernandez, F.M.: Ambient sampling/ionization mass spectrometry: applications and current trends. Anal. Chem. 83(12), 4508–4538 (2011)

Ifa, D.R., Wu, C.P., Ouyang, Z., Cooks, R.G.: Desorption electrospray ionization and other ambient ionization methods: current progress and preview. Analyst 135(4), 669–681 (2010)

Li, L.P., Feng, B.S., Yang, J.W., Chang, C.L., Bai, Y., Liu, H.W.: Applications of ambient mass spectrometry in high-throughput screening. Analyst 138(11), 3097–3103 (2013)

Venter, A., Nefliu, M., Cooks, R.G.: Ambient desorption ionization mass spectrometry. Trac-Trend. Anal. Chem. 27(4), 284–290 (2008)

Albert, A., Shelley, J.T., Engelhard, C.: Plasma-based ambient desorption/ionization mass spectrometry: state-of-the-art in qualitative and quantitative analysis. Anal. Bioanal. Chem. 406(25), 6111–6127 (2014)

Monge, M.E., Harris, G.A., Dwivedi, P., Fernandez, F.M.: Mass spectrometry: recent advances in direct open air surface sampling/ionization. Chem. Rev. 113(4), 2269–2308 (2013)

Takats, Z., Wiseman, J.M., Gologan, B., Cooks, R.G.: Mass spectrometry sampling under ambient conditions with desorption electrospray ionization. Science 306(5695), 471–473 (2004)

Flender, C., Adams, A.M., Roizen, J.L., McNeill, E., Du Bois, J., Zare, R.N.: Speciation and decomposition pathways of ruthenium catalysts used for selective C–H hydroxylation. Chem. Sci. 5(8), 3309–3314 (2014)

Ingram, A.J., Wolk, A.B..., Flender, C., Zhang, J., Johnson, C.J., Hintermair, U., Crabtree, R.H., Johnson, M.A., Zare, R.N.: Modes of activation of organometallic iridium complexes for catalytic water and C–H Oxidation. Inorg. Chem. 53(1), 423–433 (2014)

Perry, R.H., Brownell, K.R., Chingin, K., Cahill, T.J., Waymouth, R.M., Zare, R.N.: Transient Ru-methyl formate intermediates generated with bifunctional transfer hydrogenation catalysts. Proc. Natl. Acad. Sci. U. S. A. 109(7), 2246–2250 (2012)

Perry, R.H., Cahill, T.J., Roizen, J.L., Du Bois, J., Zare, R.N.: Capturing fleeting intermediates in a catalytic C–H amination reaction cycle. Proc. Natl. Acad. Sci. U. S. A. 109(45), 18295–18299 (2012)

Perry, R.H., Splendore, M., Chien, A., Davis, N.K., Zare, R.N.: Detecting reaction intermediates in liquids on the millisecond time scale using desorption electrospray ionization. Angew. Chem. Int. Ed. 50(1), 250–254 (2011)

Brownell, K.R., McCrory, C.C.L., Chidsey, C.E.D., Perry, R.H., Zare, R.N., Waymouth, R.M.: Electrooxidation of alcohols catalyzed by amino alcohol ligated ruthenium complexes. J. Am. Chem. Soc. 135(38), 14299–14305 (2013)

Chung, K., Banik, S.M., De Crisci, A.G., Pearson, D.M., Blake, T.R., Olsson, J.V., Ingram, A.J., Zare, R.N., Waymouth, R.M.: Chemoselective Pd-catalyzed oxidation of polyols: synthetic scope and mechanistic studies. J. Am. Chem. Soc. 135(20), 7593–7602 (2013)

Badu-Tawiah, A.K., Campbell, D.I., Cooks, R.G.: Reactions of microsolvated organic compounds at ambient surfaces: droplet velocity, charge state, and solvent effects. J. Am. Soc. Mass. Spectrom. 23(6), 1077–1084 (2012)

Badu-Tawiah, A.K., Li, A.Y., Jjunju, F.P.M., Cooks, R.G.: Peptide cross-linking at ambient surfaces by reactions of nanosprayed molecular cations. Angew. Chem. Int. Ed. 51(37), 9417–9421 (2012)

Bain, R.M., Pulliam, C.J., Cooks, R.G.: Accelerated hantzsch electrospray synthesis with temporal control of reaction intermediates. Chem. Sci. 6(1), 397–401 (2015)

Espy, R.D., Wleklinski, M., Yan, X., Cooks, R.G.: Beyond the flask: reactions on the fly in ambient mass spectrometry. Trac-Trend. Anal. Chem. 57, 135–146 (2014)

Badu-Tawiah, A.K., Eberlin, L.S., Ouyang, Z., Cooks, R.G.: Chemical aspects of the extractive methods of ambient ionization mass spectrometry. Ann. Rev. Phys. Chem. 64, 481–505 (2013)

