Abstract

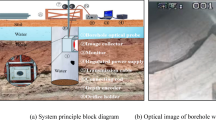

In the early stage of concrete pouring of bored piles, the high-precision quality inspection of bored piles has become an important engineering and scientific problem to be studied and solved. Firstly, to solve the technical problems existing in the current testing equipment and methods, such as the scarcity of data, poor measurement accuracy, and low work efficiency, this paper proposes a solution that uses the combination of multiple arrays of ultrasonic waves to scan the borehole contour as the leader, and forms a multi-array ultrasonic scanning technology suitable for the quality inspection of bored piles. Subsequently, a multi-element horizontal section scanning model is proposed, which realizes the position and sound velocity correction in the horizontal section acoustic scanning process, which solves the technical problems, such as the inability to locate accurately due to the swing of the probe in the single element scanning process, and the inability to calibrate the sound velocity in real time. Finally, this paper proposes a borehole quality evaluation method based on multivariate scanning data, forming a borehole quality evaluation system for horizontal section and vertical section, which realizes the borehole quality evaluation of cast-in-place pile from local to global, and from profile to all-round. The feasibility and superiority of the technical methods in this paper are verified by experimental tests. The results show that this method can obtain more effective detection data of the borehole wall, and at the same time can accurately reflect and extract the characteristic parameters of the cast-in-place pile borehole quality, which can effectively solve the technical problems of limited scanning data and low measurement accuracy in the cast-in-place pile borehole quality detection. The method in this paper expands the function of borehole quality detection technology, and lays a foundation for solving the problem of accurately judging and evaluating the borehole quality of cast-in-place piles in practical projects, which has good application prospects and promotion value.

Similar content being viewed by others

Data availability

All data generated or analyzed during this study are included in this published article.

References

Qiang Lu (2011) Ultrasonic hole forming quality inspection of large diameter deep long pile. Eng Constr 25(2):232–233

Lan S, Zhou X, Li F (2011) Application of borehole quality detection system of contact bored piles. Subgrade Eng 5:143–145

Dong-Sheng X et al (2018) A new measurement approach for deflection monitoring of large-scale bored piles using distributed fiber sensing technology. Measurement 117:444–454

Yong-Li L, Heng-Lin X, Qi-Zhi HU et al (2017) Research on integrity detection method for bored pile using distributed optical fiber temperature sensing technology. J Yangtze River Sci Res Inst 34(6):124–127

Feng Q, Kong Q, Song G (2016) Damage detection of concrete piles subject to typical damage types based on stress wave measurement using embedded smart aggregates transducers. Measurement 88:345–352

Xiaoya L (2013) Analysis of bored pile construction. Sci Technol Innov Appl 000(001):192–192

Chen X (2015) Quality control of bored pile construction. Commod Qual 000(046):381–383

Wenqi J, Jiang G (2015) Mud solid-liquid separation system and mud circulation purification and waste mud treatment method for Bored Pile Engineering. Real Estate Guide 5:457–459

Tan R, He F, Li Z (2012) Two inspection methods for hole forming quality of large diameter bored pile. Resourc Environ Eng 02:31–35

Guanghui Y (2001) Practice of ultrasonic testing of bored pile. Mineral Explor 000(011):54–56

Hongwei Z (2016) Probe into the problem of ultrasonic testing method for the hole forming quality of bored pile. Eng Qual 6:69–72

Liu DZ, Ren JM, Yang Y (2012) Ultrasonic sector scanning method in the application of the accurate determination of the concrete bored pile defect position. Adv Mater Res 430:1128–1132

Hertlein B, Verbeek G, Fassett R et al (2016) A comparison of quality management for bored pile/drilled shaft (BP/DS) foundation construction and the implementation of recent technologies. DFI J J Deep Found Inst 10(2):87–94

Ibatullin R, Shepelev A, Pischulev A (2019) Uniformity test of bored piles by method of ultrasonic sensing. IOP Conf Ser Mater Sci Eng 661:012060

Wang J, Wang C, Tang X, Han Q, Wang Y, Hu S (2020) Study on cave detection method based on multi frequency borehole sonar. Geotech Mech 41(01):353–360

Wang J-C, Wang C-Y, Han Z-Q et al (2020) Submarine karst morphology detection method based on multi-frequency ultrasound. Measurement 155:107532

Luo X, Cheng G, Meng L et al (2019) The influence of environmental parameters on the propagation characteristics of Scholte wave in two sound field models. J Naval Eng Univ 3:48–54

Li Y, Liu G, Song J et al (2019) Influence exerted by bone-containing target body on thermoacoustic imaging with current injection. China Phys B 28(4):44302–044302

Ballard MS, Lee KM, Sagers JD (2018) Measurements and modeling of acoustic propagation in a seagrass meadow. Acoust Soc Am J 143(3):1712–1712

Badiey M, Wan L, Goff JA (2018) Effects of azimuthal dependent sediment layer structure on broadband acoustic propagation during Seabed Characterization Experiment in 2017. J Acoust Soc Am 143(3):1798–1798

Tianmao Z (2019) Quality control method of bored pile in highway bridge construction. Traffic World 16:1–5

Rong Z (2017) Discussion on the application of bored pile technology in road and bridge construction. Sci Technol Innov 17:262–262

Acknowledgements

This work was supported by the National Natural Science Foundation for the Youth of China (Grant No. 41902294); the Natural Resources Research Project of Hubei Province (No.ZRZY2022KJ08).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, J., Wang, C., Han, Z. et al. Borehole quality inspection method of bored piles based on multi-array ultrasonic scanning technology. J Civil Struct Health Monit 14, 285–302 (2024). https://doi.org/10.1007/s13349-023-00723-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13349-023-00723-3