Laskin, J., Laskin, A., Nizkorodov, S.A.: New mass spectrometry techniques for studying physical chemistry of atmospheric heterogeneous processes. Int. Rev. Phys. Chem. 32(1), 128–170 (2013)

Coelho, F., Eberlin, M.N.: The bridge connecting gas-phase and solution chemistries. Angew. Chem. Int. Ed. 50(23), 5261–5263 (2011)

Muller, T., Badu-Tawiah, A., Cooks, R.G.: Accelerated carbon–carbon bond-forming reactions in preparative electrospray. Angew. Chem. Int. Ed. 51(47), 11832–11835 (2012)

Lee, J.K., Kim, S., Nam, H.G., Zare, R.N.: Microdroplet fusion mass spectrometry for fast reaction kinetics. Proc. Natl. Acad. Sci. U. S. A. 112(13), 3898–3903 (2015)

Chipuk, J.E., Brodbelt, J.S.: Transmission mode desorption electrospray ionization. J. Am. Soc. Mass. Spectrom. 19(11), 1612–1620 (2008)

Chipuk, J.E., Brodbelt, J.S.: The influence of material and mesh characteristics on transmission mode desorption electrospray ionization. J. Am. Soc. Mass. Spectrom. 20(4), 584–592 (2009)

Chipuk, J.E., Gelb, M.H., Brodbelt, J.S.: Rapid and selective screening for sulfhydryl analytes in plasma and urine using surface-enhanced transmission mode desorption electrospray ionization mass spectrometry. Anal. Chem. 82(10), 4130–4139 (2010)

Chipuk, J.E., Gelb, M.H., Brodbelt, J.S.: Surface-enhanced transmission mode desorption electrospray ionization: increasing the specificity of ambient ionization mass spectrometric analyses. Anal. Chem. 82(1), 16–18 (2010)

Perez, J.J., Harris, G.A., Chipuk, J.E., Brodbelt, J.S., Green, M.D., Hampton, C.Y., Fernandez, F.M.: Transmission-mode direct analysis in real time and desorption electrospray ionization mass spectrometry of insecticide-treated bednets for malaria control. Analyst 135(4), 712–719 (2010)

Shaw, J.B., Brodbelt, J.S.: Analysis of protein digests by transmission-mode desorption electrospray ionization mass spectrometry with ultraviolet photodissociation. Int. J. Mass. Spectrom. 308(2/3), 203–208 (2011)

Evans-Nguyen, K.M., Quinto, A., Hargraves, T., Brown, H., Speer, J., Glatter, D.: Transmission mode desorption electrospray ionization (TM-Desi) for simultaneous analysis of potential inorganic and organic components of radiological dispersion devices (RDDS). Anal. Chem. 85(24), 11826–11834 (2013)

Yang, S.H., Wang, E.H., Gurak, J.A., Bhawal, S., Deshmukh, R., Wijeratne, A.B..., Edwards, B.L., Foss, F.W., Timmons, R.B., Schug, K.A.: Affinity mesh screen materials for selective extraction and analysis of antibiotics using transmission mode desorption electrospray ionization mass spectrometry. Langmuir 29(25), 8046–8053 (2013)

Nam, W.: High-valent iron(Iv)-oxo complexes of heme and non-heme ligands in oxygenation reactions. Acc. Chem. Res. 40(7), 522–531 (2007)

Chiavarino, B., Cipollini, R., Crestoni, M.E., Fornarini, S., Lanucara, F., Lapi, A.: Probing the compound i-like reactivity of a bare high-valent oxo iron porphyrin complex: the oxidation of tertiary amines. J. Am. Chem. Soc. 130(10), 3208–3217 (2008)

Chiavarino, B., Crestoni, M.E., Fornarini, S., Lanucara, F.: Probing bare high-valent transition oxo-metal complexes: an electrospray ionization Fourier transform ion cyclotron resonance study of reactive intermediates. Eur. J. Mass. Spectrom. 16(3), 407–414 (2010)

Miao, Z., Chen, H., Liu, P., Liu, Y.: Development of submillisecond time-resolved mass spectrometry using desorption electrospray ionization. Anal. Chem. 83(11), 3994–3997 (2011)

Venter, A., Sojka, P.E., Cooks, R.G.: Droplet dynamics and ionization mechanisms in desorption electrospray ionization mass spectrometry. Anal. Chem. 78(24), 8549–8555 (2006)

Perry, R.H., Cooks, R.G., Noll, R.: Orbitrap mass spectrometry: instrumentation, ion motion, and applications. Mass. Spectrom. Rev. 27(6), 661–699 (2008)

Hu, Q.Z., Noll, R.J., Li, H.Y., Makarov, A., Hardman, M., Cooks, R.G.: The Orbitrap: a new mass spectrometer. J. Mass. Spectrom. 40(4), 430–443 (2005)

Makarov, A.: Electrostatic axially harmonic orbital trapping: a high-performance technique of mass analysis. Anal. Chem. 72(6), 1156–1162 (2000)

Makarov, A., Denisov, E., Lange, O., Horning, S.: Dynamic range of mass accuracy in LTQ Orbitrap hybrid mass spectrometer. J. Am. Soc. Mass. Spectrom. 17(7), 977–982 (2006)

Makarov, A., Denisov, E., Kholomeev, A., Baischun, W., Lange, O., Strupat, K., Horning, S.: Performance evaluation of a hybrid linear ion trap/orbitrap mass spectrometer. Anal. Chem. 78(7), 2113–2120 (2006)

Hardman, M., Makarov, A.A.: Interfacing the Orbitrap mass analyzer to an electrospray ion source. Anal. Chem. 75(7), 1699–1705 (2003)

Costas, M.: Selective C–H oxidation catalyzed by metalloporphyrins. Coord. Chem. Rev. 255(23/24), 2912–2932 (2011)

Ryabov, A.D.: Green challenges of catalysis via iron(IV)oxo and iron(V)oxo species. In: van Eldik, R., Hubbard, C.D. (eds.) Advances in inorganic chemistry, Vol 65: Homogeneous catalysis, pp. 117–163. Elsevier, San Diego, CA, USA (2013)

Otey, C.R., Bandara, G., Lalonde, J., Takahashi, K., Arnold, F.H.: Preparation of human metabolites of propranolol using laboratory-evolved bacterial cytochromes P450. Biotech. Bioeng. 93(3), 494–499 (2006)

Garcia-Bosch, I., Sharma, S.K., Karlin, K.D.: A selective stepwise heme oxygenase model system: an iron(Iv)-oxo pPorphyrin Pi-cation radical leads to a verdoheme-type compound via an isoporphyrin intermediate. J. Am. Chem. Soc. 135(44), 16248–16251 (2013)

Groves, J.T., Watanabe, Y.: Reactive iron porphyrin derivatives related to the catalytic cycles of cytochrome-P-450 and peroxidase—studies of the mechanism of oxygen activation. J. Am. Chem. Soc. 110, 8443–8452 (1988)

Wijeratne, A.B..., Yang, S.H., Armstrong, D.W., Schug, K.A.: Solvent molecules undergo homolytic cleavage and radical recombination processes during negative-mode electrospray ionization: adduct formation with antimony(III)-tartrate dianion. Anal. Chem. 82(12), 5141–5146 (2010)

Mortensen, D.N., Williams, E.R.: Theta-glass capillaries in electrospray ionization: rapid mixing and short droplet lifetimes. Anal. Chem. 86, 9315–9321 (2014)

Goure, E., Avenier, F., Dubourdeaux, P., Seneque, O., Albrieux, F., Lebrun, C., Clemancey, M., Maldivi, P., Latour, J.-M.: a Di-iron(IIII,Iv) imido species very active in nitrene-transfer reactions. Angew. Chem. Int. Ed. 53(6), 1580–1584 (2014)

Girod, M., Moyano, E., Campbell, D.I., Cooks, R.G.: Accelerated bimolecular reactions in microdroplets studied by desorption electrospray ionization mass spectrometry. Chem. Sci. 2(3), 501–510 (2011)

Acknowledgments

The Perry Research Laboratory gratefully acknowledges financial support from the University of Illinois at Urbana-Champaign (UIUC). T.J.C. thanks the National Science Foundation Graduate Research Fellowship, National Institutes of Health Chemistry-Biology Interface Training Program (NIH T32 GM070421), and UIUC Springborn Fellowship for financial support. The authors also acknowledge the work of Asenath Francis (Louisiana State University; funded by the NSF Research Experience for Undergraduates program at UIUC) for characterizing the oxidation of various substrates. Kevin Parker (UIUC undergraduate) was instrumental in early studies characterizing reactions and ion source configurations. The authors acknowledge Jedidiah Veach (UIUC graduate student) for help in designing the continuous-flow ESI-MS figure located in the SI. We also thank the staff of the UIUC School of Chemical Sciences Machine Shop for their expertise in designing and machining ion source components.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(DOC 3601 kb)

Rights and permissions

About this article

Cite this article

Peters, K.C., Comi, T.J. & Perry, R.H. Multistage Reactive Transmission-Mode Desorption Electrospray Ionization Mass Spectrometry. J. Am. Soc. Mass Spectrom. 26, 1494–1501 (2015). https://doi.org/10.1007/s13361-015-1171-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13361-015-1171-5